Moparts

Torqueflite 2-3 overlap

Posted By: f2502011

Torqueflite 2-3 overlap - 09/04/15 08:29 PM

Been working on my 1970 torqueflite for a while now. I finally got my shift point issue resolved but have overlap on the 2-3 shift. I've had the valve body out and cleaned it. At some point someone installed a 5.0 kickdown lever and the trans also has a controlled load kickdown servo (1971 and later style). I've got line pressure screw adjusted to 1 and 3/16" and the front band to 72 in/lbs and backed off 1.5 turns since it has the 5.0 lever. I pulled out the servo while in there and was going to put a blocker tube in it in place of the small inner cushion spring but it already had a thicker washer that acts as a blocker and the spring had been removed. Besides yanking the trans and switching the lever is there anything I can do with pressure or band adjustment to help with the overlap?

Posted By: JohnRR

Re: Torqueflite 2-3 overlap - 09/04/15 08:41 PM

The 5.0 lever is your problem , you don't want to lower the pressure and changing the band adjustment may not change it enough.

Sadly the fix is to change the lever , 3.8 or a 4.2.

Posted By: HotRodDave

Re: Torqueflite 2-3 overlap - 09/04/15 09:47 PM

When I do a trans in something I plan to tweak stuff in I drill a big hole near the plug for the band anchor so I can switch the lever in the car, works great and even the fat factory converters seem to have enough room (barely). You could probably do it with the trans in the car just don't drill into the converter.

Posted By: John_Kunkel

Re: Torqueflite 2-3 overlap - 09/04/15 11:54 PM

The 5.0 lever was factory installed in several transmissions and they didn't suffer from severe overlap.

The 5.0 lever, itself, isn't the bad guy, the combination of that lever and the rest of the trans setup is. It would be easier to pull the valve body and place a restrictor orifice in the front clutch circuit than to try to change the lever in situ. It there's already a restrictor in place go smaller.

Simply loosening the kickdown band adjustment is the easiest option.

Posted By: RSNOMO

Re: Torqueflite 2-3 overlap - 09/05/15 12:10 AM

I'll agree...

Have had a 5.0 lever in a 'kitted' TF for many moons...

Shifts are fine...

Posted By: f2502011

Re: Torqueflite 2-3 overlap - 09/05/15 12:43 AM

I wouldn't say it's severe but it is annoying especially now I have my shifts timed right. Restrictor orifice seems like a good approach where can I get one and what size(s)do I need? I did notice when I lowered pressure at one point the overlap was less, but the 1-2 was softer. A 5.0 lever may work fine for some, but it is prone to overlap and that's what I have and I need to find a way to compensate and eliminate it.

Posted By: DaveRS23

Re: Torqueflite 2-3 overlap - 09/05/15 01:49 AM

The 2-3 overlap is a pet peeve of mine and I have done a bunch of the restrictors. Some guys use brass pipe plugs after threading the orifice. I use a 3/8 core plug (like a mini freeze plug). Dorman #555-115. You may have to drill the orifice a bit to get the plug in.

On a street car, it is difficult to get ALL the slap out when idling around town. Light load and low speed reveal the slap from 2 to 3 the most. If you want it all out on a street car, the best way is to start with a small hole in the plug (.070" or so usually) to the point that there is a flair up between the 2-3 shift. Then keep opening up the hole until the flair up just stops. But that requires repeated dropping of the valve body. That is the way I do mine; start small enough to have a flair up and gradually get larger till there is no flair under load and little or no slap at light load, low speed.

For those that do not particularly want to repeatedly drop the valve body, .090" will usually get you close. But it does vary a little from tranny to tranny.

At the risk of getting flamed, I will make a suggestion should you decide to start with a small hole and gradually work your way up. I just put some stiff grease on the drill bit each time I go a bit larger and just leave the same plug in the orifice. Then, spray a good amount of carb cleaner or brake clean or similar product and then hit the plug with some air. Gets the chips out for me.

If you do need to pull the core plug, you can just screw in a sheet metal screw and pull the plug with a claw hammer or something similar.

