Moparts

Replacing Wheel Cylinders... Rusted Bolts and Lines.

Posted By: MuuMuu101

Replacing Wheel Cylinders... Rusted Bolts and Lines. - 10/05/12 05:07 AM

I know this sounds stupid (kind of embarrassing) and I sound like a total Noob, but where would be the proper place to jack a car if I'd like to remove one of the wheels? Do I jack it on the frame near the tire or should I jack it on some sort of center line on the car? Because if I jack it on the side of the car wouldn't it cause the frame to twist? And do I have to jack it till the tire is off the ground or to the point where the tire isn't holding as much load as the other wheels? And do I put the stand in and remove the jack before or after I take the wheel off. Gosh, please bare with me and my ignorance. (Yes, I already purged the jack)

GO TO LATER POSTS AFTER ALL THE PROPER WAY TO JACK A CAR STUFF!!!

Posted By: Jim_Lusk

Re: Proper Way to Jack a Car... - 10/05/12 05:11 AM

It kind of depends on your work area and what you are doing. You won't permanently twist the car lifting a corner unless the car is suspect to begin with. You need to get the tire off the ground and ALWAYS put the stand in before you pull the wheel, BUT loosen the lugnuts a half turn or so before you jack it up unless you have an impact.

I like to jack up A-bodies from the center of the k-member in the front or under the differential in the rear. You can jack up a corner from the sub-frame, BUT make sure you are using the sub-frame and not the rocker panel or something else.

Posted By: MuuMuu101

Re: Proper Way to Jack a Car... - 10/05/12 05:16 AM

I knew about the stand in before wheel is off. I just wasn't sure if it would be ok to lift the car from the k-frame. That's good to know. And I can also lift it from the center of the diff? Now where would I place the stand if I remove the front wheel or the rear wheel?

Posted By: Hugh Jorgan

Re: Proper Way to Jack a Car... - 10/05/12 05:17 AM

"Proper Way to Jack a Car... "

Depending on what part of the city that you're in, it's done with a weapon.

Posted By: RapidRobert

Re: Proper Way to Jack a Car... - 10/05/12 05:18 AM

jack it on the subframe near the wheel that needs to come off. This raises the fender which in some cases is needed for the tire to clear to come off/out. I like to break the lug nuts barely free then jack it up. jack the tire just off of the ground. Put the stand in/under in place then let the jack down easy. Jacking a corner will not twist the frame

Posted By: DaytonaTurbo

Re: Proper Way to Jack a Car... - 10/05/12 05:25 AM

If tire to fender clearance is not an issue to get a back tire off, I just throw the jack under the diff near one of the shock mounts, not the center. If your leaf springs are bagged out, doing this may lift the tire too far into the body to get the tire off. If you put the jack on the frame, you might have to lift the frame quite a bit before the tire gets off the ground. Worse if you have sagged out leaf springs. For the front I just throw it under one of the frame rails because the front is lower and doesn't sag as much. If it's my jeep or truck I'll put it under the control arm. If I'm just changing tires, I'll leave it on the jack. If working on anything, lower it down onto a jackstand.

Posted By: MuuMuu101

Re: Proper Way to Jack a Car... - 10/06/12 05:06 AM

God what a pain in the butt something as simple as removing wheels can be. Well, I lifted the rear and put it on stands and as I was trying to untighten the lugs, I realized I didn't engage the parking brake and remembered why some said they liked to loosen the nuts when the car's on the ground. So I bring it on the ground, apply the Parking brake, pump the brakes about 10 times (although this probably didn't do anything due to a faulty MC), put some wheel stops in front of the wheel I'm trying to loosen and man, parking brake doesn't work. I was able to loosen the passenger rear, but I'm having trouble with the driver's side. I'm pushing it both ways as hard as I can without having the car roll forwards or back (because it wants to move over the stops and I can't remember if the Driver's side is a LHT), but these bolts feel like they haven't been loosened since the car was bought new (same as passenger side but they were able to slip).

Any

or tips will be appreciated... I was thinking WD40 might loosen it up, but I don't think I have any at home.

