Moparts

Need help with Pertronix Ignitor install

Posted By: f2502011

Need help with Pertronix Ignitor install - 01/11/16 12:05 AM

I'm trying to install an Ignitor kit in my Prestolite distributor for 1970 Challenger. I've taken the points and condenser out and tried to install this kit but I can't seem to get it installed. First the holes in the ignitor plate weren't machined exactly right to line up with the holes in the breaker plate. It said to install the ignitor plate where the middle of the 3 holes on one side will go where the condenser was screwed to the plate and the other hole would line up with where the points screw was and the ground strap attached. The holes were off just enough to prevent that from working as is so I widened the hole for the ground strap enough to let it fasten to the plate and not disturb where the ignitor plate needed to be with the two outer holes allowing it to line up with the small posts for the condenser locator. After that, I can't get the ring go down far enough on the cam to let the rotor go all the way down so the cap won't go on. Is there a secret to this?

It also says to wire the red wire to the ignition or 12V side of the ballast resistor. The resistor on mine has a blue wire to one post and a blue and brown wire to the other. Assembly manual lists them as ignition 1 and ignition 2. Should I get this to install which post does it go to?

Posted By: ProSport

Re: Need help with Pertronix Ignitor install - 01/11/16 12:12 AM

Hopefully someone can help you with this. I can only say that I bought the IgnitorIII billet distributor, it took some time grinding my Edelbrock head so the distributor would clear it but after that it has ran awesome for 2 years now and it only took 2 wires to hook it up, straight to the coil, then one more wire just from a 12v ignition. Has a rev limiter too.

Posted By: f2502011

Re: Need help with Pertronix Ignitor install - 01/11/16 01:15 AM

I got the ring on. Had a small ridge in the plastic underside that was catching. Now if I could just figure out where to hook the red wire to the ballast resistor I may have a running car. I say may have because I'm not real confident in Pertronix manufacturing abilities at this point.

Posted By: red 69 runner

Re: Need help with Pertronix Ignitor install - 01/11/16 03:11 AM

If you would have got the ignitor 11 and matching coil you can by pass the ballast and just hook red wire to + side of coil and the other wire to the - side of the coil.

Posted By: f2502011

Re: Need help with Pertronix Ignitor install - 01/11/16 03:13 AM

If you would have got the ignitor 11 and matching coil you can by pass the ballast and just hook red wire to + side of coil and the other wire to the - side of the coil.

I can do that anyway. I need to know how to wire the setup while including the ballast resistor so everything looks correct too. The ballast has a single blue wire on the passenger side or upside and a blue and brown wire on the lower post or toward the drivers side. The assembly manual says the single blue wire is ignition 1 the brown and blue wire is ignition 2. The Pertronix directions say to wire it to the ignition switch side of the resistor. Which post is it? I've attached the instructions.

Posted By: Supercuda

Re: Need help with Pertronix Ignitor install - 01/11/16 03:50 AM

The switch side of the resistor has battery voltage (or close to it) on it in RUN. The coil side of the resistor will have several volts less, in RUN. Put a meter on it.

If all you have is a test light then disconnect one side and the side that lights up in RUN is the one you want.

Posted By: RapidRobert

Re: Need help with Pertronix Ignitor install - 01/11/16 04:03 AM

EDIT! keeping stock coil & stock ballast resistor. With them wired up as OE. P black wire to coil neg primary terminal. P red wire to ballast blue wire (ign1 run) end of ballast resistor. Do NOT connect (T) the P red wire to the coil positive primary terminal as in the P illustration. Done!

Posted By: DAYCLONA

Re: Need help with Pertronix Ignitor install - 01/11/16 06:42 AM

If you would have got the ignitor 11 and matching coil you can by pass the ballast and just hook red wire to + side of coil and the other wire to the - side of the coil.

I can do that anyway. I need to know how to wire the setup while including the ballast resistor so everything looks correct too. The ballast has a single blue wire on the passenger side or upside and a blue and brown wire on the lower post or toward the drivers side. The assembly manual says the single blue wire is ignition 1 the brown and blue wire is ignition 2. The Pertronix directions say to wire it to the ignition switch side of the resistor. Which post is it? I've attached the instructions.

