Moparts

46rh Governor Questions

Posted By: 46rhRebuild

46rh Governor Questions - 05/06/20 09:26 PM

Hello, I am in the process of rebuilding a donor transmission for my 1994 Dodge Ram 1500 4x4 with the 5.9L magnum engine. Upon disassembling the overdrive housing I discovered a configuration to the governor that I have not seen before. The donor transmission was advertised being out of a 1995 Ram 1500 2wd with a 5.9L. The governor has steel internal and external weights, yet has two external counterweights that feel like they are tungsten.

My question is this: Is this an appropriate setup for a gas application, or is this a diesel converter that wound up in this transmission?

I have had to replace so many of the internals due to parts failures that I am afraid that I am dealing with someone's franken-transmission. I have attached pictures below to show what I mean.

Also, I have the proper 4x4 extension housing that I'm installing, I just needed the internals and the main casing from this 2wd transmission.

Posted By: A727Tflite

Re: 46rh Governor Questions - 05/07/20 12:04 AM

The two external counterweights shown in the bottom photo are to counteract the weight of the governor.

Diesel governor weights are made of brass.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 05/07/20 05:37 AM

Thank you very much for your help, sir. I had posted this before I spoke to you earlier. To clarify, all internal weights for Diesel governors are brass? Do the diesel governors also sometimes employ external counterweights? Cobra Transmission has the only picture of an external-counterweight governor that I could find, and it was listed as a diesel unit. That led me to erroneously conclude that I was dealing with a diesel governor.

Please forgive my lack of knowledge. Though this truck is my work vehicle and daily driver, the 1994 Dodge single cabs were always my dream trucks, and I am attempting to return this truck to it's former glory, largely by myself. So, if you are amenable, I will continue to post questions as I think of them. I do have one additional one now.

When I first tore down this transmission, the thrust bearing on top of the rear overdrive planetary gear was melted directly to it, also the intermediate shaft has deformed against the pocket in the shaft in the forward clutch. Both of those shafts were ruined, the intermediate shaft was peened over so badly that I had to dremel it round to get the aluminum gear set to slip off of it. It looked as if someone had neglected to install the three tab washer and the hardened race that fits onto the end of the intermediate shaft. My question is this: What typically causes damage like this?

Posted By: Guitar Jones

Re: 46rh Governor Questions - 05/07/20 08:09 AM

It sounds like lack of lubrication to me. Trash could be stuck inside the intermediate shaft blocking fluid flow. Most typically a converter failure will fill the fluid with trash, plug the cooler and starve the lube circuit. Always replace the torque converter, and clean and flow test the cooler or better yet, replace the cooler.

Posted By: A727Tflite

Re: 46rh Governor Questions - 05/07/20 10:52 AM

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 05/09/20 02:07 AM

Thank you very much for that advice, gentleman. I have a new torque converter from Precision of New Hampton that will be installed, model 5443HS . It was recommended as being a high quality oem replacement. Any thoughts on their converters?I will procure a new trans cooler, just in case. Is the Hayden Transaver 1402 adequate for this transmission?

I sincerely appreciate the help, and apologize for my delay in replying. My older brother just came back from his last deployment to Afghanistan, two days ago, and I've been helping him move. The old truck is limping along and still managing to haul truckloads, even with the leaking front seal. I hope to have the transmission fully rebuilt and at the shop for the local mechanic to swap out, later this upcoming week. In the meantime I just keep adding fluid.

The overdrive clutch pack is assembled, and aligned. I will be rebuilding the governor on Monday. The ATSG manual says to inspect the governor sealing rings for wear or damage. It has the teflon rings installed, and there are no nicks. Does anyone happen to have the measurement of good tolerances for those rings?

Posted By: A727Tflite

Re: 46rh Governor Questions - 05/09/20 01:32 PM

Precision makes good converters, you won’t have any issues with them.

Teflon sealing rings are pretty forgiving so unless you damage them installing them you won’t have any issues. Just make sure the grooves are not damaged, clearance is not an issue with them.

Thank your brother for helping his Uncle out, I hope he is doing well.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 05/10/20 05:15 AM

Thank you for clarifying the teflon ring questions. Also, I am glad to know that Precision does good work.

This transmission build has been a very good learning experience for me. I was absolutely terrified of transmissions, prior to this. Though I understand that this is almost as bare bones as an automatic gets. Trust me, I have zero ego about my abilities in regards to them. There is a gentleman who posted a series of youtube videos detailing the breakdown and re-assembly of these units, else I never would have attempted this on my own. I believe that he owns a website called TheTransmissionBench. The Service Manual and ATSG manual also have provided much needed guidance, along the way.

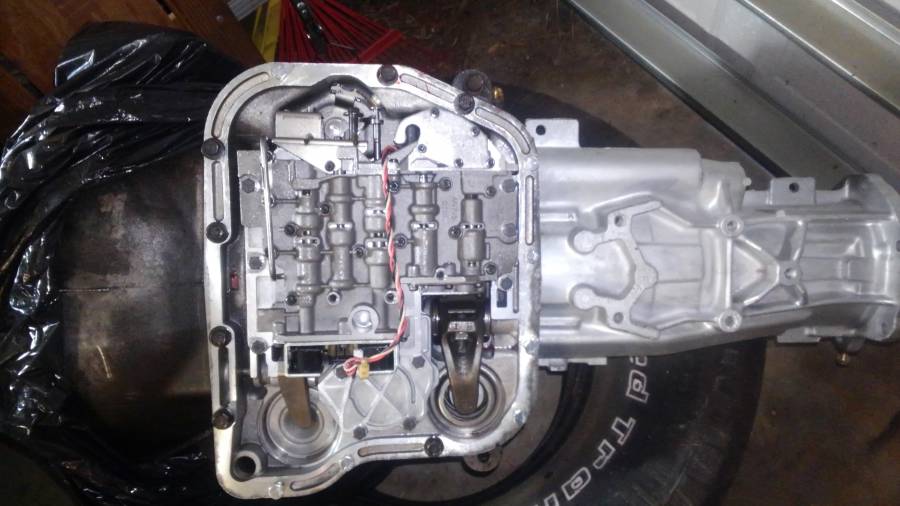

I did not attempt to tear down and rebuild the valve body on my own. I bought a two solenoid (with boost tube) valve body that had been remanufactured and updated with a Sonnax kit, from Central Valve Bodies, by way of a reseller. The gentleman who owns that shop is name Donny Lester, I believe. I hope that that was a wise move.

In regards to my older brother, he's doing well since he got back stateside. He has the full support of the family, and we're just happy to have him home. Thankfully this was the last deployment before his 20 years are complete. One more year and he's retired and moving onto the civilian trade world.

I have seen that these transmissions can be tested with an air compressor, prior to re-installation. Do you happen to know, off hand, what specialty gauges or fittings are necessary to test the servos on a 46rh? Again, thank you for all of your help, this has been an experience.

Posted By: A727Tflite

Re: 46rh Governor Questions - 05/10/20 11:44 AM

A rubber tipped blowgun with air pressure regulated down to 20 or 30 lbs. is all you need.

Listen for leakage. Some guys use real high pressure - real high will mask cut seals.

Just hit the servos to watch them actuate then the front and rear clutch.

Make sure you use a clean air source (drain your compressor of water) before using it.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 05/11/20 02:01 AM

Thank you again, sir. I drained my compressor today. Wow, I hadn't realized how much water had accumulated in there.

Are there any quirks to these transmissions that I should keep an eye out for?

I bought the special tools to measure for the correct overdrive shim thickness. Also, I picked up the sonnax shim kit. How critical is replacing the intermediate shaft spacer? I have the tool to measure for that, as well.

I am really happy with the one that's still in the truck. I have no idea how many miles are on it, total, but the fluid has always been bright and it's always shifted well. I can tell that it's tired and needs to be replaced with a fresh build, on top of the leaking seal, though. I've personally put almost 100,000 miles on that transmission. No towing, just daily driving. The shifts have gotten mushy, even with proper band adjustments, and there's substantial power loss, and I think occasional slipping in third, but it's hard to tell.

Posted By: A727Tflite

Re: 46rh Governor Questions - 05/11/20 08:10 AM

The intermediate shaft shim shouldn’t have to be changed unless you changed the intermediate or the output shaft.

