Moparts

quench, gasket bore and compressed height

Posted By: NachoRT74

quench, gasket bore and compressed height - 10/28/17 06:14 PM

If I'm using Felpro 1039 headgasket with 4.590" bore and 0.051 CH, on a 400 block +0.020" so 4.362" bore... that makes 0.228" bore difference between block and headgasket... this means 0.114" difference between cylinder wall and gasket all around being with 0.051" gap between block and head... will this area affect quench ?

DESPITE ALL THE REST OF DISCUSSION AND GET FOCUSSED ON THIS PLEASE!!!!

ONCE AGAIN!

wondering if this area around the cylinder bore being 0.051" will affect quench efficiency still if my make sit my pistons quench pad still at 0.040 on the 452 heads.

Posted By: ahy

Re: quench, gasket bore and compressed height - 10/28/17 07:17 PM

In short, the bigger bore of the gasket will not affect quench. As long as the piston to cylinder head distance is dialed in you have it.

The larger bore of the gasket does slightly increase total chamber cc's and reduce compression but not a significant impact.

Posted By: 6PakBee

Re: quench, gasket bore and compressed height - 10/28/17 07:23 PM

I think that the benefit of quench would be affected, but so minimally I doubt you could tell the difference. But practically speaking, other than having a custom head gasket made, what options do you have other than to live with what you have?

Posted By: NachoRT74

Re: quench, gasket bore and compressed height - 10/28/17 07:25 PM

I can't afford $100 per gasket, plus international shipping

other options... use the felpro kit gaskets ( 0.039 ) and felpro copper shims ( 0.020 ), decking block even lower ( 0.010 more ). All thse parts in hands.

reduce CR will be a benefit in fact

Posted By: 6PakBee

Re: quench, gasket bore and compressed height - 10/29/17 03:38 AM

I guess what I meant with living with what you have is that once you are at minimum quench distance, other than having a custom gasket made to your bore size, you are pretty much out of options. Sorry I wasn't clearer.

Posted By: CSK

Re: quench, gasket bore and compressed height - 10/29/17 03:50 AM

It will be ok.

Posted By: NachoRT74

Re: quench, gasket bore and compressed height - 10/29/17 07:48 AM

I guess what I meant with living with what you have is that once you are at minimum quench distance, other than having a custom gasket made to your bore size, you are pretty much out of options. Sorry I wasn't clearer.

Cool!

Posted By: NachoRT74

Re: quench, gasket bore and compressed height - 10/29/17 07:48 AM

Posted By: 360view

Re: quench, gasket bore and compressed height - 10/29/17 02:39 PM

The gasket to bore mismatch will create more "crevice volume" for the air and fuel mixture to be driven into. A lot more gasoline "hides here" in the crevice volume than you might at first suspect, because the rapidly rising pressure "pushes" air and fuel there. The air and fuel might get compressed by the rising piston to 160 psi, but the burning flame front that started near the spark plug can reach 1600 psi as it reaches the outer edges of the cylinder where the crevice volume is. Metal surfaces near the crevice volume "quench out" any flames so this gasoline remains unburned.

People think some of the gasoline remains unburned because the carburetor does not make smal enough droplets.

It is truer to say that some of the gasoline remains unburned because it hides near cool metal walls in the crevice volume.

Even natural gas and propane engines have unburned fuel because of crevice volume.

Glowing Hot carbon deposits

can also build up at the edges of crevice volumes,

and these can potentially set off the air/fuel to burning ( preignition)

before the spark plug fires.

Piston ring land is another crevice volume.

Newer design "Direct Injection" engines get an advantage when at the last moment they spray fuel into hot compressed air only near the spark plug. Oxygen has to come inward toward this centered "flame Kernel". Fuel gets very little time to move outward to "hide" in whatever crevice volume is out there. The crevice volume ends up with mostly Nitrogen gas in it when Direct Injection is used.

(on the downside the air passages in the intake manifolds of DI engines and intake valve backsides tend to fill up with crudy deposits since there is new liquid fuel to rinse them off)

Posted By: NachoRT74

Re: quench, gasket bore and compressed height - 10/29/17 04:46 PM

And that does mean?

