Moparts

A727 Transgo TF-2 install

Posted By: mopar67440

A727 Transgo TF-2 install - 11/18/14 05:25 PM

I'm sure this has been discussed somewhere, but couldn't locate the answer.

I just install the TF-2 shift kit in a rebuilt 1971 torqueflite for a 440 I suspect will be around 450hp for street/strip. I've added the shift command feature, and all mods went well. Just hoping to get some additional clarity on a few of the adjustments.

Pressure Regulator Adjustment;

Shims, spring seat, inner spring, and outer spring and valve were replaced per instructions. Transgo suggests 3/16" allen adjustment be backed off until spring seat is just flush to edge of retainer. Factory was 1 5/16". Some forums discuss 3 turns from flush, and up to 6 turns from flush. I'm suspecting this is more for race application. Should I just stick with instructions, and check with a pressure gauge once running? Hate to have to drop the pan again.

Throttle Valve Adjustment;

Transgo kit makes no mention of any adjustment here. Stem end was ground per instructions to 9/32". With the throttle lever touching the stop, I set the clearance to 3/16 using a drill bit. I've read on some forums many adjusting to 1/8.

Orifice Plug;

Not sure if I should install this into the case, but it appears it's used in 80% of the mods.

Any suggestions greatly appreciated.

Posted By: TJP

Re: A727 Transgo TF-2 install - 11/18/14 05:44 PM

Posted By: John_Kunkel

Re: A727 Transgo TF-2 install - 11/18/14 08:59 PM

The confusion arises from the fact that Transgo changes their instructions like I change my shorts (once a year or so).

The older instructions gave a PR spring setting of so many inches, then so many turns and finally flush.

Ditto the throttle valve, it was originally a 1/8" air gap and then no mention.

The cup orifice is a crap shoot, I would install it and remove it only is you experience RPM flareup on the 2-3 shift.

Posted By: DaveRS23

Re: A727 Transgo TF-2 install - 11/19/14 01:45 AM

I personally experiment with the size of the orifice plug. The 2-3 overlap is one of my pet peeves. You can use tiny core plugs to drill progressively smaller openings till you get a flair up, then back up a little. Others may have a better way to get to the sweet spot, but that is what has worked for me. Usually .075-.100 gets the overlap out.

Of course, that means repeated valve body pulls. It is not "one size fits all", so the only way to get it right on any given tranny is to experiment.

Posted By: mopar67440

Re: A727 Transgo TF-2 install - 11/19/14 07:17 PM

"Usually .075-.100 gets the overlap out."

Is this the typical range for a band adjustment of 2.5 turns from 72 inch lbs on a kevlar band, 4.2 ratio lever, 4 alto red clutches/kolene steels (not sure of clearance) 12 return springs, and PR adjusted flush to the retainer?

Posted By: DaveRS23

Re: A727 Transgo TF-2 install - 11/19/14 09:37 PM

I have never kept track of the combination of factors that results in any given orifice size curing the overlap. I just keep putting in smaller sizes until it just starts to flair, then I usually go back .005"-.010" larger.

It helps to have access to the numbered drill bits because the fractional ones are usually too large of a step between. Although a 3/32" (.094) might be a good place to start.

The .075"-.100" orifice was just a suggested starting range so as to help minimize the number of times you might have to pull the pan.

Dorman 3/8" cup expansion plugs part #555-115 is what I use.

Trial and error is the only way I know to get it right on any particular combo.

Posted By: John_Kunkel

Re: A727 Transgo TF-2 install - 11/19/14 09:47 PM

It's hard to predict with any certainty the shift quality of a trans even when the components/clearances are known, that's the purpose of the restrictor orifice....it can be changed without the necessity of removing/disassembling the trans to change the internal setup.

The restrictor supplied with the TF-2 has a .140" orifice and the orifice in the later factory separator plates is .125"

Tapping the case for a 1/8" NPT socket-head plug makes changes easier....drill the plug to the desired size.

