Posted By: coronet1966d

Lets talk a little more about quench - 09/29/09 04:04 AM

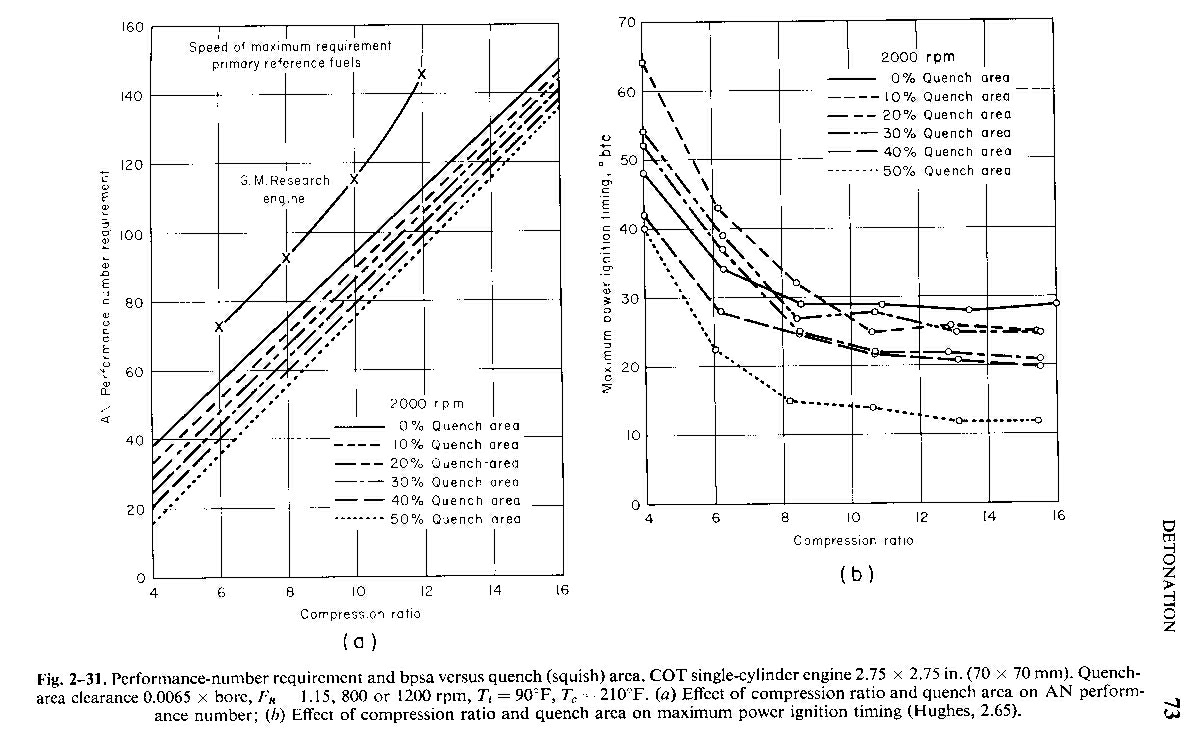

so ive read and read then i read some more about compression ratios dynamic, static and so on ive read a bunch about quench and why its important

heres my question: assuming that .040 is the IDEAL "safe" quench meaning you shouldnt get it any closer than that, how wide can you go on quench and still be effective? lets say .050 - .060 the reason i ask is im playing around with these online calculators with different head and piston combos trying to find something that works for me. the one thing ive kept the same is a zero deck with a .040 head gasket

i believe undecked the pistons will sit about .015 in the hole so undecked i would be at .055 quench, is that still a good thing or is it too wide?

just playing around with numbers and learning as i go

i apretiate all you guys helping me this far or id be asking alot dumber questions lol

heres my question: assuming that .040 is the IDEAL "safe" quench meaning you shouldnt get it any closer than that, how wide can you go on quench and still be effective? lets say .050 - .060 the reason i ask is im playing around with these online calculators with different head and piston combos trying to find something that works for me. the one thing ive kept the same is a zero deck with a .040 head gasket

i believe undecked the pistons will sit about .015 in the hole so undecked i would be at .055 quench, is that still a good thing or is it too wide?

just playing around with numbers and learning as i go

i apretiate all you guys helping me this far or id be asking alot dumber questions lol