Moparts

Crower roller hydraulics appear identical to Scorpions?

Posted By: Sxrxrnr

Crower roller hydraulics appear identical to Scorpions? - 04/09/17 12:14 AM

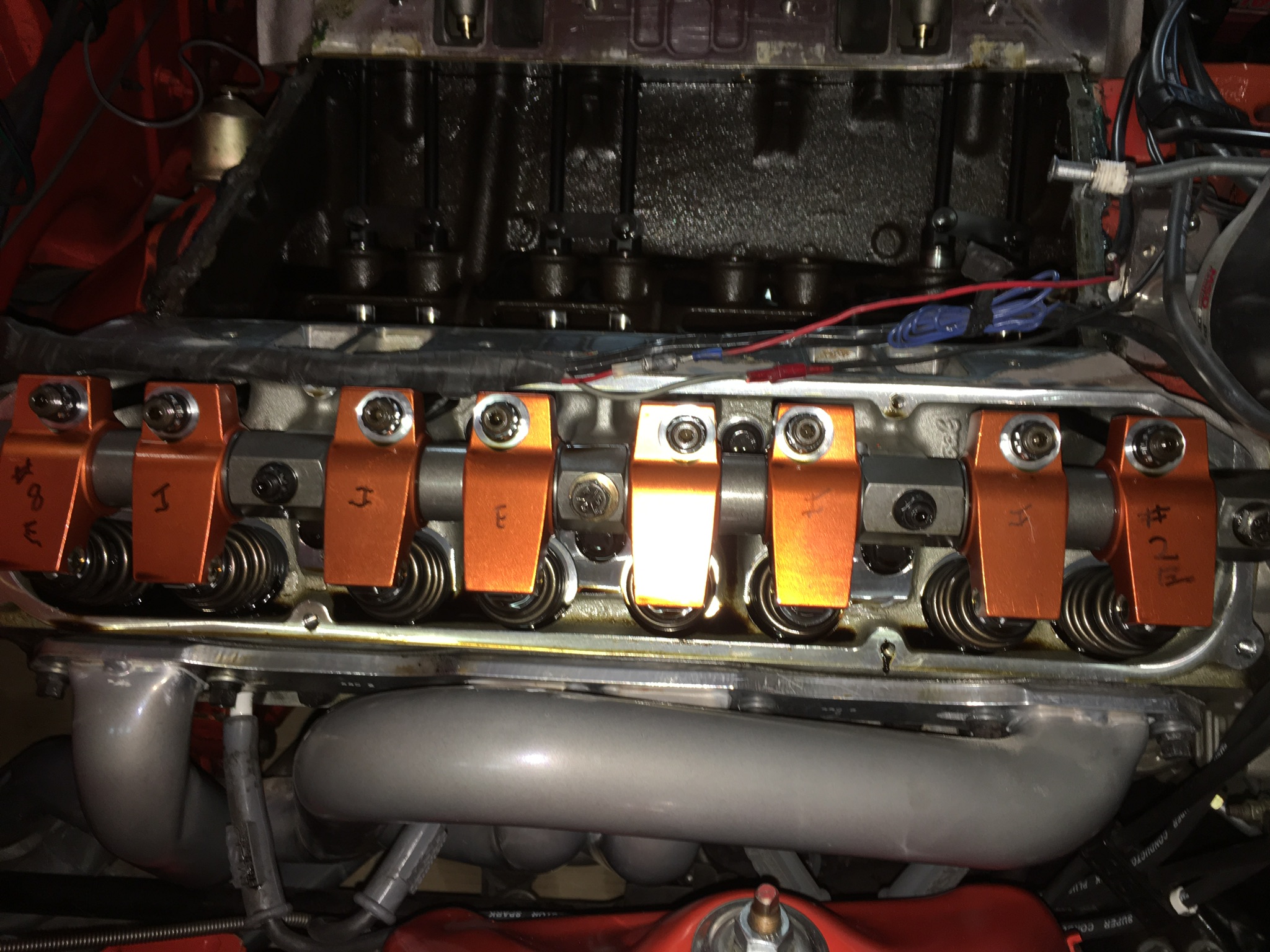

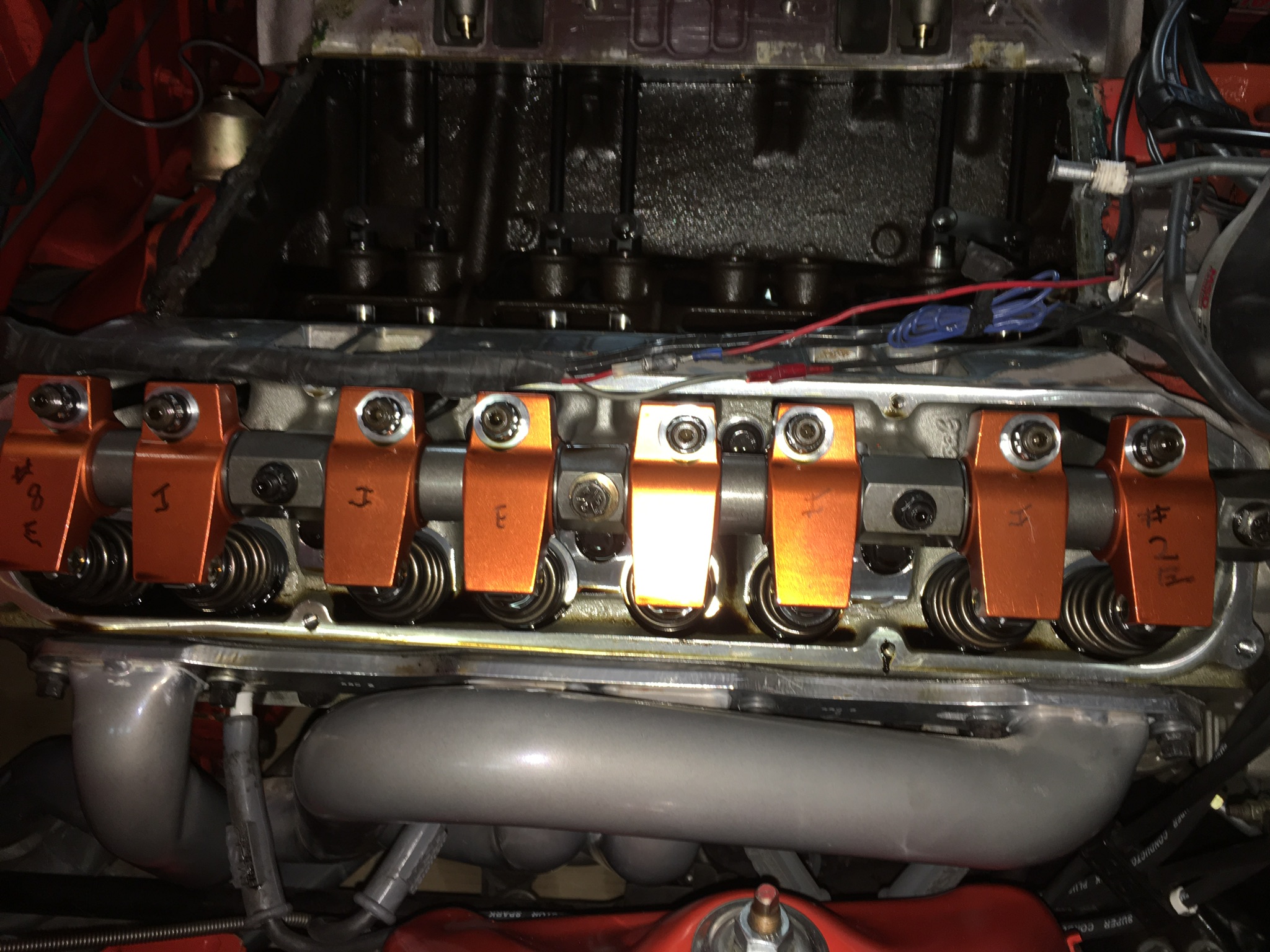

Engine is 512 BB Six Pack, Comp Cams 23-713-9 Hydraulic roller at .549 lift on intake with Scorpion lifters and beehive springs. Open valve at 350 pounds, closed at 150 with Harland Sharp rockers and Edelbrock Performer heads.

Returning from Goodguys event couple weeks ago after very short highway trip, pulled into fuel station and heard familiar clack, clack with engine running roughly.

Assumed another Scorpion collapsed lifter as some 2 years ago had lost one before.

Ordered up a new set of Crower lifters after weighing against possible Morel's who too had overall very good customer reviews.

Pulled intake today and #3 intake lifter was collapsed. Had rocker arm roller to valve stem clearance of .20 gap. Wear pattern on all valve stem tips appear spot on.

