Posted By: WannaRunner

Quench - 10/31/09 12:33 PM

How much is quench an issue when running dished pistons??

~thanks

~thanks

Quote:

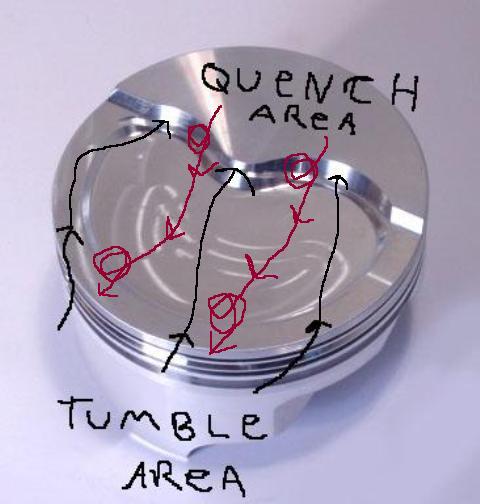

Quench is still important with dished piston design, and the area outside of the dish needs to be as large as 50% of the total crown area for optimum quench.

1994 Magnum 5.9V8 factory pistons are over 40% quench area.

The small details in the design of the edge of the dish are important too.

If the edge is designed right,

the straight line inward moving fan jets of "squished out" air and fuel

then 'tumbles' as it goes over the edge of the dish and downward.

Diesel pistons in particular make use of this tumbling turbulence in addition to the squish turbulence.

Quote:

The performance pistons I have seen are D shaped dish and that's what you need unless you need a HUGE dish ...

I'm having Diamond make me a piston with a pop up quench dome AND a D shaped dish

Quote:It is a D shaped dish and a quench pad (since it is a flat plateau). pad/dome is splitting hairs a bit but to help you a dome refers more to the sort of pyramid shape that the old pop up racing pistons had to get compression.

is the pic above considered a pop up quench dome and a D shaped dish??

Quote:

It would be helpful if you would tell us what cylinder head you are planning to use with that piston, or post a picture.

Quote:Quote:It is a D shaped dish and a quench pad (since it is a flat plateau). pad/dome is splitting hairs a bit but to help you a dome refers more to the sort of pyramid shape that the old pop up racing pistons had to get compression.

is the pic above considered a pop up quench dome and a D shaped dish??

Quote:To ans your orig Q, quench will let you run a much higher CR without pinging on your choice of fuel which is important with todays poor pump gas and CR is one of the main parameters that determines an engines power output (squeeze is power). I'm assuming that your(& all) stealths are closed chambers and a zero deck (flattop) piston & a .039" gasket would give you perfect quench but the CR would be too high and you do need valve reliefs so a quench pad gives you the quench distance and the dish takes care of the valve reliefs and in addition the dish lowers the CR to a manageable level and also makes a much more ideal shape for flame propagation as you have the domed combustion chamber and the (somewhat similar) dish which doesn't constrict the flame travel like a flattop piston top does.

Is it best to run flattop pistons?

Quote:The dish is and back to my prior post which my wording is a little misleading as it's not so much that the flat top is more restrictive it's that the dish is much better but the CRITICAL issues are CR/quench/VP clearance and if you have all those where they should be either one (dish or flattop) will work great for you.

Yes, all things being equal, would it be better running a flatop verses the piston pictured above?

Quote:Quote:

The performance pistons I have seen are D shaped dish and that's what you need unless you need a HUGE dish ...

I'm having Diamond make me a piston with a pop up quench dome AND a D shaped dish

John, is the pic. above considered a pop up quench dome and a D shaped dish??

Thanks.

Quote:

Yes, all things being equal, would it be better running a flatop verses the piston pictured above??

~thanks

Quote:

I run those pictured dishes at .010 above deck unless the bore is larger than 4.355. I also tend to have the chamber sizes reduced by milling. You want the distance tight as you can. Closer to .030 the better. You will also want to choose the cam carefully as too small will give you more grief than too large will when building for quench.

Quote:(1) correct, not out to the edge (2) I think KB expects (rightly so) a person to measure their (quench) clearance & mill the quench pad down to where it's right for each eng. that's what I'm doing on my 451.

The only thing I have to go by for a quench pad is the KB piston and they don't run it out to the edge of the piston , at least the pictures I have seen of them they do not ?? but this of course is ASSuMEing that the KB pad is correct

Quote:Quote:(1) correct, not out to the edge (2) I think KB expects (rightly so) a person to measure their (quench) clearance & mill the quench pad down to where it's right for each eng. that's what I'm doing on my 451.

The only thing I have to go by for a quench pad is the KB piston and they don't run it out to the edge of the piston , at least the pictures I have seen of them they do not ?? but this of course is ASSuMEing that the KB pad is correct

Quote:

(1) correct, not out to the edge (2) I think KB expects (rightly so) a person to measure their (quench) clearance & mill the quench pad down to where it's right for each eng. that's what I'm doing on my 451.