Posted By: RapidRobert

Re: quench, gasket bore and compressed height - 10/29/17 05:36 PM

I'm thinking that a gasket bore clos(er) to the bore perimeter would be a somewhat more efficient eng by eliminating the unburned fuel/air in the aforementioned "crevice volume" but this does not make/break quench efficiency that you asked about since the piston plateau/head interface (the quench area) is inward further from that perimeter. A gasket with a smaller bore would get a person closer to a "spot on" engine but whether it would be worth it to you to add that expense I cannot say. Just me I sleep better at night (& function better in the day) knowing I built the most efficient eng that my knowledge (& the collective knowledge of my fellow Moparts brothers) will allow me to accomplish (& my budget!). I gotta go, some hand egg is on the menu for this morning.

Posted By: NachoRT74

Re: quench, gasket bore and compressed height - 10/29/17 06:52 PM

yes! I'm pointing out in the future to the cometic headgasket on 4.380 bore 0.051 thickness, but can't make it now. Headgaskets are easy to replace in a close future though, but need to assembly the car ASAP which what I have in hands right now

http://www.cometic.com/i-24768321-chrysl...-bore-each.htmlit seems after several decking block corrections I can get pistons around 0.010-0.013 out of the bore... IF FINALLY THEY MAKE IT RIGHT!

will need to equalize the quench pads on combustion chambers too ( it seems the deeper one is around 0.120", then maybe cut some ( 0.020" ) the heads to get that area on 0.095-0.100" deepness rate to match the KB215 pistons quench pad step

Posted By: NachoRT74

Re: quench, gasket bore and compressed height - 10/29/17 07:04 PM

by I could understand that "crevice volume" area is prone to preignition due carbon deposits there becoming on a pocket for them! sooooo... the quench job could be a lost job getting another problematic area now.

Posted By: NachoRT74

Re: quench, gasket bore and compressed height - 10/29/17 07:11 PM

well thinking it now, the regular 0.039 headgasket is also bigger bore, just not that big ( barelly 0.050 to my actual cylinder bore, 3/4 less than the 1039 gasket), but still becoming on a pocket for carbon deposits

Posted By: ek3

Re: quench, gasket bore and compressed height - 10/29/17 11:32 PM

I think you are over thinking this... the - CORRECT - swirl ratio will clean all un-burned gases from the chambers... the small area you refer to would simply be unused fuel...[ if you are worried about unburnt gases ] focus on proper combustion chamber shape and piston that works with it and the proper intake port shapes ,,, that problem is gone.. proper quench will reduce burn time , lower octane requirements, lower the overall timing advance needed, resulting in more complete burn..it also reduces the pressure rise in reverse with respect to the crankshafts angle to tdc...that's why most swirl heads make best power with 32* timing ...

Posted By: NachoRT74

Re: quench, gasket bore and compressed height - 10/30/17 02:57 PM

I think you are over thinking this...

yes, probably you are right, but an opportunity to learn about

I still dunno about all this tech stuff and therms about, combustion, ignition times and everything related.

I was mainly worried about preignition ( pinging ) problems due this pocket around cylinder using this bore diameter gaskets after work on all the quench stuff.

Posted By: dogdays

Re: quench, gasket bore and compressed height - 10/30/17 07:45 PM

When you get the squish distance correct, the air that squirts out of the squish zone should move at least some of the air/fuel out of the crevice volume. Think about it - unless you have built some directional flow in the in the squish zone, the air rushes out of the chamber past the piston top in all directions. That should move things around in that gap.

You are absolutely correct to suspect that the additional crevice volume could cause knock. When the air/fuel is heated and the chemical reaction starts, pressure and temperature increase. The fuel decomposes and forms knock causing compounds. A squish chamber moves the flame around so combustion takes place more rapidly, faster than the new compounds can autoignite. No knock.

In a chamber with no squish and a pretty static volume of air/fuel, it will take the flame much longer to get to those areas farther away from the spark plug. The new compounds then have the time to autoignite and you have knock.

R.

Posted By: JohnRR

Re: quench, gasket bore and compressed height - 10/30/17 11:14 PM

yes! I'm pointing out in the future to the cometic headgasket on 4.380 bore 0.051 thickness, but can't make it now. Headgaskets are easy to replace in a close future though, but need to assembly the car ASAP which what I have in hands right now

http://www.cometic.com/i-24768321-chrysl...-bore-each.htmlit seems after several decking block corrections I can get pistons around 0.010-0.013 out of the bore... IF FINALLY THEY MAKE IT RIGHT!

will need to equalize the quench pads on combustion chambers too ( it seems the deeper one is around 0.120", then maybe cut some ( 0.020" ) the heads to get that area on 0.095-0.100" deepness rate to match the KB215 pistons quench pad step

Instead of using .039 and a shim just cut the open part of the chamber deeper and do not use the shim. That area of the chamber is .300 thick, taking an extra .020 out of that area will not be a problem.