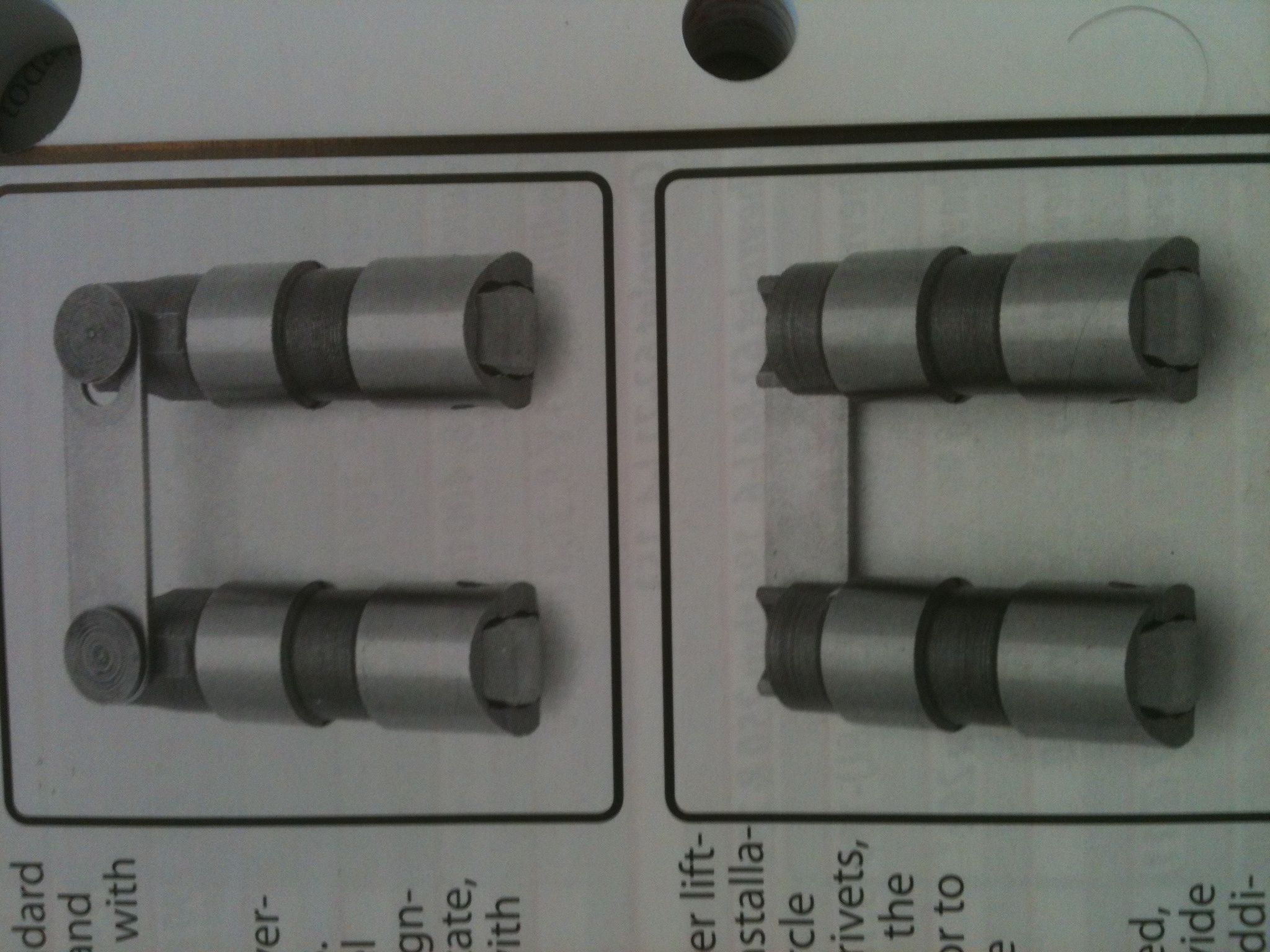

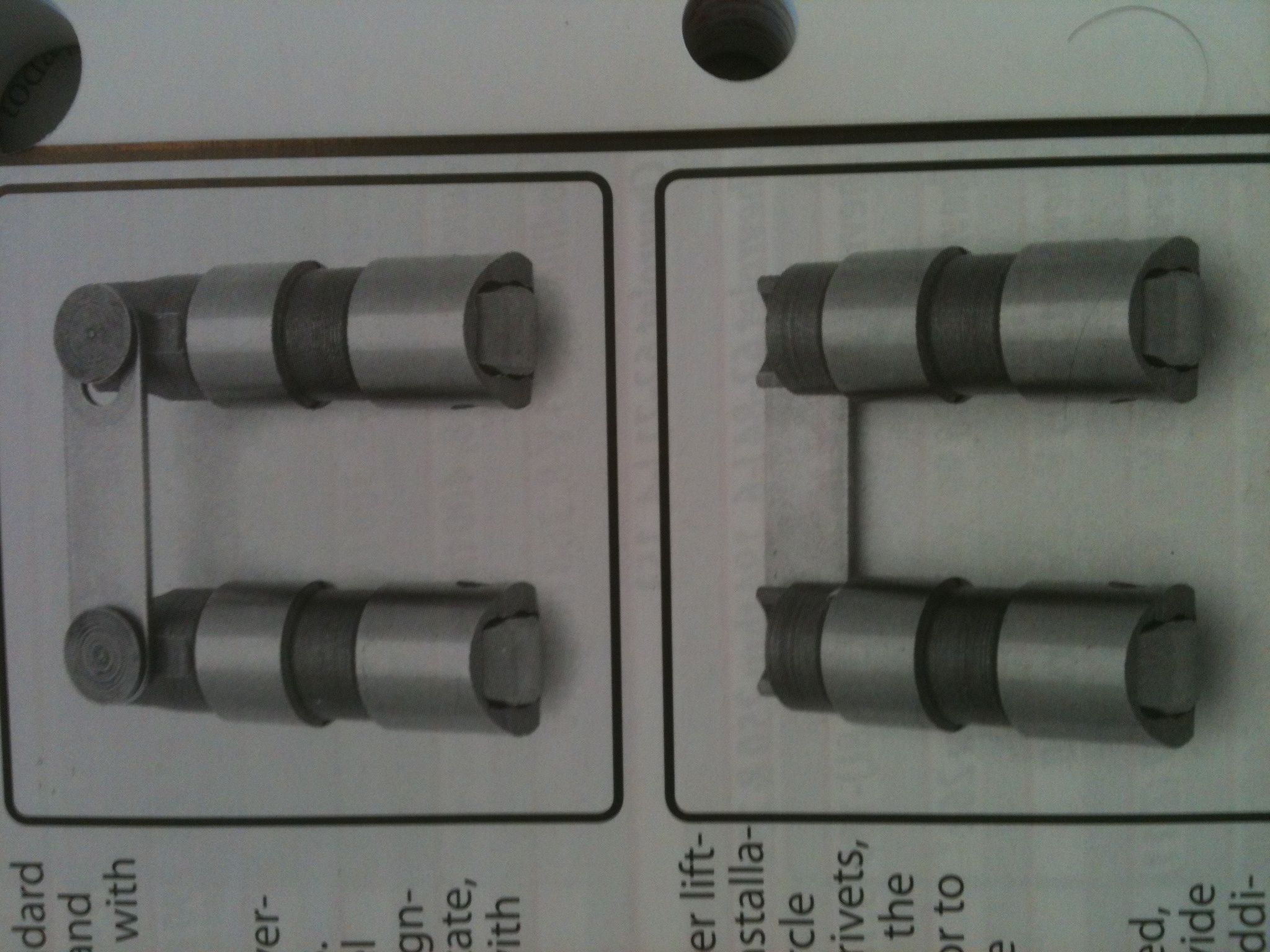

Pulled lifter pair and compared the Scorpion's being replaced to the new Crower's to determine if I may need a pushrod replacement.

To my surprise, they appear identical. With a caliper, I measured them everyday from Sunday. All measurements are identical between them.

Scorpion no longer sells lifters but when they did, I recall they were merely repackaging a Johnson product. There are now 2 Johnson firms manufacturing lifters,,,Johnson SEC and I believe a Johnson High Lyfit or some such. Johnson Hi Hylift does not offer a Mopar product, Johnson SEC told me that they make the Crower product. Crower when queried doing my diligence on what lifter to buy was unwilling to admit to whose lifter they sold,,,,except to tell me that they test every lifter for leakdown when they receive them from their supplier and subsequently reject a very substantial number as unacceptable.

The question I have is did I just purchase another set of Scorpion lifters, this time for about 800 dollars(original Scorpions were some 550) or is that perhaps just only the 'body' of the lifter is somewhat a standard used by a number of manufacturers and the higher quality lifters are perhaps internally machined to a higher tolerance level.

The photo below is from right: Crower-Scorpion-Crane. The Crane is from a set given to me by a fellow Forum member, John Cross who is converting to a Porter spec'd cam and valve train. These are older Crane's(when supposedly Crane offered a superior product) had never given John any issues,,,,however he did have other valve train inspired failures that he and a Porter are now dealing with.

So far I have been unable to disassemble my failed Scorpion for a postmortem,,,the prior one I had sent back to Scorpion for warranty replacement. Right now is is soaking in some very strong chemical product to see if I can free it up. Cannot even remove pushrod cup as appears really jammed.

I run Mobil 1, 5w20. Oil is changed often and is clean and tests so with a tester that I use.

Perhaps this thread should be on the engine tech forum,,,but I believe that most of us bounce back and forth.

Posted By: fast68plymouth

Re: Crower roller hydraulics appear identical to Scorpions? - 04/09/17 02:05 AM

Just for the record, John and I aren't "dealing" with anything, per se.

He was running a combo someone else had come up with, then a change to that combo was made, which exacerbated what I felt was a problem in the original set-up.

As such....... we discussed some options, and in the end went with a new combo........which I'm hoping he'll be pretty happy with.

Fwiw..........on your combo, I would be using different oil(Driven Hot Rod 10w40 synthetic).......... and I'd get the Morel lifters.

Fwiw 2......I have a set of Crane Hyd roller lifters here that were packaged in 2014 that don't look like those.

Posted By: Sxrxrnr

Re: Crower roller hydraulics appear identical to Scorpions? - 04/09/17 03:22 AM

Poked a dental pick into pushrod cup hole, managed to get the cup and with a mighty pull the cup came out. However not able to get 'piston' out. Magnetized a screwdriver, stuck it into 'piston' or whatever it is called,. Upon pulling it out, this metallic debris was affixed to the screwdriver, suggesting some catastrophic internal failure had occurred,,,,likely what too had befallen the original failure a couple of years and likely less than 2,000 miles ago. My suspicion is that this failure is not likely an oil failure.

I did have Morel on my short list for lifters, this whole business of lifters and who.makes what for whom was as being in the twilight zone, chasing down rabbbit holes. As I consider myself as somewhat a rookie on this whole complex topic of valve train components, I went with Crower. A main reason being that from what I could tell, but could not confirm is that Morel has 2 levels of products, one of which is retailed by various after market resellers claiming Morel as supplier at around 500 plus dollars and another which is much more costly, but sold by whom I never did determine.

Today is Saturday, Crower not available to speak to, however will be calling them Monday. If I now own another set of Scorpions, this would not be good.

Perhaps you could offer information on Morel's products and from whom I might acquire them and be certain that they truly are Morel's product and not just another reseller claiming that they are.

I did have a chance to examine the refurbishment and upgrade you performed on John's Indy heads. To my limited ability, they appeared first class and I believe he consulted you on the balance of his valve train components, thence my offhand comment that you and he were 'dealing' with the problems that may have been inherent from the beginning when his engine was originally built by a very known Mopar high performance engine builder. Please accept my apology if I had assumed incorrectly.

If I could easily replace what I have with a solid roller I would do so in a heartbeat. Even in a moment of insanity had considered running a solid roller on my hydraulic cam,,,,as some did or tried to with flat tappet cams when I was a kid.

Some have reported that 'older' Crane hydraulic lifters were excellent. 'Older' however was not defined,,,,perhaps before 2014? I can report that my 12 second small block destroked 400 inch 71 Corvette is still happily running the Crane flat tappet hydraulics and camshaft that were installed in the early 80's with nary a hiccup.

Posted By: fast68plymouth

Re: Crower roller hydraulics appear identical to Scorpions? - 04/09/17 05:30 AM

I only "know" what I'm told........ And since I don't work at the lifter manufacturers or cam grinders...... I can only go by what they say.

Howard's says they get the hyd rollers from Morel.

That's where I get "Morels" from since I can buy them for a decent price through my supplier.

Are they really "Morels"? I don't know...... But they do look like the same thing that's on the Morel website.

I can't tell what those pieces are in those pics with the shadows.

Something inside was "broken"?

There are very few lifter suppliers/manufacturers for the industry, so a lot of different brands are actually the same parts.

At one point, from what I understand, Crane did make their own hyd roller lifters, although I'm pretty sure I read somewhere that the equipment to do that was sold when they were closed, so more than likely what they are selling now is something that's being reboxed.

I can tell you this........ My "if it were me" answer is........ Is try the Morels, and if I had a problem with those....... I'd be making some other changes, besides just lifters.

Posted By: fast68plymouth

Re: Crower roller hydraulics appear identical to Scorpions? - 04/09/17 05:57 AM

My Crane lifters look similar, but are a bit darker in color and don't have the shrouded wheel.