It ultimately affects input shaft end play so make sure it’s there.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 05/11/20 11:55 PM

I have changed both the output shaft, and the intermediate shaft.

I basically had to build a complete overdrive unit from spare parts. The only parts that will be original (in the overdrive unit) are the governor, and the overdrive direct drum. The entire overdrive gear set came from a 46re, it's the newer 22 degree angled gear set. I bought it as a unit, and was told that as long as it's not mixed with any earlier 15 degree parts, then it will work fine.

The intermediate shaft was ruined and the front of the shaft galled and rounded back over the retaining snap ring groove.

Have I made mistakes in my calculations with these parts? Everything has fit together in the overdrive assembly smoothly, and the thrust bearings are all oriented properly. I paid special attention to that.

Posted By: A727Tflite

Re: 46rh Governor Questions - 05/12/20 02:41 AM

Biggest issue to new builders is forgetting to install the overdrive bearing on the back of the overdrive piston, or putting those bearings upside down.

Don’t forget you need to check with the special tool and select the correct overdrive shim. If the shim you need is in between two shim thicknesses, always go to the next thicker shim.

Good thing you know about the tooth angle changes between diesel and gas.

As for the shafts being replaced, you must check with the special tool to make sure you select the correct thickness shim that goes on the back of the intermediate shaft. Oil everything up, especially those needle bearings, and you should be golden.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 05/12/20 04:18 AM

I oiled the bearings liberally with transmission fluid before installing them. I also used Red Transjel to stick them into their respective places in order to keep the orientation straight. It helped that they only wanted to sit flush one way, and they're oriented the same way as each other. Even though I checked twice, I may pull the overdrive assembly apart again because I'm second guessing myself.

I will be taking both measurements, for both of the shims, tomorrow.

Oh, the seal on the back of the 4wd overdrive housing, should I install it with the opening (the side with the spring in it) toward the transfer case or back facing the overdrive internals?

Also, are the 22 degree angled gears appropriate for a gas application? This transmission is going behind a 5.9L Magnum.

Thank you for putting up with all of this new guy's questions. I couldn't find straight answers to these questions anywhere. Not in the FSM, the ATSG book, or in other forums.

Posted By: A727Tflite

Re: 46rh Governor Questions - 05/12/20 11:47 AM

The seal gets installed with the garter spring facing in to the overdrive unit. It keeps trans fluid in the trans. The seal on the transfer case has its spring facing in to the t/fear case. You will notice a groove cast in to the bottom of the overdrive extension housing. That is a weep hole, do not plug it up with RTV. If you see a leak from it investigate where the leak is coming from by using the color of the fluid to determine the source.

I would stick with the 15 degree parts. As for fluid I would only use Mopar ATF + 4 or equivalent. The overdrive will love you for it.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 05/12/20 09:29 PM

Ok, I need to order another seal because I installed that one backwards.

I've only ever used ATF+4 in it, from everything that I read, there's nothing like it for these Chrysler transmissions.

Unfortunately I only have the 22 degree gears. What will this effect in the long run?

Posted By: A727Tflite

Re: 46rh Governor Questions - 05/12/20 11:51 PM

I have heard of a few noise complaints in gas applications besides that won’t hurt a bit.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 05/13/20 10:08 PM

Today I began reassembling the overdrive unit to take measurements.

I ran into a huge problem. The governor key slot is different betweenthe original shaft and the 4x4 shaft I was sold. The key shown in the ATSG book is a small square whereas the key that came with the governor is a large half moon shaped.

Can you advise on whether I was sold the wrong shaft, or if I just need a different key?

Posted By: A727Tflite

Re: 46rh Governor Questions - 05/13/20 10:52 PM

It’s been too long, I don’t recall what if any differences there are but I would have to imagine you got the wrong key.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 05/13/20 10:55 PM

Lacking milling equipment, I don't trust myself to cut this key super accurately. Would you trust a key cut with a bandsaw and filed as true as I could get it, for an application like this?

On second thought, the words Precise Measurement and Transmission seem to go hand in hand. I bought the last 4x4 output shaft that I could find, and it will be here by Tuesday. I visually verified that it had the proper key way slot.

Posted By: A727Tflite

Re: 46rh Governor Questions - 05/14/20 12:05 AM

Like I said it’s been too long, can’t imagine why we would make two different keyway slots, especially in your case, both being 4 x 4.

Unless the shaft you have is an aftermarket piece.

All the key does is align and hold the governor support so the weight/valve rod passes through the shaft.

Let’s see the key ways on all the shafts when you get the next shaft.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 05/14/20 04:29 AM

I will definitely take pictures of them.

I was very surprised that this shaft had a different key way slot. The overall measurements were within spec, it has the governor hole through the shaft, and was advertised as an A518/46rh shaft. The key way is about a 1/4 as deep as the 2wd shaft that I got the governor from.

Found this interesting article detailing the endplay measurements on 46rh/re transmissions. From an ATRA March 2008 issue. Found it while searching for overdrive key specs.

https://atracom.blob.core.windows.net/gears/2008/2008-03/2008_3_10.pdf

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 05/14/20 04:57 AM

When I began this project I was proceeding with the knowledge that the only three components that were different between the 2wd and 4wd versions of the this transmission were the Extension housing itself, the Ouput shaft, and the Seal at the rear of the extension housing. So I began assembling pieces.

My parts list thus far for this build will be:

1. Transtar rebuild kit (seals, steels, Alto and Exedy frictions, etc) $88

2. Precision of New Hampton torque converter $146

3. 4x4 Extension housing $126

4. Ouptut shaft (now x2) $80 total

5. Overdrive planet assembly $60

6. Forward clutch drum and input shaft $45

7. Remanufactured valve body $260

8. Hayden 1405 trans cooler $27

9. Sonnax OD piston retainer $60

10. Various shims, bushings, assembly lube $60

11. Base price of "rebuildable" transmission $350

12. Measuring tools and alignment shaft $100.

Total price $1402 plus $500 labor to have my local mechanic swap the trans for me.

(Yes, I thought it would be cheaper to do it this way. I know, I'm an idiot.)

The Pro of all of this is that I'll know how to rebuild this truck's transmission everytime it needs it, and thanks to you, I'm learning how to rebuild it right, the first time.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 05/16/20 10:05 PM

Here are both shafts. I installed the key in each one to show the difference in depth. The key way slot on the shallow shaft is also substantially longer.

Please let me know if you'd like additional photos showing any particular part of these.

I've seen pictures of 47rh shafts that have a similar looking keyways as the original shaft. I don't know if that helps at all. Here's a link showing the picture that I found.

https://goerend.com/tcs-23-spline-billet-output-shaft-47rh-618101/

Posted By: A727Tflite

Re: 46rh Governor Questions - 05/16/20 11:22 PM

I see this as a non issue. Use either shaft you like, just make sure you have enough key sticking up enough to pilot the governor housing. As I said earlier, the housing doesn’t see any load.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 05/17/20 12:38 AM

Thank you, sir. I have cleaned and installed the shaft I just bought.

I'll have a spare should I ever need one, and can have a machine shop make a proper key for it. I'll take the measurement of how much it protrudes above the shaft and log it in my build folder, for future use.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 05/17/20 06:07 AM

Put the overdrive unit back together and pulled these measurements tonight.

Overdrive Thrust Plate

.7829

.7834

.7829

.7829

Chart is saying shim thickness .138-.140. I have the Sonnax shim kit but the base race of that kit is .175, and the spacer that I already have is .213. Luckily I was able to find the correct size for sale.

Intermediate Shaft End Play

.7470

The chart says that I need a shim that is .158-.159 thick, Moparpartsgiant.com is the only website that I could find with that size in stock.

Also, pulled the key protrusion measurement, in case anyone ever needs it. Key protrudes .180 proud of shaft.

Posted By: A727Tflite

Re: 46rh Governor Questions - 05/17/20 12:13 PM

Look at the chart and select the shim that is the size called for or the next size thicker than called for.

Never go smaller.

Don’t forget that once the overdrive is built, install it before stuffing the trans. Then build the trans.

That procedure should be called out in any of the correct publications.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 05/17/20 08:18 PM

The video series that I've been referencing says to build the transmission this way.