FYI...be sure to re-time the ignition as the Pertronix install can rephase the system anywhere from 5 degrees ATDC to 15 degrees BTDC, so depending on where your current timing is, your engine might not start because the timing is too far off

Get rid of the ballast, it's a weak link in the system, the red wire from the HallCell goes to the positive side of the coil, the black lead from the HallCell goes to the negative side of the coil, the blue/dark blue ignition lead from your bulkhead connector goes to the positive side of the coil, gut out the ballast resistor and solder in an insulated 10 gauge piece of wire in the back cavity of the resistor, now just attach the resistor leads as they were originally on the ballast, you now have the look of having the ballast, but without the issues of a ballast, plus the system is now running a true 12 volts, be sure to gap the HallCell with the plastic gauge supplied, don't use any metal feeler gauges, copper terminal cap only, no solid core wires, don't remove the green tape on the HallCell magnet, don't leave the key in the run position for more than 30 seconds without the engine running, if you need to do so, disconnect the RED lead from the positive side of the coil...you are using the correct Pertronix coil?...right

Mike

Posted By: f2502011

Re: Need help with Pertronix Ignitor install - 01/12/16 11:14 AM

EDIT! keeping stock coil & stock ballast resistor. With them wired up as OE. P black wire to coil neg primary terminal. P red wire to ballast blue wire (ign1 run) end of ballast resistor. Do NOT connect (T) the P red wire to the coil positive primary terminal as in the P illustration. Done!

That's what I was looking for. Pertronix red wire to single blue wire side of ballast resistor.

Posted By: f2502011

Re: Need help with Pertronix Ignitor install - 01/12/16 11:23 AM

If you would have got the ignitor 11 and matching coil you can by pass the ballast and just hook red wire to + side of coil and the other wire to the - side of the coil.

I can do that anyway. I need to know how to wire the setup while including the ballast resistor so everything looks correct too. The ballast has a single blue wire on the passenger side or upside and a blue and brown wire on the lower post or toward the drivers side. The assembly manual says the single blue wire is ignition 1 the brown and blue wire is ignition 2. The Pertronix directions say to wire it to the ignition switch side of the resistor. Which post is it? I've attached the instructions.

FYI...be sure to re-time the ignition as the Pertronix install can rephase the system anywhere from 5 degrees ATDC to 15 degrees BTDC, so depending on where your current timing is, your engine might not start because the timing is too far off

Get rid of the ballast, it's a weak link in the system, the red wire from the HallCell goes to the positive side of the coil, the black lead from the HallCell goes to the negative side of the coil, the blue/dark blue ignition lead from your bulkhead connector goes to the positive side of the coil, gut out the ballast resistor and solder in an insulated 10 gauge piece of wire in the back cavity of the resistor, now just attach the resistor leads as they were originally on the ballast, you now have the look of having the ballast, but without the issues of a ballast, plus the system is now running a true 12 volts, be sure to gap the HallCell with the plastic gauge supplied, don't use any metal feeler gauges, copper terminal cap only, no solid core wires, don't remove the green tape on the HallCell magnet, don't leave the key in the run position for more than 30 seconds without the engine running, if you need to do so, disconnect the RED lead from the positive side of the coil...you are using the correct Pertronix coil?...right

Mike

Ignitor for my application didn't come with a plastic gauge to gap and no green tape. I'm simply wanting to eliminate points. I want to keep the ballast, original coil, wires etc.. Timing with points was at 16 btdc.

Posted By: f2502011

Re: Need help with Pertronix Ignitor install - 01/12/16 11:49 AM

I have either NOS but likely reproduction 1970 plug wires that say electronic suppression on them and have correct date codes. Are these ok and not solid core? Not sure how to tell.

Posted By: RapidRobert

Re: Need help with Pertronix Ignitor install - 01/12/16 06:42 PM

Are these ok and not solid core?

they're OK, they are suppression

Posted By: f2502011

Re: Need help with Pertronix Ignitor install - 01/18/16 03:20 PM

This 1384 ignitor kit didn't come with anything to set the gap between the module and the magnet and it looks like it's not supposed to. So, is there a way to make sure it's in the right place?

The module has a hole in the center of 2 other holes that allows for a screw in the same place as the one for the condenser. It has two other holes, one on each side of the one for the screw, that fit over a couple of small posts that were locators for the condenser I assume. I haven't tried to start it yet, but it looks to me like a fairly large gap between the module and the magnet so I want to be sure if it doesn't crank whether it's the position of the module or the timing being way off.

Posted By: DAYCLONA

Re: Need help with Pertronix Ignitor install - 01/18/16 04:44 PM

This 1384 ignitor kit didn't come with anything to set the gap between the module and the magnet and it looks like it's not supposed to. So, is there a way to make sure it's in the right place?

