Posted By: 6PAX

Torsion bar install question - 11/26/23 08:13 PM

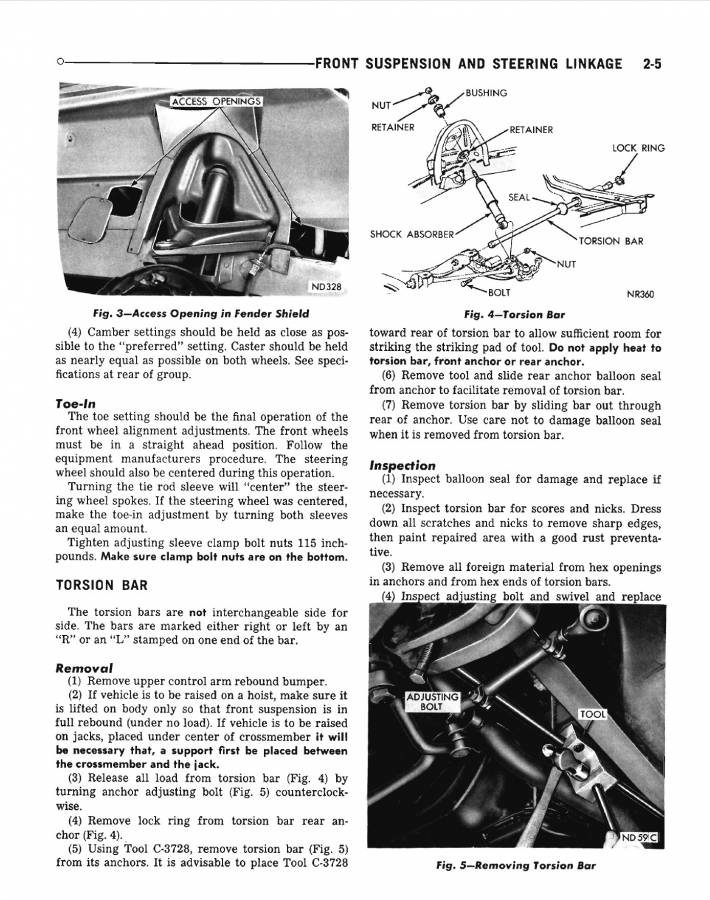

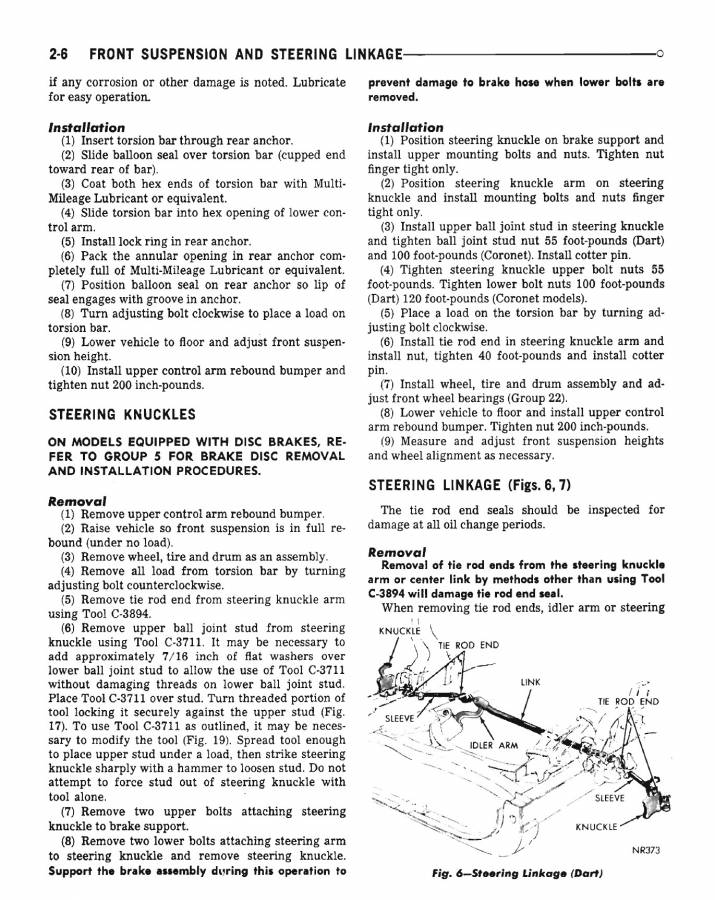

I understand that when installing torsion bars you are supposed to let the lower control arms hang and insert the torsion bar when it's hex lines up with the hex in the lca while raising it to get it to line up. How far are you supposed to let the lca hang? Right now I don't have anything bolted in place as I am installing everything from scratch. There is no suspension on the car other than the ucas (which aren't attached to the spindles as the spindles aren't mounted yet) and the lcas. I have the passenger side tbar a little way into the trans. crossmember and the lca hanging basically vertically as the strut rod isn't in place yet. I can insert the tbar into the lca by just raising the lca a little bit. But if I lift the lca up a little bit more the tbar will also go in on the next set of flats on the hex with the lca still angled somewhat toward the floor. I then have to lift it a little further to get the strut rod to go in the lca. So, how far is the lca supposed to be hanging when inserting the tbar?