What is the reasoning behind this? I am not arguing, I genuinely want to know what this influences.

I appreciate your continued instruction. I also hope that all of this helps someone else, as other forum posts got me started on this project.

Posted By: A727Tflite

Re: 46rh Governor Questions - 05/17/20 11:37 PM

Back to front because the intermediate shaft has to be in place to properly set input shaft endplay.

That’s why the intermediate shaft shim has to be selected to start with, that is a baseline dimension from the extension housing gasket face - down to the inside of the overdrive unit - if I recall to the top of the planetary.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 05/18/20 01:12 AM

So is there another endplay measurement taken once I start re-assembling the main barrel of the transmission?

I wondered that when I kept seeing intermediate shaft endplay shims for sale. Is it a good idea to go ahead and order one of those endplay shim sets to have on hand for this build?

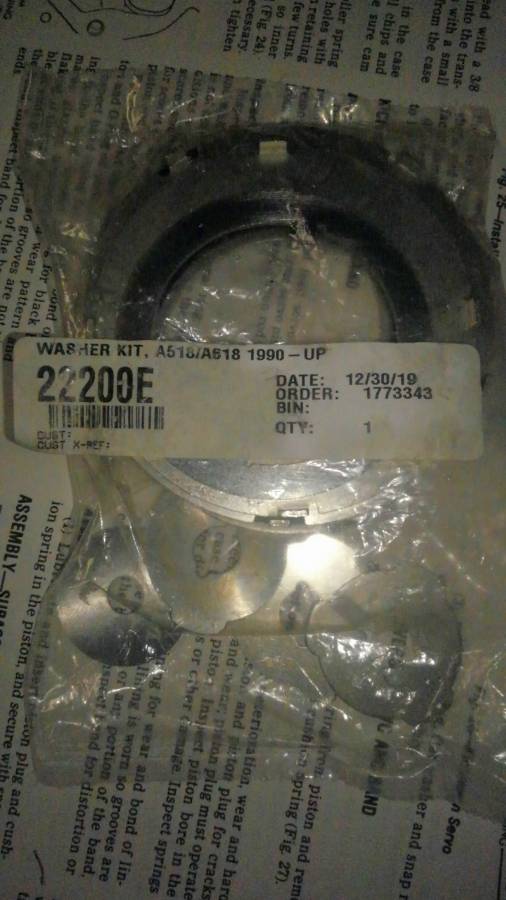

I looked at the washer kit that I bought for this build and saw that I have three of the three tab washers and a new hardened steel race. These look identical to what is pictured in the end play shim kits. Do I have what I need, sir?

Posted By: A727Tflite

Re: 46rh Governor Questions - 05/18/20 02:50 AM

Once you have used the proper tools and selected and installed the correct shims in the overdrive unit and it’s installed on the trans, then build the trans using the standard procedures. Check and set geartrain end play (front and rear planetaries and drive shell), then adjustment of input shaft end play.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 05/18/20 11:43 PM

I had to go back to the ATSG book to understand exactly what you meant there, (this is all very new to me.) I am going to list the measurements that I need to take. Please advise me if I have forgotten any critical measurements.

As I am building the main case of the transmission, I take measurements of:

1. The Front Clutch w/ feeler gauge under high point of wavy snap ring (should be within .070-.129")

2. The Rear Clutch w/ feeler gauge under high point of wavy snap ring (should be within .025-.045")

3. Planetary Gear Train End play w/ feeler gauge ( should be within .006-.048")

Once these measurements have been taken and everything is within spec, do I need to use a dial indicator to measure the total shaft endplay once the transmission has been assembled?

Posted By: A727Tflite

Re: 46rh Governor Questions - 05/19/20 12:04 AM

You have everything correct as long as the overdrive is done and bolted on, just need to set input shaft endplay.

For your application try to stay in the middle of the clutch pack clearance specs.

Don’t forget that when you build the overdrive assembly to use the tool to line up the splines in the overdrive planetary and ORC otherwise you won’t be able to install the Intermediate shaft.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 05/19/20 12:20 AM

Yes, sir. I have already made that mistake and had to take apart the overdrive to realign it. I check the alignment every time I move the unit.

Thank you for the advice about shooting for the middle of the clearance specs. Is my overdrive being on the tight end of spec a concern?

I am currently waiting on the correct spacers (overdrive thrust and intermediate shaft) to arrive, so I can begin assembly of the trans.

I was inspecting the main case last night and noticed that the overunning clutch cam was pushed very slightly forward. I can move it move forward and back on one side very slightly, but it does not want to rotate or move otherwise. Do I need to replace?

Posted By: A727Tflite

Re: 46rh Governor Questions - 05/19/20 01:45 AM

On the OD shim, use the next thicker shim if you fall in between two shims or you are close to the top of a given spec range.

As for the main ORC I would press it down in the case, re-stake all around it and make sure the set screw is

If you tow, or will be on sand, loose soil or doing pulling make sure you use low gear and not drive, the read band will help save the orc.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 05/19/20 04:00 AM

I remeasured the OD shim tonight and I got a nasty surprise. I must have messed up my original measurement somehow. I am glad that you stressed it and that I double checked it.

The correct measurement average is 1.828. The Sonnax shim plus one spacer brings me to .185. The FSM says range is 1.8250 - 1.8399. Shim thickness .183 - .185. Would you leave it at .185 or add another .010 shim?

I turn off the OD unless I'm on the highway, I was told that it would make my trans last longer.

Posted By: A727Tflite

Re: 46rh Governor Questions - 05/19/20 12:32 PM

No, you are good, you are not at the top of the range. 1.828 is closer to the bottom of the range than to the top.

ATF + 4 really helped out all the transmissions - especially the RWD OD units. You shouldn’t have any issues leaving it in OD.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 05/19/20 08:31 PM

Thank you for clarifying the shim range. I was fairly certain that I was in bottom of the range, but I'm learning to triple check when it comes to transmissions.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 05/21/20 12:14 AM

The replacement input shaft and planetary gear train came in, fully assembled. I checked the endplay measurement on it. .034. The ATSG book says that .006 - .048 is within spec.

I'll disassemble the assembly to make certain the thrust washers are in good shape. I'll recheck clearance after this. I bought all new washers, just in case.

If I understand correctly this entire assembly is inserted into the trans in one piece. Is this correct?

Posted By: A727Tflite

Re: 46rh Governor Questions - 05/21/20 12:24 AM

Yes as long as you have the shim installed before doing so.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 05/21/20 12:47 AM

Yes, sir. The shim should be here by Friday. I know to be very careful about over spreading the shim when installing.

Are there any oddities in this part of the build that I should watch out for?

Posted By: A727Tflite

Re: 46rh Governor Questions - 05/21/20 01:41 AM

Lube it, stab it, follow the service manual. From this point forward after the intermediate shaft is installed, it goes together lime a regular 727.

Just be careful when you install the valve body that the OD/LU plug that enters the case does not get cocked and broken.

Make sure to check the OD accumulator spring in the valve body, they like to break from time to time.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 05/25/20 06:34 AM

Yes, sir. Thank you for that advice. I know that the plastic housing on the pin is delicate.

I had to halt work on the trans in preparation for a busy memorial day weekend, but work resumes on it tomorrow.

First order of operation is to disassemble the planetary gear train, lube all bearings, and check thrust washer condition. Pre-dissassembly clearance is on the tighter end. I bought the gear train as an assembled unit, but I don't trust that everything is well lubed.

The video series that I have been consulting assembled the planetary gear train component by component inside the main barrel. Do you recommend this approach, or assembling the gear train beforehand and stabbing it?

Any recommendations for increasing the life of this rebuild is appreciated. I have time to order components if there are any parts that I should update.

Posted By: A727Tflite

Re: 46rh Governor Questions - 05/26/20 01:48 AM

You can assemble the geartrain either way. The transmission plant built the geartrain, checked the clearance then installed the assembled intermediate assembly.

Be clean, follow the directions in the pubs, run the unit to get the oil level qualified, then run it through the gears with the rear end off the ground through all the gears.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 05/26/20 05:14 PM

I got the servos repopulated, the intermediate shaft support installed, and seated the overdrive yesterday. It was kind of a bear to seat. I was gentle with it because of the governor tubes, but I had to wiggle and fight it on a bit. Is this normal?