All it takes is some time and patience to get all (or most) of the 2-3 overlap out.

Posted By: 451Mopar

Re: Torqueflite 2-3 overlap - 09/05/15 06:18 AM

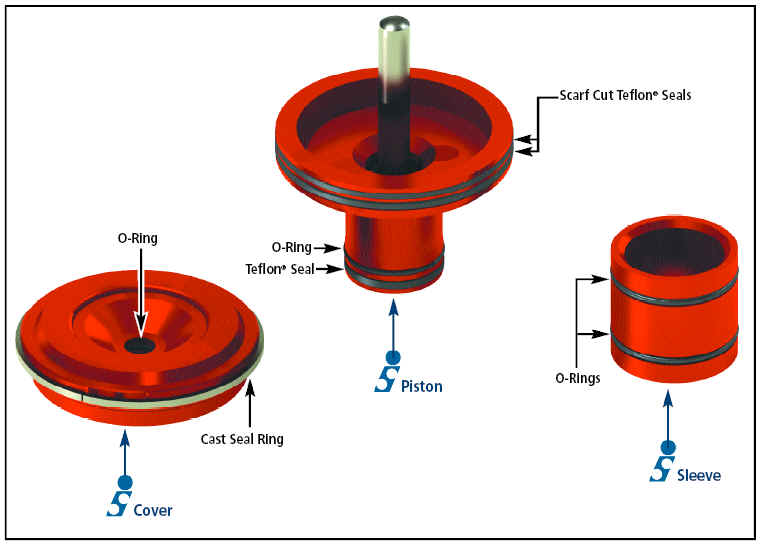

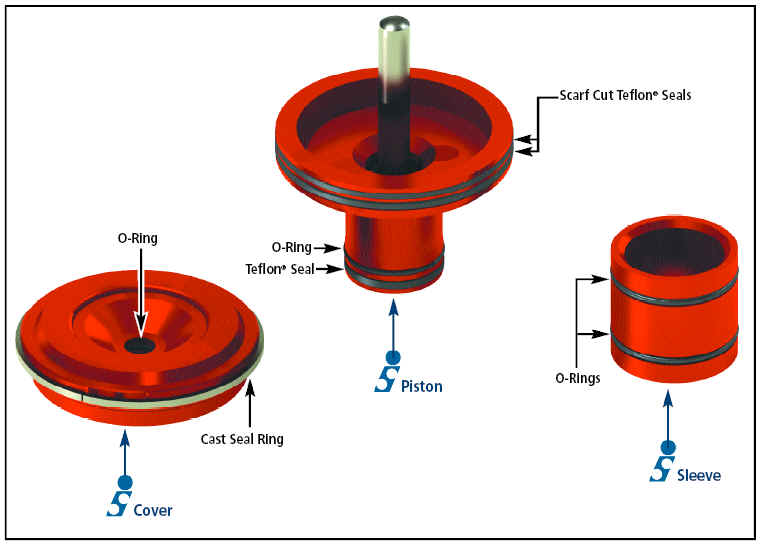

I like using the "oversize" billet front servo kit with the "O" ring servo cover. Also, the 3.8 or 4.2:1 lever.

Posted By: RapidRobert

Re: Torqueflite 2-3 overlap - 09/05/15 08:36 AM

Dave that was good stuff. I was thinking that a guy (on here) once drilled/tapped for carb jets so he could get the flow spot on that way

Posted By: John_Kunkel

Re: Torqueflite 2-3 overlap - 09/05/15 07:00 PM

I wouldn't say it's severe but it is annoying especially now I have my shifts timed right. Restrictor orifice seems like a good approach where can I get one and what size(s)do I need?

You stated that the front servo piston already had blocker installed (part of a shift kit) so the trans might also have a restrictor orifice installed. Before tearing into it try backing the band adjustment off to 2 or 2 1/4 turns.

As stated earlier, overlap is more pronounced at low speed low throttle so, if there is no noticeable overlap at WOT, you might be better off just living with it at low speeds.

The fancy billet servo pictured above would likely exacerbate overlap woes.

