Posted By: 1_WILD_RT

Will JB Weld live in this application? - 07/17/09 06:25 AM

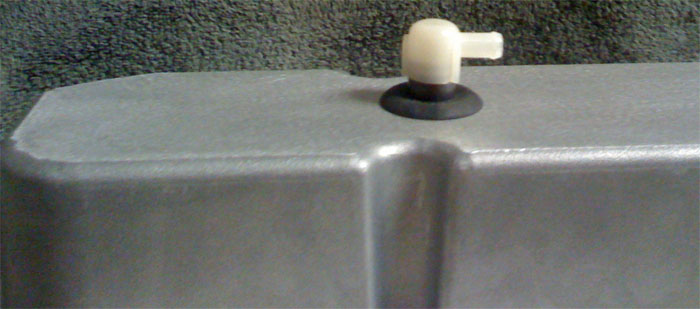

I'm gonna try it & I believe it will be fine, but a buddy of mine insists it's gonna fail.. What do you think...

Quote:

I'm gonna try it & I believe it will be fine, but a buddy of mine insists it's gonna fail.. What do you think...

My front spring eye nuts loosen all the way up about in a years time.

My front spring eye nuts loosen all the way up about in a years time.

Quote:

tack the baffle in all four corners and your done

Quote:

I would have tig welded in alumminum standoffs and used mounting bolts with saftey wire. Those little screws could do alot of damage if one comes loose. You could still safety wire and at least if something came loose it would all stay together.

Don't all the holes in the baffle kinda of defeat the purpose.

Quote:

What do you think...

Quote:

Doug Fir would be better to support the rocker shaft though...

I wonder if Simpson Strong-Tie would have motorsport support for you?

Quote:Quote:

I would have tig welded in alumminum standoffs and used mounting bolts with saftey wire. Those little screws could do alot of damage if one comes loose. You could still safety wire and at least if something came loose it would all stay together.

Don't all the holes in the baffle kinda of defeat the purpose.

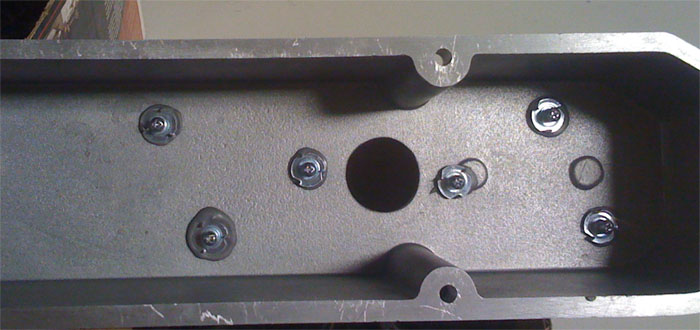

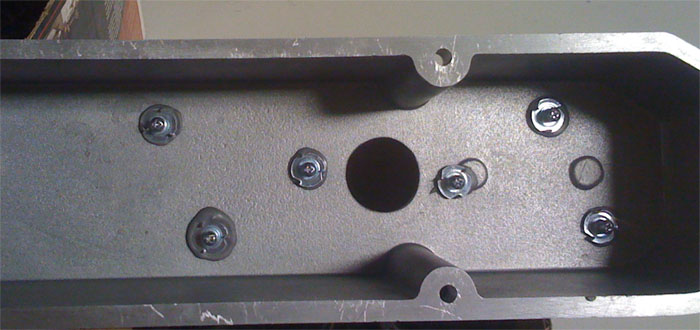

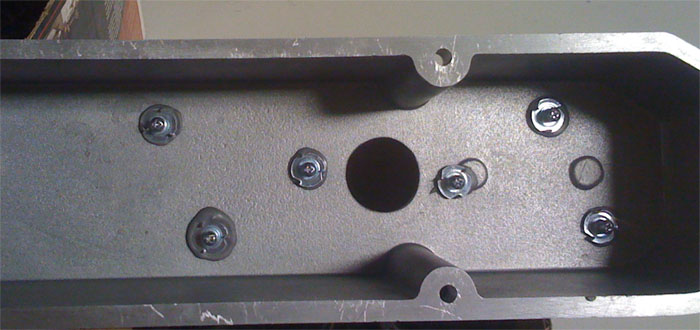

The screw I'm actually gonna use are stainless steel allens with a nylon insert so they don't loosen unless you want them to...

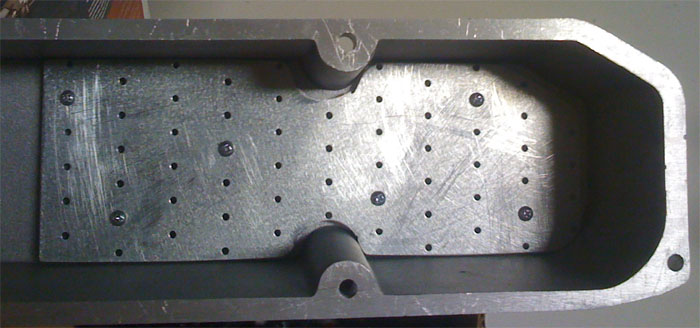

I actually feel all the little holes are gonna help improve drainage.. They started live as nailer plates for reinforcing wood construction, I've had them laying around for a few years & they were close to the right size..

Quote:Quote:

I would have tig welded in alumminum standoffs and used mounting bolts with saftey wire. Those little screws could do alot of damage if one comes loose. You could still safety wire and at least if something came loose it would all stay together.

Don't all the holes in the baffle kinda of defeat the purpose.

The screw I'm actually gonna use are stainless steel allens with a nylon insert so they don't loosen unless you want them to...

I actually feel all the little holes are gonna help improve drainage.. They started live as nailer plates for reinforcing wood construction, I've had them laying around for a few years & they were close to the right size..

Filing it with oil is a pain.

Filing it with oil is a pain.

Quote:Quote:

I actually feel all the little holes are gonna help improve drainage.. They started live as nailer plates for reinforcing wood construction, I've had them laying around for a few years & they were close to the right size..

I don't have holes in mine.Filing it with oil is a pain.

Quote:

That is exactly what I remember about trying to fill with the early stock covers & why I thought the little holes would help... The good news is we all understand the need for baffles, something the companies making most aftermarket covers seemed to forget about...

Quote:

Even with baffles mine still pukes oil. Maybe that has something to do with that 16 year old re-ring job the standard bore.

Quote:

Maybe that has something to do with that 16 year old re-ring job the standard bore.

Quote:Quote:

Maybe that has something to do with that 16 year old re-ring job the standard bore.

Or maybe from the lack of building materials in it.