Posted By: Sxrxrnr

Re: Crower roller hydraulics appear identical to Scorpions? - 04/09/17 06:32 AM

Photos as I noted were of broken pieces of thin metal retrieved from inside lifter barrel(so certain is steel) with a magnetized screwdriver once I was able to remove pushrod cup. Appears that before self destructing these pieces were the oil control disc made of spring steel which is standard to most/all hydraulic lifters.

You can understand my being flummoxed in attempting to ascertain who manufactures what and sells to whom under what name in this Wild West industry if you with your vast experience are too bewildered.

As noted earlier, valve spring pressures appear well within recommended guidelines, pushrods are not at any obtuse angles at rocker arm adjusters, wear patterns appear excellent on valve stems. engine is set to max 6,200 rpm via MSD limiter, car is street only and seldom sees even 5,000 rpm. Furthermore after some 3,000 miles only on engine and valve train, 14 lifters have not yet failed, indicating no oiling issues or orther such mechanical pitfalls. There appears a super abundance of oil everywhere it should be and lifters are set at 1/2 turn tight from initial pushrod drag.

Car does perform extremely well when no lifter is in a collapsed state.

I do recall one user on this forum I believe it was, with Scorpion lifters reporting that he collapsed 3 or 4 Scorpion lifters on initial installation and adjustment. Others reported similar experiences with these and other vendors.

This is why I am now concerned that I may have just invested 800 bucks in another set of Scorpions, now labeled as Crower.

Hence the query posted to this forum on the questions I posted.

I will contact Morel directly on their lifters, who sells them and where they are retailed, once I have spoken with Crower, if the answers I get do not increase my comfort level.

I did carefully compare your photos of Crane lifters to those I have. The only place where they definitely appear to differ is at the top where they affix to the link bar. You are correct, they are different. I do not yet know how old the lifters given to me by John. Perhaps they are from a prior generation.

Thank you for your help and advice.

Posted By: fast68plymouth

Re: Crower roller hydraulics appear identical to Scorpions? - 04/09/17 07:31 AM

Bewildered?

No....... I've understood for quite a long time now that there are a handful of suppliers for the various components in the cam industry.

A few spring coilers, a few lifter manufacturers, a few cam core sippliers...... The stuff between brands is more the same than it is different.

How sure are you that your springs are set up with the pressures/clearances you say they are?

The reason I ask is, when I've installed the beehive spring that's normally used in that application on the RPM heads, I've had to use a +.050 lock to get the installed height tall enough. From the pics of your heads, yours appear to have the std height locks.

I've also seen where the coil bind height on that spring can vary quite a bit.

If you happened to have the springs installed on the short side, and one or two go into coil bind at a height taller than spec, then you could have a situation where they are starting to stack up, which can really cause some issues with the lifters.

With those springs in particular, I make sure to check the coil bind height on evey one, and adjust the installed height where needed.

Also, the HS "1.5" rockers are usually closer to 1.55, so you could have more net lift at the valve than what's on paper.

This is tough with hyd lifters since they bleed down when you're doing this type of test/measurement, so it really needs to be done with a solid lifter, or in this case, a solid roller.

The biggest difference I saw on the lifters was yours have a completely shrouded wheel, whereas mine have the wheel exposed(although it's tough to make it out in my pic).

Posted By: Interceptor72

Re: Crower roller hydraulics appear identical to Scorpions? - 04/09/17 04:59 PM

Those Scorpion and Crower lifters look identical to the ones I got from Comp Cams. I had the same problem with pushrods popping out (and low oil pressure.)

I replaced them with Morel lifters from Howard's (on the advice of Fast68plymouth) and have had no problems since (and increased oil pressure.)

As far as I am concerned, whoever is making those Scorpion/Crower/Comp lifters is making a substandard product.

Posted By: Sxrxrnr

Re: Crower roller hydraulics appear identical to Scorpions? - 04/09/17 05:22 PM

Johnson SEC on their website, asserts that Crower among others is a distribution agent for their lifters. As I noted in a previous posting, Crower was unable when asked by me who their supplier was.

http://johnsonlifters.com/Distributors.aspx

Posted By: Sxrxrnr

Re: Crower roller hydraulics appear identical to Scorpions? - 04/09/17 06:07 PM

Just over 2 years ago i had a severe oil fouling of spark plugs. After much research and debate, including this forum to no success. Consensus was that was a valve guide problem, I disagreed as guides had been replaced and as noted in next paragraph, intake ports on heads and manifold were slathered with a coating of oil. I decided to replace my 906 heads as suspected a sealing issue between Eddy six pack intake and heads were the cause.

Pulling the intake gave no clue that there was a sealing issue except that intake ports coated with oil, but gasket showed zero evidence of leaking, , nevertheless I replaced turkey pan only(unable to replace fiber gaskets as bolt alignment was out of the question), and bolted it up. Outcome was still severe oil fouling.

Purchased Eddy Performer heads from 440 Source for my then solid hydraulic cam. Decided after receiving heads to use roller cam instead requiring valve spring change. Decided upon and ordered up beehives from CC and sent heads off to a very reputable machine shop for inspection and spring change. I had already planned to have the Eddy heads reviewed by the machine shop to double check their quality control.

Recall very well Machinist 'Angelo' calling and telling me that he would need to replace keepers with CC recommended version, and questioning open and closed valve spring pressures that CC recommended for their beehives. I asked him to call CC tech, he called me back and said that all was now ok. He did obtain and install recommended keepers and CC convinced him their specs for beehive spring pressure was correct. As I recall, Angelo was concerned of excessive spring pressure CC recommendation being used on a hydraulic cam.

Have had zero oil fouling issue since head change,,,,assuming that head/intake geometry was compromised somehow,,,likely 906 head milling at one time. Oddly the car used no oil at all, nor did it smoke. Could not be more pleased with current performance except for lifter failures.

I do intend to check out Howard's for Morel's if upon following up with Crower to find if their lifter is the same as was sold by Scorpion,,,incidentally suggested that they produced their own superior lifter when I was evaluating them as a possibility. I had almost purchased CC's when acquiring their cam,,,,but was put off by all the negative comments posted. Now suspect that they are the elephant in the room,,,,it is natural that in sheer numbers they will get more negative reviews than other smaller firms who may percentage wise come off looking better.

Also will have a look at spring gaps at full valve open,,,your point on Harland Sharp ratio well received. Could you offer up any information how I might best check out valve spring pressures and spring gaps.

Thank you

Posted By: fast68plymouth

Re: Crower roller hydraulics appear identical to Scorpions? - 04/09/17 07:48 PM

I won't get into a keyboard battle here about your heads, instead I'll just say that I've installed the beehive springs on about 20 sets of those heads, and on all of those sets, +.050 locks were required to get the the correct installed height.

The as delivered installed height for bb mopar rpm heads is a nominal 1.885", and the retainers used for the beehive springs provide less installed height than the Ede retainers when both are used with std height locks. You need + installed height locks to get back to 1.880 with the beehive retainers.

Could there have been some shims under the spring cups that were able to be removed to get back the lost installed height? Sure. But I haven't seen .050 worth of shims under the cups on any of those heads that I've done(about 100 sets).

If the valve seats have been recut, then depending on how that was done, you could gain some usable installed height, then if there were some shims, etc..... You could get there.

While it's certainly possible the installed height is as tall as it's supposed to be........ Based on my experience, I'm skeptical.

My suggestion would be, pull the spring off the valve that just killed the lifter, check the installed height, then check the coil bind height....... And see where you're at.

IMO, the feeler gauge between the coils is a useless way to test for coil bind height...... Especially with beehive springs.

I have seen where the coiling isn't all that concentric, and on those springs it's often the case where the coils will be stacked solid on one side of the spring, and there will be plenty of gap between the coils on the other side........ And the spring is stacked "solid".

And....... Those are usually the ones where the solid height is taller than spec.

I've seen those springs be stacked solid at the "open" pressure height(1.280), which is .050 higher than the coil bind spec(1.230).

I would check what you have, then you'll know for sure.

Posted By: fast68plymouth

Re: Crower roller hydraulics appear identical to Scorpions? - 04/09/17 07:55 PM

Everyone can have a bad day, and mistakes are made.

Your friends heads had springs that were supposed to be installed at 1.880.

This is what they actually were........ Which IMO was the root cause of his problems.

Posted By: fast68plymouth

Re: Crower roller hydraulics appear identical to Scorpions? - 04/09/17 08:03 PM

I don't know why I remembered the Crane lifters I had here as being "darker".

Actually, they're "shinier".

You can see the exposed wheel better in this pic.

We'll find out if these are the "good ones" or not. They will be getting used with a cam close to .600 lift with open pressures about 400lbs.

Posted By: Sxrxrnr

Re: Crower roller hydraulics appear identical to Scorpions? - 04/09/17 08:27 PM

The 'Crane' lifters given to me ok nothing as what you show. Additionally do not have any Crane logos.

I was leery of checking spring bind with the normal feeler gauge technique. Glad I asked you the question.

I will dig out the machine shop paperwork on my heads. The Eddy heads were new and included valves, hence no valve job, but as noted, springs were replaced. If memory serves, .050 keepers installed, 150# closed, not positive but 350 open.

Posted By: fast68plymouth

Re: Crower roller hydraulics appear identical to Scorpions? - 04/09/17 08:43 PM

The +.050 are gold, and have no lash cap recess, and when they are used the top of the valve barely stands proud of the retainer.

Yours look like std locks...... Comp 611-16.

I should add that even if the installed heights are on the short side, as long as the springs aren't being run into a coil bind condition, it's unlikely this is the cause of the lifter failures.

Speculating....... I can easily see a situation where you're using really thin oil, running for an expended period at highway speeds, which introduces air bubbles into the oil. The aggressive nature of the cam profile and the much higher than oem spring pressures work to marginally collapse the lifter plunger that's only being supported by this layer of now air infused hot thin oil, to the point where there is repeated internal metal to metal contact......... Which in time leads to the break down of an internal component of the lifter to the point of it failing........ And then the plunger sticks when a piece of debris gets lodged in the wrong place.

The only other way I see it happening is if a piece of debris gets into the check valve of the lifter, which doesn't allow it to stay pumped up, then that starts the chain reaction of the plunger being hammered into the lifter body until some pieces fail.

Posted By: fast68plymouth

Re: Crower roller hydraulics appear identical to Scorpions? - 04/09/17 08:51 PM

Not that this means anything....... But here is a generic pic out of the 2010 Crane catalog of there hyd roller lifters.

It looks like what you have there as a Crane lifter, and doesn't look like what I have here.

Posted By: fast68plymouth

Re: Crower roller hydraulics appear identical to Scorpions? - 04/09/17 09:04 PM

It's been a while since I've had a bb mopr hyd roller lifter from comp cams in my possession.

I didn't realize they had changed to have the shrouded wheels now(I guess they have been like this for a while), but the last time I had a set here, they looked like this:

Posted By: fast68plymouth

Re: Crower roller hydraulics appear identical to Scorpions? - 04/09/17 09:06 PM

Here are some beehive springs on rpm heads using the +.050 locks:

Posted By: Sxrxrnr

Re: Crower roller hydraulics appear identical to Scorpions? - 04/09/17 10:46 PM

Reports from Forum members and others suggest these were a quality product, however could mean what they were compared to then.

