Moparts

How do I locate the 360 flywheel drilling?

Posted By: Phoenix

How do I locate the 360 flywheel drilling? - 01/17/24 08:33 AM

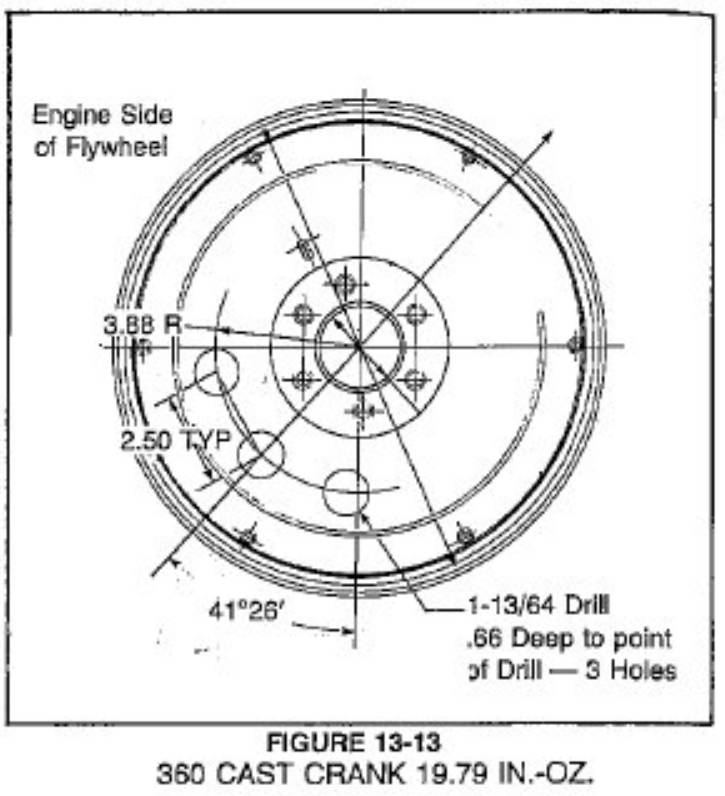

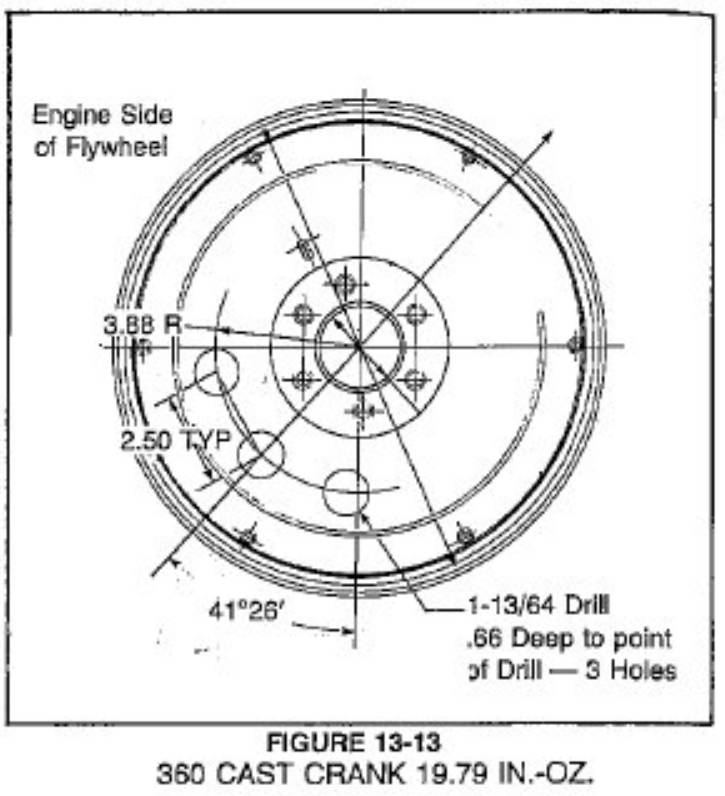

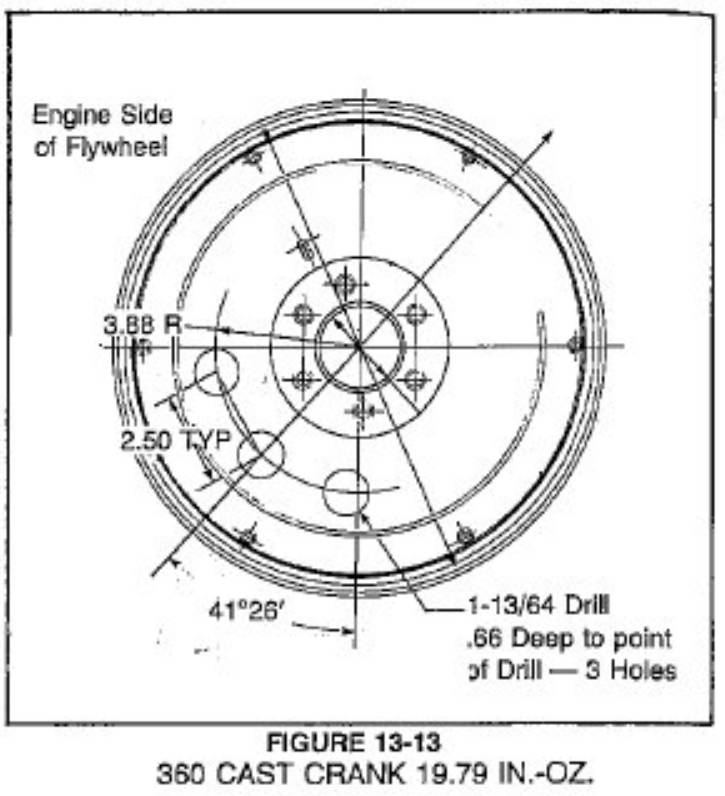

I have a diagram, I have the 1 13/64" drill, I have access to the equipment to do the job...

But the diagram, while giving plenty of detail of how the holes are to be drilled and where they are to be located in relation to each other, doesn't appear to have a workable datum line.

Here's the diagram, if anyone can help me get started on this job I'd really appreciate it.

Posted By: 6PakBee

Re: How do I locate the 360 flywheel drilling? - 01/17/24 09:01 AM

I'm not saying this is correct but years ago when I thought I was going to have to drill a flywheel for a 360 this is what I thought I saw:

1) establish the horizontal centerline through the pressure plate holes

2) establish the vertical centerline 90 degrees from the horizontal centerline through the center

3) establish the centerline of the middle hole by rotating 46 degrees 21 minutes clockwise from the vertical centerline through the center

4) establish the centers of the two outside holes by measuring 2.5 inches from the center hole at the 3.88 inch radius of the balance holes

Like I say, I never had to do this (found a flywheel) but this is the way I would have done it.

Posted By: Phoenix

Re: How do I locate the 360 flywheel drilling? - 01/17/24 09:20 AM

Thanks for responding, I really appreciate having someone who knows what they're about coming back to me.

Okay, just working from the beginning, that's where I have my problem...

The horizontal centreline on the diagram certainly looks like it's through the pressure plate holes, but I'm looking at a pressure plate which is many degrees out of sync with that. Which is actually why I'm asking the question.

If both flywheels I have had the pressure plate holes along that line I would go along with that, but even with just one of them not anywhere near it raises a question with me. This is exactly what I mean by having no datum point.

Posted By: Phoenix

Re: How do I locate the 360 flywheel drilling? - 01/17/24 09:33 AM

Actually, looking at the flywheel it appears to me that it's exactly 30° out from that diagram...

Is it possible that 143-tooth flywheels were drilled on that different axis? Mine is a 143-tooth.