Posted By: MuuMuu101

Re: Proper Way to Jack a Car... - 10/06/12 05:32 AM

Nevermind, with a little persuasion I got the lug nuts loose. Raising the car now to put in the new wheel cylinders. Hopefully I can get them tight enough when I put the wheels back on.

Posted By: DaytonaTurbo

Re: Proper Way to Jack a Car... - 10/06/12 05:33 AM

68 should still be left hand thread, so 'rightey tightey, lefty loosey' does not apply. Always break the lugs loose when the car is on the ground. So long as its in park(or gear if a stick) you should be able to break the nuts loose without the car moving around on you too much.

Posted By: MuuMuu101

Re: Proper Way to Jack a Car... - 10/06/12 05:47 AM

Quote:

68 should still be left hand thread, so 'rightey tightey, lefty loosey' does not apply. Always break the lugs loose when the car is on the ground. So long as its in park(or gear if a stick) you should be able to break the nuts loose without the car moving around on you too much.

Well, car is in park and the parking brake is engaged so there's probably something wrong with my tranny now too, huh? I got the rear on jacks and I removed the passenger side wheel. I can finally say I'm working on my car.

Posted By: DaytonaTurbo

Re: Proper Way to Jack a Car... - 10/06/12 05:54 AM

Well in park you shouldn't be able to move the car more than an inch or two before the transmission stops you.

Posted By: MuuMuu101

Re: Proper Way to Jack a Car... - 10/06/12 06:12 AM

It didn't move much, but enough to take away from loosening the bolt. And are there any household appliances that loosen rusty bolts. Having trouble getting the wheel cylinder bolts removed. Even the brake line is a being a PIA to remove. I'm barely able to turn the brake line loose about a 1/4 turn every 5 mins. It's really stuck on there.

Edit: Yeah, I think I may stop for now since I'm starting to strip the brake line fastener.

Posted By: MuuMuu101

Replacing Wheel Cylinders... Rusted Bolts and Lines. - 10/06/12 06:44 AM

So I'm trying to replace the wheel cylinders and the nuts and brake line fasteners just aren't braking loose. I tried both my line wrenches and my socket wrenches and they don't seem to be doing any good. I already started to strip the brake line fastener so I stopped that.

Do you think some WD40 or acetone sprayed on there would help any? I may have to pick some up in the morning. For now I shall take a warm shower and head to bed.

Posted By: DaytonaTurbo

Re: Replacing Wheel Cylinders... Rusted Bolts and Lines. - 10/06/12 07:01 AM

Don't be too surprised if you destroy stuff getting the brake lines off. You are working on a 45 year old car after all.

Posted By: autoxcuda

Re: Proper Way to Jack a Car... - 10/06/12 07:04 AM

Quote:

Nevermind, with a little persuasion I got the lug nuts loose. Raising the car now to put in the new wheel cylinders. Hopefully I can get them tight enough when I put the wheels back on.

Are the rear wheel cylinders leaking?

Have you pulled back the dust covers to see if there is any seepage?

Is there any oil leaking out of the axle seal?

Post of picture of each side of the rear brake assy with the drums removed. (they are already removed right?)

Posted By: hemirdrnnr

Re: Proper Way to Jack a Car... - 10/06/12 11:06 AM

Don't most left hand lug bolts have an L on them.

Posted By: bobs66440

Re: Proper Way to Jack a Car... - 10/06/12 11:33 AM

Do yourself a favor and buy an impact wrench. That's your best friend for removing wheels. They make electric ones if you don't have a compressor.

Posted By: GoodysGotaCuda

Re: Replacing Wheel Cylinders... Rusted Bolts and Lines. - 10/06/12 12:48 PM

Quote:

So I'm trying to replace the wheel cylinders and the nuts and brake line fasteners just aren't braking loose. I tried both my line wrenches and my socket wrenches and they don't seem to be doing any good. I already started to strip the brake line fastener so I stopped that.

Do you think some WD40 or acetone sprayed on there would help any? I may have to pick some up in the morning. For now I shall take a warm shower and head to bed.