Quote:Quote:Quote:(1) correct, not out to the edge (2) I think KB expects (rightly so) a person to measure their (quench) clearance & mill the quench pad down to where it's right for each eng. that's what I'm doing on my 451.

The only thing I have to go by for a quench pad is the KB piston and they don't run it out to the edge of the piston , at least the pictures I have seen of them they do not ?? but this of course is ASSuMEing that the KB pad is correct

And what happens if you dont?

Quote:Quote:(1) correct, not out to the edge (2) I think KB expects (rightly so) a person to measure their (quench) clearance & mill the quench pad down to where it's right for each eng. that's what I'm doing on my 451.

The only thing I have to go by for a quench pad is the KB piston and they don't run it out to the edge of the piston , at least the pictures I have seen of them they do not ?? but this of course is ASSuMEing that the KB pad is correct

Quote:open chambers?. that's what I was going to have to do to a set of 906's if I hadn't found some 915's for a decent price.

I did the opposite , machined the chambers so they were all the same depth considering the last set of heads I did the middle of the head was about .020 DEEPER than the ends of the head .

Quote:Quote:

It would be helpful if you would tell us what cylinder head you are planning to use with that piston, or post a picture.

CNC'd Stealths

Quote:Quote:Quote:

The performance pistons I have seen are D shaped dish and that's what you need unless you need a HUGE dish ...

I'm having Diamond make me a piston with a pop up quench dome AND a D shaped dish

John, is the pic. above considered a pop up quench dome and a D shaped dish??

Thanks.

it could be used as one but a step dome usually would not go to the edge of the piston like that , if it were used in an open chamber head you would to have to be absolutely postive the chamber did not overhang the bore , most will ... unless you are building something around a 4.280 or under bore size.

to me that looks like a piston designed to the zero decked .

Quote:Quote:

Yes, all things being equal, would it be better running a flatop verses the piston pictured above??

~thanks

That all depends on what compression ratio you need to be able to run the octane fuel you want.

If you choose a flat top and end up with 12.5 compression but want to run 89 octane fuel then yes you would need a piston that looks like the one above to get an octane friendly compression ratio and still have quench.

Quote:Quote:Quote:

It would be helpful if you would tell us what cylinder head you are planning to use with that piston, or post a picture.

CNC'd Stealths

Maybe it is in the post somewhere and I missed it, is this a 500" motor?

If it is, an option is to have the combustion chamber opened to what you need and run a flat top.

When Jeff is done with the CNC work, presuming he still cleans up the combustion chambers/unshroud the valves, they will be at about 88cc. The valve reliefs on most flat top pistons are 4 to 6 depending on the piston. Depending on your cam, you are already pretty close to pump friendly combo with 0.040 quench. Just an option.

Get the CR you want and good quench, that is what is most important. After that, piston shape is splitting hairs.

Quote:Quote:Quote:Quote:

It would be helpful if you would tell us what cylinder head you are planning to use with that piston, or post a picture.

CNC'd Stealths

Maybe it is in the post somewhere and I missed it, is this a 500" motor?

If it is, an option is to have the combustion chamber opened to what you need and run a flat top.

When Jeff is done with the CNC work, presuming he still cleans up the combustion chambers/unshroud the valves, they will be at about 88cc. The valve reliefs on most flat top pistons are 4 to 6 depending on the piston. Depending on your cam, you are already pretty close to pump friendly combo with 0.040 quench. Just an option.

Get the CR you want and good quench, that is what is most important. After that, piston shape is splitting hairs.

512 stroker, around 11.0cr

Quote:Quote:open chambers?. that's what I was going to have to do to a set of 906's if I hadn't found some 915's for a decent price.

I did the opposite , machined the chambers so they were all the same depth considering the last set of heads I did the middle of the head was about .020 DEEPER than the ends of the head .

Quote:Quote:Quote:

Yes, all things being equal, would it be better running a flatop verses the piston pictured above??

~thanks

That all depends on what compression ratio you need to be able to run the octane fuel you want.

If you choose a flat top and end up with 12.5 compression but want to run 89 octane fuel then yes you would need a piston that looks like the one above to get an octane friendly compression ratio and still have quench.

I'm running 91-93 octane E85 in my runner now. (jetted up my carb) I would like to run around 11.0cr in the new motor.

Quote:

John, I run them tighter until the bore gets large enough and the piston short enough that after a few thousand miles of use the piston rock takes up a bit of the quench. From what I've seen, which is limited I admit... Once you're past the 440 +.030 bore the pistons can rock a bit. Add to that the loss in skirt and stability from the stroked crank and the extra sideways pushing.... I want to make sure nothing hits after a bunch of miles. No other reason than that. But remember I'm starting at .030. Guys starting at .040 dont have to worry. As things wear, that distance gets tighter as the piston changes direction.

high compression and

high compression and