Moparts

recurving a stock distributor

Posted By: 440newport

recurving a stock distributor - 03/01/10 12:19 AM

Anybody have any tips on recurving a mopar dist?

I got a low compression 400 I rebuilt with a voodoo 262 cam and I figure the stock curve will leave some on the table power wise. I don't actually have the motor running and in a car yet but I figure I'll want about 15 degrees initial timing and about 32 total.

I know about welding up the slots to limit the advance but is it basically trial and error? In a Mopar Muscle article they welded up the slots in a SB dist from .480" down to .370" to get 32-34 total with 15 initial, will this be about the same on a BB?

Also is there a trick to the advance springs? I heard losing the bigger spring for a lighter one is beneficial too, can I just use another light spring in place of the stiffer one?

Posted By: 5spdcuda

Re: recurving a stock distributor - 03/01/10 02:12 AM

There is a certain amount of trial and error involved, but this should help to get you in the ball park. There should be a # stamped on the slotted part of the advance mechanism. 13 or 15 is typical. Approximately 1/16 in. in the slots is 2*. eg. If you have a 13 stamped on the mechanism closing up the slot by 1/16 in. will result in approx. 11* in the distributor. That of course will result in 22* at the crank. Ten degrees more [ initial ] and you have your 32*. Lighter springs will quicken up the rate of advance. If you're going to race it more than anything else try to bring it all in by 1500-2000 rpm. On the street I shoot for 2000-2500 rpm. Keep your final drive gear ratio in mind and try to have full advance or close to it at highway cruising rpm.

Posted By: six-barrel

Re: recurving a stock distributor - 03/01/10 02:18 AM

FBO sells a disk that goes in the distributor so you dont have to weld and file the slots. It comes with 4 degree choices.

Posted By: 440newport

Re: recurving a stock distributor - 03/01/10 02:31 AM

Quote:

There is a certain amount of trial and error involved, but this should help to get you in the ball park. There should be a # stamped on the slotted part of the advance mechanism. 13 or 15 is typical. Approximately 1/16 in. in the slots is 2*. eg. If you have a 13 stamped on the mechanism closing up the slot by 1/16 in. will result in approx. 11* in the distributor. That of course will result in 22* at the crank. Ten degrees more [ initial ] and you have your 32*. Lighter springs will quicken up the rate of advance. If you're going to race it more than anything else try to bring it all in by 1500-2000 rpm. On the street I shoot for 2000-2500 rpm. Keep your final drive gear ratio in mind and try to have full advance or close to it at highway cruising rpm.

I haven't taken apart the dist yet to check that number but was going to mess with it tomorrow. The engine is going in a 73 New Yorker with 3.23 gears so it's hardly a race car lol. With the 3.23's 65mph would be right at about 2500.

Where does full advance usually come in with the stock advance springs?

Posted By: 5spdcuda

Re: recurving a stock distributor - 03/01/10 02:40 AM

My motors manual only goes back to '75, but it shows 4000-4600 depending on which distributor was used. FWIW this is pretty much typical of what I remember older cars using as well. The old point distributors sometimes didn't achieve full advance until 4800 rpm.

Posted By: quickd100

Re: recurving a stock distributor - 03/01/10 11:30 AM

Once you've got your slots welded up so you have the correct amount of mechanical advance just install the one light spring and leave the heavy one out. Don't worry about the empty spring slot. With just the one light spring in place you should have full advance by 2000-2400rpm. You may want to increase the total timing to 38 degrees or more on a low compression motor. I've seen as much as 42 degrees mechanical advance work real nice on bb with little or no compression. You can also run up to 52 degrees advance with the vacuum advance hooked up. Dave

Posted By: Ledman_70

Re: recurving a stock distributor - 03/01/10 02:54 PM

Hey six-barrell, who is FBO? Thanks

Posted By: Mattax

Re: recurving a stock distributor - 03/01/10 03:15 PM

Will the stock specs leave power on the table?

It really depends on what the stock distributor has in it, and how much that cam changes things.

A lumpy cam likes more initial timing than a stock cam. Also lower compression will want a bit more advance high compression. You might end up setting as high as 18 degrees at idle but 15-16 seems like a good starting point. If there is enough vacuum at idle to get the vacuum advance to contribute at idle (in gear) then it may be fine with 12-15 inital.

For total advance (w/o vacuum) Mopar Performance recommended 38 deg BTDC for production iron head B/RB engines. With vacuum they recommended 56 degree BTDC for these engines. (Instruction Sheet DCF-194 for Mopar Performance Electronic Ignition Kit p.6)

Be conservative. Start with these numbers or less. Because under load (like top gear, WOT) too much advance can be destructive.

You could wait until the engine is done. Find what initial it likes. Then knowing how much advance is in the slots, weld up as needed to get the initial and total you want.

Which Springs?

