It's easy to pi$$ and moan about subpar work. But, you did take everything apart and let them decide how it went together.

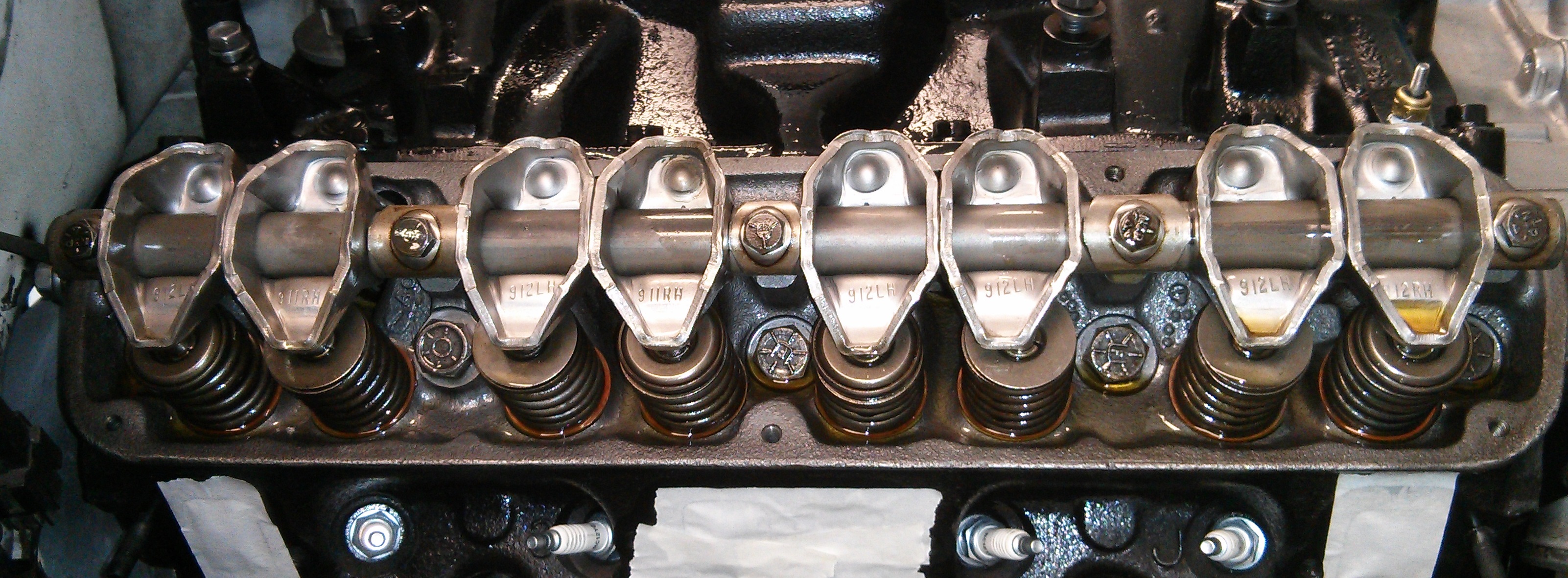

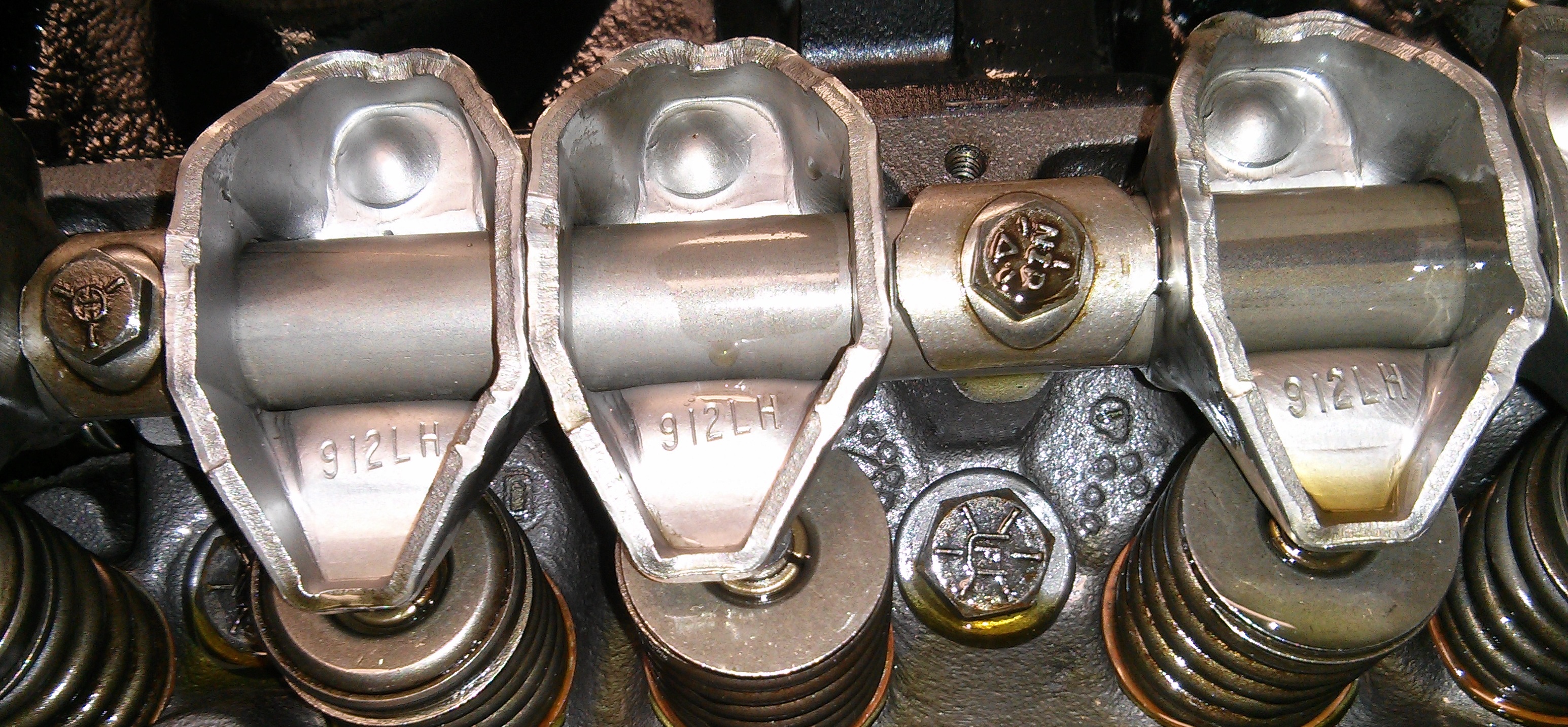

There are questions about rocker orientation and rocker shaft placement on this board all the time. By that I mean others who are doing it themselves sometimes can't remember how it goes together.

And there's no need to slag the shop, $1400 is quite a reasonable price with the engine overhauled and even run in.

No harm was done during the short time the engine ran with rockers misplaced.

