Posted By: EvilScamp

Roller rocker spacing? - 03/02/14 01:28 AM

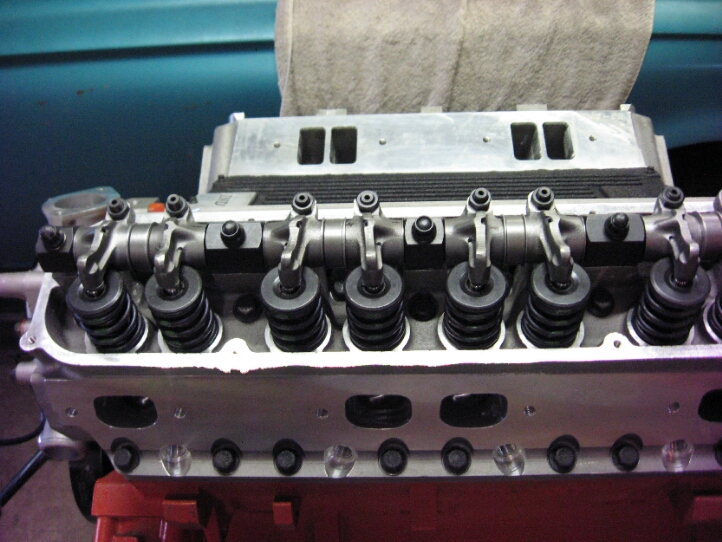

I have a 383 i'm setting up the roller rocker spacing, i know that it should be between .015 and .030 most of mine are .030 but i have 2 or 3 that are .032.

Is this to much or can i getaway without shimming them anymore?

Is this to much or can i getaway without shimming them anymore?

I try to focus on getting the roller tip as close to the center of the valve stem as possible and once that is done I work on the side clearances on each pair. Looser is better than a tiny bit to tight

I try to focus on getting the roller tip as close to the center of the valve stem as possible and once that is done I work on the side clearances on each pair. Looser is better than a tiny bit to tight

FUN!? Everytime you get it right you put everything together and one of the inner cylinders is about .05 too tight.

FUN!? Everytime you get it right you put everything together and one of the inner cylinders is about .05 too tight.

I wouldn't swap rocker assemblys from side to side once their set up, let alone set them up on another head and then expect them to be correct for a head that may be a different brand or casting number

I wouldn't swap rocker assemblys from side to side once their set up, let alone set them up on another head and then expect them to be correct for a head that may be a different brand or casting number