Posted By: dragon slayer

Re: How do I locate the 360 flywheel drilling? - 01/17/24 12:36 PM

Not an expert on the small block, but a search of the A body site states that pattern is 130T which cars used. A truck used the 143 tooth, so there may be a pattern out there for that. Unless trucks neutral balanced. Have to match FW to bell housing for starter engagement.

Posted By: moparmarks

Re: How do I locate the 360 flywheel drilling? - 01/17/24 12:52 PM

I believe that chart is for the 143T wheel which was used in trucks starting in 1972 while the 360 car 4-spd with the 130T wheel wasn't available until 1974.

Posted By: dvw

Re: How do I locate the 360 flywheel drilling? - 01/17/24 01:17 PM

I think you are looking with the flywheel pressure plate side up. Flip the flywheel over and look from the crank face side. That's where the diagram is drawn.

Doug

Posted By: 6PakBee

Re: How do I locate the 360 flywheel drilling? - 01/17/24 02:19 PM

Actually, looking at the flywheel it appears to me that it's exactly 30° out from that diagram...

Is it possible that 143-tooth flywheels were drilled on that different axis? Mine is a 143-tooth.

IIRC the 143 tooth is a truck flywheel and has a different drilling pattern. But don't take that as gospel, when I was contemplating this, it was with a 130 tooth flywheel.

Posted By: moparmarks

Re: How do I locate the 360 flywheel drilling? - 01/17/24 02:19 PM

Here is a 143T wheel.

Posted By: Sniper

Re: How do I locate the 360 flywheel drilling? - 01/17/24 03:51 PM

Why are you dicking around with this? You can buy a brand new 143 tooth 360 balanced flywheel for under $90 at rock auto.

LUK LFW219

As for the drilling pattern, why would it be different for a 130 or 143 tooth flywheel? The imbalance needed is for the engine, the flywheel is irrelevant.

Posted By: rustbuckett68

Re: How do I locate the 360 flywheel drilling? - 01/17/24 03:59 PM

Top crank bolt hole looks offset. Maybe base your datum lines off that.

Posted By: moparx

Re: How do I locate the 360 flywheel drilling? - 01/17/24 05:44 PM

as a machinist, what bothers me, there is no mention of what angle the drill is sharpened to.

135* ? 118*? 90*? something else ?

just my life experience.

your mileage will vary.

and although not looking it up, if the flywheel is available from rock auto for less than $100.00, i wouldn't bother screwing around trying to balance one to the drawing either.

Posted By: crackedback

Re: How do I locate the 360 flywheel drilling? - 01/17/24 06:58 PM

I agree that the datum line should be based off the crank holes as THAT is the item that your modifications are directly related. Datum off the pressure plate holes, as with the change in clocking, makes the entire process shot in the dark. Even if you are a little off, which drive me crazy as there should be base point, it's not likely to create an issue. JMO and the sentence below sums up some of this.

Balance tolerances on these factory setups was so poor, I doubt the drill cutting angle would make a material change in the acceptable range of error.

Just a guess here. There appears to be a locator hole in the pictured flywheel with the external balance reliefs. Does the flywheel in question have that locator. Bet it's on the datum line passing through the cranks centerline.

I'd prefer it to be spot on and for $100, wouldn't waste time on the process. Sell the current flywheel and buy a new one already balanced.

Posted By: John_Kunkel

Re: How do I locate the 360 flywheel drilling? - 01/17/24 07:18 PM

as a machinist, what bothers me, there is no mention of what angle the drill is sharpened to.

135* ? 118*? 90*? something else ?

I've been asking that for years...common consensus is 118 degrees which is considered the standard.

Posted By: Phoenix

Re: How do I locate the 360 flywheel drilling? - 01/17/24 08:39 PM

Sniper, I can appreciate your curiosity here...

First, I live about 12,000 miles from Rock Auto and we have an exchange rate problem as well as a freight issue. I have three flywheels here and drilling them is possible if I can get the location right.

Second, the drilling pattern for the external balance is, of course, the same just as you say. I have read on different forums that its different but a lot of people who don't appreciate that fact get carried away there.