John had no problems with those he gave me,,,,but as we and he are now aware, his valve spring pressures apparently were lacking. My guess might be that hydraulic rollers and high(read standard now) valve spring pressures are not yet ready for prime time.

Given that most hydraulic roller failures seem to be due to collapse, and postmortems seem to indicate broken internal discs as I experienced. Solid rollers of course care not a wit about this as they have none of these very flimsy oil control discs to deal with.

On your point on spring bind on specific cylinders/valves. The previous failure that I experienced was on number 6 exhaust. Some 2K miles later it is still ok, which suggests if there was something unique about this cylinder/valve it likely should have failed again by now. The first failure was after just a few hundred miles which suggests a QC manufacturing defect,,,just as with this most recent failure. 14 others have not yet failed.

Would be enlightening if a manufacturer would chime in,,,,but for now it appears that their tactic is to keep their heads down.

Posted By: fast68plymouth

Re: Crower roller hydraulics appear identical to Scorpions? - 04/10/17 05:04 AM

The thing I find the oddest about the proportionately high number of people having issues with hyd roller lifters in bb mopars is that......... it seems to happen proportionately less on bb chevy motors.

I rebuild a lot of BBC marine heads, and probably 75%(or more) of those are being run with hyd roller cams, and there are very rarely any lifter failures that we encounter.

Many of these use cams in the .600 lift range, and are using 1.7 rockers, which results in the lifters seeing even higher loads(spring pressure X rocker ratio), and they seem to hold up just fine.

Posted By: CSK

Re: Crower roller hydraulics appear identical to Scorpions? - 04/10/17 05:31 AM

The thing I find the oddest about the proportionately high number of people having issues with hyd roller lifters in bb mopars is that......... it seems to happen proportionately less on bb chevy motors.

I rebuild a lot of BBC marine heads, and probably 75%(or more) of those are being run with hyd roller cams, and there are very rarely any lifter failures that we encounter.

Many of these use cams in the .600 lift range, and are using 1.7 rockers, which results in the lifters seeing even higher loads(spring pressure X rocker ratio), and they seem to hold up just fine.

I could be wrong, but my thought on this is, the chevy has pushrod oiling,that helps flush out any small debris & also would let air bubbles out of the lifter, IE foamy oil, just a thought, I really think the foamy oil kills the lifters.

Posted By: SomeCarGuy

Re: Crower roller hydraulics appear identical to Scorpions? - 04/10/17 05:51 AM

Thread is a reminder of how many pitfalls mopar can have and the deep in the weeds experience needed to avoid them is hard to get building on or two engines at home in a decade. Checking parts tediously is about all one can do, but I suspect our stuff isn't given as much thought and qc as bow tie material.

Posted By: Sxrxrnr

Re: Crower roller hydraulics appear identical to Scorpions? - 04/10/17 07:21 PM

The +.050 are gold, and have no lash cap recess, and when they are used the top of the valve barely stands proud of the retainer.

Yours look like std locks...... Comp 611-16.

I should add that even if the installed heights are on the short side, as long as the springs aren't being run into a coil bind condition, it's unlikely this is the cause of the lifter failures.

Speculating....... I can easily see a situation where you're using really thin oil, running for an expended period at highway speeds, which introduces air bubbles into the oil. The aggressive nature of the cam profile and the much higher than oem spring pressures work to marginally collapse the lifter plunger that's only being supported by this layer of now air infused hot thin oil, to the point where there is repeated internal metal to metal contact......... Which in time leads to the break down of an internal component of the lifter to the point of it failing........ And then the plunger sticks when a piece of debris gets lodged in the wrong place.

The only other way I see it happening is if a piece of debris gets into the check valve of the lifter, which doesn't allow it to stay pumped up, then that starts the chain reaction of the plunger being hammered into the lifter body until some pieces fail.

As noted earlier I will be researching further the work performed on my Eddy heads by machine shop to ascertain if +.050 keeper were used as required, and follow your recommended method to check for coil bind on those valves where lifter collapsed was experienced.

Following up on your comment and another forum member regarding oil foaming as a possible cause. In each instance of lifter collapse, I experienced following immediately after or during a highway Cruise of 25 miles or so at about 80 mph(3,200rpm) with short bursts not exceeding 4,200 rpm(just over 105 mph or so). 4:10 rear axle, Passon .8 overdrive 4 speed, 28 inch tire giving 3:23 final drive. Also using fairly light 5W20 oil which as suggested more prone to foaming.

Your analysis of the chain events that can lead to ultimate failure is an excellent post mortem of possible cause. As I noted earlier, was very difficult to even remove pushrod cup from lifter barrel, it is impossible to remove inner piston as it is completely jammed in place. I have considered heating.

Nevertheless these all add up to nothing more demanding than normal driving that any properly engineered hydraulic lifter should handle with ease,,,,witness Z06 Corvettes, Hellcats and a myriad of other pushrod driven engines.