Posted By: mopar67440

Re: A727 Transgo TF-2 install - 11/24/14 08:30 PM

Where is the later year .125 orifice located in the separator plate? I'm wondering if this is one of the holes that Transgo instructs to open up, then you install a .140 orific in the housing. This doesn't make any sense. Even if not modified, why install a plug with a larger hole than the plate.

Posted By: lewtot184

Re: A727 Transgo TF-2 install - 11/24/14 09:01 PM

,140 restrictor doesn't do much for curing the overlap with the tf2 kit; been there, done that. i think most people ignore the heavy throttle pressure spring that's in the kit. that spring, in my opinion, is too heavy and creates issues.

Posted By: John_Kunkel

Re: A727 Transgo TF-2 install - 11/24/14 09:44 PM

Quote:

Where is the later year .125 orifice located in the separator plate? I'm wondering if this is one of the holes that Transgo instructs to open up, then you install a .140 orific in the housing. This doesn't make any sense. Even if not modified, why install a plug with a larger hole than the plate.

Yes, Transgo instructs you to enlarge this hole...the thought being it's easier to manipulate the orifice in the case.

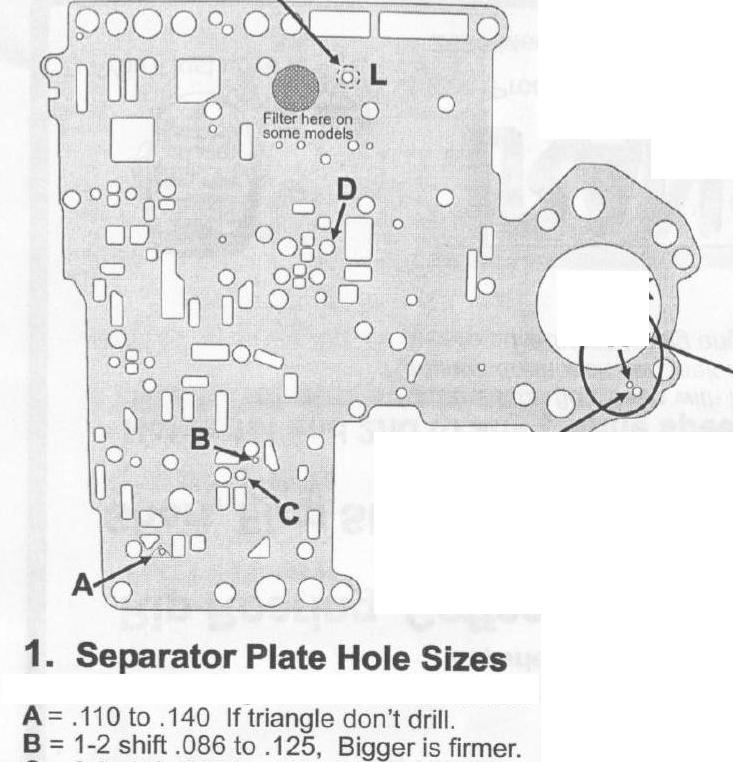

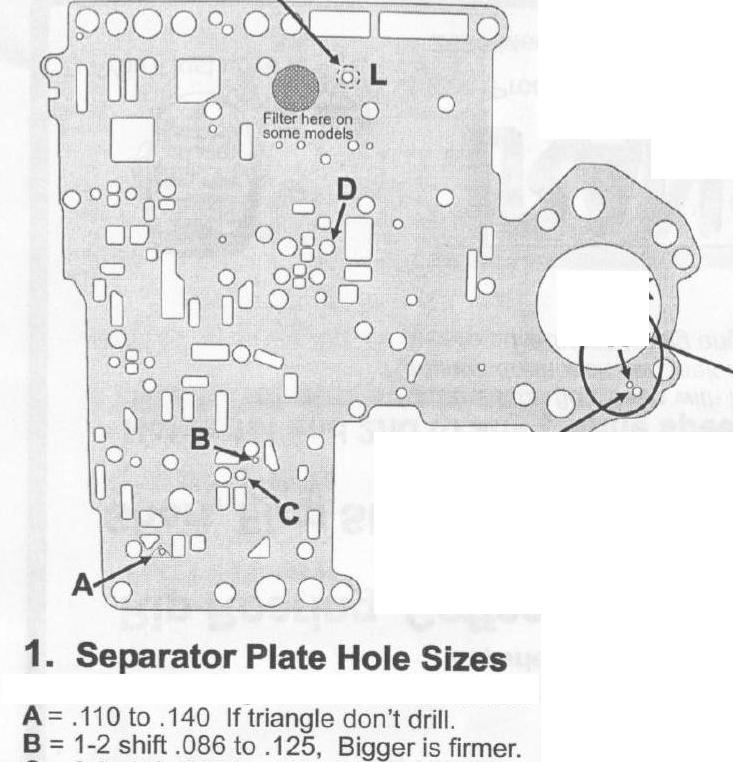

In the pic below D is the front clutch feed (3rd gear) and B is the kickdown servo feed (second gear).

Posted By: mopar67440

Re: A727 Transgo TF-2 install - 11/24/14 10:28 PM

The valve body I modified was a 1971 w/ part throttle KD to be used in a 1974 trans that we rebuilt. When I went to mod the VB, we found the seperator plate had some rust & pits in it from water that entered the case. I also discovered a few of the Transgo mods were performed, so we decided it was best to not use the 74 VB and to start fresh w/ the 71 VB.

Per the instructions for high stall convertor, street/strip, & firmest shift, I opened up A, C, D to .187" L looked like it was already opened up by someone to .187" I never thought to check the case for an orifice, but I suspect there was one.

