Moparts

Degree a cam for the 1st time. What a PITA. * UPDATE*

Posted By: Kern Dog

Degree a cam for the 1st time. What a PITA. * UPDATE* - 07/25/13 02:50 AM

I've built several engines over the years, but soon I'll do what I have yet to do : Degree in a camshaft.

The 440/493 in the Charger has had detonation problems for years. I've determined that the 185-192 PSI cranking numbers are too high for pump 91 gasoline. I have had to limit ignition timing to 30-31 degrees and

still had to feather-foot it in hot weather to avoid the knock.

Upon the guidance and advice from some helpful members here and other web forums, it was made clear that my 10.7 compression ratio and the 292/509 MP cam are a mismatch. I'd either need to lower the compression or change to a different cam. If I changed to dished pistons, the cylinder pressure and cranking PSIs would come down. If I kept the pistons but instead changed the cam to a more aggressive stick with a

later intake closing, the cylinder pressure and cranking PSIs would come down. The difference between the two?

Changing the cam will unleash much more power. Guess which way I decided to go???

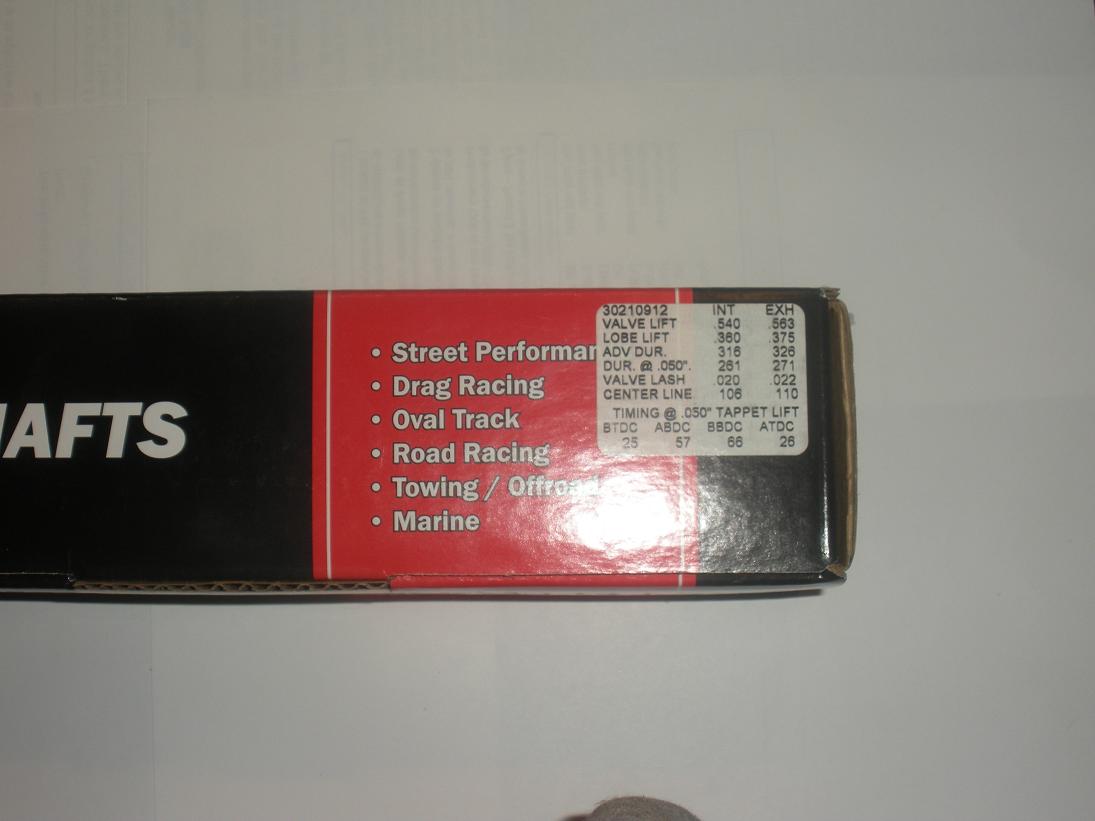

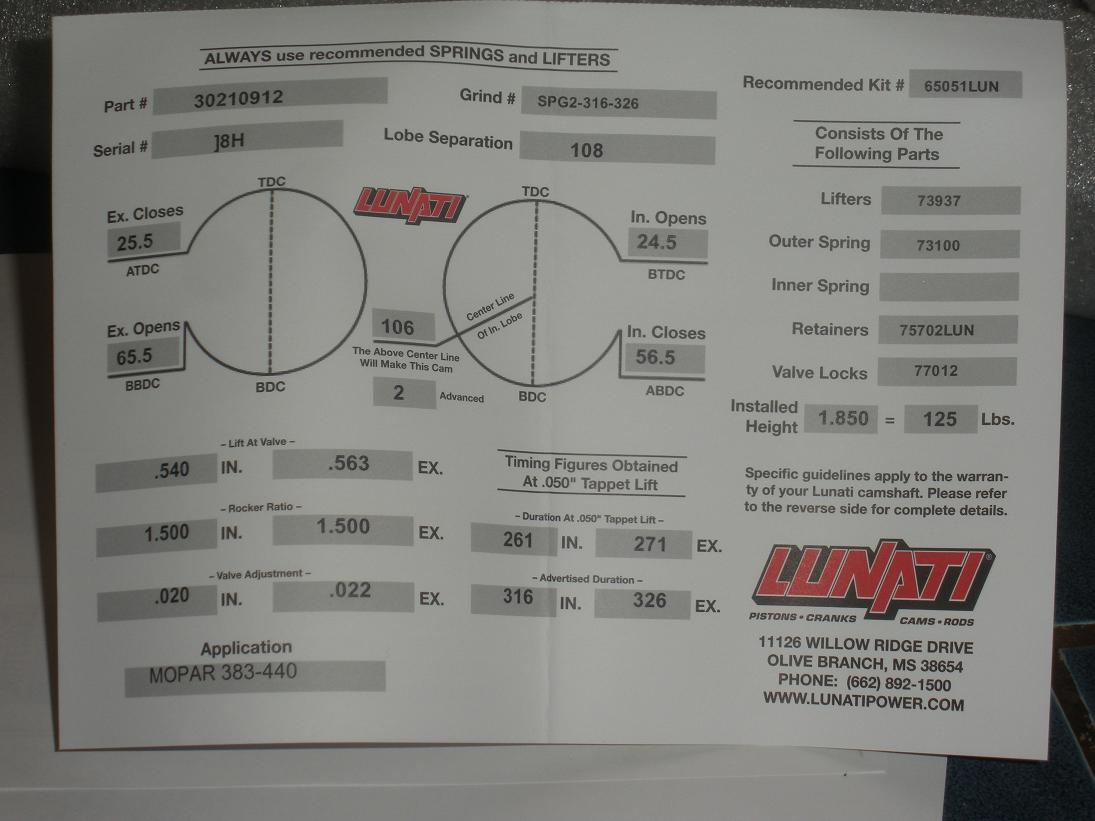

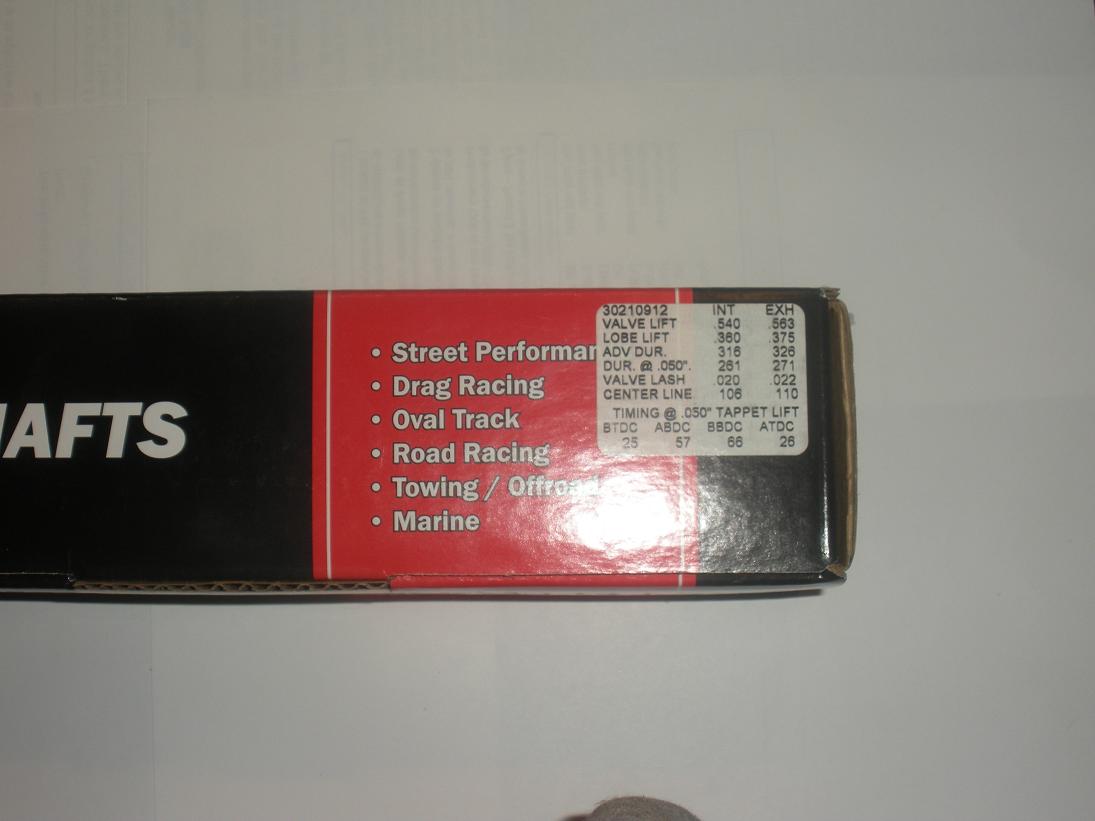

A member of another site forum suggested the cam. It is a Lunati solid flat tappet and it is much more aggressive compared to the MP 509. Check out these specs:

Posted By: Kern Dog

Re: Getting ready to degree a cam for the first time. - 07/25/13 02:52 AM

I decided to go with the Lunati EDM type lifters. Man, these things look like an hourglass!

