Posted By: 71nonRT340shaker

Running a block w/broken pass side bellhousing mount? - 02/19/14 02:53 AM

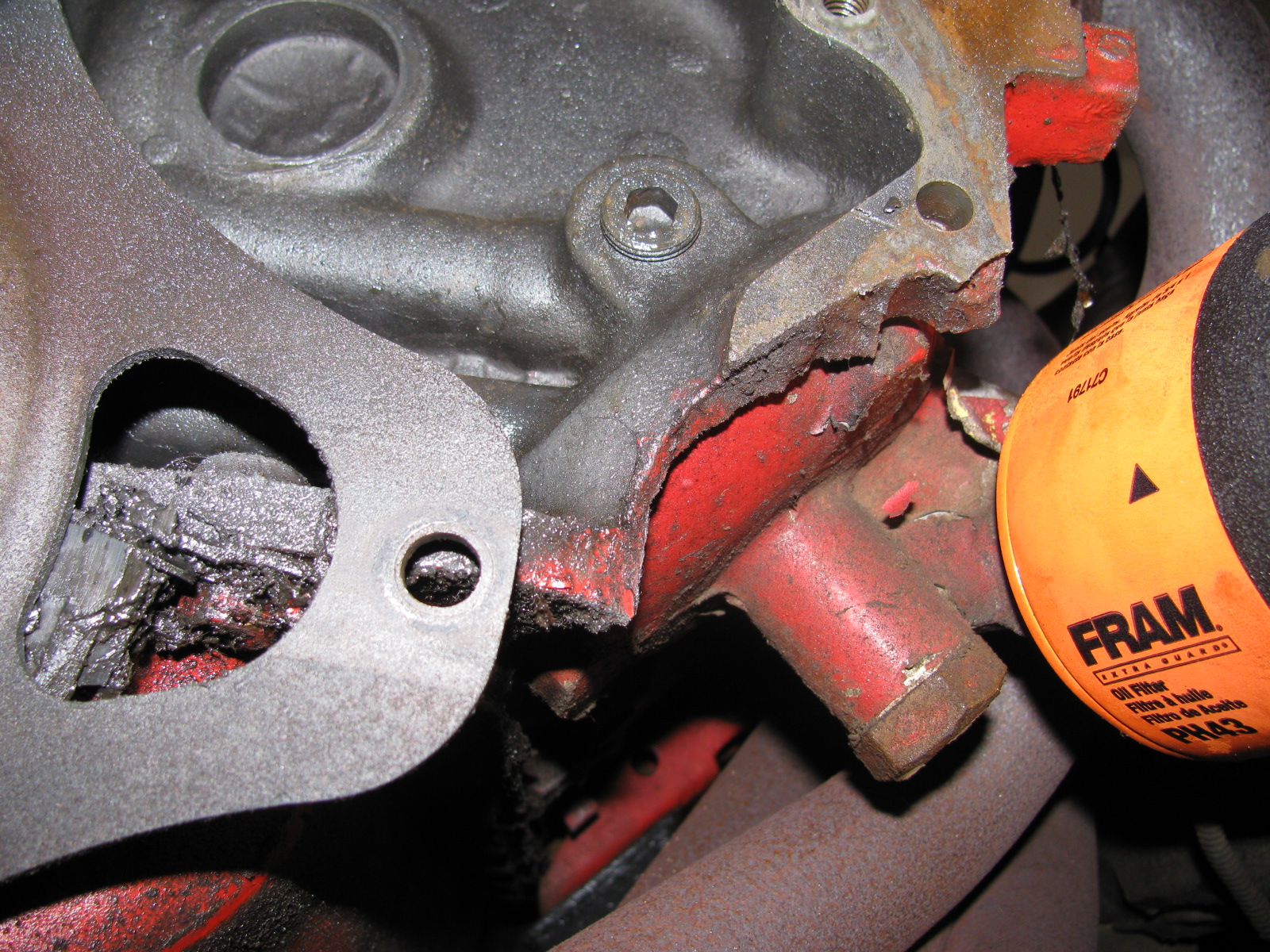

Has anyone had any sort of luck when it comes to running a block that has the pass side rear mount/dowel area broken? My car shook like crazy, when I bought it years ago it wasn't running and may have very well saved the car. Dave at ATI spun the 10" converter that was in the car and found it to be 30 grams (about an ounce) out of round. Long story short I have a new 10" ATI converter, new flex-plate, ARP bolts for plate and converter. The trans was rebuilt including a new pump and bushing kit, also has a bolt in sprag all done locally by Will that runs the Ornery Cuss 72 Dart race car that has been around Pa for decades. It's taken 6 months to get everything rounded up/paid for and I for whatever reason missed the fact that the factory alignment dowel is completely AWOL. The dowel hole that you see in the pics was obviously added to the block and trans. The pin was pushed through the back side of the trans so when the two were mounted up the first time back in 83 they didn't make sure both pins were doing their job.

What next? Risk 2k worth new parts and a trans rebuild, or who knows how much to replace a solid 340 that runs great but is missing a key component? I'm torn but leaning towards taking my chances with what I have. The car wont be raced, and if it's driven over 500 miles a year that'd be a lot even with a 180 mile round trip to Carlisle. Thanks in advance, TC.

Also I'd like to add that in the event it would cure alignment issues I'm not afraid to use a mid-plate on the car and use spacers for the converter. I'm aware nothing about this is ideal but if I had to guess I would say the converter issue was due to neglect or even being a 'great deal' piece that should have been never been put in the car 30 years ago.

Here's a link to my last posts about the car and trying to troubleshoot from September: older post

What next? Risk 2k worth new parts and a trans rebuild, or who knows how much to replace a solid 340 that runs great but is missing a key component? I'm torn but leaning towards taking my chances with what I have. The car wont be raced, and if it's driven over 500 miles a year that'd be a lot even with a 180 mile round trip to Carlisle. Thanks in advance, TC.

Also I'd like to add that in the event it would cure alignment issues I'm not afraid to use a mid-plate on the car and use spacers for the converter. I'm aware nothing about this is ideal but if I had to guess I would say the converter issue was due to neglect or even being a 'great deal' piece that should have been never been put in the car 30 years ago.

Here's a link to my last posts about the car and trying to troubleshoot from September: older post

I would be tempted to find a empty SB 727 case and indicate the front pump sealing area to verify how much run out is on it, if it is more than .030 total run out I would buy some offset dowels and correct it. My message is the motor is already broken so make the trans alignment as good as you can to lessen the chance of damaging anything else form that problem

I would be tempted to find a empty SB 727 case and indicate the front pump sealing area to verify how much run out is on it, if it is more than .030 total run out I would buy some offset dowels and correct it. My message is the motor is already broken so make the trans alignment as good as you can to lessen the chance of damaging anything else form that problem

You can get the corner welded back on(Tig Welded

You can get the corner welded back on(Tig Welded

) by a competent machine shop, find another junk SB and make a donor out of it

) by a competent machine shop, find another junk SB and make a donor out of it  It didn't even hurt the cranshaft

It didn't even hurt the cranshaft

I had another broken block and cut that corner off and had our local Hi Po machine shop weld the new corner on, as far as I know that rascal is still going down the road pushing a big (42 ft)class A motor that a freind of mine talked me out of that motor for

I had another broken block and cut that corner off and had our local Hi Po machine shop weld the new corner on, as far as I know that rascal is still going down the road pushing a big (42 ft)class A motor that a freind of mine talked me out of that motor for