Posted By: f2502011

Re: Torqueflite 2-3 overlap - 09/05/15 07:45 PM

I was just in the trans and took lots of pics. No restrictor was there. I had the KD band at 2 turns off before I saw the 5.0 lever and did 1.5 since that is the recommendation for it. When it was 2 turns it still had the overlap. The only thing that minimized the overlap was lowering the line pressure but when I did that it made the 1-2 softer too.

Posted By: f2502011

Re: Torqueflite 2-3 overlap - 09/05/15 09:52 PM

The 2-3 overlap is a pet peeve of mine and I have done a bunch of the restrictors. Some guys use brass pipe plugs after threading the orifice. I use a 3/8 core plug (like a mini freeze plug). Dorman #555-115. You may have to drill the orifice a bit to get the plug in.

On a street car, it is difficult to get ALL the slap out when idling around town. Light load and low speed reveal the slap from 2 to 3 the most. If you want it all out on a street car, the best way is to start with a small hole in the plug (.070" or so usually) to the point that there is a flair up between the 2-3 shift. Then keep opening up the hole until the flair up just stops. But that requires repeated dropping of the valve body. That is the way I do mine; start small enough to have a flair up and gradually get larger till there is no flair under load and little or no slap at light load, low speed.

For those that do not particularly want to repeatedly drop the valve body, .090" will usually get you close. But it does vary a little from tranny to tranny.

At the risk of getting flamed, I will make a suggestion should you decide to start with a small hole and gradually work your way up. I just put some stiff grease on the drill bit each time I go a bit larger and just leave the same plug in the orifice. Then, spray a good amount of carb cleaner or brake clean or similar product and then hit the plug with some air. Gets the chips out for me.

If you do need to pull the core plug, you can just screw in a sheet metal screw and pull the plug with a claw hammer or something similar.

All it takes is some time and patience to get all (or most) of the 2-3 overlap out.

I've also read about tapping the hole with 1/8 npt and using a threaded hex head brass plug, but I'm not sure where to get one of these brass plugs. Any suggestions on that? Also, I noticed one of the transgo kits comes with a restrictor with a 0.140 hole so I'm wondering if 0.070 - 0.090 may be too small or too restrictive??

Posted By: cudaman1969

Re: Torqueflite 2-3 overlap - 09/05/15 10:44 PM

How many springs are in the drum? Use all 15 that'll slow the overlap. I don't like the idea of a .090 hole keeping the high clutch applied.

I use the 3.8 lever with 10-12 springs so I don't have to adjust the band so often, of course that means removing trans

Posted By: PC-CHARGER

Re: Torqueflite 2-3 overlap - 09/06/15 12:03 AM

The size of the restrictor hole does not affect the pressure to the clutch, only the amount of time it takes to fill the area behind the apply piston. The larger the hole, the faster it fills but the pressure will equalize on both sides of the restrictor at some point.

Posted By: f2502011

Re: Torqueflite 2-3 overlap - 09/06/15 12:07 AM

How many springs are in the drum? Use all 15 that'll slow the overlap. I don't like the idea of a .090 hole keeping the high clutch applied.

I use the 3.8 lever with 10-12 springs so I don't have to adjust the band so often, of course that means removing trans

on the spring count.

It would be great if I had the 3.8 or 4.2 lever, but I don't so I need to see if and what I can do to see if I can make the current configuration work. Would be different if I had a lift and a trans-jack, then it wouldn't be that big of a deal to pull it and swap out the parts, but I don't.

Posted By: DaveRS23

Re: Torqueflite 2-3 overlap - 09/06/15 12:11 AM

The 2-3 overlap is a pet peeve of mine and I have done a bunch of the restrictors. Some guys use brass pipe plugs after threading the orifice. I use a 3/8 core plug (like a mini freeze plug). Dorman #555-115. You may have to drill the orifice a bit to get the plug in.

On a street car, it is difficult to get ALL the slap out when idling around town. Light load and low speed reveal the slap from 2 to 3 the most. If you want it all out on a street car, the best way is to start with a small hole in the plug (.070" or so usually) to the point that there is a flair up between the 2-3 shift. Then keep opening up the hole until the flair up just stops. But that requires repeated dropping of the valve body. That is the way I do mine; start small enough to have a flair up and gradually get larger till there is no flair under load and little or no slap at light load, low speed.