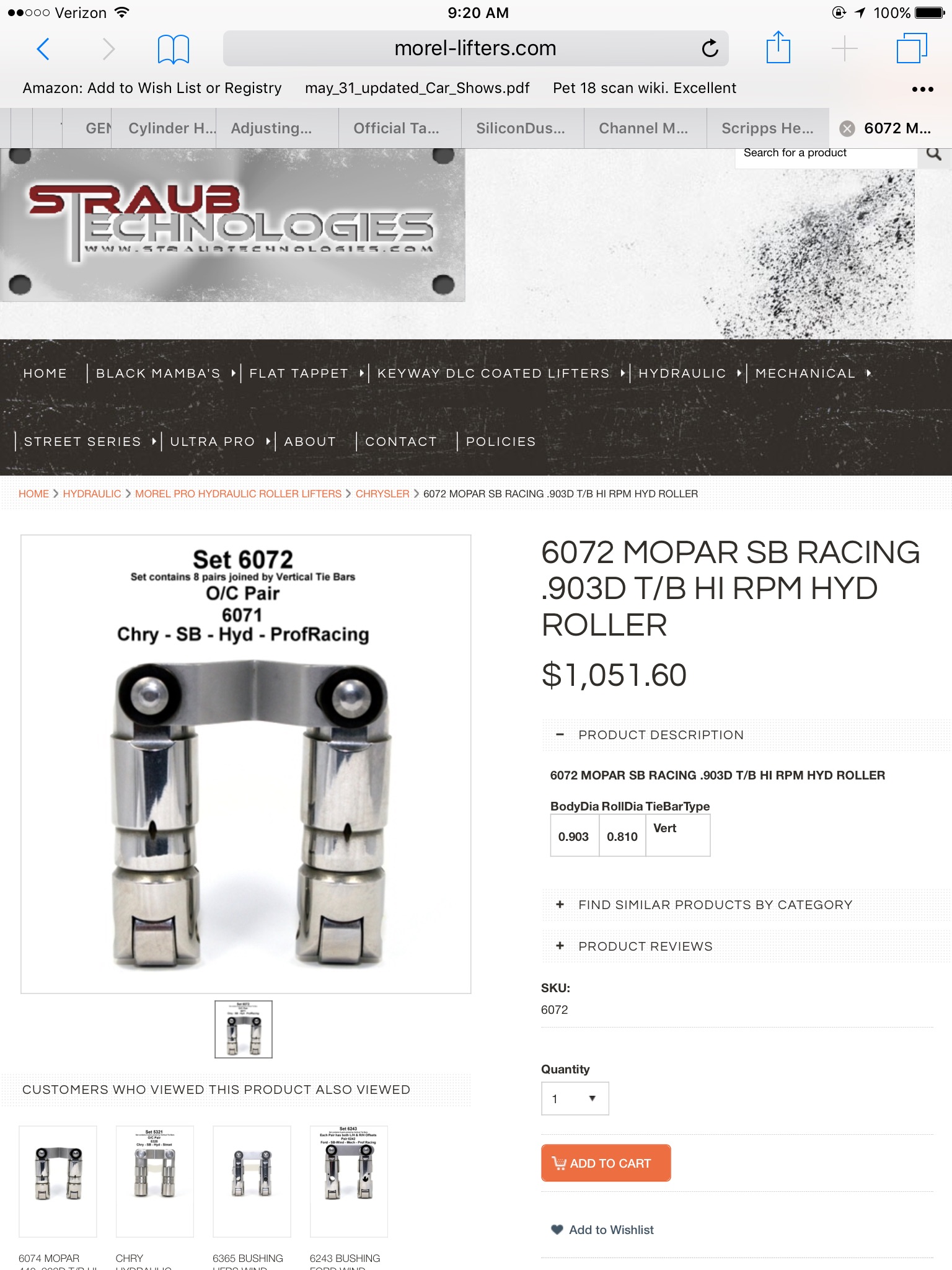

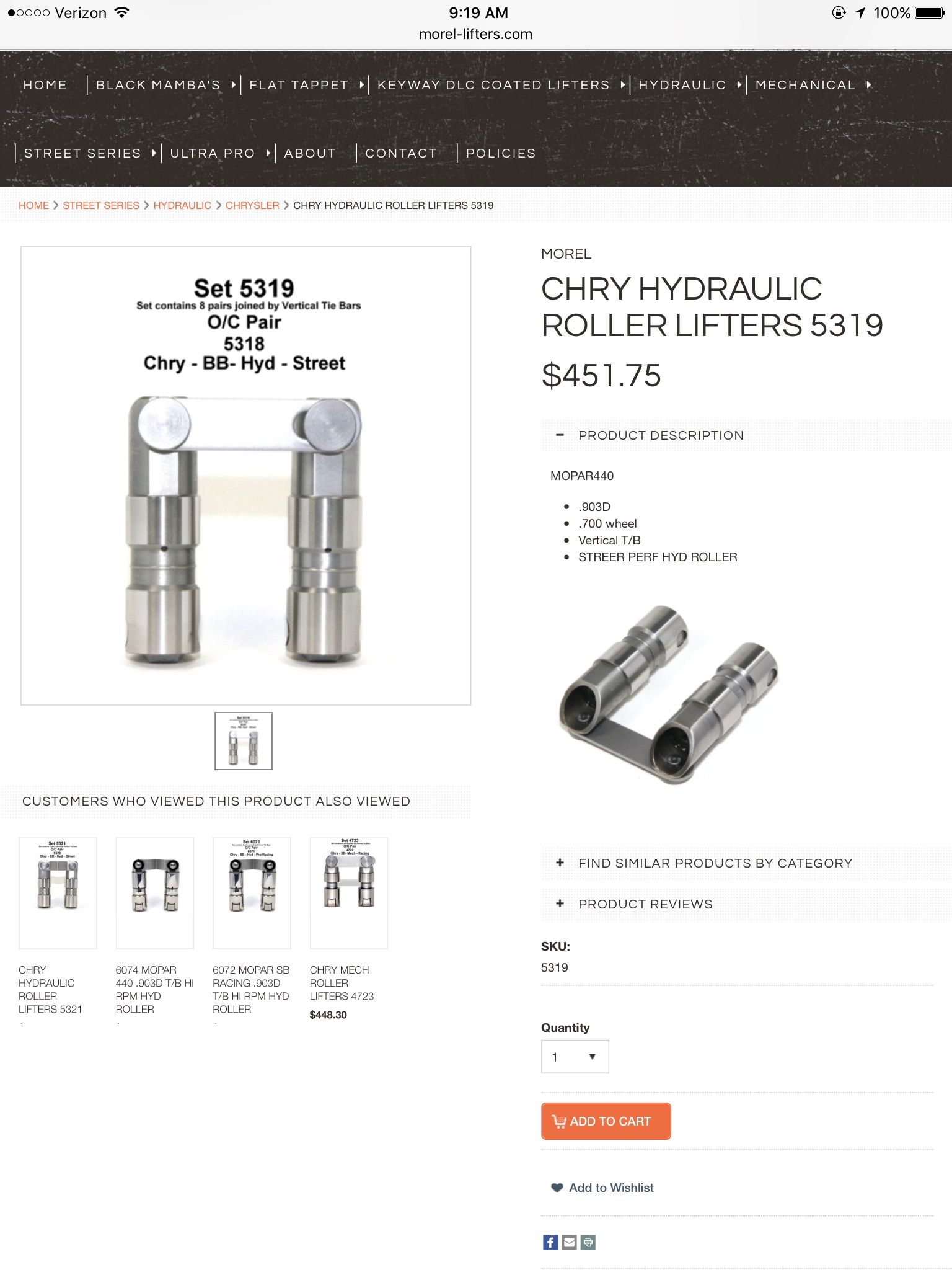

I had suggested earlier that I thought that Morel Morel offered 2 differing quality lifters.

This is what I found on their website.

http://morel-lifters.com/6072-mopar-sb-racing-903d-t-b-hi-rpm-hyd-roller/Photos below of the two products.

It is obvious that the Morel product that Howard resells as their lifter would be the lesser expensive one at 450 dollars,,,,a hell of a deal compared to the Crowers that I recently purchased at about 800 dollars, or my failing Scorpions at about 550 dollars.

You mentioned that you have jobber or some such arrangement with Morel where you have discount status. Does this also apply to their high priced and reasonable to assume higher quality lifter?

Would you know what reliability or performance advantage they offer over their lesser offering? I have been unable to find any information at all. I do plan to contact them,,,however it appears that email is only option that I have found.

I will be calling Crower today to find if their lifters that I have recently acquired differ in any way from Scorpions,,,their appearance is identical, I believe both were made by Johnson SEC. Perhaps improvements in internals,,,,who knows. I would not have to change pushrods would be a plus,,,,but if they fail too, as have the Scorpions, I prefer to change lifter vendor and pushrods.

In re-reading my prior postings on this thread, I noted a number of silly typos and grammatical errors. One finger pecking on an iPad and spell check guesses and sketchy proofreading, I apologize.

Posted By: fast68plymouth

Re: Crower roller hydraulics appear identical to Scorpions? - 04/10/17 08:19 PM

I think Chris at Staub would be able to answer your questions about the benefits of the more expensive Morels.

I really don't have any experience with them myself, so nothing I say would be from first hand experience.

However, I still stand by my first recommendation......

The std Morel/Howard's lifters and Driven Hot Rod synthetic 10w40 oil, and make sure the springs are set up to the correct height.

Trying to compare late model oem valvetrains with retrofit aftermarket parts, and thinking because it works in the oem application it should be fine in a completely different platform will lead you astray IMO.

For one thing, I'm sure there isn't any passenger car motor(hp or not) that uses a cam profile as aggressive as what most of the aftermarket stuff is.

The OE stuff is designed to be able to run with less spring pressure, which just means less wear and tear overall.

I know of a few LS motors that have aggressive aftermarket cam profiles and the associated valvetrain components that go along with that type of cam, and they don't enjoy oem type reliability either.

Posted By: fast68plymouth

Re: Crower roller hydraulics appear identical to Scorpions? - 04/10/17 08:28 PM

I could be wrong, but my thought on this is, the chevy has pushrod oiling,that helps flush out any small debris & also would let air bubbles out of the lifter, IE foamy oil, just a thought, I really think the foamy oil kills the lifters.

That's certainly a possibility, and might even be a good argument for pushrod oiling in one of these applications........ Although, the hyd flat tappet lifters would have the same lack of flow "through" the lifter, and this internal damage problem generally isn't an issue with those.

Posted By: fast68plymouth

Re: Crower roller hydraulics appear identical to Scorpions? - 04/10/17 09:46 PM

Another "fwiw"....... Even the manufacturer of all those LS motors and Corvettes, that probably use 0w20-5w30 oil, recognizes that not all platforms are candidates for "thin" oils.

The recommended oil for the zz572 crate engine is 20w50.

Everyone thinks they're an expert on what oil to use(I'm as guilty as anyone of this), but there is no way I'd even consider running passenger car, API certified 5w20 oil in my big block stroker motor.

I don't feel a stroked BB mopar has any kind of new technology in it that would exclude it from using similar weight oils as it would have when it was new.

Oh, and my 93 Dakota with a 3.9 in it, makes all kinda of valvetrain noise when it's got 5w30/10w30 in it........ But it just as happy as can be with 20w50 in it.

5w20?? Sure........ In my Civic.

Posted By: CSK

Re: Crower roller hydraulics appear identical to Scorpions? - 04/10/17 10:27 PM

I could be wrong, but my thought on this is, the chevy has pushrod oiling,that helps flush out any small debris & also would let air bubbles out of the lifter, IE foamy oil, just a thought, I really think the foamy oil kills the lifters.

That's certainly a possibility, and might even be a good argument for pushrod oiling in one of these applications........ Although, the hyd flat tappet lifters would have the same lack of flow "through" the lifter, and this internal damage problem generally isn't an issue with those.

Just asking, but don't most bb mopars have a RPM problem when running any hydro lifters when running big cams. on mine I went solid FT because of all the complaints I read about ?

Posted By: Sxrxrnr

Re: Crower roller hydraulics appear identical to Scorpions? - 04/13/17 02:59 AM

After a couple of days tending to other matters of less importance, I have gotten back to the task st hand.

In addition to speaking to other manufacturers and vendors attempting to determine who builds what lifter for what vendor I have now spoken to Crower, Competition Cams, Howard, Scorpion, Isky, Morel, Johnson SEC, and others, some more than one time.

What I have learned is that Johnson SEC manufacturers hydraulic roller lifters for Crower, Isky and at one time for Scorpion(my current collapsing lifters) and possibly others. However no long build for Scorpion who is out of the lifter business and is under new ownership.

Speaking with a very knowledgeable and helpful gentlemen tech at Johnson SEC I found the following.

Even though the external appearance of their roller appears exactly the same as my Scorpions, it has been modified internally to withstand greater abuse from higher spring loads and RPM's. So yes, current Crowers benefit.

However to further improve performance and reliability, they have modified installation instructions.

1. 3/4 to 1 full turn down from initial pushrod drag at lifter set point.

2. Recommended that. ,035 thousand longer pushrod than I now have with my Harland Sharps. I believe but not certain I understand totally the logic here...Details on request.

3. A slightly heavier oil just a Porter suggests(10/40), says 10/30 ok but no 20/50. I now understand full impact of oil aeration or as Porter suggested and some else here mentioned,,,foaming.

That logic goes as this. A lesser preload on lifter(I ran 1/2 turn down)' allows the lifter to ride higher in the lifter barrel, hence more oil under the lifter. Any tendency to foaming or aeration could allow the oil to compress(normally oil not compressible), which then could cause a gap between rocker arm roller and valve stem, just as is normal on a solid cam.

However on a hydraulic, this not suitable for what appears as two reasons. Number 1 is that this little metal disk that sits right below the lifter cup,,,and for you who recall from photos above is my failure point, which exposes this disc to severe pounding when this created gap is slammed shut, compounded by the fact that this aeration mitigates greatly the positive effects of the cam's ramping technology that eases gently the roller of the lifter to commence its travel of the lobes of the cam. So in effect the whole valve train of lifters, pushrods, rockers are getting thousands of these shocks every minute of operation.

I had earlier mentioned that both of my lifter failures only occurred after a 20 or 30 mile freeway excursion, where oil may have more of a tendency to foam.

I had mentioned all of this to a friend who is also an E Body owner, for better or worse with a very nice 2nd gen Hemi. He reminded me that I had eliminated my oil control shield when I switch to a Road Race pan,,,,and wondered if this might be a contributing factor to oil aeration. Possible excellent point in the chain of events.

I have checked beehive valve spring heights as advised by Porter. All with CC recommended as the photo below shows,,,given that measuring was done with a caliper.

I have ordered up from LSM a track side valve spring pressure tester, to double check open and closed pressures. Johnson SEC says I should easily handle over 450 and likely over 500 pounds.

https://www.amazon.com/dp/B003YF2EWK/ref...customerReviewsThis tool looks extremely well made at about 250 bucks. Summit sells or you can buy direct from LSM,,,all USA made in Calyfornua,,,yes I know perhaps not a plus. Bruxtom sells the best but at 650 bucks. The others take your chances. I recommend strongly speaking directly to LSM on their model 100 SLC. Very helpful. Tool should be here tomorrow, be putting it back together thereafter.

There is a lot more that I have learned and quite pleased to have spent the time to do so. Thank you very much to those who chimed in and a particular thanks to Porter who offer a great deal of his expertise to the issue. Perhaps others on this forum will benefit also.

I do have an abundance of information on which manufacturers build for which resellers if anyone should be interested. Morel currently now offers a hydraulic roller of very high performance good for over 6,500 rpm, that sounds like a solid, using very little preload, at 11 o12 hundred the set.

Posted By: Sxrxrnr

Re: Crower roller hydraulics appear identical to Scorpions? - 04/13/17 03:29 AM

Porter: To remind everyone of your earlier diagnoses: Worthy of a second reading.

The +.050 are gold, and have no lash cap recess, and when they are used the top of the valve barely stands proud of the retainer.

Yours look like std locks...... Comp 611-16.

I should add that even if the installed heights are on the short side, as long as the springs aren't being run into a coil bind condition, it's unlikely this is the cause of the lifter failures.

Speculating....... I can easily see a situation where you're using really thin oil, running for an expended period at highway speeds, which introduces air bubbles into the oil. The aggressive nature of the cam profile and the much higher than oem spring pressures work to marginally collapse the lifter plunger that's only being supported by this layer of now air infused hot thin oil, to the point where there is repeated internal metal to metal contact......... Which in time leads to the break down of an internal component of the lifter to the point of it failing........ And then the plunger sticks when a piece of debris gets lodged in the wrong place.

The only other way I see it happening is if a piece of debris gets into the check valve of the lifter, which doesn't allow it to stay pumped up, then that starts the chain reaction of the plunger being hammered into the lifter body until some pieces fail.