Posted By: Kern Dog

Re: Getting ready to degree a cam for the first time. - 07/25/13 02:59 AM

I'm just learning about some of this...

The wide band in the center of the lifter will allow oil flowing through the gallery to build. The hole shown in the scribed line shows where the oil enters the body of the lifter. From there, it runs to the center of the bottom face of the lifter.

Posted By: Kern Dog

Re: Getting ready to degree a cam for the first time. - 07/25/13 03:00 AM

I went with a one bolt cam.

Posted By: BSB67

Re: Getting ready to degree a cam for the first time. - 07/25/13 03:02 AM

You keep saying "more aggressive", but I think you mean larger, as that is not really an aggressive cam. Sounds like it might be perfect for you, and your power should go up. Good luck. Let us know how it goes.

Posted By: Kern Dog

Re: Getting ready to degree a cam for the first time. - 07/25/13 03:07 AM

Quote:

You keep saying "more aggressive", but I think you mean larger, as that is not really an aggressive cam. Sounds like it might be perfect for you, and your power should go up. Good luck. Let us know how it goes.

I guess it is all relative. The '509 has about 248 degrees of duration @ .050. This cam steps it up to 261/271 IN/EX. The lift jumps to .558/.578 after deducting the lash. ( Considering the 1.6 ratio rocker arms)

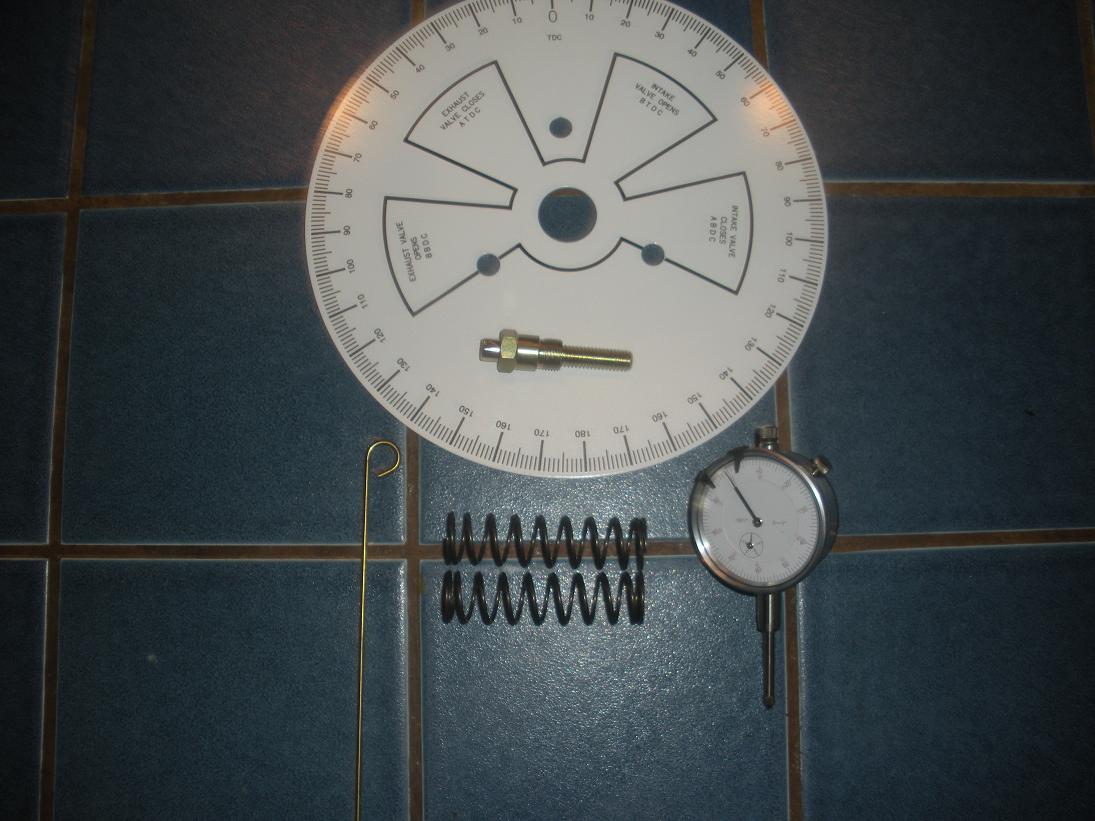

The kit I bought has a 9 " wheel, a piston stop, two light checking springs.....

Posted By: Kern Dog

Re: Getting ready to degree a cam for the first time. - 07/25/13 03:08 AM

Also a dial indicator and attachments, plus a pointer.

Posted By: Kern Dog

Re: Getting ready to degree a cam for the first time. - 07/25/13 03:13 AM

The specs seem pretty rowdy to me, but keep in mind the 292/509 is the biggest cam I've ever ran before.

Posted By: BSB67

Re: Getting ready to degree a cam for the first time. - 07/25/13 03:17 AM

Aggressive is used to describe the rate of lift, from seat to 0.050", and to .200".

The cam you got will lower your cylinder pressure, increase power, and be easy on parts. It'll have a lot of rumpity-rump.

Posted By: Kern Dog

Re: Getting ready to degree a cam for the first time. - 07/25/13 03:23 AM

The degree kit came with instructions. I've read about the process before and looked at some videos on Youtube. I actually did find 2 guys here in town that could bail me out if/when I run into a snag.

The main issue I have is WHAT DO I DO if the cam comes in with an error? The timing set I have is an Edelbrock #7804. It has 3 keyways: 4* ADV, Zero, 4* RET. The cam card shows it has 2 degrees of advance ground in on a 108 centerline. Does this mean it should be set to 106?

IF I determine that it is off by 4 degrees, I could easily switch the crank gear to advance or retard. What if it is 2-3 degrees off? The one bolt cam style has a dowel that fits into a hole in the cam gear. To get the additional offset, am I supposed to oval out the hole in the cam sprocket and use a wedge? Sorry to be such a pest on this. I have asked that question several times and if anyone had answered it, I must have missed it.

I hope to start in on the engine on Friday.

Posted By: Cab_Burge

Re: Getting ready to degree a cam for the first time. - 07/25/13 03:24 AM

Posted By: Kern Dog

Re: Getting ready to degree a cam for the first time. - 07/25/13 03:27 AM

How do you check piston to valve clearance with the heads on the car?

I have those checking springs that came with the degree wheel kit. Do I install them, then check how much more they can move at TDC?

Posted By: Cab_Burge

Re: Getting ready to degree a cam for the first time. - 07/25/13 03:39 AM

Quote:

How do you check piston to valve clearance with the heads on the car?

I have those checking springs that came with the degree wheel kit. Do I install them, then check how much more they can move at TDC?

remove the current valve springs and use the checking springs, then when the #1 piston is coming up to TDC (I start checking 15 to 20 degrees before top dead center on both valves and until it stops getting closer on the intake valves) put the dial indicator on the valve retainer aligned with the valve stem as close to perfect alignment as you can get it when both valves are closed(set the lash first) and then see how much lift you have when it starts getting close to max valve openimg and check by pushing the valves down GENTLY when the piston is near TDC until the valve touches the piston, see how much clearance you have on the dial indicator

I like to see .080 on the intakes and exhaust on a 4 speed car with good valve springs, a little closer is usually okay on a automatic trans. race car, .060 on the intakes and .080 on the exhaust sides

I like to see .080 on the intakes and exhaust on a 4 speed car with good valve springs, a little closer is usually okay on a automatic trans. race car, .060 on the intakes and .080 on the exhaust sides  Some cam grinders like to see .120 and some like .080

Some cam grinders like to see .120 and some like .080  I've accidently ran .030 on the intakes and .055 on the exhaust on my old M.W. stocker a long time ago with no damages

I've accidently ran .030 on the intakes and .055 on the exhaust on my old M.W. stocker a long time ago with no damages  Long story

Long story

Posted By: Kern Dog

Re: Getting ready to degree a cam for the first time. - 07/25/13 04:09 AM

Quote:

Aggressive is used to describe the rate of lift, from seat to 0.050", and to .200".