Yes. the early performance guidance (eg. Master Tech bulletin 1969) advised removing the heavy spring and stretching the light spring. However, if you shorten the outside of the slots, the heavy spring will not come into play very much and could actually be useful - especially on a heavy car.

There are competing theories on the best approach. This early advice is not the only way, and even DC/DC used other approaches. For example later on DC/MP liked to use a lot of mechanical advance, a very light spring and a long looped heavy spring. The engines would start easily and get roughly the advance needed at idle. Full advance might be 800-1200 rpm, with heavy spring allowing only a degree or two from there to the top. The p-partr tach drive dizzy was set up that way. My opinion is that this makes most sense for a very high compression race car, but not optimum for lower compression mixed use cars.

My suggestion for your application is to first get the slot length. Then, if the heavy spring with long loop is only controlling only a degree or two at the top of the curve (2500-4000) leave it for now. Then try lighter springs on the other side to see if bringing the curve to full advance earlier is beneficial.

With a heavy car and stock convertor or manual trans, the shorter slots might be enough. In fact you may find that instead of 1 light spring and one delayed heavy spring, it prefers two light springs.

Posted By: patrick

Re: recurving a stock distributor - 03/01/10 05:38 PM

for that cam in a low comp motor, I'd probably look at 18-20 initial, and 38-40 total timing

also, your dizzy advance plate will have a number stamped on it. that's the advance in distributor degrees (1/2 crank degrees). a 17 plate will show 34 degrees advance with a timing light. measure the length of the slot with some calipers, and divide by double the stamped number to get the amount you need to shorten the slot per degree (i.e. if you have a 15 plate, and the slot is .3" long, you need to shorten the slot .01" per degree, or .1" if you want to reduce the advance from 30 degrees to 20.)

when you weld up the slot, weld up the inside. this adds preload to the springs, which will cause the advance to start in at a higher RPM range. most stock distributors I've played with, the light spring is so light, it starts advancing at ~700 RPM or less. if your neutral idle is above where the mechanical advance starts advancing, you'll get excessive RPM drop in gear and an unstable idle. I like setting up my mechanical to start coming in at ~1000 RPM

Posted By: six-barrel

Re: recurving a stock distributor - 03/01/10 07:05 PM

Posted By: 440newport

Re: recurving a stock distributor - 03/01/10 08:12 PM

Quote:

when you weld up the slot, weld up the inside.

How does that work though? Wouldn't the amount of total advance the weights give not change then?

I can't find my calipers to measure the slots yet, but the slot plate says 17L on it and the vacuum advance arm has 10L on it. 20 degrees of vac advance seems like a lot?

Posted By: hooziewhatsit

Re: recurving a stock distributor - 03/01/10 09:18 PM

Quote:

when you weld up the slot, weld up the inside.

Couldn't that be accomplished by using heavier springs as well?

Posted By: patrick

Re: recurving a stock distributor - 03/01/10 09:29 PM

Quote:

Quote:

when you weld up the slot, weld up the inside.

How does that work though? Wouldn't the amount of total advance the weights give not change then?

I can't find my calipers to measure the slots yet, but the slot plate says 17L on it and the vacuum advance arm has 10L on it. 20 degrees of vac advance seems like a lot?

not too atypical of a smogger motor. the amount of advance is determined by the length of the slot. from a total advance standpoint, it doesn't matter where the slot is shortened, from the inside or outside.

standard motor products VC184 is a 17 degree vaccuum advance module. that's the shortest vac. advance canister I've seen for the electronic ignition dizzies...

Posted By: patrick

Re: recurving a stock distributor - 03/01/10 09:31 PM

Quote:

Quote:

when you weld up the slot, weld up the inside.

Couldn't that be accomplished by using heavier springs as well?

yes and no. a heavier spring, has a higher RATE, so the advance will be slower. it may or may not start later, depending on preload. moving the inside of the slot outboard increases the preload on the light spring, starting the advance later, but still advancing at the same RATE

Posted By: Anonymous

Re: recurving a stock distributor - 03/01/10 09:37 PM

Posted By: Mattax

Re: recurving a stock distributor - 03/01/10 11:03 PM

Amount of advance is determined by the total length of the slots.*

Closing up the inside increases the starting tension of the light spring. (The heavy spring has no tension to start because of the long loop)

Closing up the outside stops the advance earlier.

The shape and rate of advance depends on the spring rates and when they come into play relative to rpm. That's why the side welded can matter.

*When it comes to figuring the advance, measure the slot and measure the pin diameter. The weight's movement is equal to the slot length minus the diameter. Divide that by the stamped number to get movement per distributor degree.

IIRC, 20 degrees is typical on a vac can. If you subtract the two numbers I posted earlier, that is the amount of vac that Mopar Performance was shooting for on their Electronic ignition and distributor kits. You can adjust it a bit with the allen screw as somone already posted. You can also modify the arm by notching the stops.