It seated so oddly the first time that I pulled it back off, and boy did it not want to come back off. The second time it seated the same way, so I guess it's just how this one wants to go together. I lubed the intermediate support where it contacts the bushings in the OD, so I know it wasn't because of lack of lubrication.

I used the Sonnax intermediate support, and NOT the oversized one.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 05/26/20 09:14 PM

Alright, I've got another weird one.

With the reverse drum in place, and a new thrust washer installed, there isn't enough clearance for the snap ring to install into the intermediate shaft support. What did I mess up?

I'm pulling the overdrive back off and making sure that the intermediate shaft support is all the way in. Its torqued to the right specs already but it's not much. I really only need another .020 of an inch to get this snap ring to clear.

EDIT: Pulling the overdrive housing and retapping the shaft support gained me no clearance. Maybe somewhere in the build I mixed up a couple of snap rings and this one is just too thick. I'm off to find a thinner washer or snap ring. Or sand this washer down if a thinner replacement isn't available.

Any advice is welcome if you've run into this problem before.

Posted By: A727Tflite

Re: 46rh Governor Questions - 05/27/20 01:23 AM

I think the correct L/R drum snap ring is angle cut on the ends. With the drum out the snap ring should fit in the groove. The correct thrust washer should have two anti rotation tabs on it.

There is nothing in the OD unit that would cause this issue. Only thing I can think of Is the ORC cam/rollers/race are not seated. The race should be pressed on the drum. Make sure it’s pressed on all the way. The cam should be pressed in to the case without any clearance between the cam and back of case.

As for the effort to seat the overdrive, that’s not uncommon. If you used the correct tool to assemeble the OD in the press and didn’t manhandle the unit/drop it before assembly on the trans then it’s just one of those units that’s difficult.

You have to keep the planetary and direct hub lined up during the OD build process.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 05/27/20 02:22 AM

The snap ring I have is angled on the ends, and it fits in the groove without the washer installed. The washer is also .062 of an inch and has two anti rotation tabs. There isn't enough clearance for both of them, and the washer blocks the snap ring entrance, about halfway, when it's installed

I verified that the cam, and the sprag is seated well but I will tap the cam gently tomorrow with a round brass shaft to ensure that it's seated all the way. I don't have any way of fitting it in my little press.

I read that there are different drums that were used in the 727 and A518, and sometimes get mixed up. One used a delrin plastic washer and apparently didn't have as deep of an indent for the washer, from what I understood. When I was tearing down this trans I didn't find any kind of washer in that drum. I kept all the used parts just in case and I didn't see anything like it when I went through them again. I also noticed that my drum doesn't look like any of the A518 drums I'm seeing. It looks like a 46re drum. Does that change anything?

If I sand the non indented side of the washer to make this all fit, am I going to hurt anything?

Thank you for your assessment of the overdrive. I used a homemade tool to press the OD unit, but I used my alignment tool to make sure everything was lined up, and after installing the overdrive housing I found that it had stayed aligned. The third time installing the housing was much easier and it just kind of drew down into place.

Posted By: A727Tflite

Re: 46rh Governor Questions - 05/27/20 12:58 PM

I’m not aware of any differences between the very late style 727 and 518 drum, there may be.

Any drum that uses the snap ring and thrust washer must have the machined step in the drum though.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 05/27/20 05:10 PM

It has the step in, but there isn't enough clearance. The washer is .062 which seems to be stock, the snap ring is .060 even. I also tapped the cam fully seated, there was about .006 under there. Now it won't allow a .0015 feeler gauge.

I suspect the drum, because the cam is fully seated, and the washer and snap ring still don't have clearance. This is a genuine Sonnax shaft support, so I imagine that it's true.

What's your take, sir?

EDIT: I asked a couple of sellers of remanufactured drums to pull a measurement of that step in, the most common measurement I've gotten back is .088. The one that came in this trans measures .020.

New drum is on it's way. I decided to replace the sprag, as well, just in case. I'll post how it continues once the new parts are in.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 06/03/20 10:32 PM

Received the correct reverse drum. The drum, metal washer and snap ring all dropped right into place, took less than five minutes.

The first picture shows the wrong reverse drum on the left, and the correctly cut drum on the right. The incorrect cut was .020, and the correctly cut drum measured .088. All other measurements appear to be identical. I'm being specific about the measurements in case anyone else runs into this with one of these rebuilds.

The second picture shows the correctly cut drum step.

The third shows how shallow the original drum was cut. Does anyone know which application would use a .020 cut reverse drum?

Posted By: A727Tflite

Re: 46rh Governor Questions - 06/04/20 03:04 AM

Where the band rides, same diameter between the two?

Still looking for my plant info - when I find it maybe there is an explanation for the depth differences.

Sorry, I have been offline for a while.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 06/05/20 05:04 AM

I've been offline, myself. Busy, as I'm sure you are.

The two drums miked the same in all measurements that I could accurately pull, except for that step in. Aside from one being lipless, of course.

The gentleman who runs the transmission shop I bought it from sent me a new snap ring and an old plastic style (Torlone?) washer. I used the new metal washer with the relief cuts (relief cuts placed toward reverse drum).

He also pulled measurements from a half dozen drums for me and sent me the drum with the largest cup. He said that .075 was the most common he found, aside from the .088 he sent me.

It installed with almost no play, but the snap ring sits firmly in the groove and will move rotate around the groove with a fair amount of force applied. I figure this means that it's seated properly, and is not binding at all.

Posted By: A727Tflite

Re: 46rh Governor Questions - 06/06/20 02:44 AM

Finally had a chance to look for my plant info.

Info mentions changes from no thrust washer to a thrust washer.

Heat treated in that countersink area gets a snap ring without the thrust washer.

Non heat treated gets the thrust washer.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 06/07/20 02:11 AM

I don't have any way to check for specific hardness. I didn't notice any kind of washer when I removed the drum originally, so perhaps the original is a hardened drum. It's now just sitting in a box of spare parts if anyone has a specific need for it.

Thank you very much for looking that information up.

The trans is in the final stages of being built. The forward and reverse drum have been assembled, and fall within spec. The pump will be getting cleaned and checked tomorrow.

Should I air check the servos before I install the valve body?

Also, are there any pitfalls to avoid when installing the VB or inserting the parking pawl down into the overdrive section?

Posted By: A727Tflite

Re: 46rh Governor Questions - 06/07/20 02:47 AM

The drum with the blued recess has the hardening I mentioned and does not use the thrust washer.

The one without the bluing is not hardened and uses the washer.

If you plan on using air pressure I would lower it to 30 psi before testing. The rear servo is easier to test if you just install the servo piston then bring it up almost out of the bore then close the apply hole off with your finger tip. Then try to push the piston down. If you can’t the seal is good.

If you used metal seal rings on the front servo piston and retainer it’s pretty difficult to screw those up unless you used a hammer. 😀

Teflon seals should be tested with air like the rear servo using the same pressure rate.

The park rod can easily be placed in the wrong spot. I find it easier to install the rod with the trans vertical, while someone tries to turn the output shaft. The plant actually installed the rod only, then the valve body and they had a tool that held the 3/4 snap ring so it’s could be installed once the rod engaged the valve body.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 06/10/20 01:10 AM

Thank you for clarifying about the drums.

I absolutely DID NOT use a hammer to install anything internal to this transmission. Two seals on the outside, yes.

I have replaced every single teflon seal, metal seal, o ring, lip seal, plastic clutches etc that I've come across. I trust no seals a second time. Also those plastic sprags kinda scare me too.

I figured that the park rod was going to be one of the pains in the butt. Luckily the trans is vertical so I might just have to stab it and check, rinse and repeat, until I get it right.

I started to worry that I was going to wind up with a faulty build, because of all of the oddities that I've encountered. But everything is coming up within spec, the servo bores looked great, all the seals went in well, and I've got a professionally rebuilt and updated VB that I'm installing. So I should probably relax and just get this thing buttoned up.

Posted By: A727Tflite

Re: 46rh Governor Questions - 06/10/20 11:32 AM

Didn’t mean to imply you used a hammer, but that’s about what it takes to damage the metal seals.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 06/11/20 05:54 PM

I took no offense, sir. I was laughing at the thought. Your advice has been invaluable, and I sincerely appreciate all of it.