For those that do not particularly want to repeatedly drop the valve body, .090" will usually get you close. But it does vary a little from tranny to tranny.

At the risk of getting flamed, I will make a suggestion should you decide to start with a small hole and gradually work your way up. I just put some stiff grease on the drill bit each time I go a bit larger and just leave the same plug in the orifice. Then, spray a good amount of carb cleaner or brake clean or similar product and then hit the plug with some air. Gets the chips out for me.

If you do need to pull the core plug, you can just screw in a sheet metal screw and pull the plug with a claw hammer or something similar.

All it takes is some time and patience to get all (or most) of the 2-3 overlap out.

I've also read about tapping the hole with 1/8 npt and using a threaded hex head brass plug, but I'm not sure where to get one of these brass plugs. Any suggestions on that? Also, I noticed one of the transgo kits comes with a restrictor with a 0.140 hole so I'm wondering if 0.070 - 0.090 may be too small or too restrictive??

Most of the better hardware stores should have a selection of brass pipe plugs, of course you'll need one with the recessed allen head rather than the square head. But the 3/8 core plug works just as well and is easier to use, so it is the only way I do it anymore.

The .140 doesn't usually have much impact. I have changed a bunch of them out. And the only impact I have ever seen by going with the smaller opening is that it addresses the 2-3 overlap. No other issues. And since it is completely reversible, there is not any real reason not to go with the opening size that eliminates the overlap.

Posted By: cudaman1969

Re: Torqueflite 2-3 overlap - 09/06/15 01:01 AM

The size of the restrictor hole does not affect the pressure to the clutch, only the amount of time it takes to fill the area behind the apply piston. The larger the hole, the faster it fills but the pressure will equalize on both sides of the restrictor at some point.

As long as the seals and rings are tight so as no pressure loss, the trans don't seal up that good anyway, always fluid loss, pump cavitation on acceleration, things like that, I like volume plus pressure.

To the op, never had a lift or trans jack, just jack stands, floor jack and muscles. Two hours or less on the bench. It's all procedure. If you want something done you gotta do it.

Posted By: moparx

Re: Torqueflite 2-3 overlap - 09/06/15 02:45 PM

The 2-3 overlap is a pet peeve of mine and I have done a bunch of the restrictors. Some guys use brass pipe plugs after threading the orifice. I use a 3/8 core plug (like a mini freeze plug). Dorman #555-115. You may have to drill the orifice a bit to get the plug in.

On a street car, it is difficult to get ALL the slap out when idling around town. Light load and low speed reveal the slap from 2 to 3 the most. If you want it all out on a street car, the best way is to start with a small hole in the plug (.070" or so usually) to the point that there is a flair up between the 2-3 shift. Then keep opening up the hole until the flair up just stops. But that requires repeated dropping of the valve body. That is the way I do mine; start small enough to have a flair up and gradually get larger till there is no flair under load and little or no slap at light load, low speed.

For those that do not particularly want to repeatedly drop the valve body, .090" will usually get you close. But it does vary a little from tranny to tranny.

At the risk of getting flamed, I will make a suggestion should you decide to start with a small hole and gradually work your way up. I just put some stiff grease on the drill bit each time I go a bit larger and just leave the same plug in the orifice. Then, spray a good amount of carb cleaner or brake clean or similar product and then hit the plug with some air. Gets the chips out for me.

If you do need to pull the core plug, you can just screw in a sheet metal screw and pull the plug with a claw hammer or something similar.

All it takes is some time and patience to get all (or most) of the 2-3 overlap out.

I've also read about tapping the hole with 1/8 npt and using a threaded hex head brass plug, but I'm not sure where to get one of these brass plugs. Any suggestions on that? Also, I noticed one of the transgo kits comes with a restrictor with a 0.140 hole so I'm wondering if 0.070 - 0.090 may be too small or too restrictive??

brass hex head plugs are best, but somewhat hard to find. i use the standard plated steel versions. you are not really cranking them super tight, and as they are always covered with atf, i have never had a problem with removing them. if you pm me with your address, i'll send ya a few to experiment with, no charge.