IMO, the sooner you write-off the rear hard lines, the better. If it was mine and it looked remotely rusted, I'd start with PB blaster where the two hardlines meet in the middle of the axle. If you can win with those, some new hardline would be a good way to start. That way you can..get new hardline in there and just cut the hardline at the wheel cylinder and remove it. Old rusty brake line fittings are very unforgiving, sooner you decide to just replace them the better. In my opinion..

Posted By: 6PakBee

Re: Replacing Wheel Cylinders... Rusted Bolts and Lines. - 10/06/12 02:17 PM

If you are replacing the wheel cyclinders and not rebuilding them, heat is your friend. Take a common propane torch and heat the tube nut up. It doesn't have to be red hot or anything drastic, just heat it up. While it's hot, hit it with Kroil, PB, any penetrating oil you like. Try to move the nut. If you get to the point of refusal, back off and re-do the heat and penetrating oil thing. I've save numerous brake lines like this. Now be aware that the cloud that comes off the hot fitting from spraying it with penetrating oil is flammable. Turn the torch off. Good luck.

As a side note, when I go back together I CAREFULLY put anti-seize on the tube where it passes through the tube nut and on the tube nut threads. Want to get some protection here without contaminating the brake fluid.

Posted By: MuuMuu101

Re: Proper Way to Jack a Car... - 10/06/12 05:25 PM

Quote:

Quote:

Nevermind, with a little persuasion I got the lug nuts loose. Raising the car now to put in the new wheel cylinders. Hopefully I can get them tight enough when I put the wheels back on.

Are the rear wheel cylinders leaking?

Have you pulled back the dust covers to see if there is any seepage?

Is there any oil leaking out of the axle seal?

Post of picture of each side of the rear brake assy with the drums removed. (they are already removed right?)

The post you quoted were for the lug nuts that held the wheel to the axles.

I haven't been able to take off the cylinder and everything is just dry and rusty back there. I've been primarily focused on the passenger side. I barely touched the driver's side. 3-4 guys on FABO told me to use Pb Blaster to loosen up the nuts so I may have to go today and get some (maybe even replace the lines too).

Sorry for the bad cell phone pics.

Passenger side:

Driver's side:

Posted By: wally426ci

Re: Proper Way to Jack a Car... - 10/06/12 06:22 PM

Soak with PB blaster. If they stayed seized, try removing the bolts that hold it to the backing plate, put a wrench on the hard line and then try spinning the wheel cylinder itself. If it breaks loose, you can focus on freeing up the hard line after its apart.