The module has a hole in the center of 2 other holes that allows for a screw in the same place as the one for the condenser. It has two other holes, one on each side of the one for the screw, that fit over a couple of small posts that were locators for the condenser I assume. I haven't tried to start it yet, but it looks to me like a fairly large gap between the module and the magnet so I want to be sure if it doesn't crank whether it's the position of the module or the timing being way off.

The Ignitor I and II HallCell modules/magnets have an adjustable air gap, only the Ignitor III adjusts the Dwell (gap) electronically, the gap is .030, find anything other than metal (plastic, paper,etc,etc)that is non conductive or magnetic to gap the Dwell angle

Posted By: f2502011

Re: Need help with Pertronix Ignitor install - 01/18/16 06:18 PM

The Ignitor I and II HallCell modules/magnets have an adjustable air gap, only the Ignitor III adjusts the Dwell (gap) electronically, the gap is .030, find anything other than metal (plastic, paper,etc,etc)that is non conductive or magnetic to gap the Dwell angle

This kit doesn't really have any adjustment potential that I see unless I start machining things. It has two small round holes that just fit over the small posts used to help locate the condenser and a round hole for the screw. The holes aren't slotted to allow for movement. I've seen the 0.03 gap listed in multiple places for different kits, but for this one it's like it is made to only go in as is. Maybe that's why it didn't come with the plastic gaping tool included with other kits?

Posted By: RapidRobert

Re: Need help with Pertronix Ignitor install - 01/18/16 06:37 PM

you might see what the gap is (right now) with something non metallic & mike it

Posted By: f2502011

Re: Need help with Pertronix Ignitor install - 01/18/16 07:08 PM

Posted By: DAYCLONA

Re: Need help with Pertronix Ignitor install - 01/18/16 07:15 PM

The Ignitor I and II HallCell modules/magnets have an adjustable air gap, only the Ignitor III adjusts the Dwell (gap) electronically, the gap is .030, find anything other than metal (plastic, paper,etc,etc)that is non conductive or magnetic to gap the Dwell angle

This kit doesn't really have any adjustment potential that I see unless I start machining things. It has two small round holes that just fit over the small posts used to help locate the condenser and a round hole for the screw. The holes aren't slotted to allow for movement. I've seen the 0.03 gap listed in multiple places for different kits, but for this one it's like it is made to only go in as is. Maybe that's why it didn't come with the plastic gaping tool included with other kits?

Is this kit for the Prestolite dual point dist?, if it is, then there is no adjustment feature for the HallCell, I just hope you indexed the magnet pick up ring properly before seating it fully on the dist lobe (usually an issue with this kit), the only play there should be with the magnet pick up ring is what end play the actual shaft of the dist has, if the magnet can rock/shift about on the base dist lobe, then it's either damaged or not installed properly, otherwise your good to go, be sure to check/re-time the ignition

Mike

Posted By: f2502011

Re: Need help with Pertronix Ignitor install - 01/18/16 09:06 PM

Is this kit for the Prestolite dual point dist?, if it is, then there is no adjustment feature for the HallCell, I just hope you indexed the magnet pick up ring properly before seating it fully on the dist lobe (usually an issue with this kit), the only play there should be with the magnet pick up ring is what end play the actual shaft of the dist has, if the magnet can rock/shift about on the base dist lobe, then it's either damaged or not installed properly, otherwise your good to go, be sure to check/re-time the ignition

Mike

How do I know if it's indexed properly? It's seated all the way and has no play other than the up down that's in the shaft itself.

Posted By: f2502011

Re: Need help with Pertronix Ignitor install - 01/18/16 09:35 PM

I've got another ballast resistor I plan to gut if everything works. Could I try it by temporarily wiring the two ends that attach to the ballast and then hooking the red wire to the + on the coil?

Posted By: DAYCLONA

Re: Need help with Pertronix Ignitor install - 01/19/16 05:06 AM

I've got another ballast resistor I plan to gut if everything works. Could I try it by temporarily wiring the two ends that attach to the ballast and then hooking the red wire to the + on the coil?

Yes

Posted By: RapidRobert

Re: Need help with Pertronix Ignitor install - 01/19/16 06:50 AM

I've got another ballast resistor I plan to gut if everything works. Could I try it by temporarily wiring the two ends that attach to the ballast and then hooking the red wire to the + on the coil?

If you still have the OE coil I would suggest not bypassing the ballast as it is needed with the coil for it to have a long life and instead concentrate on the P unit in the dist for what ain't right cuz bypassing it wont fix what is the culprit here. If you have a specific P coil for your level of P system (I II or III) or another brand of coil intended for full 12V then by all means bypass it for max power

Posted By: f2502011

Re: Need help with Pertronix Ignitor install - 01/19/16 07:25 AM

I've got another ballast resistor I plan to gut if everything works. Could I try it by temporarily wiring the two ends that attach to the ballast and then hooking the red wire to the + on the coil?