The drilling pattern, however, for the fitment of the clutch is clearly different. Could it be that it's exactly 30° different to the 130-tooth flywheel?

Posted By: Phoenix

Re: How do I locate the 360 flywheel drilling? - 01/17/24 08:55 PM

Originally posted by moparmarks

I believe that chart is for the 143T wheel which was used in trucks starting in 1972 while the 360 car 4-spd with the 130T wheel wasn't available until 1974.

It is possible, but if it's possible (and it is) to drill to the same pattern as the 130-tooth flywheel it will (must) achieve the balance required.

Originally posted by dvw

[B]I think you are looking with the flywheel pressure plate side up. Flip the flywheel over and look from the crank face side. That's where the diagram is drawn.

The drawing says to be looking from the 'engine side' of the flywheel, so that's what I am doing.

Originally posted by moparx

[b]as a machinist, what bothers me, there is no mention of what angle the drill is sharpened to.

135°? 118°? 90°? something else?

Yes, a good point... I am pretty sure, however, that one of the diagrams I've seen was accompanied by a note saying 120°. I will be checking what my drill is, but it's a new and unused drill so I'd expect it to be right.

Posted By: Phoenix

Re: How do I locate the 360 flywheel drilling? - 01/17/24 09:34 PM

I have now taken pics of all four of my 143-tooth flywheels as well as a couple of 130-tooth flywheels...

I don't have time now to set these pics up, but I will do so in a few hours. I do thank everyone for their input, I really have to get somewhere with all of this and I think we will get that way.

Posted By: crackedback

Re: How do I locate the 360 flywheel drilling? - 01/17/24 09:39 PM

I have now taken pics of all four of my 143-tooth flywheels as well as a couple of 130-tooth flywheels...

I don't have time now to set these pics up, but I will do so in a few hours. I do thank everyone for their input, I really have to get somewhere with all of this and I think we will get that way.

Your location makes it more of a do it yourself situation without a doubt. Good luck with the job.

Posted By: stumpy

Re: How do I locate the 360 flywheel drilling? - 01/17/24 10:24 PM

Can't you use the wider crank bolt spacing position at the 1 O'clock orientation the instruction picture to figure out the way to lay out the drilling pattern? Blow the pattern up to actual size and lay it in position to mark the drilling spots.

Posted By: mkdart

Re: How do I locate the 360 flywheel drilling? - 01/17/24 10:33 PM

PM sent

Posted By: Phoenix

Re: How do I locate the 360 flywheel drilling? - 01/17/24 11:17 PM

Posted By: dvw

Re: How do I locate the 360 flywheel drilling? - 01/17/24 11:37 PM

Mark you 130 tooth flywheel per the diagram. Bolt the 143 and the 130 together. Transfer the marking points from the 130 to the 143. The engine doesn't care what flywheel is on it. As long as the imballance is clocked right on the crank.

Doug

Posted By: Phoenix

Re: How do I locate the 360 flywheel drilling? - 01/18/24 12:41 AM

Interesting that you should mention that...

I don't know how you would bolt them together, nor transfer the marking points. I guess if you made a mandrel of some kind that fitted between the flywheels you could get them on the same axis.

Ultimately I think I might make a drilling jig based on this kind of idea, then I could repeat the process on both sizes of flywheel whenever I need to.

There'd be a lot of machining involved but I can take care of that.

Speaking of the flywheel sizes, here are a couple of 130-tooth flywheels I photographed as well: One is untouched (as far as 360 external balance is concerned) and the other is the one I had drilled in Spokane when I bought my van there. Unfortunately, that drilling isn't repeatable because the bottoms of the holes are round. Anyway, notice these have the different pressure plate bolt locations:

Edit: I've changed the second pic in this post as I realised it was a Slant flywheel. This one is a 318 flywheel, but maybe a 340 with the scallops and the ⅞" deep drillings in it. I have a couple with these deep drillings, the other having four of these holes (approximately ⅝" diameter) rather than the five in this one.