Added Note: The Mopar Performance instructions mentioned above use 2500-3000rpm as the range for total advance should be stable. YMMV.

Posted By: 440newport

Re: recurving a stock distributor - 03/02/10 01:48 AM

Quote:

standard motor products VC184 is a 17 degree vaccuum advance module. that's the shortest vac. advance canister I've seen for the electronic ignition dizzies...

I've been looking at vac advance cans for the last little while. I can't see anything for a big block that's less than 18. The VC184 you mention has the arm the opposite way, like for a slant or SB. They actually have a 13 degree can for a SB or slant, VC173.

Posted By: BSB67

Re: recurving a stock distributor - 03/02/10 02:20 AM

Quote:

I know about welding up the slots to limit the advance but is it basically trial and error? In a Mopar Muscle article they welded up the slots in a SB dist from .480" down to .370" to get 32-34 total with 15 initial, will this be about the same on a BB?

Yes. A 0.370" slot length will give you about 16 degrees of mech. advance. If you want 34 degrees total, you would then set initial at 18 degrees.

Posted By: RapidRobert

Re: recurving a stock distributor - 03/02/10 02:27 AM

cut a pair of strips from your choice of thickness feeler gauge & epoxy them on both sides of the notch on the arm where it goes into the can to limit the total vac advance the can will provide

Posted By: Flatblack

Re: recurving a stock distributor Food for Thought - 03/02/10 02:54 AM

There is a guy in Calgary Alberta Canada that recurves only mopar distributers. You can find his ad on kijiji.ca calgary alberta under parts.

Posted By: patrick

Re: recurving a stock distributor - 03/02/10 02:10 PM

Quote:

Quote:

standard motor products VC184 is a 17 degree vaccuum advance module. that's the shortest vac. advance canister I've seen for the electronic ignition dizzies...

I've been looking at vac advance cans for the last little while. I can't see anything for a big block that's less than 18. The VC184 you mention has the arm the opposite way, like for a slant or SB. They actually have a 13 degree can for a SB or slant, VC173.

VC184 is for a small block dizzy....

wish I woulda known about the VC173 before I bought mine...of course, my mag heads don't like a lot of timing at WOT (32 seems to work best), so the 17 degree can is about right for me.

Posted By: 440newport

Re: recurving a stock distributor - 03/04/10 10:34 PM

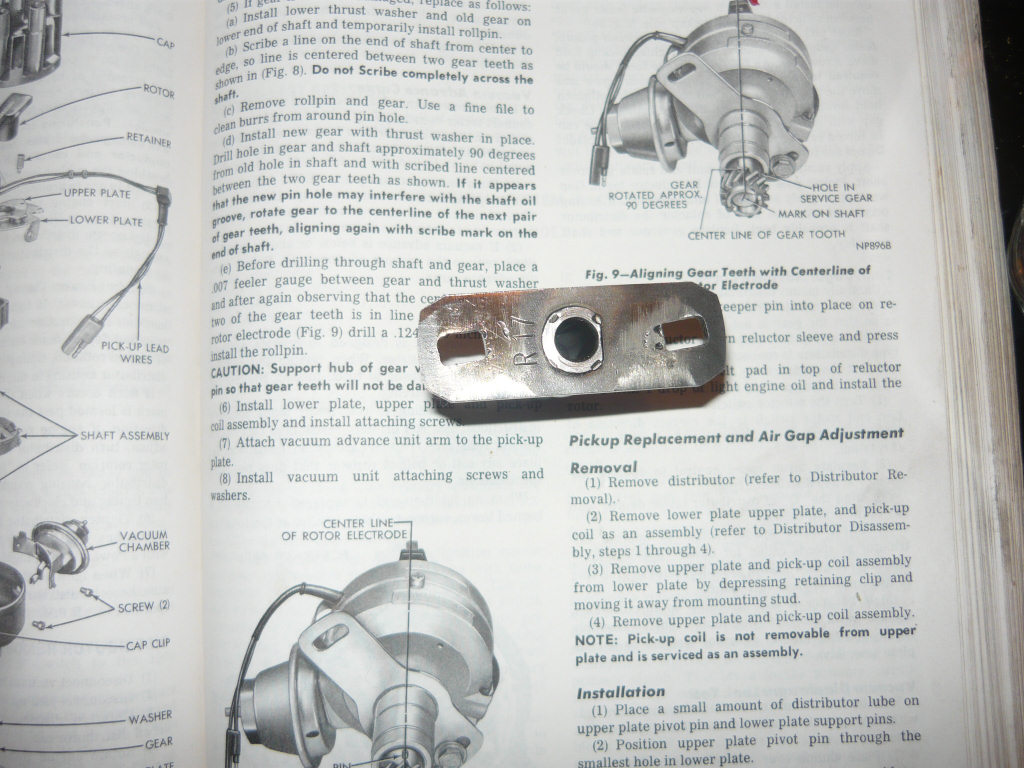

Ok I measured the slot with digital calipers and came up with 0.480. It's a 17 degree plate so I get 0.01411" per degree. I was gonna make it advance 20 degrees so that means I need to take 14 at 0.197 off leaving 0.283 which doesn't seem like a lot, the weights are barely going to move in that space but I guess its right?