Yes

I want to try some temporary connections to help decide whether the new setup is going to work. Once I figure out what will and will not work, I'll make adjustments with guidance from here and go from there.

Posted By: f2502011

Re: Need help with Pertronix Ignitor install - 01/19/16 07:27 PM

It runs, but it runs rough and I can't advance the distributor any more the vacuum diaphragm is hitting the oil pressure sending unit and wired up to the spare ballast resistor the resistor gets hot and smokes on the blue wire end. Any ideas?

Posted By: f2502011

Re: Need help with Pertronix Ignitor install - 01/20/16 02:02 AM

Is there a way for me to change the position of the distributor case/vacuum diaphragm so it doesn't hit the oil pressure sending unit and allow for more adjustment of timing without throwing the current timing off? I hope that makes sense.

When I adjusted the timing the diaphragm hit the oil pressure sending unit and must have shorted out the unit cause the pressure gauge immediately went to H and won't come back down. I got a new unit and when the ignition switch is turned on it will stay at L. I can't seem to get the old unit out of the car to replace it with the new one but plugging the new unit in the needle went to L plugging the wire back into the old installed unit goes back to H so it must be the sending unit.

Posted By: RapidRobert

Re: Need help with Pertronix Ignitor install - 01/20/16 02:47 AM

Get the dampener slit on 15 BTDC. pop the dist cap & see if the rotor is on or very close to #1 or #6 plug wire. loosen clamp & turn housing CCW till the can is on the pass side in the ballpark where you want it with room to be turned back & forth either way so you can adj it. turn housing some more slightly (either way) till the magnet is lined up dead even with the nearest tooth. take the wires out of the cap. plug in the #1 or the #6 plug wire (whichever one the rotor was originally at/under) into the cap terminal above the rotor. route em CW starting with the #1 you just started with and go 8-4-3-6-5-7-2 or if you are starting with #6 then going CW plug in 5-7-2-1-8-4. Fire it up!

Posted By: f2502011

Re: Need help with Pertronix Ignitor install - 01/20/16 03:19 AM

Magnet lined up with the nearest tooth?

Posted By: RapidRobert

Re: Need help with Pertronix Ignitor install - 01/20/16 03:32 AM

Opps my bad I keep forgetting we are on the P system! EDIT with the marks on 15 you want the P lined up to where it is ready to fire

Posted By: f2502011

Re: Need help with Pertronix Ignitor install - 01/20/16 11:49 AM

Get the dampener slit on 15 BTDC. pop the dist cap & see if the rotor is on or very close to #1 or #6 plug wire. loosen clamp & turn housing CCW till the can is on the pass side in the ballpark where you want it with room to be turned back & forth either way so you can adj it. turn housing some more slightly (either way) till the magnet is lined up dead even with the nearest tooth. take the wires out of the cap. plug in the #1 or the #6 plug wire (whichever one the rotor was originally at/under) into the cap terminal above the rotor. route em CW starting with the #1 you just started with and go 8-4-3-6-5-7-2 or if you are starting with #6 then going CW plug in 5-7-2-1-8-4. Fire it up!

How will I know when the Pertronix is ready to fire? Is it when the rotor is lined up with a post on the cap??

Also, my distributor is in the back of the engine and I can't turn the housing any more counter clockwise. That's the problem because the vacuum diaphragm hits the oil pressure sending unit. It needs to go back clockwise so I can advance it more (CCW) without running into the sending unit with the diaphragm. I've got it at about 12 right now as it is, but it's dangerously close to the wire on the sending unit. I need to keep timing where it is, but somehow change the position of the distributor body/housing/diaphragm so I can advance it more (CCW) up to 16 without getting into trouble with the sending unit.

Can I just pull the distributor rotate housing to where I want it then reinstall with the rotor in the same place?

Posted By: DAYCLONA

Re: Need help with Pertronix Ignitor install - 01/20/16 04:23 PM

Can I just pull the distributor rotate housing to where I want it then reinstall with the rotor in the same place?