I know that slipping that servo into the bore was tricky. I used the back of a screwdriver to tap it so that it would sit flushly and I could press it in by hand. I don't imagine that that could have hurt it, though. The guy in the videos used the back of a hammer, oddly enough.

I grew up working on diesel engines. I've seen people do dumb things to delicate parts with hammers so I do my best to avoid that behavior. I watched a guy deform a very expensive fuel rail because it wouldn't slip into place for him.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 07/10/20 06:11 PM

I apologize for the long absence, but had to focus on more immediate work for the last month.

I'm assembling the front direct clutch drum, and the frictions that I was supplied are the hi-energy waffle pattern frictions. Will this affect anything if I use these in place of the flat frictions that I see depicted in the book and videos I'm referencing?

This are the frictions that shipped with my rebuild kit, part number A22008E.

Also the gentleman in the videos says that if the clearance is tighter than .090 then binding will occur between the 2-3 shifts. The FSM states that .070-.129 is good to go. Is there any truth to this? I ask because my assembly measures at .078.

Posted By: A727Tflite

Re: 46rh Governor Questions - 07/10/20 08:36 PM

Using production hard parts and following production specs won’t cause binding.

That’s usually caused by messing with servo internals, front clutch release spring stack, and sometimes messing with the valve body.

Most guys tend to stick with the middle of the spec range for clurch clearance but you will be fine where you are.

As for the waffle discs, they provide more lube to the clutch discs which helps cool the clutch - like in snow plow use, frequent reverse applications.

The other theory is that the waffle grid wipes the oil off the steels faster instead of hydroplaning.

Like sipes in a tire.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 07/10/20 08:47 PM

Thank you for explaining that. I had a feeling that was the purpose, but wanted to double check before I installed it all.

And.....it happened again. I was sold another part that does not match the specs for what I need. The front input shaft has a flared edge that is two different sizes, where it mates with the inner pump bushing. I'll take a picture and post it below.

The new one I was sold measures 1.235, whereas the old one measures 1.172. So I guess I get to go find another shaft. Because the original one is ruined where it mates with the intermediate shaft.

The new one is on the left.

Posted By: A727Tflite

Re: 46rh Governor Questions - 07/10/20 10:01 PM

If you are talking about the journal below the two input shaft seal rings, yes there are two sizes for the more modern units.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 07/10/20 10:05 PM

Yes, sir, that is exactly what I mean. I realize that I was solely focused on the front sealing ring diameter, not even thinking about the large journal that rides in the stator bushing. I'm trying to track down the smaller correct size.

Are there any major pitfalls to avoid when pressing one out and into that front drum?

Posted By: A727Tflite

Re: 46rh Governor Questions - 07/11/20 12:13 AM

Look closely just below that journal and you will notice a wire retainer ring. That has to come out first.

Then press the input shaft out - “up” as shown in your images.

Support the rear clutch piston support in your press as close to the diameter of the input shaft as possible, like where the thrust washer seats.

I have seen guys crack the support when not doing so.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 07/11/20 08:44 PM

Thank you, sir. I hope it does not come to that. The seller says they are going to make it right. Hopefully they have the correct OD shaft and drum assembly.

Posted By: 360view

Re: 46rh Governor Questions - 07/12/20 11:18 AM

This wonderful thread should be expanded into a book.

As an owner of a 1995 46RH that needs an overdrive unit rebuild I never knew there were so many important part variations.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 07/13/20 01:04 AM

If it hadn't been for Transman, I would never have been able to tackle this build with any success. I had zero knowledge of the parts differences in these transmissions, either.

I'm happy if my build can help any other people. The actual assembly isn't hard, just follow his hints! He's saved me alot of time and pulled me out of the woods everytime I've gotten stuck.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 07/13/20 11:54 PM

In case anyone needs to know the two different journal sizes on these input shafts, here they are.

The small shaft measures 1.159 OD on the land that rides in the stator bushing.

The large shaft measures 1.243 OD on the land that rides in the stator bushing.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 08/09/20 10:40 PM

Alright, back at it for the last part of the build before install.

The three tab thrust washer was missing on this build originally, What is the correct thickness washer to use?

I ordered a three tab thrust washer and hardened steel race kit, but am unsure which thickness I should be using.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 08/10/20 12:26 AM

Doing further research, I see that I need to install the rest of the assemblies, including the pump with no o-ring for ease of removal. Then measure total endplay with my Starret dial indicator. If I fall within specs, then I'm good to go. I've installed the intermediate of the three thrust washers first.

Endplay comes to .030 with the intermediate of the three washers installed. I'm searching through all my publications to find out if this is within spec. If anyone has specs around please post so that I can confirm.

Posted By: A727Tflite

Re: 46rh Governor Questions - 08/10/20 02:07 AM

.036 - .086” seems to be the number. I’ll check in a bit.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 08/10/20 03:48 PM

Thank you sir. Using the thinnest of the three washers will get me there, it looks like.

Here's what I did, if you don't mind checking my work.

1. Install input shaft, rear drum, then pump, aligning everything (washer and hardened race installed). I did not intall the kickdown band

2. Install gasket and hand tighten two of the pump bolts to hold it in place

3. Used a lever against the shaft (unit is upright) to move it to the extreme upward range before the transmission wants to move as a unit.

Dial read exactly .030

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 08/10/20 07:36 PM

With the thin washer installed, the endplay is now .041.

Got the drums, kickdown band, and pump installed. All that's left is the valvebody, as far as I can tell.

Posted By: A727Tflite

Re: 46rh Governor Questions - 08/10/20 08:58 PM

2000 MY manual calls for .034” to .084” so hit me with a 2 x 4 - I was off .002” on min/max.

You will usually get a different number if you stand the trans up versus checking while horizontal.

At .041” I think you are good to go.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 08/10/20 10:11 PM

Thank you, sir. Once the valvebody is installed at some point this week (trade school is back in full swing again, so that's most of my time) I'll check the endplay while horizontal.

Is it worth it to try to track down one of the tools used for attaching the eclip onto the valve body, rather than trying to stab it as one unit? I remember you saying it was really easy to screw up the location of the parking pawl.

Posted By: A727Tflite

Re: 46rh Governor Questions - 08/11/20 01:04 AM

Since your unit is vertical already I would just install the vb and rod as an assembly. Just be aware of the position of the rod passage and focus on that during installation. It helps to have someone turn the output shaft as you install the vb/rod assy.

Don’t forget to be careful installing the vb in regards to the od plug - lightly grease that bore and the pass through plug. Start a couple vb bolts then work the linkage to make sure park works.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 08/13/20 01:06 AM

Thank you, sir. I appreciate all of the advice. I will report back once the VB is installed this weekend, and let you know how it went.

VB install will be this upcoming weekend. Still trying to find someone to swap this thing, my normal mechanic is a month and a half out.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 09/05/20 02:03 PM

Finallly have room at my mechanic's shop for him to do the swap either this upcoming week. The truck is finally succumbing to the brutal Florida heat, and I can feel the loss of power on the highway in third gear.

So, today is VB installation. I don't have another hand to help turn it, so will just do my best to get it stabbed right.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 09/05/20 08:38 PM

Finally assembled. New Precision of New Hapton TC and 36,000 GVW Hayden cooler going in with this rebuild.

I could not have done this without Transman. Thank you sir. I sincerely appreciate your patience in teaching this complete new guy how to do this. This is my first transmission build, and I was completely lost in the wood until you came and bailed me out.

I hope all of this different information helps out another guy who has to do this on his own, and maybe runs into some of the same problems that I did.

To whomever did this horrible damage to this first transmission, you're something I won't say here. However, your idiocy turned into a teachable moment for me, so I guess I owe them alittle thanks.

I will post a report after the trans is installed, and after I've driven it for a bit. Thank you all.

Posted By: A727Tflite

Re: 46rh Governor Questions - 09/05/20 08:58 PM

Glad you got it back together.

One last suggestion, leave the return line off at the cooler line fitting at the back of the main case, place it in a clear jug like a windshield solvent bottle.

Install approx 8 quarts of trans fluid in the trans. Have an assistant start the engine with the trans in park. Unless the valve body has been modified you should not have fluid flow to speak of.