Posted By: fast68plymouth

Re: Crower roller hydraulics appear identical to Scorpions? - 04/13/17 03:44 AM

That measurement is from the bottom of the retainer, down to the spring cup?

If so, you chould be good.

One of the design criteria of the Driven oil is it's supposed to release air bubbles quicker.

I'm glad to see you're doing your homework.

Another little tidbit:

The cam you're running has fairly fast lobes, which can be a challenge for the lifters.

Posted By: Sxrxrnr

Re: Crower roller hydraulics appear identical to Scorpions? - 04/13/17 03:50 AM

Yes did measurement from head surface(Eddy,s make it easy). Just a bit problematic at spring's entrance into upper retainer. Close enough for government work,,,no I did better than that.

Posted By: fast68plymouth

Re: Crower roller hydraulics appear identical to Scorpions? - 04/13/17 03:55 AM

Yes did measurement from head surface(Eddy,s make it easy). Just a bit problematic at spring's entrance into upper retainer. Close enough for government work,,,no I did better than that.

The measurement should be from the flat portion of spring cup(where the spring sits) to the underside of the retainer.......not from the

head to the retainer(unless there are no longer any shims or cups being used......which would be its own problem).

Edit: I just looked at the pic of your heads without the rockers again, up close.

The Edelbrock spring cups have been removed, and it looks like I can make out the edge of what is likely an inner spring seat. The inner spring seats are usually .060 thick, so if you measured down to the head itself, and there is indeed a spring seat there....... you can basically take .060 off that measurement you got.

And if that's the case....... and you actually want to be in that 1.880 installed height range......you'll need the +.050 locks.

Posted By: Sxrxrnr

Re: Crower roller hydraulics appear identical to Scorpions? - 04/13/17 04:15 AM

Eddy head has a very broad "spring cup" so easy to get abbreviated tip of caliper to head surface avoiding the shim that usually shifted a bit to one side giving access to top of head where shim makes contact.

At retainer could see where spring tucks up under the retainer and made a bit of judgement here. I do not have a installed height tool as such, but have a valve spring removal tool and compressed air chuck. When spring pressure tool arrives, I will measure out more accurately spring height. Perhaps I may find that to get back to recommended level, I may find I need to shim a bit.

A thought just occurred to me, that some enterprising tech could set up a smart phone app in conjunction with "FaceTime" to offer an onsite consulting automobile service via iphone..

Posted By: Sxrxrnr

Re: Crower roller hydraulics appear identical to Scorpions? - 04/13/17 04:22 AM

There are no inner springs. I can see the very edge and pointy tip of the beehive where it tucks under the "track" on the underside of the retainer. I may be off a very few thousandths, this is a reason that I wish to measure current spring pressures.

Would .050 keepers tend to negatively affect rocker arm to retainer clearance is something that I will checkout.

Posted By: fast68plymouth

Re: Crower roller hydraulics appear identical to Scorpions? - 04/13/17 04:30 AM

If you look at the pic I posted of the E head with the beehives and +.050 locks, and look at the bottom of the spring, you'll see it's sitting in a stamped steel "cup".

Those are the cups that come on the assembled heads.

They are not on your heads, but it looks like I can see the edge of the other device used for locating the spring...... a spring "seat", under the spring.

I always figured they were called "inner" spring seats is because the located the spring off the "inner" diameter.

Comp actually makes a few different ones specifically for the beehive springs.

If you measured all the way down to the head surface itself, and there are spring seats there(and you hope there are, otherwise the spring would be chewing a hole into the head), the installed height is .060 shorter than what you measured.

Which is what that combination of parts(Comp 26120 springs, 795 retainers, 611 locks, spring seats) should end up being, on those heads.......about 1.825.

Posted By: fast68plymouth

Re: Crower roller hydraulics appear identical to Scorpions? - 04/13/17 04:38 AM

With the way the retainers are shaped for the beehive springs, there is no problem using the +.050 locks with regards to rocker clearance.

Plus, Harland's have pretty large diameter wheels that help keep the rocker body up away from the retainers.

I came across that pic of the RPM heads with the +.050 locks when I was searching for something else.

I'm pretty sure that's a pic of one of AndyF's motors....... and I think I actually did those heads.

Posted By: Sxrxrnr

Re: Crower roller hydraulics appear identical to Scorpions? - 04/13/17 04:43 AM

There is a spring seat under each spring, I may in error referred to them as shims. As noted the spring sits squarely upon them, but they are all shuffled a bit one side or the other, thereby permitting me to find a spot at each valve to place the tip of the caliper directly on the head at the outside edge of the spring seat or shim.

I am certain this is koppa septic,,,,however at top where retainer is, I could be very slightly off.

Posted By: fast68plymouth

Re: Crower roller hydraulics appear identical to Scorpions? - 04/13/17 04:52 AM

thereby permitting me to find a spot at each valve to place the tip of the caliper directly on the head at the outside edge of the spring seat or shim.

You should be taking the measurement from the

top of the shim/cup, and you've said it a couple of times that you're measuring down to the "head".

If you are measuring from the surface of the "head" to the bottom of the retainer........ that is

not the installed height.

The installed height is the measurement from the top of the seat/shim to the bottom of the retainer.

You say you're sure the spring height is set up right, but going by how you say you're doing it, it's not.

Soooooo, if the installed height is actually closer to 1.825(based on how you say you're checking it), and the rocker ratio is really closer to 1.55(like most Harland's are)...... now how far away from coil bind are you?

Posted By: Sxrxrnr

Re: Crower roller hydraulics appear identical to Scorpions? - 04/13/17 05:25 AM

My measurement is to the bottom of the retsiner. Unfortunately there is s very small lip on the outside perimeter of it that hangs down a tiny bit, so as I am unable to get the caliper to the actual surface that the top of the spring contacts.

However I believe that I am very close in judging just how much how much higher this contact point is than this so called hang over lip.

Visualize a pie pan laying upside down. This hang over is not that extreme, but that is an example. I will post a up close photo tomorrow.

Visually coil bind is non existent by a large amount. Same for open valve rocker to top of retainer.

Posted By: fast68plymouth

Re: Crower roller hydraulics appear identical to Scorpions? - 04/13/17 05:37 AM

I can't believe we're still talking about this.

I am not worried about your visual reference at the top of the spring.

It's what you say you're doing at the bottom ....... that you are either doing it wrong, or describing it wrong.

If there is a spring seat/shim between the spring and the head, and you're putting the caliper down against the head..... you're doing it wrong........period.

Doing it that way does not account for the thickness of the seat.

The caliper needs to be on top of the seat.........or you need to know how thick it is and subtract that from your measurement if you're measuring down to the head.

I'm not there watching you do it, so I can only go by what you say........ and you say you're putting the tool down against the head.........and when you do that you get 1.885.

The seats are usually .060....... so if you subtract the thickness of the seat from your measurement of 1.885.......the installed height should be 1.825...... based on how you say you're doing it.

Do you have a solid lifter adjusted to zero lash(or at least a bottomed out hyd lifter)when you're visually checking for space between the coils?

Posted By: SomeCarGuy

Re: Crower roller hydraulics appear identical to Scorpions? - 04/13/17 06:01 AM

Ups could have these in Dwayne's hands in mere days, and back shortly thereafter...

Posted By: Sxrxrnr

Re: Crower roller hydraulics appear identical to Scorpions? - 04/13/17 09:05 AM

You are correct. This is what I have been saying all along. My misunderstanding is at fault in believing that I should be measuring from the head surface and not the top of the bottom base or shim.

I now grasp that what I should have for the installed spring height is the actual compressed length of the spring itself, after it has been squozen between the upper retainer and the lower base or shim, not from the head to the bottom of the retainer. Spring height is in a sense a misnomer which confused me.

Therefore my spring pressures may be higher than recommended if my original measurements are correct, which remains somewhat uncertain subject to how well I have visualized the spring's position at its actual contact point at the shrouded upper retainer lower surface. This .060 could increase pressures substantially, I have not a clue as to by how much until I can measure them.

Without the specified tool as your photo of John's spring height measurement illustrates, this appears to be a bit problematic for me.

I believe however if I remove a regular valve spring and replace with a ' test' spring this will be simpler in obtaining a correct measurement using a caliper. I do not understand the purpose of a test lifter(however which I do have) in obtaining this spring height measurement. Unless possibly your concern is rocker arm retainer contact in the event that installed height must be corrected.

Tomorrow if the ordered valve spring tester should arrive, I will measure spring pressures.

I would have this question: If all pressures remain within CC's specifications and no coils are binding(which they are not) and no rocker/retainer contact is noted,,,are all systems go regardless if installed heights are shy by your .060 thousandths figure? My theory being with springs no longer new, they likely have already lost 10 to 20 percent of initial pressures.

This has been a learning experience for me in an area of engine technology(cams and valve trains specifically) where I suspect very few outside of the industry understand slightly and fewer still understand well. I suspect there are on this forum of those who may not have become too bored with this thread and are still following our exchanges and particularly your commentary have learned as much as I have on this topic of "when things go wrong in your valve train and why they did and how do you fix it".

As a fellow Moparts forum member traveler stated to me earlier this evening, this shines a light onto and exposes a previous little dark corner of the Mopar world.

Posted By: CSK

Re: Crower roller hydraulics appear identical to Scorpions? - 04/13/17 09:44 AM

You have to use a solid lifter, if not the hydro lifter push rod seat will compress as the lobe of the cam comes up, the valve wont start to open until the push rod seat bottoms out in the lifter, the solid lifter set with 0 lash starts opening the valve as soon as the cam lobe starts lifting the lifter. This has nothing to do with the installed spring height, this is to check for the actual lift at the valve.

Posted By: Sxrxrnr

Re: Crower roller hydraulics appear identical to Scorpions? - 04/13/17 10:05 AM

You have to use a solid lifter, if not the hydro lifter push rod seat will compress as the lobe of the cam comes up, the valve wont start to open until the push rod seat bottoms out in the lifter, the solid lifter set with 0 lash starts opening the valve as soon as the cam lobe starts lifting the lifter. This has nothing to do with the installed spring height, this is to check for the actual lift at the valve.

Yes, this I understand, my misunderstanding was that I was to be concerned about this in dealing with spring height measurement.

I have found and obtained what I will call an adjustable solid roller lifter, BB Mopar specfic to assist in establishing pushrod length and actual valve lift, thereby eliminating the concern of the the pushrod seats requirement to bottom out before valve any movement occurs.

This also allows you to use your normal production pushrods and not require the switch to a solid lifter pushrod of likely a differing length when checking actual valve lift.

Posted By: jbc426

Re: Crower roller hydraulics appear identical to Scorpions? - 04/13/17 04:32 PM

It looks like you have 3 options here, Roger. Order up a spring height measuring tool like Dwayne's, stuff some rope through the spark plug hole, pop off the retainer and measure the height accurately, take the heads off and take them to a shop, or continue to guestimate and roll the dice.

I would also put the windage tray back in your motor. I had to modify mine slightly to fit, but the Milidon tray does fit with the Road Race pan. Mine is off now, if you want to match the cuts.