Posted By: MuuMuu101

Re: Proper Way to Jack a Car... - 10/06/12 08:51 PM

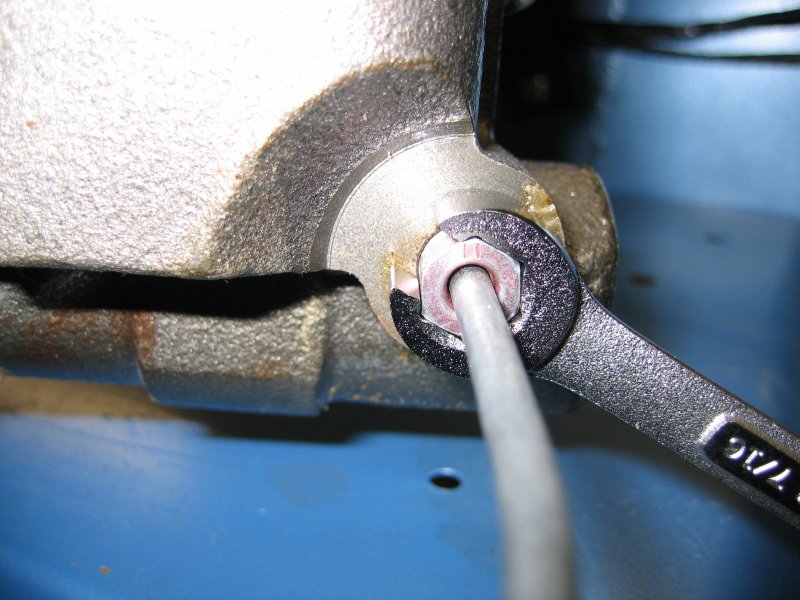

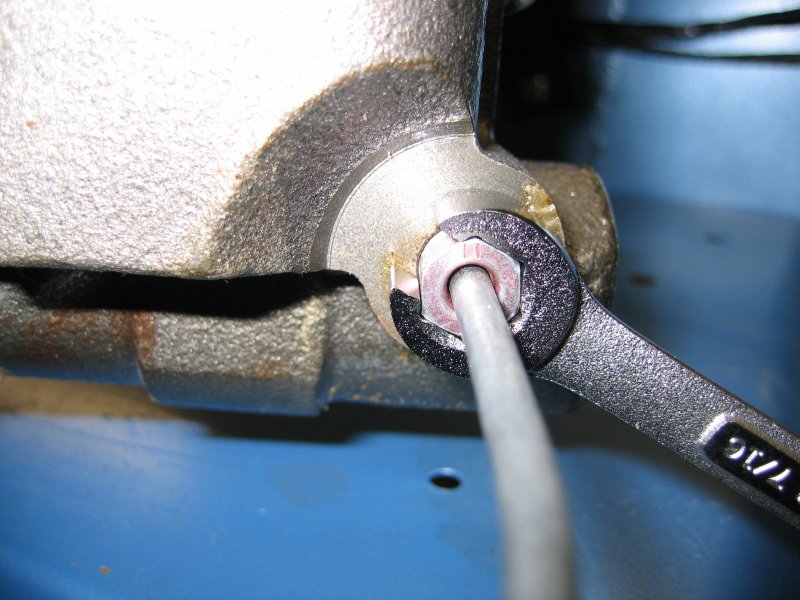

Sprayed the PB Blaster and all the rust is gone but the hard line fastener is too stripped (both of them) and wrenching isn't doing anything but rounding it off. And something I noticed... There are 3/8" bolts on the passenger side and 1/2" bolts on the driver side and none of the driver or passenger side bolts or fasteners are budging.

Passenger side:

Posted By: snuggles

Re: Proper Way to Jack a Car... - 10/06/12 11:15 PM

Thats rust? Must be CA rust and not MI rust

Posted By: Stroked_Hemi

Re: Proper Way to Jack a Car... - 10/06/12 11:24 PM

Quote:

Sprayed the PB Blaster and all the rust is gone but the hard line fastener is too stripped (both of them) and wrenching isn't doing anything but rounding it off. And something I noticed... There are 3/8" bolts on the passenger side and 1/2" bolts on the driver side and none of the driver or passenger side bolts or fasteners are budging.

Passenger side:

If you can get the bleeder off for room, a medium size pair of visegrips always worked for me, get the visegrip jaws seated good and tight around it... give it a hard short crank.

Posted By: MuuMuu101

Re: Proper Way to Jack a Car... - 10/06/12 11:54 PM

Thanks guys! Well, I've run out of time for this weekend and I have other priorities to attend to. I'm going to ask my friend if he'd be willing to help me out next weekend so I can get it ready for the Fling.

Posted By: ahy

Re: Proper Way to Jack a Car... - 10/07/12 01:39 AM

It looks like you will be replacing the end sections of brake line... not uncommon.

With that, just get a bolt cutter and nip the brake lines off near the slave cylinders. The slaves should unbolt and slide out as normal.

If you are saving the slave cylinders, you can put them in a vise and use a little heat and vise grips to get the stubs off. Easier on the bench.

Posted By: wally426ci

Re: Proper Way to Jack a Car... - 10/07/12 02:06 AM

Invest in Line wrenches (flare nut wrench). They are more closed at the end so it will slip over the line.

Posted By: MuuMuu101

Re: Proper Way to Jack a Car... - 10/07/12 02:51 AM

Quote:

Invest in Line wrenches (flare nut wrench). They are more closed at the end so it will slip over the line.

One of my coworker told me to get some a couple weeks ago. I guess I should have. It seems my friend is on board with doing the entire brake system next weekend.