When idling place the trans in neutral, once flow starts you should pump a quart of fluid out in about 10-12 seconds.

Once a quart is pumped place in park and shut the engine off.

This will make sure the whole cooler circuit is good, clean and that the anti-drain down valve is not stuck closed.

Top off the fluid and you should be good to go.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 09/05/20 09:20 PM

The VB has an updated Sonnax kit installed. I will go find the specs that they gave me. Ok, here they are: Upgraded Manual Valve, Upgraded Switch Valve, Upgraded Pressure Regulator Valve, all Solenoids are tested, rebuilt or replaced with new.

Unfortunately, I won't be the one installing this. I'm not set up to do it. My mechanic has been doing this for 30 plus years, so I hope he verifies that everything is flowing. If not, I can do this once I get the truck back home, its only a five minute drive. Is it common for the anti-drain down valve to be stuck after a rebuild?

A new cooler is going in, but I'm reusing the same lines. As of right now the fluid in the old unit is still bright, and when I had the pan down it had no bad sludging or metal flakes. My mechanic said he'd blow the lines out with compressed air, to check for any blockages.

Posted By: A727Tflite

Re: 46rh Governor Questions - 09/06/20 12:05 PM

My guess is the Sonnax regulatormvalve has the pump prime feature which means it should have cooler flow in Park. That’s good.

As for blowing out the lines with compressed air, he wil only be able to blow in one direction if the valve is in the line.

With a new cooler and since the old trans fluid was nice and red you are probably fine.

Posted By: Magnumguy

Re: 46rh Governor Questions - 09/07/20 06:30 PM

Not to hijack your thread, but since trans guys are on here, I have a 98 Dakota, V6, not sure what trans is in it.

It's not been changed, so what's in it, and is there anything to do to take out some of the "slack". Slow from drive to reverse and visa versa, upshifts are good.

Posted By: moparx

Re: 46rh Governor Questions - 09/07/20 07:26 PM

i believe you have an A500 transmission.

if the unit is in good repair, a shift kit should solve your problem.

just my opinion, your mileage will vary.

Posted By: Magnumguy

Re: 46rh Governor Questions - 09/07/20 09:47 PM

I was thinking a newer style, I hope you’re right

Posted By: A727Tflite

Re: 46rh Governor Questions - 09/08/20 03:11 AM

A500 also goes by 42/44RE.

42/44 is the later industry designation that went in to use.

First digit is number if shifts, second number is relative torque capacity, R is rear wheel drives and E is electronic.

As for the slack you are talking about, if it does this first time in the day and does not occur the remainder of the day then it’s likley torque converter drain down.

Need more info.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 09/18/20 07:36 PM

Update on the transmission project.

Took the truck to mechanic's shop, tuesday before last. Popped in today to find out why I hadn't gotten any news. Found out he'd just moved the truck, with the transmission in the bed, over to his side open lot, and left it sitting in the back the entire time, and through the hurricane. He said "It was covered." I had covered the ends with heavy garbage bags and wrapped a tarp around it.

I pulled the bags off when I drove the truck back home and didn't see any signs of water inside the bags, around the seals, or anywhere near the entrances.

Do I pull the transmission apart to check everything, or do I sound ok? Please advise, I do not want all of my work to be in vain.

Posted By: A727Tflite

Re: 46rh Governor Questions - 09/19/20 01:47 AM

If the bags and tarp are totally dry inside you are likely ok. If the converter was in place only way for water to enter is the OD unit or dipstick opening.

As a quick check, pull the pan and make sure.

No converter, water could enter the pump and not get in to the pan but you should see rust I would think.

But you said things were dry so......

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 09/19/20 05:26 PM

So, just to be safe I went and dropped the pan.

The valvebody and filter were dripping water after I unbolted them.

I have the case and OD unit apart, and have pulled everything in the main case, am drying, and cleaning. Next I will pull the OD unit and double check that everyhing is dry. Hey, at least I get to double check the orientation of the thrust bearings again.

Do I need to take the valvebody completely apart or just soak in mineral spirits? It came full of test fluid from the valve body shop and was wet with it when I put it in.

As always, I will follow any advice you have for me.

Posted By: A727Tflite

Re: 46rh Governor Questions - 09/19/20 06:37 PM

So much for dry tarp. 😅😅

At this point anybodies guess if the valve body got wet.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 09/19/20 10:30 PM

Oh no, the valve body definitely got wet. At least the filter was pouring water and there were water droplets on the bottom of the VB once I removed the filter.

What's the easiest way to ensure that it's purged of water?

Can I dunk and flush with mineral spirits, or does this need a complete tear down of the valve body?

Posted By: A727Tflite

Re: 46rh Governor Questions - 09/20/20 12:07 AM

If it were me I would split the valve body.

It’s already clean so just a matter of making sure all the steel valves are free and no rust forming.

Spray with WD-40 then rinse with mineral spirits.

Don’t even dry it, let it drip dry and assembled. Don’t use any towels to dry anything. Lint will screw things up.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 09/20/20 12:58 AM

Thank you! That is happening tomorrow. I will carefully split it open and do exactly what you recommended.

Do I need to be concerned about the solenoids?

I have been extremely careful about lint in this transmission. If I needed a rag for anything I used an old t shirt. I learned quickly that shop rags leave a ridiculous amount of lint.

Posted By: A727Tflite

Re: 46rh Governor Questions - 09/20/20 01:46 AM

I would hit everything with the WD-40 followed with mineral spirits. Get the trans running as soon as you can.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 09/20/20 01:55 AM

It's going into Tribb's transmission this upcoming week. I will definitely hit everything with WD-40 and mineral spirits, per your recommendations, sir.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 09/21/20 12:04 AM

The OD unit was dry, so bolted it back up to the main case. Only place I saw any rust was on the sun gear shell, it was nixed immediately.

VB is split, was doused in WD40 and then in mineral spirits. It's now drying inside a cracked open garbage bag. All check balls were removed, after taking clear pictures of their location, and stored safely.

Thank you for your help.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 10/01/20 12:24 AM

The new shop installed the trans today. I could not be happier.

I cannot believe how much smoother and stronger this truck is, with a fresh rebuild. I followed your advice, all the way through, and it turned out perfectly.

The only thing that the trans does that makes me think I need to adjust something is when it shifts down to a stop, it feels like the kickdown band hangs for a split second, and it's lurched a couple of times when getting to a complete stop. Other times it just has it's normal little "bump" and then stop.

Other than that I cannot believe how smooth these shifts are. The fluid was nice and bright when I got home, and as I drove it (first low speed around town and then on the highway after about 10 miles) it felt like it settled in and the shifts were smooth and felt right on time.

Here's the old dirty trans in the back of the truck.

Posted By: A727Tflite

Re: 46rh Governor Questions - 10/01/20 02:04 AM

Normally you should not feel a downshift when coming to a stop. Usually when you do you have a sticky TP linkage setup. Kickdown band (2nd gear band) is only on in 2nd. When slowing down it should never engage unless you manually pull it in to 2nd or stay on the throttle while pulling a grade and force 2nd gear with throttle pressure.

Closed throttle coming to a stop if you really work at it you may feel a slight bump around 1-2 mph but that’s rare most of the time.

Make sure the throttle pressure linkage is free and adjusted properly and a return spring is usually found on the TP lever to trans case.

Try shutting OD off and see if this bump disappears, it shouldn’t make a difference. The direct clutch in the OD unit comes on when OD come see off but the ORC in the OD should prevent any bump.

One other thing that I have seen is on two piece driveshafts the slip yoke at the center bearing can hang up on the splines.

Coming to a stop and depending on rate of decel the yoke can hang up on the splines then snap free/forward giving you what feels like a shift.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 10/01/20 01:03 PM

Thank you, sir.

I tried turning off the O/D switch and it didn't influence it at all. I believe that it is the driveshaft, or at least some component outside of the transmission, because a loud clang accompanies the lurch sometimes.

Another oddity, it was chilly here today, and O/D would not engage, even on the highway. It engaged perfectly yesterday. Do I have a faulty Solenoid, sir?

I checked the fluid this morning and it was still bright and clear.