Posted By: 451Mopar

Re: Torqueflite 2-3 overlap - 09/06/15 04:48 PM

The threaded aluminum plugs are pretty easy to find and drill.

Posted By: RapidRobert

Re: Torqueflite 2-3 overlap - 09/06/15 05:18 PM

The threaded aluminum plugs are pretty easy to find and drill.

X2 X2 on the drilling! I just drilled a .015" hole in an iron 3/8 NPT plug to go in the back end of the pass SB horizontle oil gallery for a mini pressurized squirt of oil onto the intergear/cam gear mesh. No mas. alum next time. speedway mtrs if you have time for mailorder or you could source em local

Posted By: f2502011

Re: Torqueflite 2-3 overlap - 09/06/15 06:46 PM

The threaded aluminum plugs are pretty easy to find and drill.

Where can I easily find them?

Posted By: 451Mopar

Re: Torqueflite 2-3 overlap - 09/06/15 07:33 PM

Posted By: f2502011

Re: Torqueflite 2-3 overlap - 09/06/15 09:45 PM

Posted By: JohnRR

Re: Torqueflite 2-3 overlap - 09/07/15 07:24 AM

Posted By: moparx

Re: Torqueflite 2-3 overlap - 09/07/15 01:55 PM

[quote=451Mopar]The threaded aluminum plugs are pretty easy to find and drill.

aluminum works, but i have found over the years working with aluminum recessed hex plugs, that all hex wrenches are not created equal. and when the wrench doesn't fit EXACT, the hex strips, or rounds out, causing me lots of grief removing them after the fact. i prefer steel or brass for just this reason alone. stainless plugs are good, but you have to make sure the threads are coated with something that will prevent galling. if you don't, same grief applys. just my experience and preference.

Posted By: DaveRS23

Re: Torqueflite 2-3 overlap - 09/07/15 03:37 PM

[quote=451Mopar]The threaded aluminum plugs are pretty easy to find and drill.

aluminum works, but i have found over the years working with aluminum recessed hex plugs, that all hex wrenches are not created equal. and when the wrench doesn't fit EXACT, the hex strips, or rounds out, causing me lots of grief removing them after the fact. i prefer steel or brass for just this reason alone. stainless plugs are good, but you have to make sure the threads are coated with something that will prevent galling. if you don't, same grief applys. just my experience and preference.

All good points. And the port must be drilled and taped. So why go to all that trouble when you can just tap in the core plug? Pipe plugs are a lot more trouble to install, can be a problem to remove, and do not any better job.

Posted By: f2502011

Re: Torqueflite 2-3 overlap - 09/07/15 04:22 PM

What about putting the restrictor in the front clutch port of the valve body instead?

Posted By: JohnRR

Re: Torqueflite 2-3 overlap - 09/08/15 04:48 AM

What about putting the restrictor in the front clutch port of the valve body instead?

Put it in the case It's much easier . Grease the tap to catch the chips.

Posted By: 451Mopar

Re: Torqueflite 2-3 overlap - 09/08/15 06:49 AM

Putting the screw in restrictor in the case is pretty easy.

I had a stainless steel plug I was going to use, but my drill bits did not want to drill it. The aluminum drills easy, and the plug does not need to be installed tightly, so it is easy to remove. Not to mention it will be covered in trans fluid. The steel core plug is what comes in the Transgo shift kits, but if you want to experiment with different orifice sizes, the screw in plug is easier to remove, drill, and re-install. Brass would be easy to drill also, and might be able to find in the plumbing section at the local hardware store?

Posted By: f2502011

Re: Torqueflite 2-3 overlap - 09/08/15 01:52 PM

[quote=451Mopar]The threaded aluminum plugs are pretty easy to find and drill.

aluminum works, but i have found over the years working with aluminum recessed hex plugs, that all hex wrenches are not created equal. and when the wrench doesn't fit EXACT, the hex strips, or rounds out, causing me lots of grief removing them after the fact. i prefer steel or brass for just this reason alone. stainless plugs are good, but you have to make sure the threads are coated with something that will prevent galling. if you don't, same grief applys. just my experience and preference.