Posted By: Phoenix

Re: How do I locate the 360 flywheel drilling? - 01/18/24 12:44 AM

And here is moparmark's flywheel pic from page 1 with the flywheel rotated to the 'standard' position...

This is a 143-tooth flywheel I now realise.

Posted By: moparmarks

Re: How do I locate the 360 flywheel drilling? - 01/18/24 03:06 AM

It's a 143T from a 72-80 truck. I've parted out a lot of those over the years and I used to have several of these wheels. My 73 W200 360 has it's original wheel which is the same as this one. I don't have any other 143T wheels left but I do have an original 130T 360 wheel.

Posted By: Phoenix

Re: How do I locate the 360 flywheel drilling? - 01/18/24 08:33 AM

Thanks for that information, Mark...

I'd imagine there's a few of these hanging around places like Delta, Montrose and Grand Junction. While looking at different stuff, here's another flywheel I have, it's for a 9¼" clutch (slant or early 273?), it has the large holes drilled into it, but at a much greater distance from the centre than the 3.88" specified, more like 5.5":

Posted By: JohnRR

Re: How do I locate the 360 flywheel drilling? - 01/18/24 02:33 PM

Do you have a way to , or a shop that could , check the wheel you plan to use to confirm it is neutral balance before you attempt to drill it ?

Most of the flywheels you show all have been balanced for something except for the top left one in the post with 4 flywheels pictured ...

Posted By: Phoenix

Re: How do I locate the 360 flywheel drilling? - 01/18/24 07:19 PM

I'd have assumed all of them had some form of factory balancing done...

The location of the (relatively small) balancing marks is nowhere near the balancing necessary for externally balanced cranks.

Posted By: moparx

Re: How do I locate the 360 flywheel drilling? - 01/18/24 07:44 PM

as a machinist, what bothers me, there is no mention of what angle the drill is sharpened to.

135* ? 118*? 90*? something else ?

I've been asking that for years...common consensus is 118 degrees which is considered the standard.

118* is standard.

if i had a factory flywheel to look at, i could easily determine the drill angle.

however, i'm an automatic guy, as i have never been able to speed shift a stick worth a hoot.

therefore, all my parts stash contains just "shift for you" items.

Posted By: JohnRR

Re: How do I locate the 360 flywheel drilling? - 01/18/24 08:49 PM

I'd have assumed all of them had some form of factory balancing done...

The location of the (relatively small) balancing marks is nowhere near the balancing necessary for externally balanced cranks.

Yes , the ones with the small scallops are more than likely the factory balance for neutral , the ones with the holes drilled are for some other balancing of some sort. I had a funny vibration in my 383 dart , when I had my machine shop cut the flywheel and check it balance it was way out and part of the reason was because at one point someone somewhere along the line cut the flywheel at an angle when resurfacing it , it was about .030 thinner on one side vs. the other.

If it were me ... and the shops around me were capable of doing it ... I would clean the wheel I want to use that I ASSuME is neutral, have it re surfaced .... if all the heat check marks were out of it then I would have it neutral balanced WITH the pressure plate I plan on using , then do the drilling for the external balance. When I have my neutral flywheels done it's with the pressure plate and the shop marks the 2 pieces of the assembly so I can assemble it as balanced .

Posted By: Phoenix

Re: How do I locate the 360 flywheel drilling? - 01/19/24 10:13 AM

I'm pretty happy now that I'll be able to use the first one, without any balancing marks and drill to the plan satisfactorily...

I have worked out how to make a drilling jig for the job and that's the way I think I'll go.

With regard to the other flywheels, to avoid any problems, I'd probably send them to a shop with a 360 crank and have it done there. The 130-tooth flywheels especially, I feel, need proving. Now that I look at my 'stocks' I'm surprised that I have so few unaltered flywheels. Or more to the point, so many which appear to have been altered.

When I get around to making the jig I'll post progress pics etc. Thanks very much to Mike (mkdart) for the additional help he gave me.