Posted By: NITROUSN

Re: 46rh Governor Questions - 10/01/20 02:04 PM

One other thing that I have seen is on two piece driveshafts the slip yoke at the center bearing can hang up on the splines.

Coming to a stop and depending on rate of decel the yoke can hang up on the splines then snap free/forward giving you what feels like a shift.

There was a TSB on that many years ago. It also affected the single piece rear shafts. The slip spline at the rear shaft on the transfer case could bind and release. My experience the shorter the wheel base the worse the condition. It never hurt anything but was a common concern by many customers.

Posted By: A727Tflite

Re: 46rh Governor Questions - 10/01/20 07:12 PM

Thank you, sir.

I tried turning off the O/D switch and it didn't influence it at all. I believe that it is the driveshaft, or at least some component outside of the transmission, because a loud clang accompanies the lurch sometimes.

Another oddity, it was chilly here today, and O/D would not engage, even on the highway. It engaged perfectly yesterday. Do I have a faulty Solenoid, sir?

I checked the fluid this morning and it was still bright and clear.

I think OD is defeated by the PCM until engine temperature gets up to a certain threshold. Additionally in certain applications there is an external temp sensor for the trans and in others it’s internal - part of the OD/LU solenoid assembly which has a thermistor built in. If it sees a low temp you won’t get OD, too hot and OD is defeated as well.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 10/01/20 09:33 PM

NitrousN, thank you very much! I have the shortest wheelbase 1500 for that year. This makes alot of sense, and is what I believe is happening to my truck.

Transman, this makes perfect sense, because overdrive engaged this afternoon after school. It operated smoothly and strongly for two hours, with no glitches. So the low temp thermistor must be exactly what was preventing my OD from engaging. Thank you so much for your help through all of this.

Posted By: J_BODY

Re: 46rh Governor Questions - 10/03/20 12:18 PM

On the RH trans the trans temp sensors are often on the output/front line on the trans. Close to where it screws into the case. 2 wire connector

Posted By: A727Tflite

Re: 46rh Governor Questions - 10/04/20 12:37 AM

On the RH trans the trans temp sensors are often on the output/front line on the trans. Close to where it screws into the case. 2 wire connector

I believe diesel gets this external sensor.

I believe gas uses the internal sensor - part of the OD/LU solenoid assembly.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 10/06/20 12:23 PM

I've got a weird issue, now. So, when I was coming to a light earlier today my transmission felt like it didn't downshift all the way, and went I went to roll forward the engine just revved, without catching.

I pulled off onto the shoulder, and the transmission downshifted, and then I was able to jump back out into traffic normally. About ten minutes later I was pulling out of a neighborhood, and the same issue happened. I let back on the throttle, and eased forward and first gear engaged normally.

I tested it going to school, and when I started forward with light throttle pressure the transmission would engage normally.

There have been no hard shifts, the fluid is bright and does not smell burned in any way. What am I facing here?

I do not rev the motor hard, so my throttle input for all of this was light to medium, no more than 1500 rpms.

Posted By: A727Tflite

Re: 46rh Governor Questions - 10/06/20 01:52 PM

If it does it again and you are at a slow enough speed try doing a manual pull down of the shifter without getting off the throttle.

If it instantly starts to engage my first guess is it is stuck in high gear. May feel like neutral but most stock converters stall around 1700-2000 so if it’s in 3rd you aren’t against the converter. The true test for a gov issue is to install a 0-80 lb. gauge and see what’s happening when you get this issue. Pressure should track close to vehicle speed, 5 psi tab 5 mph, etc.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 10/06/20 04:07 PM

Is this an odd issue to have occur a few days after a new rebuild?

It had no issues shifting, up until this morning. If it turns out to be the governor, then what could I have messed up during the rebuild, sir?

Posted By: A727Tflite

Re: 46rh Governor Questions - 10/06/20 05:37 PM

If it shifted ok then developed this issue I don’t think you screwed anything up.

My first guess is debris.

There are valve body issues that can cause strange behaviors so that is why I always start by checking governor pressure as part of the process of elimination.

If the truck upshifts and downshifts manually then your clutches and bands are fine, likely It’s your control system that is causing issues. Governor and valve body.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 10/06/20 05:44 PM

Is there any chance of it working itself out, if it's debris? Or would I have to have the trans pulled again and manually clean the governor? I know that I can drop the valve body and clean it with it in place.

Not this weekend, unfortunately I am close to the impact path of Hurricane Delta.

Posted By: NITROUSN

Re: 46rh Governor Questions - 10/06/20 06:08 PM

Most of the time a sticky governor can fix itself. Lots of quick stop and go and shifting to reverse can help loosen a sticky governor. Seems like the more you work it by jarring the output shaft the better it can get. I would say in my experience 90 percent fix them selves.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 10/06/20 06:17 PM

Thank you, Nitrous!

I will take this to heart and do as much quick stop and go as I can.

The transmission started shifting really well, with the shift points almost exactly where my transmission used to be. Until the lack of engagement this morning I was thinking that it was breaking in really well. The transmission did this under identical conditions both times, this morning. Coming to a stop, transmission doesn't feel like it shifted fully into first, then trying to start rolling forward, engine revs up but truck doesn't want to catch. Give it more throttle, then engages.

Posted By: NITROUSN

Re: 46rh Governor Questions - 10/06/20 06:36 PM

When that happens try manual 1st gear and see what it does. As soon as you feel the slippage when trying to go shift it to first. If it then takes off like it normally should the governor had hung up.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 10/06/20 06:52 PM

Thank you again, sir. The first part of my drive is all rural highway. It wasn't until I got into the town where my trade school is at that I encountered this. So about 45 mins of highway driving and then the first light, it did this.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 10/07/20 08:43 PM

Update.

Truck started lurching when I pulled into my neighborhood coming home from school today.

Manged to limp rest of way home with truck jumping between what felt like 1st and 2nd gear.

Truck now dies after engine revs up and down 1000 rpms when shifting into Drive, 1, or Reverse.

Please help.

Fluid is still bright and clean. No burned smell.

Is this a bad torque converter? Could I have a band issue?

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 10/08/20 02:04 AM

Now the engine won't start. The starter cranks the motor over strongly, and I can hear the fuel pump engaging strongly, too.

I had just filled up the tank, and it wasn't a mile and a half down the road that all of this happened. Is there an engine condition that can cause this, and this is just coincidental with the trans issues?

I appreciate everyone's help. I'm out of my depth here, and this truck has been great to me. The truck not starting has only ever happened when my battery was going out, or an ignition switch was bad. This is definitely not normal for this truck.

Posted By: NITROUSN

Re: 46rh Governor Questions - 10/08/20 02:31 AM

Can you check for codes? Its either something electronic that's failed or else you got a bad tank of fuel. If possible try to pump a sample through from the tanks pump into a clear container.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 10/08/20 09:24 PM

Thank you, Nitrous. Unfortunately I didn't have the time or the ability to pull a fuel sample. This makes perfect sense that it would be electrical, and is only coincidental that it is happening around the time of my trans rebuild. The truck is a 1994 1500 with the 5.9 and is OBD 1. I do not have a code reader, so was unable to check codes. I did check the connection to the ECM, and checked my fuses. I even swapped my fuel pump relay with a known good relay.

This morning it cranked normally, gave me no issues on the way to school, and drove really well. When passing by an overpass I thought I heard a loud whining, but figured this could just be the gearsets that I changed in the OD unit. Transman warned me there could be more noise. To be fair I was in OD pushing 2000 rpms, so my rate of speed was up.

When trying to leave the school this afternoon the truck was doing the exact same thing as yesterday. Lurching, not wanting to go over 5mph, running really rough, sounding like it almost wanted to backfire. I limped to a parking lot, and had the truck towed to the mechanic who did the trans swap. I suspect a fuel pump going bad, and only acting up in the heat, now. It was pretty hot yesterday afternoon and today. This morning was nice and cool so may have been able to operate normally.

I did put the truck in park and revved the engine. It revved up to 2500 rpms normally, with no stuttering. I don't know if this is a sign of anything, or the truck simply being able to make rpms because in a zero load situation.