Okay, I wasn't aware of that. I thought bigger/more lift& duration meant aggressive. Your description makes more sense though. Thanks. I'm always willing to learn.

********************************************************************

Thanks to you too, Cab. Your method sounds like the same as I was thinking. The specs are a big help too.

Posted By: RapidRobert

Re: Getting ready to degree a cam for the first time. - 07/25/13 02:53 PM

Quote:

The main issue I have is WHAT DO I DO if the cam comes in with an error? What if it is 2-3 degrees off? The one bolt cam style has a dowel that fits into a hole in the cam gear. To get the additional offset, am I supposed to oval out the hole in the cam sprocket and use a wedge? Sorry to be such a pest on this.

Not being a pest at all as that's what we're here for is to help each other/solve problems. You would drill out the hole the dowel fits into to a larger OD then get the cheap bushing kit for this which has a hole drilled in each one but the hole is offset so you turn it to adv or ret 1 or 2 or 3 & so on degrees. A pic on mancini or similar site will let you grasp it better than a written descrip. OT I'm assuming that you are set on the octane you'll use. If that's a measured SCR it is real high (for your octane). What about opening up the chambers (unshrouding the valves on the ends works well for more flow also) or deependng the valve notches or thicker head gaskets if you have no quench or a combination of one or more of the above or maybe even a piston change which may very well require rebalancing. Just me & I may be way off here but the 509 is an old school wild cam & I cant see that going more wild with a cam will get the the DCR down to where you can run the octane you desire. Just me I'd feed this monster the octane it wants (& needs) & put the exact cam in there you want for your driving style rather than having to compromise your driveability with a wilder cam to run the inadequate octane you want & I dont think ANY cam is going to lower the DCR enough OR bite the bullet & do it right & lower the SCR & put the corect cam in there to suit your driving. You'll be happier in the long run. Holler how it turns out

Posted By: GTX MATT

Re: Getting ready to degree a cam for the first time. - 07/25/13 03:04 PM

If you come up less than 2 degrees of where it should be, leave it, as 1 degree isn't enough to warrant moving it for a minimal difference (maybe on a SuperStock car or something similar but not in your case). I like to err on the advanced side as far as error goes, i.e. the cam in my engine had a recommended centerline of 106, I installed it straight up and measured it with a 104.5 installed centerline. This is almost perfect, since the timing chain will stretch a bit and probably put me at 105-106 in a few thousand miles. From what I've seen chains stretch pretty fast initially (they're really tight when installed but it doesn't last long).

Posted By: Challenger 1

Re: Getting ready to degree a cam for the first time. - 07/25/13 05:03 PM

Posted By: Dodgem

Re: Getting ready to degree a cam for the first time. - 07/25/13 05:47 PM

What kind of heads?? You sure the fire wire on the fel pro gaskets is not hanging in the combustion chamber and glowing red hot?? a common problem.

Lean jetting and too low a power valve number can cause light throttle ping too!

Posted By: Supercuda

Re: Getting ready to degree a cam for the first time. - 07/25/13 06:09 PM

You know there is a way to degree a camshaft that uses feeler gauges rather than a bunch of math and such, Feb 97 Mopar Action has it in there I believe.

Posted By: Kern Dog

Re: Getting ready to degree a cam for the first time. - 07/25/13 06:58 PM

Quote:

You know there is a way to degree a camshaft that uses feeler gauges rather than a bunch of math and such, Feb 97 Mopar Action has it in there I believe.

A guy on FBBO told me about that trick. It involved using 2 deep well sockets sitting in place of the lifters. You center the cam between the closing ramp of the exhaust and the opening ramp of the intake while at TDC of the exhaust stroke. The OD of the deep well sockets needs to be really close to the size of the .904 Mopar lifter. THERE lies the problem. 5/8" and 16 mm sockets measure .85. the 11/16" and 17 mm measure .94/.95, so that is out. I don't know if the lip on these solid lifters sits above the lifter boss. If so, I could just use them as I would ise the taller deep sockets.

*********************************************************************

Regarding the detonation:

The reason that I went with the bigger cam isn't just because of the higher lift and duration numbers. It is also because of the later point when the intake valve closes. Because the intake valve hangs open longer, this means that less pressure is built for each compression cycle. This will reduce the cranking PSI and the Dynamic compression while allowing the engine to run on 91 octane with more spark advance.

**********************************************************************

When I chose the '509 cam for this engine, I thought I was making the right move. At that time, Mopar performance offered a crate 440/500 that used the same cam. Their engine was built with 9.0 compression. I thought I'd have an edge on power since my engine was going to have almost 2 point more squeeze. I absolutely had no clue of the close relationship of compression and camshafts! My ignorance led to an engine that sounds great and runs okay until I tried to mash it to the floor. Yeah, I've ran it on Sunoco 110. the knock did go away, but I wanted to run the car on pump gas. This was/is because I like to drive the car on road trips. I didn't want to resort to questionable octane boosters either.

On some of this stuff, I am only relaying what I have read and heard. The well chosen combination of compression and camshafts is how some engines can make ungodly power while running pump premium. I am hoping to be that guy.

Posted By: Kern Dog

Re: Getting ready to degree a cam for the first time. - 07/25/13 07:04 PM

Quote:

What kind of heads?? You sure the fire wire on the fel pro gaskets is not hanging in the combustion chamber and glowing red hot?? a common problem.

Lean jetting and too low a power valve number can cause light throttle ping too!

Edelbrock aluminum heads. The block bore is 4.35 and the gasket bore is 4.410. Pretty close, but I should be okay there.

Regarding the jetting, I'm running a Demon 850 with 85/92 jets and a 3.5 PV. I'll agree the PV is too small. The knocking I get though is at full throttle.

I have a few other PVs to use in the parts stash.

Posted By: 67Satty

Re: Getting ready to degree a cam for the first time. - 07/25/13 07:05 PM

There is an article about the straight edge method in the May '97 High Performance Mopar.

They say a Craftsman deep 17mm socket is just a couple thousandths shy of the Mopar lifter bore I.D. and tall enough to protrude so you can lay your straight edge across.

They claim they've double-checked the straight edge method against using a degree wheel and found no difference in results.

Posted By: Kern Dog

Re: Getting ready to degree a cam for the first time. - 07/25/13 07:09 PM

I was at Sears yesterday. The Craftsman sockets must have been redesigned since the article came out. The ones I measured were .95 in diameter. I was hoping to try that method.

Posted By: 67Satty

Re: Getting ready to degree a cam for the first time. - 07/25/13 07:14 PM

You could measure the ID of the lifter bore and then just find whatever deep socket has an OD that will fit in there.

Posted By: Kern Dog

Re: Getting ready to degree a cam for the first time. - 07/25/13 07:17 PM

I tried!

I measured all sorts of sockets at Sears. I thought the clerk was going to kick me out.

I measured the impact sockets, the standard chrome sockets, the shallow sockets....

I went to an auto parts store and measured their sockets.

I measured some of my old sockets. Since I'm an American car guy, I had no 17 mm sockets to measure.

Posted By: Supercuda

Re: Getting ready to degree a cam for the first time. - 07/25/13 07:18 PM

Quote:

I was at Sears yesterday. The Craftsman sockets must have been redesigned since the article came out. The ones I measured were .95 in diameter. I was hoping to try that method.

You putting new lifters in?

Then use two old lifters glued together to be tall enough, if need be.

Posted By: RapidRobert

Re: Getting ready to degree a cam for the first time. - 07/25/13 08:43 PM

Quote:

Then use two old lifters glued together to be tall enough.

Exactly what I was thinking

Posted By: dogdays

Re: Getting ready to degree a cam for the first time. - 07/25/13 09:22 PM

The split overlap method is a quick-and-dirty way to get a cam in straight up, works well with camshafts that:

a. have a single pattern lobe, AND

b. have a symmetrical lobe.

Most modern camshafts don't have symmetrical lobes, that is they open the valve quickly and close it a little slower to avoid valve bounce. Plus most aftermarket cams have split duration meaning the exhaust lobe is more duration than the intake.

Split overlap doesn't work so well on those!

R.

Posted By: Dodgem

Re: Getting ready to degree a cam for the first time. - 07/26/13 01:32 AM

I think it is the edelbrock heads that leave a bit of the fire ring exposed in to places??

I would definatly go with a higher number PV 1.5 to 2 under in gear idle vacuum works out about right on a performance engine. so if you have 8.5 a 6.5 will work if you have 7.5 a 5.5 if you have 10 or 11 a 7.5 as the vacuum gets higher the spread can be more. to small no extra fuel on light to medium acceleration so lean ping.

definetely go the bigger cam it is still small by 493 standards. 4000 stall will help reduce ping too!

O degree the cam right don't try any back yard or back woods red neck short cuts! IMHO!!!!