NO...the dist on the SmBlk or BB installs 0 or 180 degrees only based on the dist/cam gear, your problem with the advance houseing having interference can happen even with the install of a hi rise manifold

In layman's terms what you need to do is put #1 cylinder at TDC, confirm the current rotor position is under the #1 terminal on the cap, or close to it, then loosen the dist. and rotate the housing/advance diaphragm where you would like it to be for proper clearance to rotate the dist back/forth to establish timing, once you have the dist housing where you desire, then see under what terminal on the dist cap the rotor tip is pointing to, this is now your #1 cylinder plug wire, move all the corresponding wires clockwise/counter clockwise on the dist cap depending on what NEW dist wire terminal is closest to the rotor tip to establish a new firing order location on the cap, attempt to start the motor, you may have to rotate/time the dist by ear until you can establish an idle while attempting to start the engine, DO GET RID OF THE BALLAST, check to see if your coil your using is of the recommended OHM/turn ratio rating for the Ignitior I system your using

Mike

Posted By: f2502011

Re: Need help with Pertronix Ignitor install - 01/20/16 05:56 PM

Can I just pull the distributor rotate housing to where I want it then reinstall with the rotor in the same place?

NO...the dist on the SmBlk or BB installs 0 or 180 degrees only based on the dist/cam gear, your problem with the advance houseing having interference can happen even with the install of a hi rise manifold

In layman's terms what you need to do is put #1 cylinder at TDC, confirm the current rotor position is under the #1 terminal on the cap, or close to it, then loosen the dist. and rotate the housing/advance diaphragm where you would like it to be for proper clearance to rotate the dist back/forth to establish timing, once you have the dist housing where you desire, then see under what terminal on the dist cap the rotor tip is pointing to, this is now your #1 cylinder plug wire, move all the corresponding wires clockwise/counter clockwise on the dist cap depending on what NEW dist wire terminal is closest to the rotor tip to establish a new firing order location on the cap, attempt to start the motor, you may have to rotate/time the dist by ear until you can establish an idle while attempting to start the engine, DO GET RID OF THE BALLAST, check to see if your coil your using is of the recommended OHM/turn ratio rating for the Ignitior I system your using

Mike

Could I alternatively rotate the distributor clockwise the distance needed to get to the next terminal then move the wires clockwise over one place? It really needs to rotate clockwise about the distance from one plug to the next so it doesn't hit the sending unit.

Posted By: RapidRobert

Re: Need help with Pertronix Ignitor install - 01/20/16 06:03 PM

If you rotated the housing 1/8 of a turn CW, the rotor is still (back) where it (originally) was so you would reclock the wires CCW

Posted By: DAYCLONA

Re: Need help with Pertronix Ignitor install - 01/20/16 07:16 PM

Can I just pull the distributor rotate housing to where I want it then reinstall with the rotor in the same place?

NO...the dist on the SmBlk or BB installs 0 or 180 degrees only based on the dist/cam gear, your problem with the advance houseing having interference can happen even with the install of a hi rise manifold

In layman's terms what you need to do is put #1 cylinder at TDC, confirm the current rotor position is under the #1 terminal on the cap, or close to it, then loosen the dist. and rotate the housing/advance diaphragm where you would like it to be for proper clearance to rotate the dist back/forth to establish timing, once you have the dist housing where you desire, then see under what terminal on the dist cap the rotor tip is pointing to, this is now your #1 cylinder plug wire, move all the corresponding wires clockwise/counter clockwise on the dist cap depending on what NEW dist wire terminal is closest to the rotor tip to establish a new firing order location on the cap, attempt to start the motor, you may have to rotate/time the dist by ear until you can establish an idle while attempting to start the engine, DO GET RID OF THE BALLAST, check to see if your coil your using is of the recommended OHM/turn ratio rating for the Ignitior I system your using

Mike

Could I alternatively rotate the distributor clockwise the distance needed to get to the next terminal then move the wires clockwise over one place? It really needs to rotate clockwise about the distance from one plug to the next so it doesn't hit the sending unit.

Whatever gets the job done, either way CW or CCW

Posted By: f2502011

Re: Need help with Pertronix Ignitor install - 01/20/16 11:39 PM

Can I just pull the distributor rotate housing to where I want it then reinstall with the rotor in the same place?

NO...the dist on the SmBlk or BB installs 0 or 180 degrees only based on the dist/cam gear, your problem with the advance houseing having interference can happen even with the install of a hi rise manifold

In layman's terms what you need to do is put #1 cylinder at TDC, confirm the current rotor position is under the #1 terminal on the cap, or close to it, then loosen the dist. and rotate the housing/advance diaphragm where you would like it to be for proper clearance to rotate the dist back/forth to establish timing, once you have the dist housing where you desire, then see under what terminal on the dist cap the rotor tip is pointing to, this is now your #1 cylinder plug wire, move all the corresponding wires clockwise/counter clockwise on the dist cap depending on what NEW dist wire terminal is closest to the rotor tip to establish a new firing order location on the cap, attempt to start the motor, you may have to rotate/time the dist by ear until you can establish an idle while attempting to start the engine, DO GET RID OF THE BALLAST, check to see if your coil your using is of the recommended OHM/turn ratio rating for the Ignitior I system your using

Mike

Could I alternatively rotate the distributor clockwise the distance needed to get to the next terminal then move the wires clockwise over one place? It really needs to rotate clockwise about the distance from one plug to the next so it doesn't hit the sending unit.