Posted By: Phoenix

Re: How do I locate the 360 flywheel drilling? - 01/19/24 11:56 AM

Originally posted by John_Kunkel

I've been asking that for years...common consensus is 118 degrees which is considered the standard.

Hi John, over 11 years since we had a chat...

I have to work out properly what the drill is. As stated, it's an unused one as far as I know, there are no marks at all on the fluting and it otherwise looks like it's been lying around without any use at all.

Trying to calculate the angle from a photo I find it's very hard to do this. I got 132° using this method, but it is fraught with variables.

Posted By: B1MAXX

Re: How do I locate the 360 flywheel drilling? - 01/19/24 12:43 PM

I have to laugh, all these variables and you guys are worried about the angle of the bit......

Posted By: moparx

Re: How do I locate the 360 flywheel drilling? - 01/19/24 06:53 PM

looks like a 135* bit.

Posted By: Phoenix

Re: How do I locate the 360 flywheel drilling? - 01/21/24 10:23 AM

Originally posted by B1MAXXI have to laugh, all these variables and you guys are worried about the angle of the bit......

Which variables?

I don't think there are any variables, it's all pretty exact. Which makes asking about that angle relevant.

Posted By: B1MAXX

Re: How do I locate the 360 flywheel drilling? - 01/21/24 01:59 PM

Just how close do think any of this stuff will be (factory balance)? I can tell you from balancing crankshafts that the tip of that bits angle will be insignificant compared to the overall bobweight. I'm sure the rods are out further than the difference in point angles.

If you are trying to duplicate a factory tolerance just drill the holes was my point

. They are notoriously horrible which is why the point angle is not worth debating.

Posted By: 360view

Re: How do I locate the 360 flywheel drilling? - 01/21/24 05:17 PM

Since you have examples, you could obtain “real numbers” on the unbalance weights needed, by spinning those flywheels on a balance machine.

Electric motor repair shops usually have balance measuring machines for large rotors.

Hunter computerized tire and wheel balance machines could calculate a result if an adapter can adjust to flywheel center hole.

You correctly are trying to “get the correct balance.”

By knowing the numerical imbalance you could drill slightly smaller balance holes in the flywheel, then “dial in” a nearly exact balance by enlarging the holes.

There has to be matching “bob weight correction” at the other end of the engine.

When balancing large electric motor rotors it is very common that the two shaft ends need different weight corrections for smooth high speed rpms.

Posted By: B1MAXX

Re: How do I locate the 360 flywheel drilling? - 01/21/24 06:09 PM

just drill the holes, some of those engines would rattle your fillings out from new.

They were never a precision balance.

Posted By: dvw

Re: How do I locate the 360 flywheel drilling? - 01/21/24 06:45 PM

Since you have examples, you could obtain “real numbers” on the unbalance weights needed, by spinning those flywheels on a balance machine.

Electric motor repair shops usually have balance measuring machines for large rotors.

Hunter computerized tire and wheel balance machines could calculate a result if an adapter can adjust to flywheel center hole.

You correctly are trying to “get the correct balance.”

By knowing the numerical imbalance you could drill slightly smaller balance holes in the flywheel, then “dial in” a nearly exact balance by enlarging the holes.

There has to be matching “bob weight correction” at the other end of the engine.

When balancing large electric motor rotors it is very common that the two shaft ends need different weight corrections for smooth high speed rpms.

To do that assumes all the pistons, rod small ends, rod big ends, crank weigh the same to start with. Which is not case from the factory.

Doug

Posted By: Phoenix

Re: How do I locate the 360 flywheel drilling? - 01/21/24 09:56 PM

Originally posted by B1MAXX

just drill the holes, some of those engines would rattle your fillings out from new.

They were never a precision balance.

That's fine...

Now I know that if I do the best job I can it will be all that's needed. And I intend doing the best job I can.