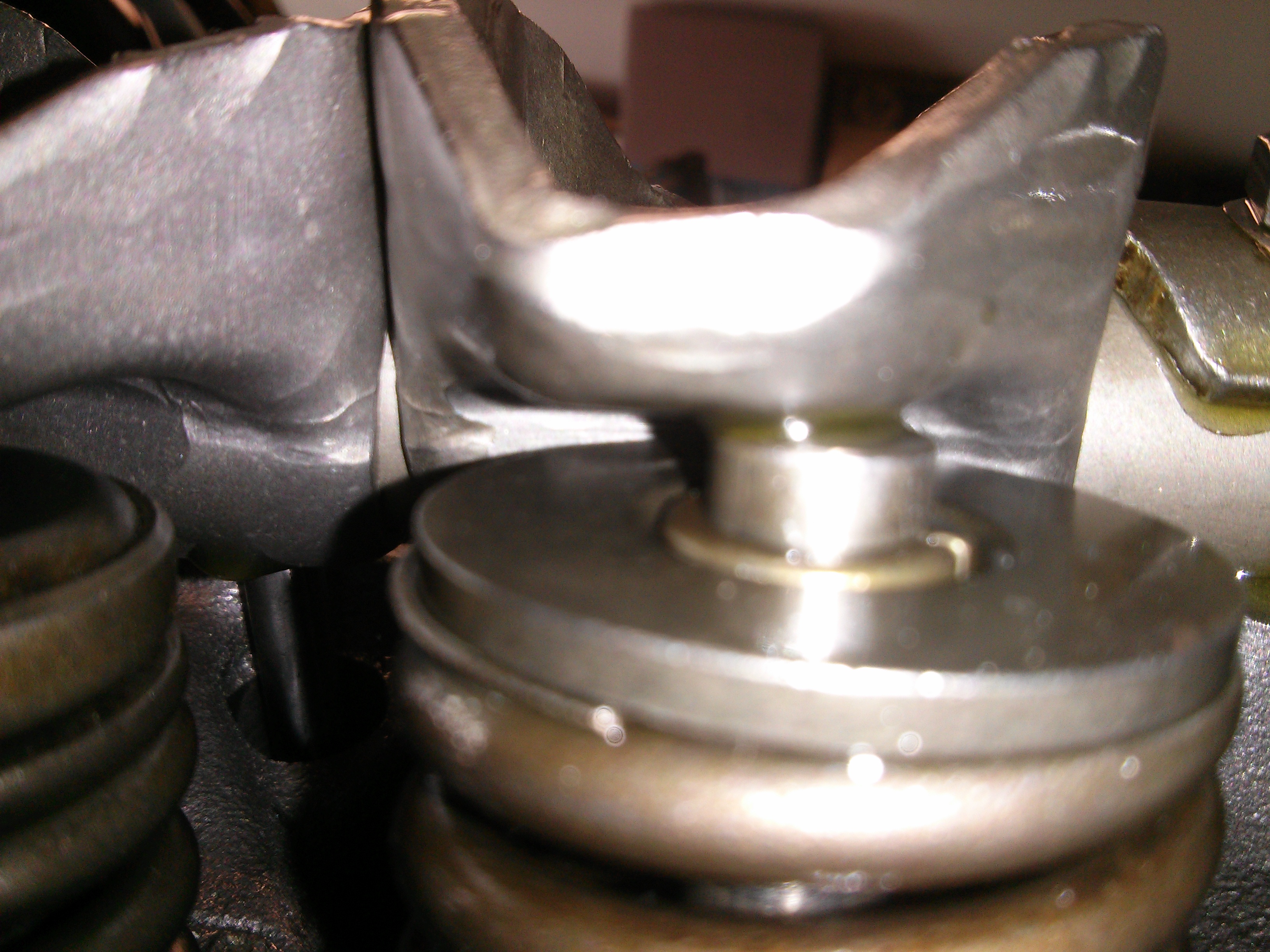

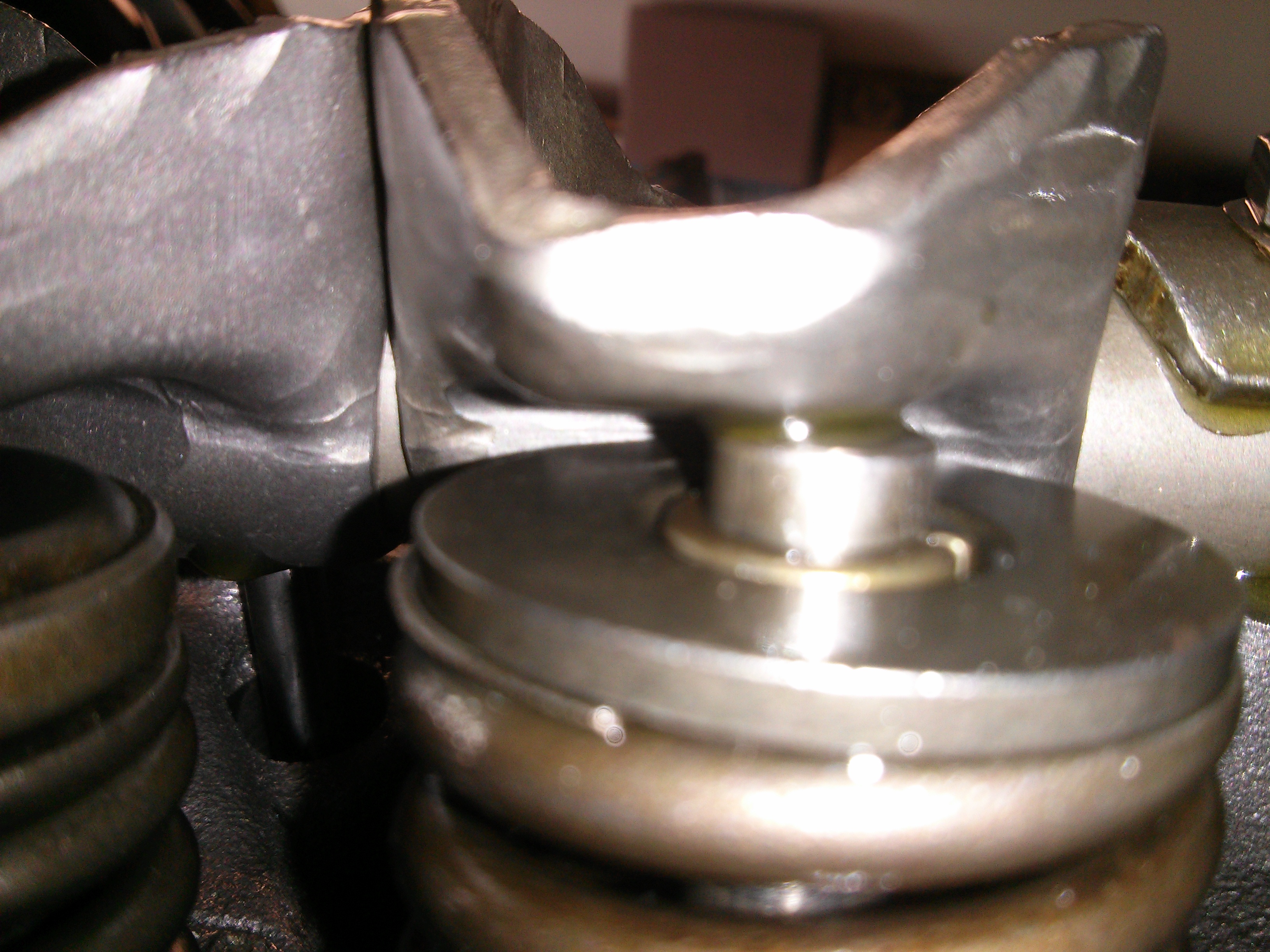

So I say, take some ownership of the engine. Pull the rocker shafts, it takes less than 5 minutes to do both sides. Put the shafts in the right orientation, driver side notch forward and down, pass side notch near the firewall and down. Put the rocker arms on in the correct order. Reinstall the rocker shafts with a torque wrench, I believe it's something like 20 lb-ft. DO make sure all the pushrods are in their correct rocker arm and not sticking off to the side. Reinstall valve covers and drive it.

If you have removed the distributor and I can't figure out why that would have happened, reinstall it per RR's method. I guess that comes between the valve covers and the "drive it" part.

We do not live in a perfect world and it'll take you less time to put things right than it'll take to either go to court or run it back to the shop.

About whether they did something else wrong, there's no reason to infer they did based on the rockers and shafts. I'm sure 99% of their work is stud-mounted rocker arms, a shaft-mounted rocker is an area in which they have little experience. Everything else is generic to all engines, except maybe the distributor shaft bushing.

Try to take that word "should" out of your vocabulary. You'll live longer that way.

R.

(no poison in mine though)

(no poison in mine though)

)

)

/gun the throttle repeatedly (read "breakin secrets")

/gun the throttle repeatedly (read "breakin secrets")