Whatever gets the job done, either way CW or CCW

Just to make sure I'm clear on this. All I need to do is rotate the distributor clockwise one terminal worth and then move all wires counter clockwise one terminal?

I had someone also tell me I could use a flat screwdriver and shove it in the Intermediate Shaft keyway and rotate the shaft on the cam gear so it aligns better for clearance, but I'm not really sure what this means and if I can do it with this distributor.

Posted By: RapidRobert

Re: Need help with Pertronix Ignitor install - 01/21/16 12:25 AM

Just to make sure I'm clear on this. All I need to do is rotate the distributor clockwise one terminal worth and then move all wires counter clockwise one terminal?.

Correct. And "one terminal worth" is an eighth of a turn. This might help clarify: say the #3 plug wire for instance is above the rotor right now then after you move the housing forward (CW) you need to move the wires backward (CCW) so the #3 plug wire is back above the rotor just like it (originally) was

Posted By: f2502011

Re: Need help with Pertronix Ignitor install - 01/28/16 11:54 AM

Ok I have the timing right and it seems to run good, but the distributor is not where I want it. I rotated the housing 1/8 turn clockwise and moved all wires back 1 position. The vacuum advance is pointing toward the passenger seat/firewall. How can I keep timing where I want it at 16 and get it to point toward the passenger side without running into the oil pressure sending unit?

Looking down in the hole for the distributor is the distributor drive that has a slot in the middle of a gear. I'm assuming this is what I will need to reposition get things where I would like? ? How do I do this without messing things up? Not sure how it's all put together here so I want to be sure what I'm supposed to do first before I try.

Posted By: DAYCLONA

Re: Need help with Pertronix Ignitor install - 01/28/16 12:33 PM

Then move the wires another terminal position on the cap, or put a 90 degree fitting on the oil sender unit to relocate it...

Posted By: f2502011

Re: Need help with Pertronix Ignitor install - 01/28/16 02:11 PM

Then move the wires another terminal position on the cap, or put a 90 degree fitting on the oil sender unit to relocate it...

Moving the wires another terminal will only throw everything off more. Repositioning the oil sending unit is really not any different than the vacuum advance pointing toward the passenger seat when it should be pointing toward the fender. Both look wrong. I'm thinking if I can put it to TDC or whatever plug I want to reference when I pull it then I can reposition the slot in the distributor gear to allow the distributor to be in the position I want it.

My question is to reposition the drive gear for the distributor do I simply put a flat screwdriver in the slot of the distributor drive gear and turn it to allow it to walk out of the mesh with the cam, then turn it to where I want the slot to be to allow the distributor to be in the position I want and then mesh it back in? This is what I'm not familiar with how it works. I've had people mention using a flat screwdriver to reposition things and allow to line up better but I'm not sure what it means exactly.

Posted By: moparx

Re: Need help with Pertronix Ignitor install - 01/28/16 03:27 PM

the drive gear goes through a bushing in the block, then indexes in the oil pump drive[ 5/16" hex at the end of the shaft]. observe how the drive gear is in relationship to the cam gear to get an idea how far the two gears mesh with each other. then, as has been stated, use a very large flat tip screw driver to "unwind" the distributor drive shaft from the cam. position the drive gear as you want, then screw it back into the cam gear with the slot pointing as you need it to index your distributor for the amount of adjustment needed. not as difficult as it seems. just make sure the gears are meshed properly, insuring the hex at the oil pump drive is properly in position. if the distributor does not seat on the block, you know the drive gear is not engaging the oil pump properly. just may need a little fiddling, but the only way you can mess something up is by forcing things together. hth.

Posted By: scratchnfotraction

Re: Need help with Pertronix Ignitor install - 01/28/16 03:37 PM

yes, that's how I have done it. I had the intake off but can be done with it on.

when you reset the gear mesh of the drive to the cam it may not want to reseat the hex on the oil pump.

you can either rotate engine turn cam/gear/pushing down with screwdriver till it drops in the pump. then recheck TDC and see if it is where you want it. (I spin engine over with starter a couple turns, then bump back to TDC)

or you can use a long hex oil priming tool to turn the oil pump then see if it will drop back in repete as needed.

sometimes a wire looped around the gear to pull up on will work/help with intake on.

