Posted By: mcat4321

filling firewall holes, welding help - 08/26/18 02:03 AM

i am a mediocre mig welder at best, i do best with thicker stuff.

i have a little 110 wire feed argon deal.. what is the best process for filling all the smaller holes in inner fenders and firewall?

Posted By: moparclown

Re: filling firewall holes, welding help - 08/26/18 02:16 AM

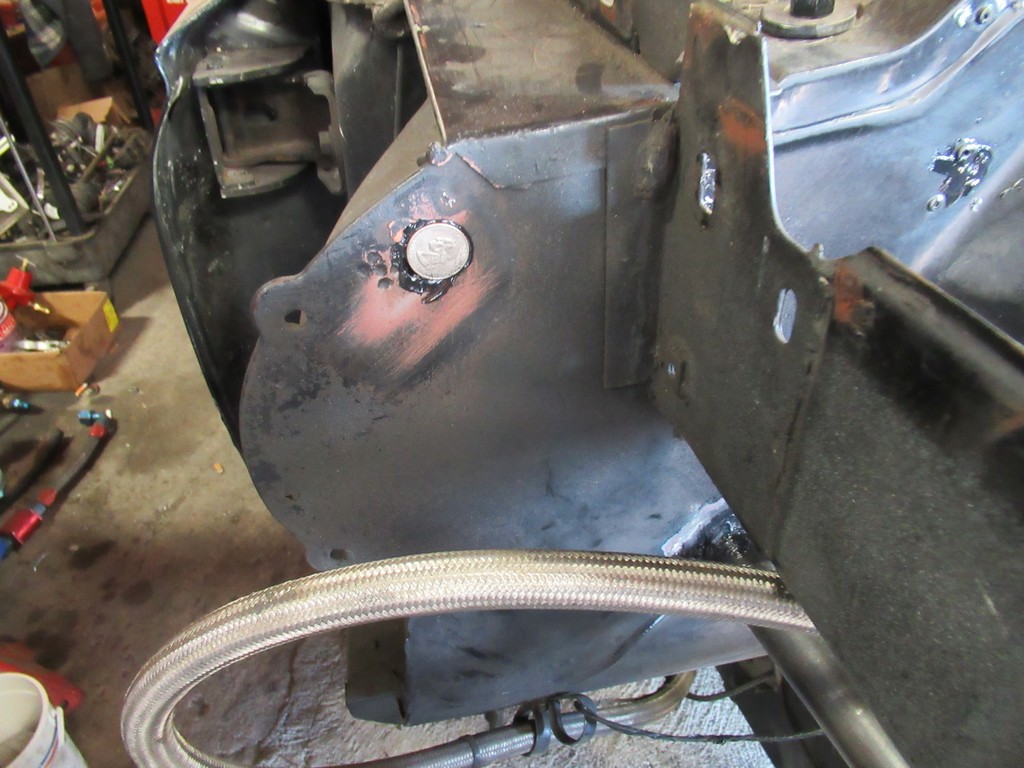

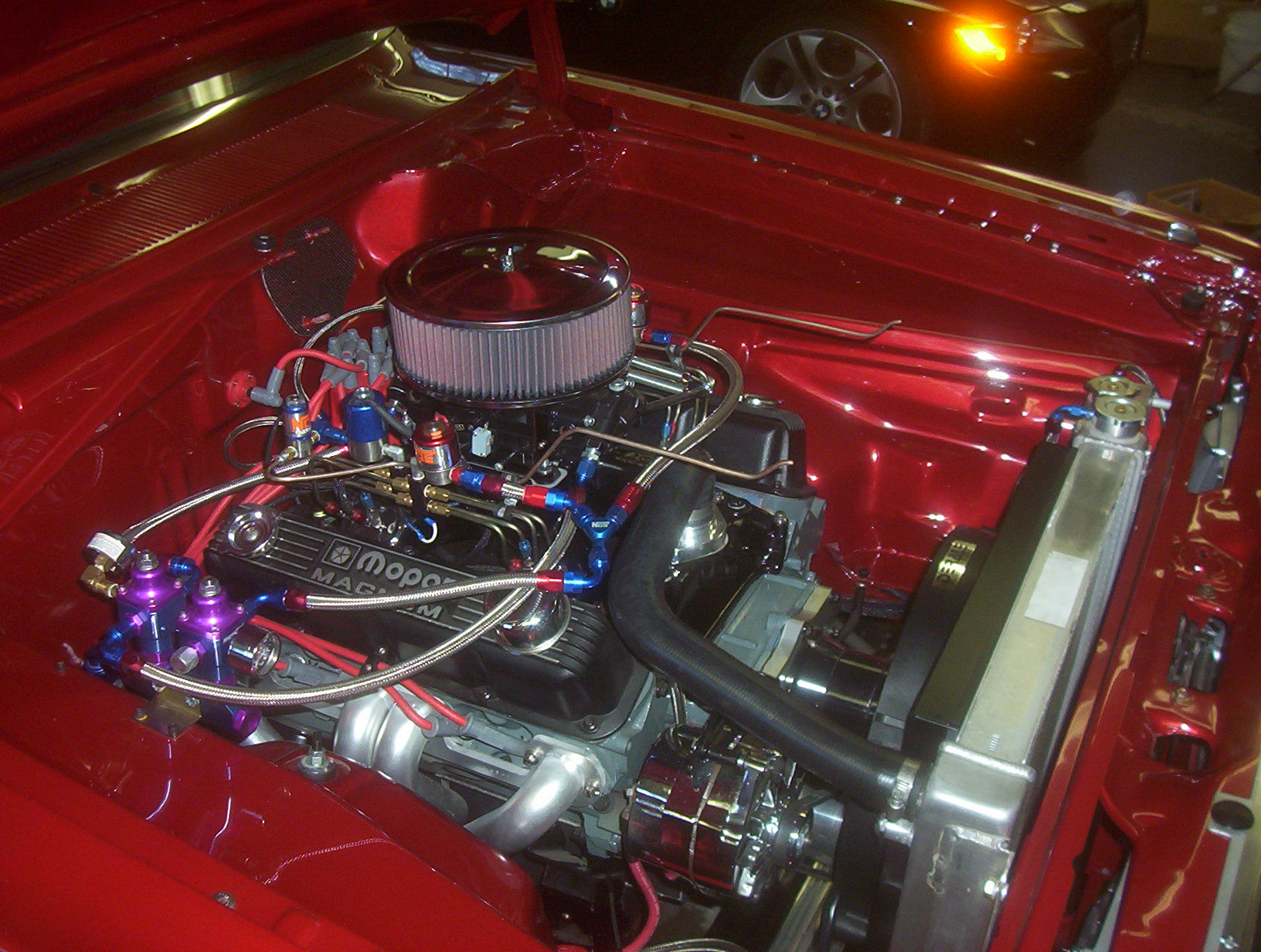

I welded all this up for a good friend, hammer and dolly were essential

Posted By: CSK

Re: filling firewall holes, welding help - 08/26/18 02:17 AM

get a piece of copper, & hold it on the backside of the hole & weld the hole up, be sure & wear thick gloves

CLICK HERE

Posted By: cudaman1969

Re: filling firewall holes, welding help - 08/26/18 03:53 PM

Use a headed nail, many sizes made, pull through the hole, hold with vise gripes. Weld, grind off excess, non galvanized roofing nails work best (thin head)

Posted By: CKessel

Re: filling firewall holes, welding help - 08/26/18 05:27 PM

For bigger holes, I found out that the left over plug from using Blair RotaBroaches work out slick. Measure what size the hole is then find one of the broaches by measuring the inside of the unit. The plug will have somewhat of a flange on it that makes it easy to hold in place for welding.

Posted By: HemiRick

Re: filling firewall holes, welding help - 08/26/18 10:29 PM

To easily weld sheet metal you to use .023 wire w gas and a welder that that is infinitely adjustable rather than fixed steps. Otherwise burning it up is all to easy....the copper backing behind helps too.

Posted By: Stanton

Re: filling firewall holes, welding help - 08/27/18 04:08 AM

Start by ditching the argon and getting the right gas !! CO2/Argon mix.

All above advice is good. In addition, you want to cool those welds quickly - use a wet rag or compressed air.

Some holes will take more than one hit to fill. Let them cool before hitting them a second or as many times as needed.

Any hole 1/4 inch or larger needs a plug of some sort. Doesn't need to be a perfect fit, just to help fill the hole.

When grinding the welds a lot of guys use flap discs or those interchangeable discs. I find they flex too much and often remove (softer) metal around the weld and leave a bump where the weld is. I prefer a hard grinding disc to carefully grind down the weld and only the weld.

Posted By: hemi-itis

Re: filling firewall holes, welding help - 08/28/18 04:32 AM

Quarters epoxyied in place.....LOL