Posted By: NachoRT74

Re: quench, gasket bore and compressed height - 10/31/17 04:43 AM

dogdays:

yes that was my thought, but my doubt was that because per what I have read on several places the quench/squish area can be on 0.050" rate and still be good even the advice is around 0.040"

John:

that could be good too! and will make to keep the heads unmilled, saving from ANOTHER mistake from machine shop. However that could make also to get really close the piston diameter out of the quench pad close to the head around the combustion chamber to allmost 0.020" I think... isn't that some dangerous ? I recall the combustion chamber bore is sligthly smaller bore than the cylinder bore... isn't ?

Wouldn't actually need to cut 0.020" but maybe the 0.010-12 extras the thicker felpro headgaskets got with bigger bore, and keep using the 0.39 with small bore... in another words, cut the combustion chamber quench area same ammount the pistons leaves the deck. Maybe in fact they are actually close to what I need. I'm pretty sure this area is deeper than the piston quench pad height and maybe close to what I need as mentioned on a previous reply.

I will know just once the block is correctly decked and once assembled measured with clay

Posted By: NachoRT74

Re: quench, gasket bore and compressed height - 10/31/17 05:20 PM

making maths without actual measurements yet...

If I have to get the quench area deepness on heads equalized up to .120" taking the deeper one as a starting point( to be confirmed, thats was a rude measurement I made once ), plus .039" of gasket makes .159"

less .095" of piston step and .012" ( or so ) of pistons leaving the deck... total 0.052" of quench. It seems not to be bad. To be used on 95 octanes gas in Vzla, and once move to Spain, probably 98 octanes

Definitelly I'm overthinking the deal with the 0.051 gasket!!!

just thinking on the area out of the combustion chamber, being smaller than the piston bore, that should be on 0.027" rate. Am I fine with it ?

That will get me also the static CR close to 10.5 on the iron heads.

I have 6 and 7 NGKs heat range spark plugs to play... also platinum Bosch plugs WR9FP

Opinions

Posted By: RapidRobert

Re: quench, gasket bore and compressed height - 10/31/17 05:32 PM

other than a low performance daily driver, I would want .035"-.040" quench.

Posted By: NachoRT74

Re: quench, gasket bore and compressed height - 10/31/17 05:36 PM

sure... but meaning I can still mill down heads still using 0.039 gaskets... and still have to confirm the corrected block decking.

( I have read around 0.050 is still good )

Once again I still have to get the parts correctly machined ( if that's posible locally!!!!! ) to get the final decision...

Posted By: dogdays

Re: quench, gasket bore and compressed height - 10/31/17 08:12 PM

I wouldn't bother about the differences you describe. Here's my reasoning: The late roller 318s had the 302 closed chamber heads. The stock replacement piston I can find is 1.745". Block height is 9.577.

9.577 - 1.745 -6.123 - (3.31/2) = 0.054". I measured 0.055" on my '86 318. add the gasket of at least 0.027 and you get 0.082" from head to piston top

Look at the 5.2 Mag. The Mag cylinder head has an area that was most likely added for squish. Yet the 5.2 Mag piston is at least 0.072" from the deck at TDC.

So while I'm sure that narrowing the gap would make a good thing even better, there may be a lot of cost between "good" and "good enough".

R.

Moving to Spain, huh? I've enjoyed my times there, in Madrid and Andalusia.

Posted By: NachoRT74

Re: quench, gasket bore and compressed height - 10/31/17 08:30 PM

I'm actually working on a good enough job... trying to keep the static CR lower as posible keeping on good enough quench numbers, also trying TO NOT SEND MORE PARTS TO UNNEFICIENT MACHINE SHOPS!!! I get really scared everytime I have to send anything to any machine shop!. Before all this squared deck deal I was riding on 10.2-10.3 CR. I guess had pinging due of course the bad quench. Front ones pistons down the deck around 0.015-0.017 and the rears right on zero deck, and using stock composite headgaskets. Diff combustion chambers deepness everywhere, etc... well, what you already know.

I have asked about this many times, I know, and being tiresome. This project has being taking an eternity.

Posted By: RapidRobert

Re: quench, gasket bore and compressed height - 11/01/17 01:46 AM

I have asked about this many times, I know, and being tiresome. This project has being taking an eternity.