B was left alone and I removed the .125" bearing.

Looks like I definitely need to install the .140 plug minimum.

Posted By: John_Kunkel

Re: A727 Transgo TF-2 install - 11/24/14 11:29 PM

Quote:

B was left alone and I removed the .125" bearing.

Removing the .250" bearing pretty much overrides the size of the B orifice.

Posted By: mopar67440

Re: A727 Transgo TF-2 install - 11/26/14 03:37 AM

ok...so I think I basically have a handle on where this is going. It's really down to taking the valve body for a spin to see what issues if any I might have to deal with(shift rpm at wot in drive...hopefully around 6k based on engine combo, 2-3 overlap or flareup).

Still not confident on the PR adjustment being flush vs the stock 1 5/16". Even Munroe skips this in the TF-2 details. Maybe flush is ok with the added spring tension, and I can always throw a gauge on it to measure line pressure if there are shift issues.

Also decided to simply go with Dex/Merc ATF, and not type F or synthetic.

Thanks for all the help!

Posted By: John_Kunkel

Re: A727 Transgo TF-2 install - 11/26/14 10:28 PM

PR setting depends on the spring, a stiffer spring allows the adjuster to be flush. Go with the instructions for your kit.

Posted By: mopar67440

Re: A727 Transgo TF-2 install - 11/27/14 01:30 AM

Yes I plan to leave it flush for now with the additional spring tension and spacers.

I still find it odd that the kit instructions dated Nov 2011, make no mentioned of an adjustment, and Munroe's handbook 1st edition 2003 where on page 107 the kit install is detailed, there is no mention either. This leads me to believe it's left at the factory 1 5/16". I suspect line pressure then is well over 100 psi with the kit.

That said, what can I expect for line pressure? Stock is 54-60 psi at 1k rpms, and 90-96 psi with TV fully depressed, and f/r servo within 3 psi of line.