Posted By: Kern Dog

Re: Getting ready to degree a cam for the first time. - 07/26/13 02:17 AM

The Holley site suggested to take the idle vacuum number and use a PV that is 1/2 that number. I was running about 8-9 inches of vacuum at an in gear idle, so I went with the 3.5. I do have several others to try. After the cam swap I'm sure that the idle vacuum will be different. I may have to adjust the idle speed above the 600 rpms in gear! Is it fair to guess that a bigger cam will need a higher numbered Power Valve?

Posted By: Cab_Burge

Re: Getting ready to degree a cam for the first time. - 07/26/13 04:29 AM

Quote:

I may have to adjust the idle speed above the 600 rpms in gear! Is it fair to guess that a bigger cam will need a higher numbered Power Valve?

I look at the rpm change from nuetral to in gear, 150 to 200 RPM is good  1000 RPM in nuetral, 800 to 900 in gear

1000 RPM in nuetral, 800 to 900 in gear

As far as the numbers on the power valves, bigger cams idling at lower RPM make less manifold vacume so you should be good with the 3.5 if it has 7.0 or higher vacume inches idling in gear

As far as the numbers on the power valves, bigger cams idling at lower RPM make less manifold vacume so you should be good with the 3.5 if it has 7.0 or higher vacume inches idling in gear

You wouldn't want to try a 6.5 power valve in a motor that has 7.0 inches idling in gear

You wouldn't want to try a 6.5 power valve in a motor that has 7.0 inches idling in gear

Posted By: Kern Dog

Re: Getting ready to degree a cam for the first time. - 07/26/13 05:14 AM

Quote:

You wouldn't want to try a 6.5 power valve in a motor that has 7.0 inches idling in gear

In 2005 I took the car to a dyno shop. The man recurved the distributor and tweaked the carb. He changed the power valve to a 6.5 too. Much later as I was trying to diagnose an engine smoke issue, I tried the 3.5 PV.

What are the effects of running the higher rated valve? Does it make the engine run leaner during transition from the primaries to the secondaries?

Posted By: Cab_Burge

Re: Getting ready to degree a cam for the first time. - 07/26/13 08:01 AM

The power valve enrichens the primary circuit(front two barrels) at the vacume level or below that level the power valve is rated at, a 6.5 power valve will open and stay opened at or below 6.5 inches of vacume, same thing on the 3.5, it will open and stay opened at or belwo 3.5 inches of manifold vacume. IHTHs Some racers use the power valve enrichment channel to add or reduce fuel into that circuit by enlarging or reducing those hole in the metering blocks

That is a fine tuning option at WOT

Posted By: Kern Dog

Re: Getting ready to degree a cam for the first time. - 07/26/13 08:05 AM

Seems I can be a little slow sometimes.

This means that by going to the lower rated 3.5 valve, I made the carb run leaner than with the 6.5?

Posted By: Cab_Burge

Re: Getting ready to degree a cam for the first time. - 07/26/13 07:41 PM

Quote:

Seems I can be a little slow sometimes.

This means that by going to the lower rated 3.5 valve, I made the carb run leaner than with the 6.5?

Not at WOT  the 3.5 opens at a lower manifold vacume, both P.V. will be opened at WOT

the 3.5 opens at a lower manifold vacume, both P.V. will be opened at WOT  The 6.5 will open sooner at part throotle cruise than the 3.5 will

The 6.5 will open sooner at part throotle cruise than the 3.5 will

The main thing to check before selecting the power valve to use is to check the manifold vacume with the trans in gear, then select a power valve that is 1 to 2 inches lower than idle vacume

The main thing to check before selecting the power valve to use is to check the manifold vacume with the trans in gear, then select a power valve that is 1 to 2 inches lower than idle vacume

I had the same saet of six pak carbs on several different motors, one with abg cam and another with a lot smaller cam, 518 C.I. versus 446 C.i. The big motor wanted a 2.5 P.W., it had 4.5 inches vacume idling in gear at 850 RPM

I had the same saet of six pak carbs on several different motors, one with abg cam and another with a lot smaller cam, 518 C.I. versus 446 C.i. The big motor wanted a 2.5 P.W., it had 4.5 inches vacume idling in gear at 850 RPM  the 446 C.i. motor had over 8.0 inches idling in gear, I found out that the little motor would make vacume in high gear at WOT on a 1/4 mile track making the 2.5 power open and close

the 446 C.i. motor had over 8.0 inches idling in gear, I found out that the little motor would make vacume in high gear at WOT on a 1/4 mile track making the 2.5 power open and close  I put a 6.5 in it and that fixed the problem

I put a 6.5 in it and that fixed the problem  I had to put the lower(2.5) P.V. back in the center carb for the bigger motor when i put those carbs. back on it

I had to put the lower(2.5) P.V. back in the center carb for the bigger motor when i put those carbs. back on it  Going fast is never easy

Going fast is never easy  Be prepared to work and be disappointed some times while you learn

Be prepared to work and be disappointed some times while you learn

Posted By: Kern Dog

Re: Getting ready to degree a cam for the first time. - 07/30/13 12:35 AM

Quote:

I'm assuming that you are set on the octane you'll use. Yeah, I want the engine to run well on pump premium fuel. Here in CA, we're limited to 91 octane. I want to be able to drive it without having to resort to any sort of octane boosters. What about opening up the chambers (unshrouding the valves on the ends works well for more flow also) or deependng the valve notches or thicker head gaskets if you have no quench I thought of the thicker head gasket idea, but at .056 quench distance, I at least have some quench going on. I'm considering having the heads ported over the winter. I may be way off here but the 509 is an old school wild cam & I cant see that going more wild with a cam will get the the DCR down to where you can run the octane you desire. I agree to a point, but there is more to it. The Lunati has a later intake closing event. This will bleed off some cylinder pressure, reducing the dynamic compression ratio. The goal , and hopefully the result, is to reduce the octane requirements and allow the engine to make more power. Just me I'd feed this monster the octane it wants (& needs) & put the exact cam in there you want for your driving style rather than having to compromise your driveability with a wilder cam to run the inadequate octane you want & I dont think ANY cam is going to lower the DCR enough OR bite the bullet & do it right & lower the SCR & put the corect cam in there to suit your driving. You'll be happier in the long run. Holler how it turns out

I had the engine out in 2011 to deglaze the cylinders and put in new rings. My tuning was waaay off and running too fat for too long wasted the rings. I really should have just replaced the pistons when I had them out. Another idea was to have the valve sides of the pistons milled .040 while leaving the quench side alone. With that, I could run a .027 MLS gasket, gaining quench while still lowering the static compression ratio about 3/10ths of a point.

I just didn't feel like pulling the engine to replace pistons. I've come to understand that a 500 inch engine is UNDERcammed with the '509 anyway.

Posted By: Kern Dog

Re: Getting ready to degree a cam for the first time. - 08/10/13 02:22 AM

It has been awhile, but I'm busy with the project. I'm following the instructions and doing what makes sense, yet I've bent the piston stop twice and the crank hub wont stay tightly in position.

Cranking this engine over isn't easy. As I am leveraging the breaker bar to crank it over, it is hard to determine if the resistance is from the compression OR the piston stop. Am I supposed to take the spark plugs out to allow the engine to spin over easier? I'm pulling them out tomorrow just to see if it helps.

I really didn't want to do a half ass job on this. This is the biggest cam I've ever dealt with and I want to do it right.

Posted By: Dodgem

Re: Getting ready to degree a cam for the first time. - 08/10/13 02:30 AM

Maybe get this piston stop. It has an air bleed and is better stronger.

http://www.summitracing.com/parts/crn-99412-1/overview/get one of these

http://www.summitracing.com/parts/pro-67493I have this one

http://www.summitracing.com/parts/cca-4799Pull all the spark plugs.

And why not the rockers way less work..

Posted By: Dodgem

Re: Getting ready to degree a cam for the first time. - 08/10/13 02:33 AM

Hope these work many helpfull things i saved

If you buy this total kit has video and instructions

http://www.summitracing.com/parts/CCA-4796/another using @ .050 method think it's a ford by where number 1 is

http://www.youtube.com/watch?v=azLX1pi2oVE&feature=relatedplus these to read

http://www.carcraft.com/howto/116_0701_how_to_degree_a_camshaft/video. I like to do the @ .050 but often do both a little extra advance especially on street or heavy cars is a big plus! depending on the cam.

http://www.youtube.com/watch?v=-VwsbEg7Z4I&feature=relatedanother one using .50 before and after max lift method (i do them all :-))

http://www.youtube.com/watch?feature=endscreen&v=bcMuttJ9RFc&NR=1some info! try not to get informatoin overload

http://www.wallaceracing.com/cambasics.htmGenerally in theory they are 0 + 4 and - 4 deg as always a cam should really be degreed in for best performance as they are all over the place with the stacking effect of the crank key, cam key/dowel, bottom gear Keyways and placement of dowel hole or keyway in top gear.

Hear is instructions for a comp cam 3 keyway set

http://static.summitracing.com/global/images/instructions/cca-2100.pdfI just did a 509 that was 7 deg retarded form spec in straight up position the + 4 postion got it withing .5 deg 106.5 on 106 suggested install it was a 4 speed 4.56 gear so runs great but on an auto i would have liked 102 to 104 for better bottom end.

