Posted By: Guitar Jones

Electrical experts please take a look. UPDATED - 11/14/16 04:26 PM

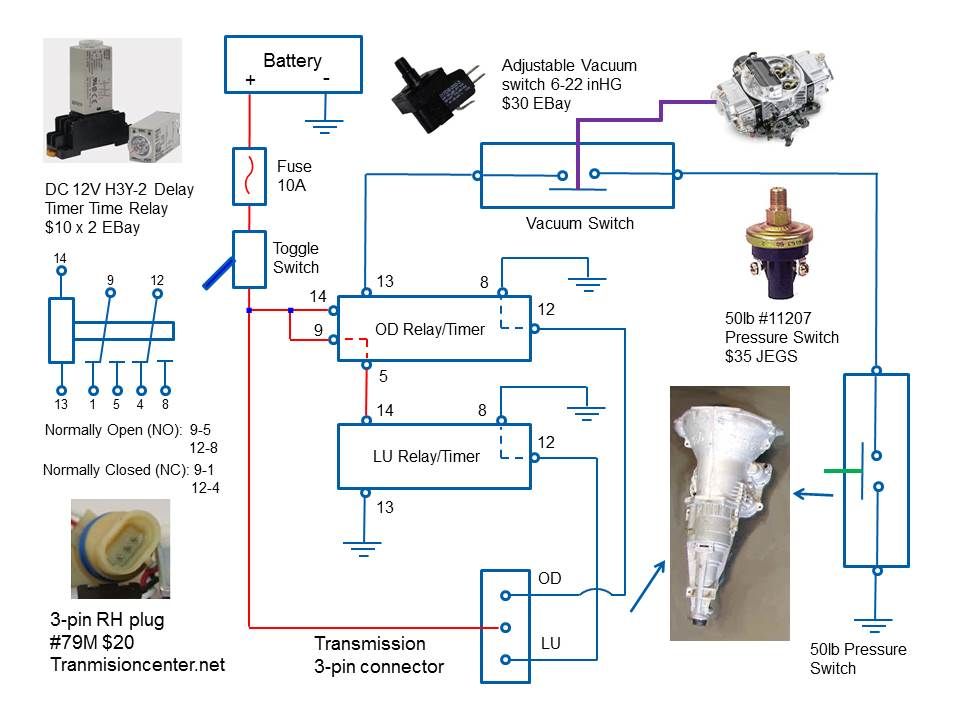

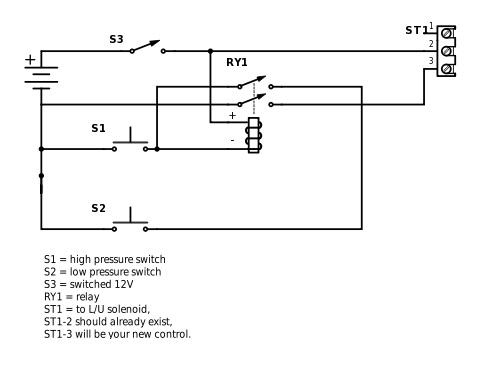

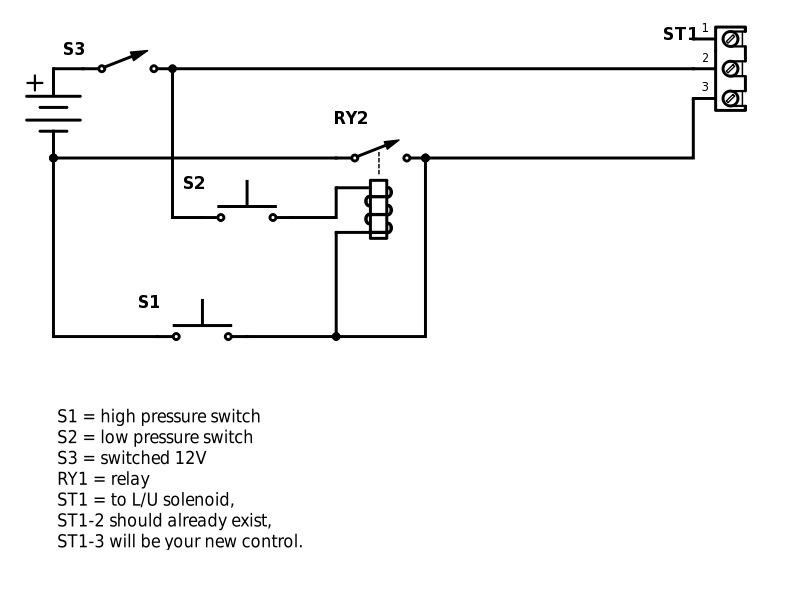

I have a 92 D250 CTD 2WD with the 518 auto that I've converted to lockup. I'm using a Hobbs pressure switch off the governor pressure port to activate the ground circuit for the L/U solenoid. It is tied to the O/D ground circuit so I don't get L/U unless it's in O/D. But this method leaves a little to be desired because at certain speeds I get an annoying, in and out of L/U action. Normally it's not a problem but getting caught in traffic sometimes I can't get around it without slowing down. So what I'm looking to do is find a way to activate the circuit at a higher speed or pressure and have it stay engaged until it reaches a lower speed than the activated speed. Maybe a 5 MPH difference or something. I've not been able to find a switch like this in my internet searches so if anyone has any ideas I'm all ears.

Thanks.

Thanks.