Posted By: roe

Re: Proper Way to Jack a Car... - 10/07/12 03:32 AM

Someone above mentioned visegrips. I have to agree, I never use wrenches on stuff like this, they strip out pieces way too much. I always just use a nice set of the angled grip pliers or some vicegrips. They knock it out no problem, and you wont strip it.

roe

Posted By: autoxcuda

Re: Proper Way to Jack a Car... - 10/07/12 06:01 AM

Quote:

It looks like you will be replacing the end sections of brake line... not uncommon.

With that, just get a bolt cutter and nip the brake lines off near the slave cylinders. The slaves should unbolt and slide out as normal.

If you are saving the slave cylinders, you can put them in a vise and use a little heat and vise grips to get the stubs off. Easier on the bench.

You're going to get him overwelmed and stuck on this little project.

He does not have a flaring tool. Nor I'm sure has ever used one. He just got his first hydraulic jack and jack stands and barely has enough hand tools to do this job.

I think that connection can be finesesed out by someone with experience and right tools.

Posted By: autoxcuda

Re: Proper Way to Jack a Car... - 10/07/12 06:23 AM

Quote:

Quote:

Invest in Line wrenches (flare nut wrench). They are more closed at the end so it will slip over the line.

One of my coworker told me to get some a couple weeks ago. I guess I should have. It seems my friend is on board with doing the entire brake system next weekend.

That side wheel cylinder does not appear to be leaking. Please take some pictures with a real camera so we can see the thickness of the brake shoe lining material. Get a fine marked steel ruler and measure the thinnest section of material on each shoe.

I don't see that you rear wheel cylinders are leaking. Carefully take a dull screwdriver and pull the dust boot from the wheel cylinder back. Then look to see if any fluid runs out.

STOP and go to other side and inspect the wheel clyinder and take picture of that side.

If both sides are not leaking and the brake shoe lining material is ok, just change the master cylinder for now.

Go to harbor freight and get a set up brake line wrenches. http://www.harborfreight.com/5-piece-sae-double-end-flare-nut-wrench-set-68865.html

Or Craftsman: http://community.craftsman.com/Craftsman-4-pc-Standard-Flare-Nut-Wrench-Set-reviews

Posted By: therocks

Re: Proper Way to Jack a Car... - 10/07/12 12:57 PM

Line wrenchs from Harbor Freight?I think vice grips are better.Buy a real line wrench.SnapOn.It will las a life time and pay for itself.When the lines are rust and stuck I have a set of side cutters.Cut the end off and use a 6 point socket.Same with the whl cyl bolts.Use a 6 point.If they snap just get new bolts and use anti sieze.Same with the hard lines.I also have SnapOn bleeder wernchs.They will turn the bleeders 99% pf the time without snapping.Yeha they are pricey but they work.I had to have them for work but also had them at home.You havent seen rust till you work on Ohio stuff.I just hope your helper has some tools and can flare lines.Best to replace them if they are rusty.Rocky

Posted By: GoodysGotaCuda

Re: Proper Way to Jack a Car... - 10/07/12 02:06 PM

Quote:

Someone above mentioned visegrips. I have to agree, I never use wrenches on stuff like this, they strip out pieces way too much. I always just use a nice set of the angled grip pliers or some vicegrips. They knock it out no problem, and you wont strip it.

roe

Sounds like cheap line wrenches. After a time or two those vice grips are going to knurl up the soft metal of the brake line fitting. I'll use vice grips on a fastener I'll never use again.

Posted By: bboogieart

Re: Proper Way to Jack a Car... - 10/07/12 02:27 PM

First purchase should be a shop manual for your year and model. It's all there. That's how I learned befor there was an inner net.

I always use four good jack stands on a level surface, then cut the break lines with a saw or diagonal cutter pliers, and use a 6 point socket and a breaker-bar for the bolts. The flare wrenches are handy for installation. Your gonna need to remove all the springs and might as well pull the shoes too, to remove the cylinders. These should be replaced as well. When doing brakes on older cars I replace everything, from the master or booster right down to the hardware and pads. I used to just fix what was leaking but soon found out where the next weakest point was.