Degreeing in you cam even if you buy a a kit the peformance is day and night when off a few degrees from optimum

kits

http://www.summitracing.com/parts/pro-66787/overview/http://www.summitracing.com/parts/cca-4796/overview/instructions

http://static.summitracing.com/global/images/instructions/pro-66787_camshaftdegreewheelkit.pdf

Posted By: 71birdJ68

Re: Degreeing a cam for the first time. What a PITA. - 08/10/13 02:57 AM

Did you have detonation or pre ignition?

Posted By: Twostick

Re: Getting ready to degree a cam for the first time. - 08/10/13 03:58 AM

Quote:

It has been awhile, but I'm busy with the project. I'm following the instructions and doing what makes sense, yet I've bent the piston stop twice and the crank hub wont stay tightly in position.

Cranking this engine over isn't easy. As I am leveraging the breaker bar to crank it over, it is hard to determine if the resistance is from the compression OR the piston stop. Am I supposed to take the spark plugs out to allow the engine to spin over easier? I'm pulling them out tomorrow just to see if it helps.

I really didn't want to do a half ass job on this. This is the biggest cam I've ever dealt with and I want to do it right.

You will find that once you take out ALL the plugs, things will go much easier.

You will find that once you take out ALL the plugs, things will go much easier.

Once you don't have to muscle it thru compression strokes you will feel it bump the piston stop and you will be able to make 1 degree adjustments if needed.

Kevin

Posted By: Kern Dog

Re: Getting ready to degree a cam for the first time. - 08/10/13 05:48 AM

Kevin, I sure hope so!

Posted By: Kern Dog

Re: Degreeing a cam for the first time. What a PITA. - 08/10/13 05:54 AM

Quote:

Did you have detonation or pre ignition?

Oh yeah.....10.7 compression and a cam that was too small for 500 inches of engine added up to 185-190 cranking compression and a dynamic CR of almost 9.0. I couldn't run even 31 degrees of advance on 91 octane. I ran a mix of 91 and 110 and it didn't knock at all. This cam I swapped in is bigger in every spec including a later intake closing. It should drop my Dynamic CR to aroun 8.10, the cranking comp to under 180 and I should be able to run on 91 octane safely.

Posted By: Kern Dog

Re: Getting ready to degree a cam for the first time. - 08/10/13 05:58 AM

Quote:

Maybe get this piston stop. It has an air bleed and is better stronger.

http://www.summitracing.com/parts/crn-99412-1/overview/

That one looks plenty beefy!

get one of these

http://www.summitracing.com/parts/pro-67493

I have one that looks just like that one!

Pull all the spark plugs.

And why not the rockers way less work..

I was thinking about backing off the rocker arms..... good point!

Posted By: BigBlockMopar

Re: Getting ready to degree a cam for the first time. - 08/10/13 10:21 AM

By the way,

if you still have an open aircleaner, your engine is inhaling 140-150F hot air all the time. This is where part of the ping-problems will be.

Posted By: Kern Dog

Re: Getting ready to degree a cam for the first time. - 08/13/13 07:22 AM

I pulled the plugs today and resumed the degree process. With the plugs out, I was able to feel the piston stop easily. I came up with a 110 number. The cam card shows a 108 LSA with an installed centerline of 106, so I guess I am 4 degrees retarded. I have the 3 keyway type of timing set, so tomorrow I'll switch the crank gear to the 4 degree ADV setting and recheck the numbers.

My piston to valve clearance was a whopping .250 + at TDC ! I checked it at 15 degrees BTDC and ATDC, so I'm sure it is fine there.

I am happy that I didn't just install the cam dot to dot. Thanks to the many that chimed in to help!

Posted By: Cab_Burge

Re: Getting ready to degree a cam for the first time. - 08/13/13 08:14 AM

Quote:

I pulled the plugs today and resumed the degree process. With the plugs out, I was able to feel the piston stop easily. I came up with a 110 number. The cam card shows a 108 LSA with an installed centerline of 106, so I guess I am 4 degrees retarded. I have the 3 keyway type of timing set, so tomorrow I'll switch the crank gear to the 4 degree ADV setting and recheck the numbers.

My piston to valve clearance was a whopping .250 + at TDC ! I checked it at 15 degrees BTDC and ATDC, so I'm sure it is fine there.

I am happy that I didn't just install the cam dot to dot. Thanks to the many that chimed in to help!

Make sure and START checking the P to V clearances at 15 BTDC and keep checking it in 2 or 3 degrees crank travel until the P to V starts to get bigger on both valves

Posted By: Dodgem

Re: Getting ready to degree a cam for the first time. - 08/13/13 01:38 PM

wow 4 deg retarded would be way lazy.

to bad you could not go 2 advanced? :-) I did one last year in the straight up was 7 retarded and in the 4 advanced it came out .5 retarded (106.5) in a 4 speed so all is well!

Posted By: Dodgem

Re: Getting ready to degree a cam for the first time. - 08/13/13 01:45 PM

When you are done and running put a PV that is no more than 1 1/2 to 2 1/2 numbers below your "in gear" idle vacuum I/m guessing a 6.5 will be in the mark. And if your fuel is 10% ethanol go up two jet sizes from stock all the way around.

If it still pings I hate to say the fire rings from the head gaskets my be hanging into the bores/combustion chamber and a bigger 4.5 gasket may be needed.

Posted By: Kern Dog

Re: Getting ready to degree a cam for the first time. - 08/13/13 06:41 PM

Quote:

When you are done and running put a PV that is no more than 1 1/2 to 2 1/2 numbers below your "in gear" idle vacuum I/m guessing a 6.5 will be in the mark. And if your fuel is 10% ethanol go up two jet sizes from stock all the way around.

Interesting point about the Ethanol. Here in CA, our SMOG Nazis set the tone for the nation. My 07 Ram runs fine on the fuel we have. My 75 Power Wagon vapor locks though. The 67 Dart runs fine.

I'm pretty confident that the cam with the later intake closing should make the difference. I was impressed that I had so mich piston to valve clearance.

Posted By: Challenger 1

Re: Degreeing a cam for the first time. What a PITA. - 08/13/13 07:29 PM

Oh wow, yes the plugs have to be out and all the rockers backed off, removed.

Wish someone could be there to show you the first time. it sounds like your doing it in the car which makes it tougher. I always do it on the engine stand when the motor is getting built. I do it with out any pistons(one piston for TDC) and no heads, makes it real easy and fast.

Good luck

Posted By: Kern Dog

Re: Degreeing a cam for the first time. What a PITA. - 08/14/13 01:20 AM

Just as it appeared to be making sense, I run into more troubles.

The crank hub I bought wont stay in position. The Woodruff key is a fraction smaller than the key notch in the hub and I get about a 2 degree slip in the hub when alternating from clockwise to CCW. I cant tell if it is

exactly 2 degrees, just around that much.

I ended up using the crank dampner bolt directly against the degree wheel. I had already moved the crank gear and was set up to degree it at the 4 degree ADV setting. Somehow it went from the 110 C/L to 103. Huh??? How did the switch of 4 degrees get me a 7 degree difference? Add to this the crappy piston stop I've been using. You'd think the dang thing was made from compressed aluminum foil because the part that threads into the head is bent along with the bolt that threads inside it. Pretty hard to get any reliable numbers with such crappy equipment. A few times, the piston stop wanted to thread UNDER the exhaust valve and into the exhaust port! The exhaust valve seats are hardened steel so I'm cautiously optimistic that no damage was done. Maybe I should have established TDC with the rockers totally backed off? I guess this would ensure that the exhaust valve stays closed. The way the piston stop threads into the head at an angle, it is easy to bend it when spinning the engine over. Since it is only 3/8" thick and being bent 2 or 3 times already made it too crappy to trust. I tossed it in the scrap pile.

Moparts member "Dodgem" suggested this:

http://www.summitracing.com/parts/crn-99412-1/overview/I just ordered one. By the look of it, theres not much chance of bending this one.

I'm wondering if the wide spread of degree (110 vs 103) is due to my crappy tools or the Timing set.

Posted By: Dodgem

Re: Degreeing a cam for the first time. What a PITA. - 08/14/13 07:01 PM

Can you tap and thread a set screw or two to help hold crank tool?

The keyways are not exact and the one I did last year went 7 straght up keyway to 4 avanced

Anyway get a good stop. start again take slop out same way each time.

I have this crank tool but put a new set screw i as it was set up more for the GM slots and not the 1/4 inch

http://www.summitracing.com/parts/cca-4799I always take up the slack clockwise lock it inn with the set screw then o in the 0 mark. do all my checks twice when I am all done before i take it apart i recheck o mark.

you will get it.

I had way better luck with homemade stop using a gutted spark plug than the comp cams one.

Posted By: Challenger 1

Re: Degreeing a cam for the first time. What a PITA. - 08/14/13 07:28 PM

Quote:

Just as it appeared to be making sense, I run into more troubles.The crank hub I bought wont stay in position. The Woodruff key is a fraction smaller than the key notch in the hub and I get about a 2 degree slip in the hub when alternating from clockwise to CCW.