Just reading up on the drill tip angles, it would seem to me very likely that the 135° angle is the one. All the stuff I read suggests that the 118° drill is most efficient in 'soft metals' and cites aluminium as the standard there while the 135° drills come into play in harder metals. And while it would be nice to know just to be more correct, it's also good to know that my tooth fillings are likely to stay in as I cruise the B350 at 2,500rpm.

This discussion has pretty much forced me to add an avatar to my membership here... here's the full picture which really identifies that it's important for me to get things right as I work on this van:

Posted By: markz528

Re: How do I locate the 360 flywheel drilling? - 01/21/24 10:59 PM

-All I know is that over 40 years ago my buddy needed them drilled. Opened the Mopar book to the page with the drawing and showed my Dad. He drilled them (probably on a Jig Borer) and all was good..........

Posted By: PhillyRag

Re: How do I locate the 360 flywheel drilling? - 01/22/24 01:59 AM

I have to laugh, all these variables and you guys are worried about the angle of the bit......

It really does matter if you're drilling brass/alum/wood or metal.

Most off-the-shelf bits are general purpose.

Angle is to steep for most metals.

Posted By: Cab_Burge

Re: How do I locate the 360 flywheel drilling? - 01/22/24 08:26 AM

Posted By: Phoenix

Re: How do I locate the 360 flywheel drilling? - 01/22/24 11:23 AM

Don't worry...

I can do this. I might take a while, I might ask for a lot of advice, but I can (and will) do it.

Posted By: B1MAXX

Re: How do I locate the 360 flywheel drilling? - 01/22/24 12:36 PM

Originally posted by B1MAXX

just drill the holes, some of those engines would rattle your fillings out from new.

They were never a precision balance.

That's fine...

Now I know that if I do the best job I can it will be all that's needed. And I intend doing the best job I can.

Just reading up on the drill tip angles, it would seem to me very likely that the 135° angle is the one. All the stuff I read suggests that the 118° drill is most efficient in 'soft metals' and cites aluminium as the standard there while the 135° drills come into play in harder metals. And while it would be nice to know just to be more correct, it's also good to know that my tooth fillings are likely to stay in as I cruise the B350 at 2,500rpm.

This discussion has pretty much forced me to add an avatar to my membership here... here's the full picture which really identifies that it's important for me to get things right as I work on this van:

Nice

Posted By: RAMM

Re: How do I locate the 360 flywheel drilling? - 01/22/24 01:03 PM

Originally posted by B1MAXX

just drill the holes, some of those engines would rattle your fillings out from new.

They were never a precision balance.

That's fine...

Now I know that if I do the best job I can it will be all that's needed. And I intend doing the best job I can.

Just reading up on the drill tip angles, it would seem to me very likely that the 135° angle is the one. All the stuff I read suggests that the 118° drill is most efficient in 'soft metals' and cites aluminium as the standard there while the 135° drills come into play in harder metals. And while it would be nice to know just to be more correct, it's also good to know that my tooth fillings are likely to stay in as I cruise the B350 at 2,500rpm.

This discussion has pretty much forced me to add an avatar to my membership here... here's the full picture which really identifies that it's important for me to get things right as I work on this van:

Nice

Did this years ago.....worked out perfect... I still have the print. J.Rob

[url=https://www.forabodiesonly.com/mopar/threads/making-sort-of-360-130-tooth-flywheel.192786/][/url]

Posted By: Phoenix

Re: How do I locate the 360 flywheel drilling? - 02/17/24 03:18 PM

I've been unable to progress things much over the past few weeks, but today I was idly looking at websites about 118° vs 135° drill tips and learned something interesting...

The 135° tips seem to have been something of a 'Johnny come lately' and probably weren't well known when the 360 engines were first appearing. Therefore, I feel, the Chrysler instructions for drilling the holes is based on the ready availability of 118° drills and therefore that's the way to go.

I have located, by the way, all the items I need to make up a drilling jig. Necessity being the mother of invention, as usual. I have to have a minor operation next week, but by the end of the week I should be able to get to the Men's Shed and start machining parts to make that jig.