Posted By: fast68plymouth

Re: Crower roller hydraulics appear identical to Scorpions? - 04/13/17 05:56 PM

You have to use a solid lifter, if not the hydro lifter push rod seat will compress as the lobe of the cam comes up, the valve wont start to open until the push rod seat bottoms out in the lifter, the solid lifter set with 0 lash starts opening the valve as soon as the cam lobe starts lifting the lifter. This has nothing to do with the installed spring height, this is to check for the actual lift at the valve.

Exactly.

You need to know the net lift, at the valve, with full spring pressure to determine if the springs are set up properly and won't cause problems.

This will also tell you what your net effective rocker ratio is.

To determine if things are going to be problematic or not, you need to know;

- spring installed height

- true spring coil bind height

- net full lift at the valve

You should have at least .050-.060 remaining spring travel from net peak lift to true coil bind height.

A spring height mic is not needed to get accurate measurements. You just need to be measuring the right way/right thing.

I'm sure his 1.885 reading is within a few thou of actual......so, take out the .060 for the cup....... You're at 1.825.

Replace the std locks with +.050 locks, and you should be fine.

I hate to seem like a "know it all", but....... As soon as I saw the heads assembled with the std locks, I was 99.999% sure the installed height was shorter than "normal".

Posted By: fast68plymouth

Re: Crower roller hydraulics appear identical to Scorpions? - 04/13/17 06:28 PM

More speculating.......

Had the springs been set up at 1.880-ish, and the motor run with Driven HR 10w40 synthetic motor oil........ The OP would still be happily motoring along, and would be perfectly happy with his Scorpion lifters.

Several set of those have been installed in BBC marine motors around here, which all get hammered pretty good for hours on end...... And I haven't heard of any failing yet.

Those are all running either 15w40, 25w40, or 20w50 oil.

Posted By: Sxrxrnr

Re: Crower roller hydraulics appear identical to Scorpions? - 04/13/17 07:06 PM

I reviewed notes taken by me when Eddy performer heads were converted to beehive valve springs when first installing heads and switching from flat tappet hydraulic lifters to hydraulic roller with Scorpion lifters.

These notes confirmed my conversation with machinists, Mike Angelo where he had called me to voice a concern that CC instructions for setting up valve springs with a seat pressure of 155 pounds at an install height of 1.886 inches. He wondered if this might be excessive and suggested could reduced to a more nominal 110 pounds by installing 10 degree keepers.

I then called CC for their input. Was told by CC tech that 155 pounds at 1.886 was recommended. This past Monday, I called and spoke with Angelo. He remembered all of this and did go with CC's recommendations and set up heads accordingly. CC accosting my notes suggested 155 pounds that would break in and settle at 140 pounds.

I would think that if I were experiencing any coil bind issue at all, that those springs subject to it would not have taken 3,000 miles in the most recent collapsed lifter failure nor 800 miles in the much earlier failure.

As of now, I fully agree with the cause of failure is attributed to the analysis as put forth by Porter and detailed further by Joe of Johnson SEC, was oil foaming, with contributing factors as laid out by Johnson SEC(lifter manufacturer) of only having given a lifter preload of 1/2 turn following their at that time instructions, instead of their now recommended 1 full turn from preset,,,,plus an improved metallurgical materials as used in the failing oil control disc that sits directly under the pushrod cup of the lifter.

As noted in my earlier posting recapping my conversation with Joe of Johnson. Was fascinated by his description of how oil foaming sets up the chain of events leading to catastrophic failure of lifter. Foaming creates a compressible oil situation. This leads to a gap between rocker arm roller and valve stem that nominally should always be at zero clearance on hydraulic lifters, this causes a massive shock when rocker contact valve stem that is then broadcast via pushrod to pushrod cup then that slams this oil control disc until ultimate failure occurs. Also in effects defeats the purpose of cam ramping action prior to valve opening time.

Solid rollers of course do not experience this phenomenon as their life and death does not depend on pressurized oil and does not have this disc that is subject to failure.

UPS just now dropped off valve spring pressure tester. As spring height tool is not too expensive, most likely to order one up,,,,now that you all have convinced me of the value in properly setting all up. At times however,,,,,wonder how I ever got by with just a few hand tools from Sears and perhaps a ruler and a few other such hi tech tools that most of us grew up with. And our old cars still seemed to quite well then.

John. Perhaps I will stop by Friday and borrow Dwayne's spring height tool while you are putting his new Eddy heads on his car.

Posted By: ZIPPY

Re: Crower roller hydraulics appear identical to Scorpions? - 04/13/17 07:50 PM

Hats off to you guys for putting the effort into this. Hydraulic rollers interest me, but I heard about a few too many folks having trouble with them I figured I'd be safer with solid rollers instead. (that was circa 2001). Maybe things have improved now(?).

Posted By: fast68plymouth

Re: Crower roller hydraulics appear identical to Scorpions? - 04/13/17 08:50 PM

Frankly, I'm confused by the op's last post.

He measured the installed height for himself, and after waaaaay too much discussion about it, it seems the installed height is actually not 1.885, but rather 1.825.

He has determined this by measuring it himself....... Yet when the person who put them together tells him they're set up at 1.885, he accepts that's as correct info....... Even though he has found that not to be the case.

I don't know who put the heads together, but anyone who is recommending 110bs of seat pressure for a Mopar big block hydraulic roller application......especially one that has fast ramps......... Doesn't seem to be up to date with what are the normal practices for these motors.

IMO, more measuring at this point isn't really necessary to move forward......

Swap out the locks for some +.050's, install the new lifters, run thicker oil......done.

If there is no windage tray, I'd probably put that back in.

Posted By: fast68plymouth

Re: Crower roller hydraulics appear identical to Scorpions? - 04/13/17 09:20 PM

As noted in my earlier posting recapping my conversation with Joe of Johnson. Was fascinated by his description of how oil foaming sets up the chain of events leading to catastrophic failure of lifter. Foaming creates a compressible oil situation. This leads to a gap between rocker arm roller and valve stem that nominally should always be at zero clearance on hydraulic lifters, this causes a massive shock when rocker contact valve stem that is then broadcast via pushrod to pushrod cup then that slams this oil control disc until ultimate failure occurs. Also in effects defeats the purpose of cam ramping action prior to valve opening time.

I disagree with the foaming oil "creating a gap" at the valve.

There is a spring under the pushrod cup, which is what maintains the zero lash condition after the motor is shut off.

There wouldn't be a gap at the valve even if there was nothing in the lifter but air.

The foaming oil compresses under the load of the valve spring during the lift cycle, which allows the plunger to crush the disc inside the lifter.

The only way there can be a gap in the valvetrain is if the lifter has collapsed and the plunger is stuck in the "down" position.

Posted By: BSB67

Re: Crower roller hydraulics appear identical to Scorpions? - 04/13/17 09:21 PM

Hats off to you guys for putting the effort into this.

God bless all of ya. I would never make it in the service industry.

Posted By: fast68plymouth

Re: Crower roller hydraulics appear identical to Scorpions? - 04/13/17 09:26 PM

Trust me Russ.......... I've been really close to "tapping out" a few times here.

Posted By: jbc426

Re: Crower roller hydraulics appear identical to Scorpions? - 04/13/17 10:04 PM

Trust me Russ.......... I've been really close to "tapping out" a few times here.

I'm glad you stuck it out, Dwayne. I enjoy and learn a lot from your explanations and sharing of your experience. Thank you for indulging us.

I'll talk further with Roger this weekend. He's a good man.

Posted By: Sxrxrnr

Re: Crower roller hydraulics appear identical to Scorpions? - 04/14/17 01:38 AM

To end all debate on my installed height, I ordered up a CC spring install height micrometer, specifically designed for beehive springs,,,,,yea guess they are different enough to not allow use of the regular low priced by everyone spread. I strongly believe that my efforts to achieve an accurate spring height measurement was lame at best, particularly doing so with a caliper and the spring remaining in position in the way and tucked as it is under the upper retainer and mispositioned at the spring seat. My experience in this area is almost nil at best.

I agree that Angelo could remotely have been in error, will not know until I measure the height which is what he set using CC's recommendations. In support of him, who I believe is a good competent machinist in a small town shop, he likely does not often deal with high performance engines, in particular BB Mopars with their idiosyncratic characteristics. If in error not yet in evidence he deserves a pass from me. He certainly had the sense to call me when he had doubts regarding CC's instructions, which prompted me to call CC for verification. I do not believe that any errors that he might have made contributed to my issues unless proven otherwise by further analysis and measurement. I suspect that if it were his errors, that it would not have taken 100's or even thousands of miles of miles(some at over 6,000 rpm) before experiencing the 2 failures witnessed.

I fully subscribe to the oil foaming postulate as put forth initially by Dwayne and again by technical Engineer Joe of Johnson SEC,,,,,no manner the method initiated and by what.

I believe either's theory has credence, however Dwayne's sounds more the likely as his argument regarding the internal lifter spring maintains zero gap is persuasive. Interesting that of the at least one dozen personnel that I spoke to at these many valve train firms, no one else suggested an oil aeration issue, nor what might relieve it as a possible cause of lifter failure.

The use of a heavier oil with less foaming tendencies and the tightening down a full turn from set point as recommended by Johnson SEC has very strong merit, also giving a quieter valve train relief to the usual big block notorious Mopar underhood cancaphony would be welcomed by most owners. Additionally with the claim of revised internals of the hydraulic roller now sold by both Isky and Crower, manufacturered still by Johnson SEC , perhaps all will be again well.

Posted By: CompWedgeEngines

Re: Crower roller hydraulics appear identical to Scorpions? - 04/16/17 02:14 AM

[quote=fast68plymouth]Frankly, I'm confused by the op's last post.

He measured the installed height for himself, and after waaaaay too much discussion about it, it seems the installed height is actually not 1.885, but rather 1.825.

I dont even want to comment, but can't help it. I just lost a good 30 minutes of my life, reading all this...holy cow. Dwayne and I agree 100% on this, less the oil choices, and we're close enough there to call it good. I have a buddy who does a LOT of BBC marine engines, mostly all blown 2 and 3 screw boats, ALL hydraulic roller. Not going into all that, but lets just say, he isnt having issues. After all the analysis here, and the ( sorry) waste of a lot of time and money, there is one simple answer that will work, and its been mentioned many times, but seems to be getting brushed off for some reason? Just buy the Morels, make sure the heads are set up correctly ( as Dwayne has stated, probably one of the best Mopar cylinder head guys out there BTW, what he says is truth)I'm going to say it again, stop all the rambling, buy the Morels. Doesnt matter who packages them or who you buy them from, but your wasting a TON of time over an inevitable result. Chris Straub will more than handle your needs. Just in case no one heard me..( yes, inserting humor here) buy the Morels and please put this post to rest! Yes, I have experience with hydraulic roller Mopars, Chevies and Fords. By far, the Mopars are the more " problematic" of the bunch for several reasons ( no, I am not going to get into all that), but they WILL work, work fine, work in your application, and you can be back on the road. I would really consider if I were you, having someone look at those heads too. Just my opinion based what I have read here. Ok...signing out, going to go find some Excedrin!