. I cant tell if it is exactly 2 degrees, just around that much.

I ended up using the crank dampner bolt directly against the degree wheel. I had already moved the crank gear and was set up to degree it at the 4 degree ADV setting. Somehow it went from the 110 C/L to 103. Huh??? How did the switch of 4 degrees get me a 7 degree difference? Add to this the crappy piston stop I've been using. You'd think the dang thing was made from compressed aluminum foil because the part that threads into the head is bent along with the bolt that threads inside it. Pretty hard to get any reliable numbers with such crappy equipment. A few times, the piston stop wanted to thread UNDER the exhaust valve and into the exhaust port! The exhaust valve seats are hardened steel so I'm cautiously optimistic that no damage was done. Maybe I should have established TDC with the rockers totally backed off? I guess this would ensure that the exhaust valve stays closed. The way the piston stop threads into the head at an angle, it is easy to bend it when spinning the engine over. Since it is only 3/8" thick and being bent 2 or 3 times already made it too crappy to trust. I tossed it in the scrap pile.

Moparts member "Dodgem" suggested this:

http://www.summitracing.com/parts/crn-99412-1/overview/

I just ordered one. By the look of it, theres not much chance of bending this one.

I'm wondering if the wide spread of degree (110 vs 103) is due to my crappy tools or the Timing set.

This why I showed you the crank hub, the black oxide one, it bolts solid to the crank and won't move.

Posted By: Kern Dog

Re: Degreeing a cam for the first time. What a PITA. - 08/14/13 07:42 PM

The crank hub I got has a set screw with an allen wrench head. I tighten it but the dang thing still slips. I pulled it and set it aside. I can't recall the brand it was... Maybe ProForm?

I put the degree wheel directly against the crank and tightened down the dampner bolt. I was able to get it close but the flimsy piston stop didn't inspire confidence. This one I ordered through Summit should help.

Part of the problem is that crappy tools, coupled with my lack of experience with cam degree work makes this somewhat frustrating. The initial result of 110 degrees may have had an error of 2 degrees, meaning it actually could have been as close as 108 degrees C/L, right? I have no intention of relying on a margain of error to be reliable. I want actual accurate numbers. The 103 C/L number amazed me for being so far the other direction.

In 2004 I had help degreeing the 509 cam. At ZERO, it showed 1.5 degrees retarded. At the 4* ADV keyway, it showed a true 4 degrees.

Posted By: Challenger 1

Re: Degreeing a cam for the first time. What a PITA. - 08/14/13 07:45 PM

I won't screw a set screw into my cranks, it'll mess up the snout of the crank and that's not good when it comes time to install the damper. Good luck again!

Proform are among the cheapest tools out there, sorry. I got my stuff from B&B.

Posted By: Diplomat440

Re: Degreeing a cam for the first time. What a PITA. - 08/14/13 08:06 PM

is your crank socket grooved for a keyway? my comp cams one has 3 keyways and a brass tipped setscrew just to snug it up a little.

Posted By: Cab_Burge

Re: Degreeing a cam for the first time. What a PITA. - 08/14/13 09:36 PM

Posted By: RapidRobert

Re: Degreeing a cam for the first time. What a PITA. - 08/14/13 10:54 PM

Quote:

which two pistons are at bottom dead center when #1 and #6 are at top dead center,

#4 #7

Posted By: Kern Dog

Re: Degreeing a cam for the first time. What a PITA. - 08/15/13 05:10 AM

Quote:

is your crank socket grooved for a keyway? my comp cams one has 3 keyways and a brass tipped setscrew just to snug it up a little.

The hub has 3 grooves, all different widths for different Woodruff key sizes. The tightest one still allows the slop. The set screw has a flat end and has yet to damage the crank snout. I worry though about cranking it too tight. Maybe it will be okay with this new piston stop that I ordered. It has a small hole through it to allow compression to escape.

NOW that I have all the plugs out and all the pushrods out except for cyl #1 (With light checking springs) I may be able to spin the engine over without the hub slipping.

If I only spun one direction, it would be fine. I read online about degreeing cams and one place wrote to "....keep turning the engine in the same direction to maintain tension on the chain..." Yeah... sorta flies in the face of the common method of finding TDC and cam centerline though.

Posted By: Dodgem

Re: Degreeing a cam for the first time. What a PITA. - 08/15/13 01:14 PM

yea but when your finding TDC your findng where the piston is not finding where the cam is! After is when you want to go Clockwise direction only!

Posted By: dogdays

Re: Degreeing a cam for the first time. What a PITA. - 08/15/13 04:29 PM

See if you can find a key that's thicker than your slot, then file it down until it just fits.

Sort of like the offset key that some setups use to advance or retard a cam.

BTW, I did this years ago on a toyota 20R motor that was saddled with an automatic transmission. Found a Wodruff key with the same shape but thicker width and with a flat file, created my own offset key. I believe it advanced the cam about 5 degrees. That made a lot of difference starting out with the auto tranny.

R.

Posted By: Kern Dog

Re: Degreeing a cam for the first time. What a PITA. - 08/15/13 06:17 PM

Quote:

yea but when your finding TDC your findng where the piston is not finding where the cam is! After is when you want to go Clockwise direction only!

I'm going from memory here since the directions are out in the shop, but I'm sure they wrote that I am to turn the engine CW to maximum cam lobe lift then set the dial indicator to zero. Turn engine CCW to .100 then CW to .050 and record the number on the degree wheel. Continue rotating the engine CW until I reach .050 on the closing ramp and record that number. Add the 2 numbers and divide by 2.

If that is correct, that first switch to CCW would give me an inaccurate .100 point, right?

Maybe I am worried over nothing.

Posted By: BSB67

Re: Degreeing a cam for the first time. What a PITA. - 08/16/13 02:30 AM

CW and CCW to find TDC. CW only for degreeing the cam.

Posted By: RapidRobert

Re: Degreeing a cam for the first time. What a PITA. - 08/16/13 03:09 AM

Quote:

I am to turn the engine CW to maximum cam lobe lift then set the dial indicator to zero. Turn engine CCW to .100 then CW to .050 and record the number on the degree wheel. Continue rotating the engine CW until I reach .050 on the closing ramp and record that number. Add the 2 numbers and divide by 2.

If that is correct,

Correct Yes, that number will be the intake lobe centerline (the # of crank degrees the centerline is away from piston TDC such as 102 or 105 degrees which is the final # you're after when degreeing a cam. The only other thing you need is to first before that is to find exact piston TDC with the piston stop (CW & CCW) then set the degree wheel to TDC (zero) at that piston position then the above lobe centerline. (1) piston at its' exact TDC (2) set degree wheel at that piston position to TDC zero (3) find peak intake lobe height (centerline) location on the degree wheel. That # (before + after divided by 2) is your final answer. A centerline at 102 degrees away from TDC is more advanced (closer to TDC) than a centerline that is 105 degrees away from TDC. EDIT wouldn't hurt to in addition check that the dampener slit is at zero (TDC) on the timing tab when the piston is at EXACT TDC at the top of the cyl. Make a new mark with white paint across the dampener if need be. You need that to be accurate so when you time it so that 36 degrees on the light is actually 36 degrees of advance. but some timing lights ain't accurate, another story...

Posted By: Dodgem

Re: Degreeing a cam for the first time. What a PITA. - 08/16/13 03:09 AM

Quote:

CW and CCW to find TDC. CW only for degreeing the cam.

Posted By: Kern Dog

Re: Degreeing a cam for the first time. What a PITA. - 08/16/13 04:23 AM

You guys are great! I'm feeling more confident now. Hopefully I'll be able to finish up this weekend. I'm changing the oil pan along with this other stuff. Its a Milodon 6 quart Hemi spec pan.

Posted By: Cab_Burge

Re: Degreeing a cam for the first time. What a PITA. - 08/16/13 04:52 AM

Posted By: Kern Dog

Re: Degreeing a cam for the first time. What a PITA. - 08/16/13 05:07 AM

Quote:

I always check every cam at .200 before max lift, .100 BML and at .050 BML and after on all three

Do you do this like the .050 method? ( Take the .200 numbers, add them, then divide by 2)

Is this a more accurate method than measuring at .050?

I have found that once all the tools are out and the setup is done, the actual degreeing of the cam doesn't take that long.

I will clearly admit here and now that I am converted. Since I have all the stuff, I will degree the cam in future engine builds.

Posted By: Dodgem

Re: Degreeing a cam for the first time. What a PITA. - 08/16/13 01:44 PM

I often like to use .200 add numbers divide by 2 .100 same and .050 most times all the same.

Then there is the actual .050 opening method where you turn till it is at 0 lift then turn till lifter lift is .050 off seat and check the number.

So a 261 @ .050 cam you divide by 2 so 131.5 then subtract the 106 installed centerline gives you 25.5 so you should have .050 lift at 25.5 before TDC. That would be installed at a true 106 centerline.

so if it comes in at 21.5 that would be 4 degree retarded from suggested install or 110 intake centerline

if it comes in at 27.5 that would be two degrees advanced from the suggested install of 106 or in at 104.

