Posted By: 318Bruiser

Welders or body men help plz. - 07/14/08 03:55 AM

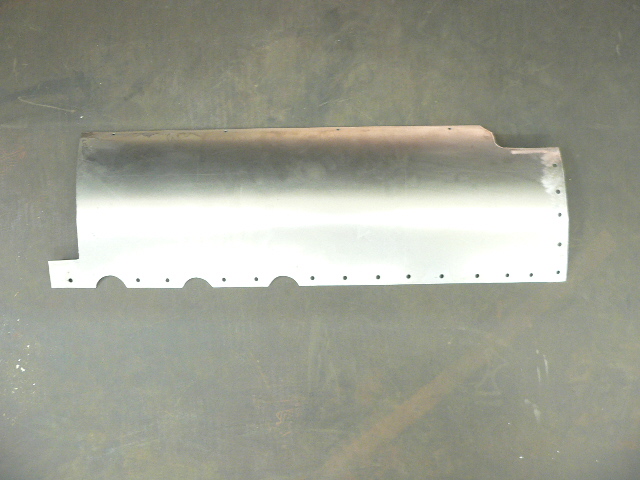

Can someone tell me or point me in the direction on how to repair my lower quarters on my Volare. I think I want to just weld some metal there but I need to know a few things first.

1. I know to cut the rust out and cut the new metal to form into the new hole but, how does one get the curvature.

2. Will a hobbiest mig welder be ok for doing this, 110v.

3. I need more car friends that know what they are doing, Steaks, beer and a bon fire, have at it boys.

1. I know to cut the rust out and cut the new metal to form into the new hole but, how does one get the curvature.

2. Will a hobbiest mig welder be ok for doing this, 110v.

3. I need more car friends that know what they are doing, Steaks, beer and a bon fire, have at it boys.