Posted By: mopar67440

Re: A727 Transgo TF-2 install - 11/27/14 03:17 AM

"Dorman 3/8" cup expansion plugs part #555-115 is what I use"

Dave...I like the idea. Certainly cheap and easy enough to drill and install. One question... similar to the Transgo .140 orific, I'm curious how you remove the plugs?

Posted By: DaveRS23

Re: A727 Transgo TF-2 install - 11/27/14 04:14 PM

I screw a sheet metal screw into it and use a claw hammer or wrecking bar to lever the screw out. Quick and easy.

Posted By: mopar67440

Re: A727 Transgo TF-2 install - 12/03/14 04:42 PM

I ordered 3 of the Dorman plugs, and plan on drilling them out to .125, .110, 095.

Will most likely start with the .125 vs the .140 provided in the kit, then depending on results, make a change up or down.

Thanks for the suggestion.

Posted By: DaveRS23

Re: A727 Transgo TF-2 install - 12/04/14 02:05 AM

Start with the .110. Starting there may save a tear down. Let us know how it goes.

Posted By: mopar67440

Re: A727 Transgo TF-2 install - 12/04/14 09:49 PM

Will provide an update once the engine/trans are installed and broken in. Should be in the next few weeks. What a xmas present

Any idea on what the Transgo TF-2 kit pressures would be if I throw gauges on the various ports?

Posted By: DaveRS23

Re: A727 Transgo TF-2 install - 12/05/14 01:22 AM

With the heavier replacement spring backed all the way off, mine are usually around 100lbs at kick-down.

Posted By: mopar67440

Re: A727 Transgo TF-2 install - 12/05/14 04:27 PM

Is that 100 psi at around 1k rpms with TV fully depressed? If so, that's just a bit above stock.

Posted By: DaveRS23

Re: A727 Transgo TF-2 install - 12/06/14 02:44 AM

Yes, at fast idle with the kick-down nearly all the way back. With the original spring, my line pressure was 85 to 90lbs. At 100lbs or so, there isn't as much spread in RPM between the 1-2 and the 2-3 shifts.

I had 125lbs or so for awhile but that caused the 1-2 shift to be several hundred RPM higher than the 2-3. Even with A&A's springs, the two shifts were too different for me. Besides, with the line pressure at 100lbs or so, the low speed shifts are much smoother. Which is nice running around town.

With 100lbs of line pressure the tranny seems to hold up okay. It has been there for a couple of years now.

Posted By: mopar67440

Re: A727 Transgo TF-2 install - 12/06/14 04:09 PM

I'm guessing the 125 line pressure was with the adjustment at 1 5/16" which is approx 6 turns from flush, and raises pressure approx 16-20 PSI. I presonally wouldn't mind the rpm diff or firmer 1-2 shift being a weekend driver.

Posted By: 451Mopar

Re: A727 Transgo TF-2 install - 12/06/14 08:07 PM

I agree, trans go changed the throttle pressure spring and instructions several years ago, so go by the instructions that came in the kit.

When I rebuilt my transmission, I tapped the front clutch apply hole for an aluminum plug that I drilled slightly larger than the plug that came in the kit. That makes it easy to remove, and change the restriction size, but seemed like overkill since I never changed it.

Posted By: mopar67440

Re: A727 Transgo TF-2 install - 12/06/14 08:59 PM

"I agree, trans go changed the throttle pressure spring and instructions several years ago, so go by the instructions that came in the kit.

"

451Mopar...that's where the confusion arrises. As pointed out earlier in the thread, the instructions I have with the kit dated Nov 2011, there's no mention of adjustment after springs are installed. Only the TP/TV bracket adjustment for 1 7/8". Therefore, one has to assume you leave it at the factory 1 5/16" adjustment. Only after extensive on-line research did I find it's set flush.

I screw a sheet metal screw into it and use a claw hammer or wrecking bar to lever the screw out. Quick and easy.

I screw a sheet metal screw into it and use a claw hammer or wrecking bar to lever the screw out. Quick and easy.