Nacho, Keep em coming, we are here to help as much as we can/solve as manny issues as we can/gain & share as much knowledge as we can.

Posted By: JohnRR

Re: quench, gasket bore and compressed height - 11/01/17 06:09 PM

dogdays:

yes that was my thought, but my doubt was that because per what I have read on several places the quench/squish area can be on 0.050" rate and still be good even the advice is around 0.040"

John:

that could be good too! and will make to keep the heads unmilled, saving from ANOTHER mistake from machine shop. However that could make also to get really close the piston diameter out of the quench pad close to the head around the combustion chamber to allmost 0.020" I think... isn't that some dangerous ? I recall the combustion chamber bore is sligthly smaller bore than the cylinder bore... isn't ?

Wouldn't actually need to cut 0.020" but maybe the 0.010-12 extras the thicker felpro headgaskets got with bigger bore, and keep using the 0.39 with small bore... in another words, cut the combustion chamber quench area same ammount the pistons leaves the deck. Maybe in fact they are actually close to what I need. I'm pretty sure this area is deeper than the piston quench pad height and maybe close to what I need as mentioned on a previous reply.

I will know just once the block is correctly decked and once assembled measured with clay

Once the block is decked drop the heads on the empty block without a gasket ... mark heads for what side they are on ... , now turn the block upside down and look in at the heads for chamber overhang into the bores , scribe the areas that overhang and clean them back to a little outside the scribed marks on the open chamber side of the head and roll over the edge on the plug side , or blend the plug side back also if you need to lower the compression some. the .039 you are getting , is that from the web or from actual crushed gasket that is measured ? I have found the 8519 to be more like .041 ???

Posted By: NachoRT74

Re: quench, gasket bore and compressed height - 11/02/17 01:52 AM

From manufacturer specs

( good idea on the method you described )

