Posted By: mcmopars

torque to yield bolts? - 02/04/13 10:34 PM

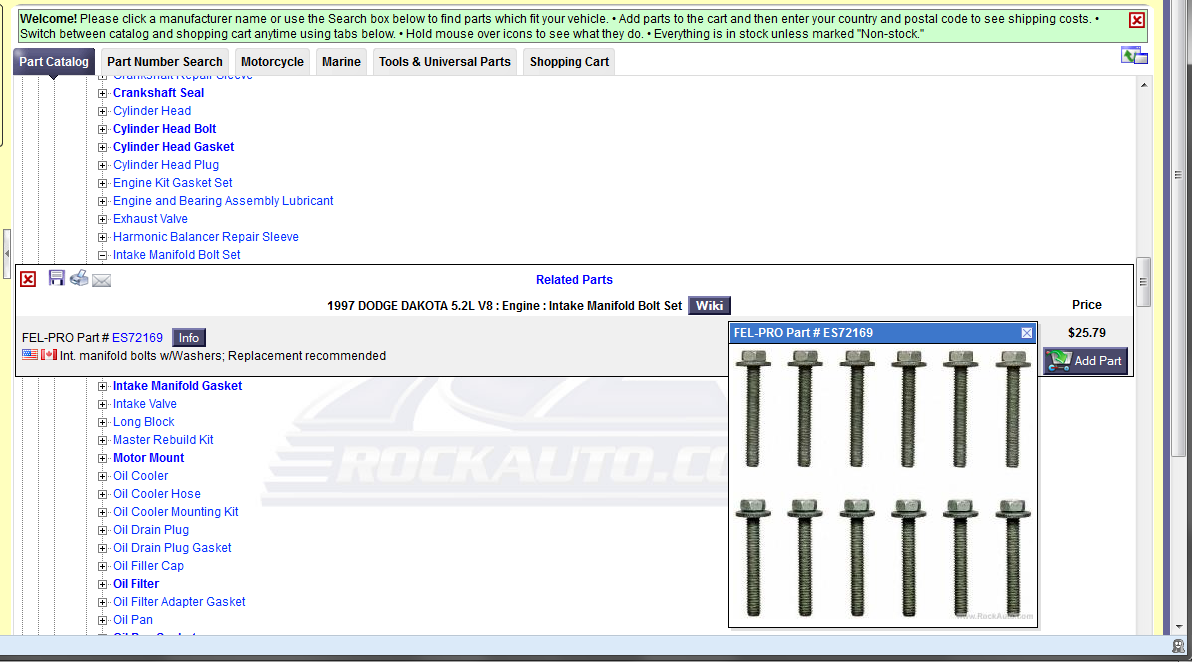

been waiting for a month from jegs for magnum intake bolts.on back order.they are tty bolts,i have used ones,reuse?wait on new?

Quote:

does anyone know why i cant use reg.bolts? magnum 360 using edelbrock rpm air gap intake ,if it matters.

what are the odds of taking a true/false test (50/50) with 4 12-part responses, guessing blindly at each one, and getting a 100% overall score?

what are the odds of taking a true/false test (50/50) with 4 12-part responses, guessing blindly at each one, and getting a 100% overall score?

Quote:

Thanks!! I'm a tad sketchy on mine though, the book said torque is 45 ft/lbs and I had a feeling that was high. Made a couple calls to take a census of opinion and decided on 25. I'm sure it will be ok tho.

Quote:

I USED TO WORK FOR A MAJOR GASKET MANUFACTURER AND WE TAUGHT THESE NEW CLAMPING TECHNIQUES (CAME INTO THE INDUSTRY ~MID-80S) TO OUR CUSTOMERS.

Quote:Is that the new torque angle method that Mitch mentioned?

on the 2.2, 2.0, and 2.4 motors that have TTY head bolts. They all have some type of initial target torque followed by a "plus 90 degree" tightening instruction.

Quote:Quote:Is that the new torque angle method that Mitch mentioned?

on the 2.2, 2.0, and 2.4 motors that have TTY head bolts. They all have some type of initial target torque followed by a "plus 90 degree" tightening instruction.