You can also check the total duration @ .050 by checking the .050 before closing which at 106 install should be 180 - 106 = 74 then 131.5 - 74 = 57.5 After bottom dead center.

again 4 retarded from 106 (110) would be 61.5

and 2 advanced from 106 would be 55.5

I like to use this and max lift (.050/.100/.200 methods) right at the top of your pad paper .200 .100 .50 and record the numbers at each stop

.200 .100 .50 .50 .100 .200 ad and divide by 2.

Posted By: Dodgem

Re: Degreeing a cam for the first time. What a PITA. - 08/16/13 01:52 PM

PS if you want to try the .050 opening method it is best done on lifter (or in pushrod cup) but if you do want to check at valve retainer you must use rocker ratio so if you have 1.5 rockers it's .075 at the spring retainer solid lifter 0 lash.

Max lift does not mater as that is all about average from arbitrary points.

Posted By: Kern Dog

Re: Degreeing a cam for the first time. What a PITA. - 08/16/13 05:56 PM

How the heck do you know all of this stuff?

Very impressive!

Posted By: Cab_Burge

Re: Degreeing a cam for the first time. What a PITA. - 08/16/13 06:10 PM

Quote:

Quote:

I always check every cam at .200 before max lift, .100 BML and at .050 BML and after on all three

Do you do this like the .050 method? ( Take the .200 numbers, add them, then divide by 2)

Is this a more accurate method than measuring at .050?

I have found that once all the tools are out and the setup is done, the actual degreeing of the cam doesn't take that long.

I will clearly admit here and now that I am converted. Since I have all the stuff, I will degree the cam in future engine builds.

The main reason I check them at all three locations is to make sure what the lobe grind is like, I've seen a cam have 105 at .200, 106 at .100 and 107 at .050

I'll usually check the cam timing on the lobes first, both of them ,and then when I get ready to check piston to valve clearances I will check at the retainers due to finding so many rocker arm sets not haveing the correct ratio on all of them

I'll usually check the cam timing on the lobes first, both of them ,and then when I get ready to check piston to valve clearances I will check at the retainers due to finding so many rocker arm sets not haveing the correct ratio on all of them  I go ahead with the light checking springs and verify what the valves are seeing as far as cam lobe centers and intake lobe position

I go ahead with the light checking springs and verify what the valves are seeing as far as cam lobe centers and intake lobe position

As far as the math I make my sheet up with .200 first,.100 and then .050, find max lift and back the cam up to .300 or a little less befome max lift and then move the crank to get .200 BML, write it down, then do .100 and then .050, go to .050 after max lift and write it down under the .050 BML and do the math, same thing on the other two

As far as the math I make my sheet up with .200 first,.100 and then .050, find max lift and back the cam up to .300 or a little less befome max lift and then move the crank to get .200 BML, write it down, then do .100 and then .050, go to .050 after max lift and write it down under the .050 BML and do the math, same thing on the other two

Posted By: BSB67

Re: Degreeing a cam for the first time. What a PITA. - 08/17/13 02:48 AM

Quote:

....I've seen a cam have 105 at .200, 106 at .100 and 107 at .050

That is because it is an asymmetrical lobe.

Posted By: Cab_Burge

Re: Degreeing a cam for the first time. What a PITA. - 08/17/13 04:19 AM

Quote:

Quote:

....I've seen a cam have 105 at .200, 106 at .100 and 107 at .050

That is because it is an asymmetrical lobe.

It wasn't suppose to be, according to the cam grinder

Posted By: BSB67

Re: Degreeing a cam for the first time. What a PITA. - 08/17/13 01:46 PM

Something not right there.

More often than not, posters seem to get lost on why you degree a cam. First, it is to make sure that the stack up of tolerances of all the parts is about right and something is not screwed-up. It almost seems like the advent of the multi-keyway timing set was an excuse to make junk quality. Second, to put the ICL where YOU want it, and to have a baseline for future cam timing adjustments.

The cam manufacturer has simply given a recommended ICL. Measure it how you like, but be consistent, as the ICL will change on most modern lobes based on the method you use. Then install it where you want.

Posted By: Dodgem

Re: Degreeing a cam for the first time. What a PITA. - 08/17/13 04:52 PM

Quote:

How the heck do you know all of this stuff?

Very impressive!

You learn this stuff as you go along trial and error lots of error and it's what you want or need to learn as you go.

I had to learn the .050 off the seat the first time i did a milodon gear drive on a hemi there are no marks on the BB milodon gear drive You 0 your degree wheel turn crank to say 24 BTDC my current roller then you turn the cam by hand to .050 lifter lift and then the top gear that has 7 non concentric bolt holes is put together where it will line up and done. well then you run through all your checks other checks max lift -.050, -.100 and so on but usually it's bang on. (i now have two milodon gear drives myself)

My first time degreeing a 533/320 mopar cam had watched the mopar cam degree video talked with people and decided to retard my cam as i wanted more top end (pull better in third out the end) well it was in at 106.75 i drilled a hole in the top gear and using an offset bushing and put it in at 109.5. off to the track and wow more than three tents slower. So I go back and put 0 offset bushing in but since hole and bushings are not 100% it went back in at 106.25. well then it was always .05 to .075 faster than it had been before for certain weather after a few years i had a good feel plus in the fall my PB went to .075 faster than before.

so what i learned was when the talk retarding a cam for more top end power they mean in the 7000 to 10000 rpm range it works good not out the top end of the 1/4. and advancing a cam kicks ass 0 to 7000 rpm.

My next time was installing an ultradyne 263/271 108 talking with him he explained why i would want more cam advance 102 if we could get it as opposed to the 106 on the cam card. well the valves got as tight as we felt comfortable at 104 so we left it there. later with head changes and things i thought oh I have more room so went to 102 and gained a tenth.

But as with anything there is a ton of things in the mix as to where you degree your chosen cam. 1st the cam itself then compression, cubic inches, torque converter stall (or stick) final gears car weight

use and a lot of little things a couple cam degrees can make quite a difference.

Guys like cab have a ton more experience.

The internet is a great source for info lots of good stuff. Then opinions some good and some bad.

Posted By: Kern Dog

Re: Degreeing a cam for the first time. What a PITA. - 08/17/13 07:38 PM

Quote:

Something not right there. I agree. The 7 degree spread between settings shows me either the slop in the degree wheel is a factor or the machining of the timing set is waaaay off.

More often than not, posters seem to get lost on why you degree a cam. I have a history to getting impatient and bypassing the details, but this time I am sticking with it.

The cam manufacturer has simply given a recommended ICL. Measure it how you like, but be consistent, as the ICL will change on most modern lobes based on the method you use. Then install it where you want.

Install it where I like it. There is the "problem". I don't have enough experience to know where I'll like it. Maybe you mean to race it at different settings and pick the one that results in the best ETs? My goals are to eliminate the detonation and at the same time, make more power. My cam card called for an installed C/L of 106. I would have left it if it came in at 108.

What are the opinions of timing chain stretch? Would it be better to err to the ADV side? If it calls for 106 and the 4* ADV keyway gets me at 104-105, is that better than starting off at 107-108? Just a newbie perspective, but as the chain stretches, the cam timing comes in later. Is this a factor than you consider when degreeing the cam?

Posted By: BSB67

Re: Degreeing a cam for the first time. What a PITA. - 08/17/13 08:09 PM

Quote:

Quote:

Something not right there. I agree. The 7 degree spread between settings shows me either the slop in the degree wheel is a factor or the machining of the timing set is waaaay off.

More often than not, posters seem to get lost on why you degree a cam. I have a history to getting impatient and bypassing the details, but this time I am sticking with it.

The cam manufacturer has simply given a recommended ICL. Measure it how you like, but be consistent, as the ICL will change on most modern lobes based on the method you use. Then install it where you want.

Install it where I like it. There is the "problem". I don't have enough experience to know where I'll like it. Maybe you mean to race it at different settings and pick the one that results in the best ETs? My goals are to eliminate the detonation and at the same time, make more power. My cam card called for an installed C/L of 106. I would have left it if it came in at 108.

What are the opinions of timing chain stretch? Would it be better to err to the ADV side? If it calls for 106 and the 4* ADV keyway gets me at 104-105, is that better than starting off at 107-108? Just a newbie perspective, but as the chain stretches, the cam timing comes in later. Is this a factor than you consider when degreeing the cam?

Like your're doing, ask a couple people, people that you trust.....

Starting with 2 to 4 degrees advanced is a reasonable starting point. If it still pings, you can back it up 4 degrees. If it does not ping, but the bottom end is too soft for your liking, add additional advance.

Posted By: RapidRobert

Re: Degreeing a cam for the first time. What a PITA. - 08/17/13 08:10 PM

installing it more retarded (IE 108 rather than 106) will reduce cyl psi & decrease detonation then you'd want to optimize the ign curve (I'm assuming more octane ain't an option) & as you know more octane would let you run a faster ign curve & adv or ret it to get the power band closer to where you want it. People have suggested setting it to where you get the most cranking compression. You might set it where the mfr want's it then adjusting the ign curve & see where you're at. #1 you mentioned detonation & it MUST be eliminated ASAP!