Posted By: 360view

Re: quench, gasket bore and compressed height - 11/02/17 01:02 PM

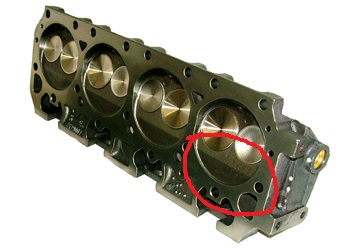

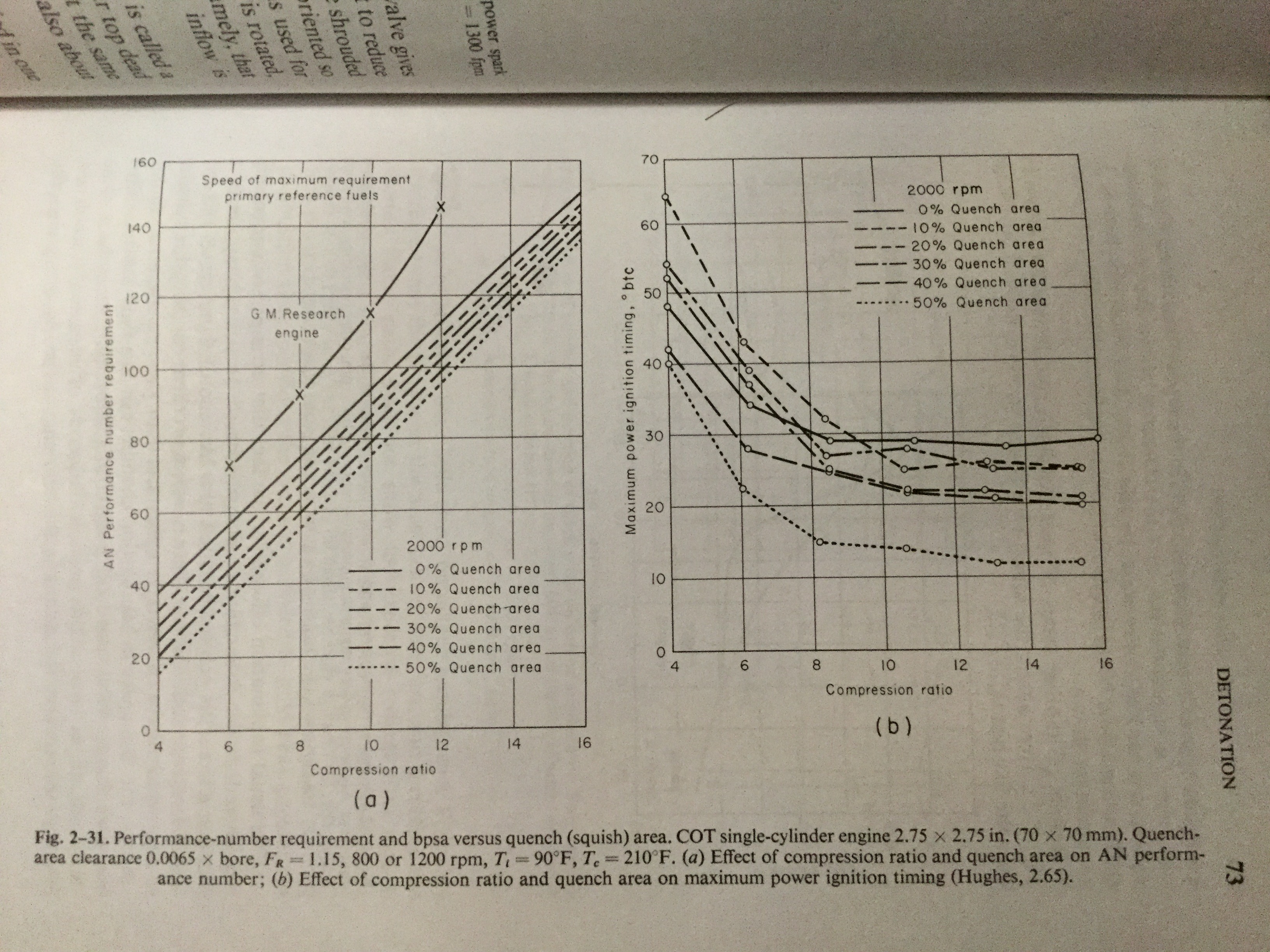

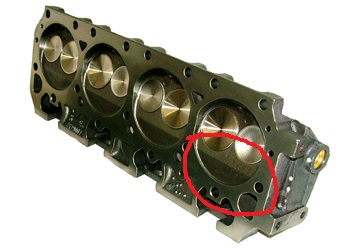

General Motors research on effect of a tight quench where they varied the percent area of the flat piston surface that nearly touches a matching surface on the cylinder head. Note that if you multiply a 4.00 inch bore by their ratio it is 0.026 inches, which is very tight. Many years later Honda wrote up a technical paper on the science of their first V-Tec design. Honda wrote that the quench had to be a tight 0.75 millimeters, nearly the same clearance as GM found.

Posted By: 360view

Re: quench, gasket bore and compressed height - 11/02/17 01:15 PM

Look at the left figure, with (a) at bottom.

Look at the lowermost dotted line, for 50% Quench Area.

Notice that at a 10 to 1 static compression ratio, the engine can run with fuel of 78 AN Performance Number.

What is AN Performance Number?

It is the Army Navy improved Octane rating number,

A "new & better" test method than either

the original 1930s RON (research octane number)

or the somewhat newer MON (motor octane number)

Pure 100% chemical Octane

is rated a number of 100

in all three test methods: AN Performance Number, RON and MON.

78 AN Performance number is approximately 85 AKI like we see on USA gas pump signs.

Posted By: 360view

Re: quench, gasket bore and compressed height - 11/02/17 01:18 PM

So what compression ratio does figure (a) predict you could run with just "a trace of knock" on 100% pure chemical Octane which rates 100 in all three methods?

At a quench clearance of 0.026 inches with 50% quench area

Static compression should not be above

12.2

Posted By: 360view

Re: quench, gasket bore and compressed height - 11/02/17 01:26 PM

Also look at the 0% quench area black solid line at top way above the doted 50% quench line.

Only a static compression ratio of

10.4

could be run with "trace knock" on 100% pure chemical Octane.

There is approximately a 7% gain in both torque and horsepower going from 10.4 to 12.2 static compression ratio

How much money and aggravation should you endure to get that 7% gain?

Would it be better to just get 7% more cubic inches?

Would it be better to just buy more expensive higher Octane number rated fuel?

Your choice.

Posted By: 360view

Re: quench, gasket bore and compressed height - 11/02/17 01:28 PM

Now study the ignition timing stuff in figure (b)

Posted By: NachoRT74

Re: quench, gasket bore and compressed height - 11/03/17 04:31 AM

General Motors research on effect of a tight quench where they varied the percent area of the flat piston surface that nearly touches a matching surface on the cylinder head. Note that if you multiply a 4.00 inch bore by their ratio it is 0.026 inches, which is very tight. Many years later Honda wrote up a technical paper on the science of their first V-Tec design. Honda wrote that the quench had to be a tight 0.75 millimeters, nearly the same clearance as GM found.

we talked about this on an old thread I asked about a similar topic, and I remember this diagram being posted, and being honest, I'm not clear on everything said there

Posted By: 360view

Re: quench, gasket bore and compressed height - 11/03/17 02:12 PM

In a nutshell:

A tight quench combined with 50% piston flat area is helpful to get

100 Octane gasoline like performance

on cheaper lower Octane pump gasoline.