Posted By: NITROUSN

Re: 46rh Governor Questions - 10/09/20 01:25 AM

For now you need to get it running correctly. Once running you can work out the bugs. A poor running or erratic running engine can cause a person to think there are other problems. Was the check engine light on? Knowing codes would be helpful. One other item that comes to mind is the crank sensor. I have seen these damaged with transmission removals.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 10/09/20 01:43 AM

The check engine light was not on, which I thought was odd.

I wish I had had time to get an OBD 1 reader hooked up. The local auto parts stores don't have one (I've asked before), and I hadn't had issues that I couldn't diagnose myself with this truck, in years.

I got up to go to school, after having given up the night before, swapped the relay and depressed the schrader valve on the fuel rail after letting the fuel pump engage. I got a good squirt of fuel, and turned the truck over for grins. Fired right up perfectly. A good lhard test drive showed no signs of further issues. I chocked it up to a bad fuel pump relay and drove to school. Trans and engine worked perfectly.

Got out of school about 8 hours later, truck baking in the Florida sun. Ran like absolute garbage. I barely got 300 yards down the road. Check engine light still wasn't on.

I am not experienced enough with transmissions to know if this is an internal issue in the transmission. My common sense says no, because other than the sticky governor, it's worked perfectly. I suspect that they could have damaged that sensor during the install, or that the fuel pump is just going out.

I appreciate your help, Nitrous. I will post everything that they tell me.

Posted By: NITROUSN

Re: 46rh Governor Questions - 10/09/20 02:14 AM

Just because the fuel seems to squirt strong a gauge needs to be used to get actual pressure. I can tell you how many times customers said the pressure was good on the squirt test so the pump is ok. Not.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 10/09/20 02:21 AM

That's actually a huge relief. I am absolutely not an expert, and I really want this to be a single simple issue like a bad fuel pump. I've gotten over 80,000 miles out of this pump, and it does surge alittle bit first thing in the morning, so it's probably been getting weaker for a while. And who knows how long it was driven before I bought it on this fuel pump. I'm the third or fourth owner.

Again, thank you Nitrous, all of this is being extremely educational.

Posted By: NITROUSN

Re: 46rh Governor Questions - 10/19/20 07:40 PM

Did you get it back up and running?

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 10/20/20 09:20 PM

I got the truck back from the shop yesterday.

They kept it and tried to get it to replicate the issues that I was having. They were unable to, thankfully said that they were uncomfortable replacing the fuel pump, and just put some fuel dryer in the tank. For the diagnostics and the fuel dryer I was out the door for $89.

I got the truck most of the way home and then it started doing the exact same thing. I guess it would only act up when the truck was hot, running at highway speeds in overdrive. I limped the truck back to the shop. They diagnosed a bad distributor component. They replaced the whole distributor and the truck only missed twice minorly on the way home yesterday. Bill was $260. Super honest people, and their prices are VERY good.

Driving back home today from school I was doing 1800 to 2000 rpms in overdrive and it started missing. Every ten or fifteen seconds it will miss and lurch alittle. Not nearly as badly as before, but very noticeably.

What in the world am I facing here? This is all new, post transmission rebuild.

Posted By: stumpy

Re: 46rh Governor Questions - 10/20/20 09:31 PM

still could be water in the fuel.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 10/20/20 09:43 PM

Could water in fuel have caused my old distributor to fail? I ask because I genuinely believe that I did get water in my fuel, and replacing the distributor has helped immensely. I'm stumped.

The distributor replacement did help immensely, so I believe that it really did go bad.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 10/21/20 09:50 PM

Drove the truck to and from school today. It misses when accelerating, and at highway speeds, pretty much all the time. It's not anywhere near as bad as it was before the distributor was replaced. Before then it would shudder and lurch and try to die. Now it's a light miss that is like the truck is missing a beat, rather than a hard shudder.

I'm going to ohm out all of the injectors over the weekend. Does anyone have any recommendations for things to check? If this is a timing issue, outside of the injectors and the distributor, where else should I look?

Posted By: NITROUSN

Re: 46rh Governor Questions - 10/22/20 12:04 AM

Plugs or wires would be my guess.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 10/22/20 12:47 AM

The plugs and wires have less than 10k miles on them, but I will swap them if you think it's possible something has gone bad in there, Nitrous.

I'm using NGKs, but have heard good thing about Champions, for the 5.9L Magnum.

Posted By: NITROUSN

Re: 46rh Governor Questions - 10/22/20 01:19 AM

I like NGK and with either them or Champion I have had no issues. You could OHM each plug wire. Most likely it is just one hole not firing 100%. Lots of cheap wires on the market. Seeing the distributor was replaced there are a couple things you should check. One make sure all the wires are seated correctly. And secondly ask the shop how they set the distributor. The distributor needs to have the sync signal set. If it is not set correctly it can cause some erratic running.

Posted By: NITROUSN

Re: 46rh Governor Questions - 10/22/20 01:22 AM

One other item is there was a TSB on erratic running due to plug wire routing. Take some time to find that TSB and follow what it says on routing.

Posted By: NITROUSN

Re: 46rh Governor Questions - 10/22/20 01:26 AM

TSB 18-48-98

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 10/22/20 01:34 AM

Thank you, I will follow that TSB down now, Nitrous. I will call the shop and ask them if they set the sync signal, tomorrow after class. They're really helpful so should be a non issue if it needs to be adjusted.

Found it. Here's the link for anyone else who might need it. I also have it saved as a pdf, in case link is down I can email it.

https://testing-public.carmd.com/Tsb/Download/31575/080022dc80bbf784Nitrous, do you recommend running some injector cleaner through, just in case? If so, any recommended products? The gas that I normally use is Chevron, so should have a mild cleaner in it. This is also the gas station that I may have gotten some contaminated fuel at, though.

Posted By: NITROUSN

Re: 46rh Governor Questions - 10/22/20 02:01 AM

When they changed your fuel pump they should of made sure the tank was clean. For the most part injectors are relatively trouble free. However if a fuel system is compromised with contaminants the injectors could be restricted. As I recall that system does not have a return so all particles can get trapped on the injectors inlet screen. Normally this is not a service repair to clean them. Most just replace them. However here is a trick I have used. Remove the injectors. Rig up a power and ground to power the injector from a 12 volt source. With the injector powered it will open the pintle off the seat. Take a nice clean white rag and you can reverse flush the injector with carb cleaner and compressed air. I like to clean and blow the contaminants into the rag just to see what comes out. Reverse flush will push the debris back out of the injector. I would do the other items I mentioned first. Check plugs, wires, wire routing, distributor sync signal .

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 10/23/20 03:16 AM

The shop said that the fuel pressure tested ok, so they didn't change the fuel pump. They put a drying chemical in the tank and did a diagnostic.

Today I traced out the plug wires, following the TSB and did the best I could with it. I realized that one of the wires was laying on my passenger side header, cylinder number six. I replaced this wire because I just went ahead and assumed that it was damaged by the heat, as the plastic wire loom was burned. I also replaced the single ignition coil for the system, located near the idler pulley.

The truck ran better and only missed a few times on the way home. I also added half a container of marvel mystery oil to the tank when I changed the ignition coil. I noticed a power gain, whether it was from the coil or the mystery oil I am unsure.

When it missed today it felt the same as the other days, it was only the frequency with which it happened that was different.

I called the shop and they acted baffled when I asked about the distributor sync signal. They just said that they installed the distributor at TDC and hooked the wires up. I don't know what the sync signal refers to, honestly.

Posted By: NITROUSN

Re: 46rh Governor Questions - 10/23/20 02:27 PM

You need to have the sync signal set. All they did is install the distributor. It is not like the old days of using a timing light. Some scan tools have functions that will allow setting the signal. There are more complicated ways with setting the crank balancer at a certain position and using an OHM meter on the distributor pick up to adjust it. Very important setting.

Posted By: NITROUSN

Re: 46rh Governor Questions - 10/23/20 02:29 PM

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 10/23/20 03:54 PM

This shop has no idea what that adjustment is, so I may have to source another technician. I do not believe that this is something that I can do myself.

A call to the Dodge dealership let me know that they don't work on anything older than 2005. So I sent an email to the automotive department at my school to see if they'd be able to do this adjustment. I included the pdf from the link that you sent me, Nitrous. Thank you so much for your help.

Posted By: 46rhRebuild

Re: 46rh Governor Questions - 10/23/20 05:05 PM