Posted By: Dodgem

Re: Degreeing a cam for the first time. What a PITA. - 08/17/13 08:18 PM

I would lean toward a little extra advance if it still pings I would look to head gaskets.

power valve 1.5 to 2.5 below the in gear idle vacuum so it gets some fuel right away on light acceleration .

looser torque converters help. slightly rich is better than slightly lean and a colder range spark plug can all help!

I think Edelbrock sells these bigger bore head gaskets for a reason as many of us have seen the the fel pro 1009 hanging in the combustion chamber and burnt off in some cases

http://www.summitracing.com/parts/edl-7325/overview/make/plymouth

Posted By: Dodgem

Re: Degreeing a cam for the first time. What a PITA. - 08/17/13 08:31 PM

I would definately go with a higher power valve and maybe up 2 jet sizes all the way around.

looking at demon 850's 3 had 85/93 with 6.5 power valve

and one was 85/94 with 6.5 power valve

since your fuel is most likely ethanol blend I would start at

87/96 with 6.5 power valve.

Posted By: Kern Dog

Re: Degreeing a cam for the first time. What a PITA. - 08/18/13 06:24 AM

I have a 3.5 PV in there now. I'm guessing that is too low?

I suppose that the Holley suggestions were a baseline to start from, right? The 1/2 of idle in gear vacuum one?

Posted By: Dodgem

Re: Degreeing a cam for the first time. What a PITA. - 08/18/13 11:32 PM

well the holley performance tuning books say 1.5 to 2.5 below in gear idle. So it's a stock vac mod cam thing! Holley now say half so a 17 in vac cam would want a 8.5 power valve (I ran a dual 10.5/8.5 on a stock cam 318 once)

Trust me the vac drrops much more faster on a 17inc vacuum cam than a 9 inch vacuum cam to get the power valve open to get the fuel running to accelerate

!

Posted By: Kern Dog

Re: Degreeing a cam for the first time. What a PITA. - 08/19/13 06:43 AM

I hope I didn't offend!

I can bolt stuff on like anyone. It the actual tuning skills that I am in need of help. Thanks for the tips. I'm going to print all this stuff and save it in a binder.

Thanks!

Posted By: Dodgem

Re: Degreeing a cam for the first time. What a PITA. - 08/19/13 05:50 PM

A lot is trial and error and some help from asking questions.

My thoughts on the 3.5 power valves that pop up now is it takes the power valve out of the equation in tuning for dummies but then it does not work the way it should on the road lowest I ever used was a 5.0 with some pretty big ass cams.

Not a bad ideal if you don't understand things to use one with way to low a number with hotter cams until you get your in gear idle right (ideal in gear idle advance set) usually with faster advance curve or shortened advance slots.

me I like long slots and real light springs for ease of starting but final destination is a tomato tomato thing.

Posted By: Kern Dog

Re: Degree a cam for the 1st time. What a PITA. * UPDATE* - 08/23/13 09:24 PM

Isn't it a funny moment when things that were once a pisser just suddenly start to fall into place?

It is a common theme with me. Being the adventurous type, I often jump into projects with no experience and fumble my way through. When I encounter poor results, I wonder if it is due to my inexperience or the cheap tools that I am using.

THIS time I bought some decent stuff. Not top of the line, but not from Harbor Freight either. I went about the degree process and came up with some odd results. The flimsy piston stop and loose fitting crank hub made it difficult to establish TDC. Having the spark plugs in and rocker arms on made the engine hard to turn. With the advice of some helpful members, I forged ahead and am happy to report the following:

I decided to skip the crank turning hub and instead I mounted the degree wheel directly to the crank using the stock dampner bolt. ZERO slop, so now TDC was accurately established. Next I followed the instructions and checked the #1 intake valve timing. My first number was 73 degrees and the second number was 139 degrees. This totalled 212. I almost crapped a brick ! The cam card calls for a 106 centerline and I am exactly at 106 with the timing set at the ZERO/dot-to-dot setting. The slop in the crank turning hub was a full 4 degrees. Now with the degree process finished, I can proceed with the rest of the job.

Posted By: RapidRobert

Re: Degree a cam for the 1st time. What a PITA. * UPDATE* - 08/23/13 10:53 PM

That was TOO easy! Glad ya got it

Posted By: Cab_Burge

Re: Degree a cam for the 1st time. What a PITA. * UPDATE* - 08/24/13 12:44 AM

Quote:

Isn't it a funny moment when things that were once a pisser just suddenly start to fall into place?

It is a common theme with me. Being the adventurous type, I often jump into projects with no experience and fumble my way through. When I encounter poor results, I wonder if it is due to my inexperience or the cheap tools that I am using.

THIS time I bought some decent stuff. Not top of the line, but not from Harbor Freight either. I went about the degree process and came up with some odd results. The flimsy piston stop and loose fitting crank hub made it difficult to establish TDC. Having the spark plugs in and rocker arms on made the engine hard to turn. With the advice of some helpful members, I forged ahead and am happy to report the following:

I decided to skip the crank turning hub and instead I mounted the degree wheel directly to the crank using the stock dampner bolt. ZERO slop, so now TDC was accurately established. Next I followed the instructions and checked the #1 intake valve timing. My first number was 73 degrees and the second number was 139 degrees. This totalled 212. I almost crapped a brick ! The cam card calls for a 106 centerline and I am exactly at 106 with the timing set at the ZERO/dot-to-dot setting. The slop in the crank turning hub was a full 4 degrees. Now with the degree process finished, I can proceed with the rest of the job.

Lots of gremlins out there blocking the light

I'm glad it is starting to make sense

I'm glad it is starting to make sense  Now is the time to check the exhaust lobe center before changing the intake to verify the actual cam LSA

Now is the time to check the exhaust lobe center before changing the intake to verify the actual cam LSA

Posted By: Dodgem

Re: Degree a cam for the 1st time. What a PITA. * UPDATE* - 08/24/13 02:27 AM

How did that new piston stop work??

let us know how it runs.

Posted By: Kern Dog

Re: Degree a cam for the 1st time. What a PITA. * UPDATE* - 08/24/13 07:11 AM

Quote:

How did that new piston stop work??

let us know how it runs.

That thing is great. There was virtually NO chance of bending it, so it was easy to determine TDC.

I started in on the rest of the job: Changing valvesprings, installing the rocker arms and setting lash...I totally forgot CAB'S suggestion about checking exhaust lobe centerline. I hope that I didn't screw up by forgetting that!

The Lunati cam card showed a valve lash setting of .020 INT and .022 EXH. I set the lash on the engine, but then remembered that their specs are for "hot lash". Obviously I can't do that yet, so what would be an acceptable spec for a cold engine with aluminum heads? I may check the Lunati website to see if they have a tech section. Of course I need info and the weekend is here...JUST in time for these companies to take 2 days off!

Posted By: Kern Dog

Re: Degree a cam for the 1st time. What a PITA. * UPDATE* - 08/24/13 08:18 AM

The Lunati site had no tech info on setting valve lash hot or cold, so I checked the tech archives here.

The consensus for aluminum heads on an iron block is to set the lash .006 tighter with a cold engine. The belief is that as the engine warms up, the lash grows.

Looks like I need to relash the valves tomorrow.

Posted By: Dodgem

Re: Degree a cam for the 1st time. What a PITA. * UPDATE* - 08/24/13 01:34 PM

Yea I had better luck with my home made piston stops then when a friend got a comp cams one it's just to wimpy.

I have not had a chance to try the new crane one yet but it sure seems nice? I should just but my bigger cam in so I can use it! :-)

yup almost everybody does lash cold 6 tighter on Eddy heads seems to work great. Hot the job really sucks and almost impossible to get very far before the aluminum heads start to cool and contract. So do them cold 6 tighter and don't worry be happy. Just make sure lock nuts are tight.

on 906 iron heads I used to go 2 looser intake 4 looser exhaust hot that seemed bang on.

Check and time the intake lobe first, once you get it where you want it(106 degrees after top dead center max lift on the intake(+ 1 or minus 1 degree) then check the exhaust side

Check and time the intake lobe first, once you get it where you want it(106 degrees after top dead center max lift on the intake(+ 1 or minus 1 degree) then check the exhaust side

) locations, .050 before max lift and again at .100 and I do .200 before max lift also

) locations, .050 before max lift and again at .100 and I do .200 before max lift also

I've accidently ran .030 on the intakes and .055 on the exhaust on my old M.W. stocker a long time ago with no damages

I've accidently ran .030 on the intakes and .055 on the exhaust on my old M.W. stocker a long time ago with no damages  Long story

Long story

I'll usually check the cam timing on the lobes first, both of them ,and then when I get ready to check piston to valve clearances I will check at the retainers due to finding so many rocker arm sets not haveing the correct ratio on all of them

I'll usually check the cam timing on the lobes first, both of them ,and then when I get ready to check piston to valve clearances I will check at the retainers due to finding so many rocker arm sets not haveing the correct ratio on all of them