All good points. And the port must be drilled and taped. So why go to all that trouble when you can just tap in the core plug? Pipe plugs are a lot more trouble to install, can be a problem to remove, and do not any better job.

If I went the core plug route, what do you recommend tapping it in with to tap it in even? Do I drill the 3/32 hole before or after the core plug is in place?

Posted By: moparx

Re: Torqueflite 2-3 overlap - 09/08/15 02:15 PM

[quote=451Mopar]The threaded aluminum plugs are pretty easy to find and drill.

aluminum works, but i have found over the years working with aluminum recessed hex plugs, that all hex wrenches are not created equal. and when the wrench doesn't fit EXACT, the hex strips, or rounds out, causing me lots of grief removing them after the fact. i prefer steel or brass for just this reason alone. stainless plugs are good, but you have to make sure the threads are coated with something that will prevent galling. if you don't, same grief applys. just my experience and preference.

All good points. And the port must be drilled and taped. So why go to all that trouble when you can just tap in the core plug? Pipe plugs are a lot more trouble to install, can be a problem to remove, and do not any better job.

If I went the core plug route, what do you recommend tapping it in with to tap it in even? Do I drill the 3/32 hole before or after the core plug is in place?

i would drill the hole first. reason being it's possible to get a chip or two behind the core plug you would not be able to get out. then it's possible they would migrate at some point to places you would not want them to be, causing problems. to tap it in even, i would use a punch of the appropriate size to get it almost flush, then finish it off with a flat piece of material that would lightly contact the surface of the case. and a side note to those that think brass is "easy" to drill. while brass is not really difficult to drill, the problem lies in the "breakthru" of the bit. at that time, it is super easy to have the bit "catch", and when doing so, the bit, because it is on the small side, will almost always break. another caveat with hardware store brass plugs is the alloy used can vary from super hard/VERY difficult to drill, to super soft/very gummy, also difficult to drill. this is just my 42 years as a machinist working with almost every material except titanium.

Posted By: DaveRS23

Re: Torqueflite 2-3 overlap - 09/08/15 03:49 PM

[quote=451Mopar]The threaded aluminum plugs are pretty easy to find and drill.

aluminum works, but i have found over the years working with aluminum recessed hex plugs, that all hex wrenches are not created equal. and when the wrench doesn't fit EXACT, the hex strips, or rounds out, causing me lots of grief removing them after the fact. i prefer steel or brass for just this reason alone. stainless plugs are good, but you have to make sure the threads are coated with something that will prevent galling. if you don't, same grief applys. just my experience and preference.

All good points. And the port must be drilled and taped. So why go to all that trouble when you can just tap in the core plug? Pipe plugs are a lot more trouble to install, can be a problem to remove, and do not any better job.

If I went the core plug route, what do you recommend tapping it in with to tap it in even? Do I drill the 3/32 hole before or after the core plug is in place?

I use a small 1/4 drive socket that fits inside the plug on a short extension to tap them in. That way I don't dimple the tranny case. It doesn't matter how deep you go with it as long as it is past flush with the case. And it doesn't have to fit very tight because it is essentially trapped and cannot go anywhere.

I drill them after they are in place. It's just easier. Grease the drill bit to catch as many chips as possible and then use the straw to spray brake clean or carb cleaner or the like above the plug to wash out any surviving chips.

Have done quite a few that way and have never had a problem.

Posted By: f2502011

Re: Torqueflite 2-3 overlap - 09/15/15 03:04 PM

Many thanks to moparx who sent me a 1/8 NPT tap and several hex head plugs at no charge!, I'm much improved and nearly overlap free. There is still a slight bit. I used a 5/64 (0.078125) drill bit for the hole. I would really like to get rid of all the overlap, but I'm just not sure that's possible without changing out the 5.0 lever. I guess a slight bit of overlap is ok?