FYI, if it's a used engine it may have carbon build up on the gear shaft and want to pull the block bushing up/out of block. be hard to turn by hand ect.

be sure it stays seated or replace if it wants to come out.

FYI, if you need to replace the bushing, it comes in a freeze/core plug kit about 16 bux at napa.

for less headache, I suggest pulling the intake to rephrase the dist drive gear.

Posted By: RapidRobert

Re: Need help with Pertronix Ignitor install - 01/29/16 03:05 AM

I would suggest: (1) turn dampener till the slit is at your preferred initial setting on #1 compression & if that ain't set in stone you might set it at 15 BTDC (2) clock the intergear anywhere it needs to be so the rotor is facing forward and slightly to the pass side (start with the slot parallel to the eng). (3) (final) install of dist & turn housing so can is on pass side in the general range of motion it needs to be for adjustments. (4) turn housing slightly till the P is in position to fire (just like the MP magnet/tooth setup would be doing). (5) plug in #1 plug wire in the cap right above the rotor location. Fire it up! Caveats: Sometimes the intergear will rise up off of the cam gear with a large screwdriver. Sometimes it takes a pair of coat hangar wires with an L bent on the ends or a loop of very thin wire so it will nestle in the teeth root on opposite sides of the gear cuz it is tight in there. As said you might need to slightly turn the oil pump with a 5/16" hex rod. Locating the #1 plug wire location in the cap to be forward and slightly to the pass side maintains the OE order (helps prevent future mistakes) & lets the wires nestle in place the neatest with the shortest lengths possible for their routing (As you know clocking is CW from #1)

Posted By: f2502011

Re: Need help with Pertronix Ignitor install - 01/29/16 05:47 PM

I would suggest: (1) turn dampener till the slit is at your preferred initial setting on #1 compression & if that ain't set in stone you might set it at 15 BTDC (2) clock the intergear anywhere it needs to be so the rotor is facing forward and slightly to the pass side (start with the slot parallel to the eng). (3) (final) install of dist & turn housing so can is on pass side in the general range of motion it needs to be for adjustments. (4) turn housing slightly till the P is in position to fire (just like the MP magnet/tooth setup would be doing). (5) plug in #1 plug wire in the cap right above the rotor location. Fire it up! Caveats: Sometimes the intergear will rise up off of the cam gear with a large screwdriver. Sometimes it takes a pair of coat hangar wires with an L bent on the ends or a loop of very thin wire so it will nestle in the teeth root on opposite sides of the gear cuz it is tight in there. As said you might need to slightly turn the oil pump with a 5/16" hex rod. Locating the #1 plug wire location in the cap to be forward and slightly to the pass side maintains the OE order (helps prevent future mistakes) & lets the wires nestle in place the neatest with the shortest lengths possible for their routing (As you know clocking is CW from #1)