Posted By: fast68plymouth

Re: Crower roller hydraulics appear identical to Scorpions? - 04/16/17 05:44 AM

Can't let it go quite yet Todd.......

I wanna see a pic of the new-made-special-for-beehive-retainers height mic in action!!

Btw...... I think Staub is a pretty strong proponent of the Driven HR 10w40 synthetic too

However, if I'm coming clean........ since I have a few cases of Brad Penn 15w40 sitting on the shelf........ that's what would go in it "if it were mine".

Posted By: CompWedgeEngines

Re: Crower roller hydraulics appear identical to Scorpions? - 04/16/17 01:49 PM

Yes, but its Easter, and I am promising myself to not get into grief counseling today!!!.Ah yes, specialty tools.....oh where to start!...

I know Morel in general, has some specific suggestions on oils. As you know, we all have our preferences, and you know the deal with the hyd rollers. I have been watching a lot of testing by Lake Speed Jr....still hasnt tested my Schaeffers brand, but its coming.I've always been a guy who tries to limit and diminish phsyco babble, and simply go with what is known to work.call me crazy..lol...ok...back to Sunday....Happy Easter everyone.

Posted By: Sxrxrnr

Re: Crower roller hydraulics appear identical to Scorpions? - 04/17/17 04:08 AM

[quote=CompWedgeEngines][quote=fast68plymouth]Frankly, I'm confused by the op's last post.

He measured the installed height for himself, and after waaaaay too much discussion about it, it seems the installed height is actually not 1.885, but rather 1.825.

I dont even want to comment, but can't help it. I just lost a good 30 minutes of my life, reading all this...holy cow. Dwayne and I agree 100% on this, less the oil choices, and we're close enough there to call it good. I have a buddy who does a LOT of BBC marine engines, mostly all blown 2 and 3 screw boats, ALL hydraulic roller. Not going into all that, but lets just say, he isnt having issues. After all the analysis here, and the ( sorry) waste of a lot of time and money, there is one simple answer that will work, and its been mentioned many times, but seems to be getting brushed off for some reason? Just buy the Morels, make sure the heads are set up correctly ( as Dwayne has stated, probably one of the best Mopar cylinder head guys out there BTW, what he says is truth)I'm going to say it again, stop all the rambling, buy the Morels. Doesnt matter who packages them or who you buy them from, but your wasting a TON of time over an inevitable result. Chris Straub will more than handle your needs. Just in case no one heard me..( yes, inserting humor here) buy the Morels and please put this post to rest! Yes, I have experience with hydraulic roller Mopars, Chevies and Fords. By far, the Mopars are the more " problematic" of the bunch for several reasons ( no, I am not going to get into all that), but they WILL work, work fine, work in your application, and you can be back on the road. I would really consider if I were you, having someone look at those heads too. Just my opinion based what I have read here. Ok...signing out, going to go find some Excedrin!

Questions for the overwhelming majority of us who do not already know everything there is to know about Mopar BB valve trains with particular emphasis on hydraulic roller lifters.

*. Why Morel's rather than Johnson Sec(among others sold under Isky and Crower branding and manufactured in the USA). Not just opinion just as everyone has their favorite oils or gasolines, but hard evidence that they indeed are superior. Which Morel's,,,they sell one Mopar model under the Howard name at 450.00 per set and another so called race version at something like 1,200.00 per set of 16. Crower sets are at about 850.00 at Summit, which makes the Morel/Howard at 450.00,,,which would be a screaming deal especially if superior to others and better yet if USA manufacturer.

*. Hopefully will have the install height beehive CC tool to get an exact measurement tomorrow,,,,calipers and yardsticks be damned. Yes, i am a rookie at this as likely 95 percent of the non-pros and 9 second racers likely are on this forum. Many of us are trying to learn, however to be as informed as some who have uncounted years of experience is just not in the cards for most of us who are and always be merely be advanced hobbyists at best, so we tune in regularly to perhaps learn something of interest or value.

So some some unanswered questions even after the wearying manifesto that you have admittedly painfully endured.

1. I suspect my height install numbers on beehive springs will come out as they should be,,,,just the feeling that my machinist who set heads up did a good job. Given that if they are, and having today measured a number of my valve spring pressures(only on one bank as rockers are off left bank) using recently acquired LSM valve spring on car tester,,,I find pressures immediately off seat running about 130 pounds, whereas the were originally set at 155 pounds. Not horribly bad after a couple of years or so, but down 25 pounds. I was expecting perhaps 140 pounds.

I have ordered up a couple of shim sets to perhaps bring back to 150 or thereabouts.

The question becomes,,,,install spring heights will decrease some amount by shimming. What are if any the potential ramifications of modest decreases of install height beyond the increased possibility of spring bind?

Right now just eyeballing my right bank rocker arms, which again are still mounted,,,,there is a very wide gap between the coils of each spring(remember beehive, only a single spring per valve. Adding a .050 shim would appear to have little significance to the gap between coils,,,,how much pressure would this add at valve close time.

How does one accurately measure potential for spring bind while mounted on engine. Is their any other potential downside to shimming to regain spring pressure, and by doing so any other potential downsides other than spring bind. Or must they be measured on the bench.

Another question that I have pondered, a bit more complicated. Using the LSM pressure tool, you measured pressure when on valves fully seated,,,,lifter on cam heel. Possibly can do so for open,,,,I will call them tomorrow. By the way, I am quite pleased with this company and their responsiveness. Before you but this tool elsewhere, call and speak to Heidi directly. I have another tool made by a LSM competitor in spring testing,,,it appears of very low quality. The LSM product appears of very well engineered and high quality. Both companies sell at Summit and Amazon. Just saying

If one were to measure spring pressure on a valve that is full open,,,lifter peak of lobe,,,would I have an accurate reading for open valve spring pressure if I tugged on the handle of the tool just enough to have created a minuscule rocker arm to valve stem gap?

A somewhat related imponderable would be if I had say 150 pounds at valve seated, and knew the spring tension characteristics and rocker arm ratio, could the open valve pressure be calculated without actually measuring it. In simpler terms, does one even need to know open pressures to reliably assume springs are still sound if closed is known? Are tensions linear from full closed to full open.

For those who believe this thread is wasted time and space,,,,delete or bypass is an option available to all,,,Jeeeze,,,,I have seen 47 pages of discussions on Jamie Passon's 5 speed over some 4 years,,,I still check it out from time to time and I do not even have one in my future,,,,I suspect that many forum members have gotten far more useful out of some of the expertise bantered about on this thread, particularly with Porters shared insights.

By the way Dwayne, the Hot Rod oil you recommend, who is the manufacturer, is it Lucas? I have used synthetic for years should I not? Has zinc any value to an engine not running a flat tappet cam?

The entire subject of hydraulic rollers , who manufacturers them and who markets them, and why they often fail has been a big black hole for myself, it is no longer.

Any typos I will correct later

Posted By: Sxrxrnr

Re: Crower roller hydraulics appear identical to Scorpions? - 04/17/17 04:54 AM

Yes, I did with a Caliper and the spring still mounted about the valve, measure 1.884,,,I will repeat, I had stated in several prior posts that I had measured from bottom side of retainer and the surface of the head, and with design of retainer, almost impossible to determine where spring coils were contacting retainer for an accurate estimate.

It was only much later in the discussion that Porter noticed that I was measuring the bottom of the spring from the surface of the head, and posted this observation,,,and not the spring so called "seat".

Once he noticed this he said I was off by .050 or .060 as that is the depth of the seat. I agreed. This is where 1.825 or so came in.

Where did I get the information to measure from the surface of the head, I very carefully read this information from 2 different should have known,,,,websites that stated to measure from head surface,,,URL's upon request. Reflecting now, I can only assume that these sites likely were not thinking aluminum,,,subject to gauling,,,,and only cast iron.

My first time hitting my first tennis balls I was not very good either,,,even though I read a lot of books on tennis as I was taking up the sport.

Posted By: fast68plymouth

Re: Crower roller hydraulics appear identical to Scorpions? - 04/17/17 05:19 AM

Again.......without using some sort of solid, or bottomed, or blocked lifter, looking at you're springs isn't going to tell you anything.

You set you're preload at say, 3/4 of a turn. How far is the plunger from being bottomed at that point? Cuz whatever it is, multiply it by the rocker ratio, and that's how much lift you're losing when the lifter is at peak lobe lift.

The oil I was referencing is made by "Driven", formerly called Joe Gibbs.

I'm also a fan of Brad Penn oils.

I have freshened several sets of heads using the Comp 26120 springs, and they are made from very durable, premium material. I've had some here that had over 10,000 miles on them and over 400 1/4 mile passes, run on an aggressive solid lifter cam, and those hadn't lost 15lbs.

If yours are down 25lbs in a few thousand miles...... something is very unhappy.

As for why do I recommend Morels?

Why does anyone recommend anything?

Good past experiences.

If you were looking for a small car I'd tell you to buy a Honda Civic.........because I've had a really good experience with mine.

There is a thread over on fbbo about a guy who just had a Hughes(morel) hyd roller lifter collapse.

There are questions, theories, etc.......until he mentions what his spring pressure is.......like 220/550.

Well, those lifters are rated for 360lbs open, so the mystery is over.

I responded in your other thread about the possible pitfalls with trying to run lobe profiles that require big spring pressure and hyd roller lifters.

I know of several builds that used modest lobes and the std Morel lifters, and kept the spring pressures reasonable........ and those combos seem to survive just fine.

If you're tired of working on it........that's the direction I would look to.

Posted By: fast68plymouth

Re: Crower roller hydraulics appear identical to Scorpions? - 04/17/17 05:28 AM

If you are competent at all with that caliper, I don't see how you could be off by more than .010(meaning the installed height is about 1.825)......... and yet it sounds like you still think when you try that new height mic the number is gonna come up around 1.880.

I guess we'll see who is doing the better job here.

If the height mic shows something close to 1.825 you did a good job, and the head assembler didn't.

If the number is closer to 1.880, then the head assembler did a good job, and you didn't.

Posted By: SomeCarGuy

Re: Crower roller hydraulics appear identical to Scorpions? - 04/17/17 06:03 AM

There was a rumor circulated at the family gathering today that several companies do in fact send trucks all over for a small fee, taking with them items you find mystifying so a wizard on the receiving end can decode the hidden magic within. Then those same trucks find their way back to your door.

Posted By: CSK

Re: Crower roller hydraulics appear identical to Scorpions? - 04/17/17 06:17 AM

There was a rumor circulated at the family gathering today that several companies do in fact send trucks all over for a small fee, taking with them items you find mystifying so a wizard on the receiving end can decode the hidden magic within. Then those same trucks find their way back to your door.

YES!!!! take the heads off & send them to fast68plymouth !!!!!!!

I also have the 26120 comp springs & had to use the gold +.050 locks to get 1.880 installed height.

Posted By: Sxrxrnr

Re: Crower roller hydraulics appear identical to Scorpions? - 04/17/17 06:23 AM