On a 500 hp engine you might gain

60 hp or so,

after taking considerable care and extra steps during assembly.

The main problem in the graph above is that

GM only shared with the public the 2000 rpm results on a small bore 2.75" bore by 2.75" stroke engine.

They kept the valuable to racing

big bore, big stroke, 4000 to 6000 rpm results

they certainly also tested for confidential.

It is possible that a big bore engine at 4000+ rpm only needs 0.060 or more quench clearance, perhaps with piston quench flats area less than 50%.

Posted By: NachoRT74

Re: quench, gasket bore and compressed height - 11/03/17 04:51 PM

KB pistons quench step are less than 50% of the piston, that's a fact. Maybe 25% being optimistic

Posted By: 360view

Re: quench, gasket bore and compressed height - 11/03/17 05:11 PM

Flat top pistons seem to be the recent trend.

Perhaps a totally flat top allows the flame kernel to grow fastest?

Maybe a flat top piston crown has less "hot spots" at edges.

Maybe a flat top piston under heat is easier to keep round for bore seal?

Maybe flat tops are inherently stronger and therefore lighter?

Posted By: Alchemi

Re: quench, gasket bore and compressed height - 11/04/17 04:25 AM

Kb made those pistons for stock heads

That pistons pad fits the 452 head pad area close to perfectly - any more meat towards the valve would have been excess weight and more compression

Posted By: NachoRT74

Re: quench, gasket bore and compressed height - 11/04/17 04:19 PM

Yes I know, and not just 452s, but any open chambers. The deal is that quench pad area is quite often deeper than 0.095" which is the KB215 pistons step height ( my heads were NOS and they are closer to 0.110", but I got them after the pistons ). For a custom step will need KB251s, which are cheaper just right because they need to be cut to needs. I went with KB215s trusting on published expects around for the heads. Maybe KB251 was to be easier to match everything.

Of course the quench step surface on piston matches the quench pad on open chambers, but still is maybe just 25% of the piston area LOL... thats just what I said, not saying just matches 25% of the quench pad on heads

Posted By: 360view

Re: quench, gasket bore and compressed height - 11/05/17 06:37 PM

25% quench area at a C.R. of roughly 10

still allows you to run

82 grade instead of 92 grade

on the AN PN Octane gasoline scale.

Every little bit helps.

Better to have that aid than not.

Another way to think of it is

if the engine runs hot for some reason

it is a degree of protection from damaging detonation.

Posted By: RapidRobert

Re: quench, gasket bore and compressed height - 11/05/17 08:53 PM

If I may hijack: with 9-1 SCR (class rules) & adequate octane so detonation ain't a concern, would there be a significant power bennie from achieveing quench? better mixture homogenization (sp)?? and less timing needed cuz of a faster burn?? If so I wanna do it the next build.

Posted By: 360view

Re: quench, gasket bore and compressed height - 11/05/17 11:56 PM

If CR is a modest 9 and fuel AKI is 92 (?)

Then Figure (b)

Shows that full throttle ignition timing can be less advanced

And that should yield some power and torque gain

... but like said above

those graphs are for 2000 rpm

and we really need to see the equivalent figures for

4000, 5000 and 6000 rpm.

Posted By: 383man

Re: quench, gasket bore and compressed height - 11/15/17 04:04 AM

I ran the KB quench pad pistons in my old 440 combo as I used 906 heads. I do remember I had to buy .074 Cometic head gaskets to make it work. My heads had been milled already and my combustion chambers were right about .025 deep. My quench pads were .054 above the deck. So when I used the .074 gaskets with .054 quench pad above the block I had .020 from the gasket and the .025 deep chambers as I had right around .045 quench. The comp came out right at 10.0 and I can tell you I ran 92 or 93 pump in it with 36 to 38 total timing and it did not ping or detonate at all. In fact the eng is still running in a Duster and running fine on the 92 pump. Ron

Posted By: Scojodak

Re: quench, gasket bore and compressed height - 11/17/17 05:04 AM

A tight quench is mechanical octane!