Posted By: Mattax

Re: recurving a stock distributor - 03/04/10 10:59 PM

Quote:

Ok I measured the slot with digital calipers and came up with 0.480. It's a 17 degree plate so I get 0.01411" per degree. I was gonna make it advance 20 degrees so that means I need to take 14 at 0.197 off leaving 0.283 which doesn't seem like a lot, the weights are barely going to move in that space but I guess its right?

It is not right. You also need to measure the pin that sticks out of the top of the weight. See the * in my previous post.

Posted By: 440newport

Re: recurving a stock distributor - 03/04/10 11:27 PM

Quote:

It is not right. You also need to measure the pin that sticks out of the top of the weight. See the * in my previous post.

Doh!  Yes that makes perfect sense. Ok I come with .380 now which seems more like it.

Yes that makes perfect sense. Ok I come with .380 now which seems more like it.

Posted By: 1_WILD_RT

Re: recurving a stock distributor - 03/04/10 11:57 PM

What I do is not worry about total advance at first, instead with the engine warmed up I start adding timing to see what the engine will take without the starter kicking back.. The more initial timing you can give it the better it will launch... Your not looking to rev the engine above 3000 rpm here just see what the starter will take & see how the car comes out of the hole... So now you know how much initial lead you want & you just need to limit the total to around 34-36 degrees

This chart may help...

Modifying advance slots

degrees / slot size

6.............. .340

7................355

8................375

9................390

10...............405

11.5 ...........420

12...............435

13...............445

14...............460

15...............475

16...............490

17...............505

18...............520

Posted By: 440newport

Re: recurving a stock distributor - 03/05/10 12:49 AM

I went with .375. I'll try that until I get the car running, if it needs to be changed it's no big deal to do it over.

Thanks everybody for the help.

Posted By: 1_WILD_RT

Re: recurving a stock distributor - 03/05/10 12:50 AM

Should put you real close...

Posted By: 440newport

Re: recurving a stock distributor - 03/08/10 12:37 AM

One more question on this...

Before I took the dist apart I marked which way the reluctor was on the advance plate shaft, but I didn't mark which way the advance plate was on the main shaft. I believe if its 180* out the reluctor wont line up with the pick up correctly.

Is there a way to tell?

Posted By: RapidRobert

Re: recurving a stock distributor - 03/08/10 03:01 AM

Quote:

I believe if its 180* out the reluctor wont line up with the pick up correctly.

Is there a way to tell?

It'll be the same either way but I would drill a hole in the top of your (or a spare) dist cap between the center and #1 terminals & check rotor phasing so if it (Phasing) is off you can correct it but dropping the adv plate on the pins 180 off keeps the phasing the same in spite of the directional arrow and the 2 choices of roll pin slots on the reluctor wanting to convince you otherwise and be aware when you freeze the rotor w the light that vac adv (if used) will shift the rotor (phasing) CCW on a SB and CW on a BB and that mechanical advance does not change phasing.

Posted By: 440newport

Re: recurving a stock distributor - 03/08/10 03:16 AM

Quote:

dropping the adv plate on the pins 180 off keeps the phasing the same in spite of the directional arrow and the 2 choices of roll pin slots on the reluctor wanting to convince you otherwise

Ok thanks. I thought that since the reluctor can go 2 ways and the "teeth" are not lined up with the pick up the same way between the 2, I thought turning the advance plate on the pins backwards would be the same as having the reluctor on backwards.

Posted By: RapidRobert

Re: recurving a stock distributor - 03/08/10 03:28 AM

visualize an analog clock showing 5 minutes before 5 o'clock and if you epoxied the hands to lock the hour and the minute hand together as one then rotated the hand assy 1/2 turn (180 deg) the offset would end up being the same and if you 1st changed the roll pin hole and if this put the hands at 10 minutes in front of 4 and you locked them together as before and again swapped them 180 the top hand would still be 10 minutes away from (12)

Posted By: Magnum

Re: recurving a stock distributor - 03/08/10 09:56 AM

It's too bad these are big $$ and only for small blocks. I've been down that road of welding, completely dissasembling for springs and swapping cannisters. Never again.

This will be my next distributor.

http://www.summitracing.com/parts/MSD-8504/

Yes that makes perfect sense. Ok I come with .380 now which seems more like it.

Yes that makes perfect sense. Ok I come with .380 now which seems more like it.