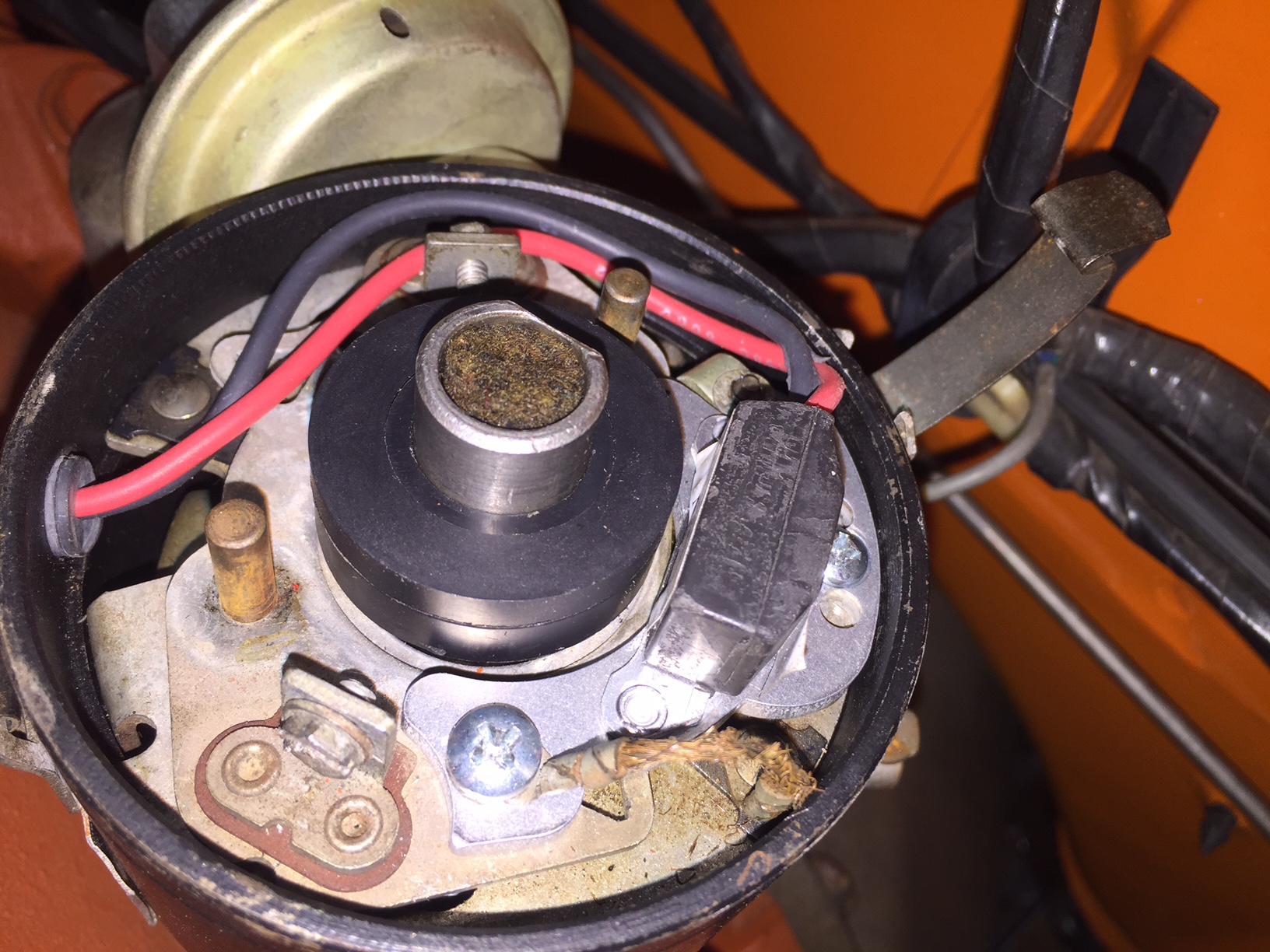

Are you talking about a big block or maybe I'm confused. Mine is a 340 with the distributor on the back of the engine. Clockwise rotation and my no 1 cylinder is supposed to be the one on the front left so I was thinking the slot should point slightly toward the driver side to put the distributor where I want it. In line with the no 1 front left cylinder. Here's a pic.

Posted By: RapidRobert

Re: Need help with Pertronix Ignitor install - 01/29/16 06:23 PM

Yes SB and the #1 piston/cyl is on the DR side at the front & agreed the shop manuals/MP info says to have the intergear slot pointed a bit to the DR side (the #1 intake manifold bolt iirc) then plug in the #1 plug wire wherever the rotor happens to be by doing it that way & that works fine and most of the time that WILL locate the rotor forward and slightly to the pass side, however some dists have a different bottom tang to top rotor clocking & IDEALLY you want the rotor (not the intergear slot) to be pointing forward and slightly to the pass side (for the #1 wire location) which is the OE pattern no matter where the intergear slot points to and actually the intergear slot and therefore the rotor location can be ANYWHERE. The diagrams show pointing it to the #1 intake bolt cuz most of the time with OE dist it WILL locate the rotor forward and slightly to the pass side. Maybe to Keep It Simple Sam we should plug in the #1 plug wire wherever the rotor ends up at when you clock the intergear slot pointing to the #1 intake bolt and there's a VG chance that the rotor WILL be forward & to the pass side. What I would do right now is turn the dampener to the initial you will be going with & note where this locates the rotor then turn the housing so the can has clearance (which is what we are trying to fix here, sounds like I need to k.i.s.s.)! AND the P is ready to fire then snug the dist holddown moderately tight then plug in the #1 plug wire above the rotor & continue on around CW. The ONLY reason we would need to reclock the intergear is if we wanted to change where the rotor is at & intergear work is a pain at best and the only reason to have the rotor forward/slightly to pass side is it lets the plug wires nestle the neatest with the shortest lengths & maintaining OE standardization can prevent future mistakes and and it is a good thing to have but it ain't a dealbreaker. Holler when you can