The lines are cheap to replace and easy to bend, just copy the parts you remove. Don't make it too hard on yourself, it's really just a simple job once you do a couple times. Take your time and keep saftey in mind and you will be O.K.

If you decide to replace just the master as rcomended, you will still need to break away the bleeder screws. If those break off you will be replacing the wheel cylinders any way.

Posted By: DoctorDiff

Re: Replacing Wheel Cylinders... Rusted Bolts and Lines. - 10/07/12 05:03 PM

If the tubing nuts are rusted to the lines, you can unbolt the wheel cylinders then spin them loose while holding the tubing nuts stationary.

Posted By: MuuMuu101

Re: Replacing Wheel Cylinders... Rusted Bolts and Lines. - 10/07/12 06:22 PM

Well, my friend is most likely coming over next week to help me out. He has the proper tools and know how since he's done all of this on his car. We're basically going to go through the entire braking system (i.e. wheel cylinders, lines, and MC).

Posted By: mikemee1331

Re: Proper Way to Jack a Car... - 10/07/12 07:08 PM

Quote:

Line wrenchs from Harbor Freight?I think vice grips are better.Buy a real line wrench.SnapOn.It will las a life time and pay for itself.When the lines are rust and stuck I have a set of side cutters.Cut the end off and use a 6 point socket.Same with the whl cyl bolts.Use a 6 point.If they snap just get new bolts and use anti sieze.Same with the hard lines.I also have SnapOn bleeder wernchs.They will turn the bleeders 99% pf the time without snapping.Yeha they are pricey but they work.I had to have them for work but also had them at home.You havent seen rust till you work on Upstate New York stuff.I just hope your helper has some tools and can flare lines.Best to replace them if they are rusty.Rocky

and corrected

and corrected

Posted By: bonefish

Re: Replacing Wheel Cylinders... Rusted Bolts and Lines. - 10/07/12 07:10 PM

idont care what kind of line wrenches you have when the nuts are that rusty they usually strip.vise grips are your freind and even if you have stripped them as long as you didnt twist the line you can reinstall them tight enough with the vice grips.

Posted By: MuuMuu101

Re: Proper Way to Jack a Car... - 10/07/12 07:35 PM

Quote:

Quote:

Line wrenchs from Harbor Freight?I think vice grips are better.Buy a real line wrench.SnapOn.It will las a life time and pay for itself.When the lines are rust and stuck I have a set of side cutters.Cut the end off and use a 6 point socket.Same with the whl cyl bolts.Use a 6 point.If they snap just get new bolts and use anti sieze.Same with the hard lines.I also have SnapOn bleeder wernchs.They will turn the bleeders 99% pf the time without snapping.Yeha they are pricey but they work.I had to have them for work but also had them at home.You havent seen rust till you work on Upstate New York stuff.I just hope your helper has some tools and can flare lines.Best to replace them if they are rusty.Rocky

and corrected

and corrected

All my line wrenches and sockets I've been using are brand new Craftsmans I've bought within the past 3 months. Idk where Harbor Freight came from.  I know for a fact my friend has the tools, he used to flip tools off of CL for extra money. Not only that but he did the brakes on his car and is going to convert the front to discs soon. Even when I showed him the pics of the fastener he said to me, "You do realize they have specific tools to take those off, right?"

I know for a fact my friend has the tools, he used to flip tools off of CL for extra money. Not only that but he did the brakes on his car and is going to convert the front to discs soon. Even when I showed him the pics of the fastener he said to me, "You do realize they have specific tools to take those off, right?"

Posted By: autoxcuda

Re: Proper Way to Jack a Car... - 10/07/12 08:16 PM

Quote:

Quote:

Quote:

Line wrenchs from Harbor Freight?I think vice grips are better.Buy a real line wrench.SnapOn.It will las a life time and pay for itself.When the lines are rust and stuck I have a set of side cutters.Cut the end off and use a 6 point socket.Same with the whl cyl bolts.Use a 6 point.If they snap just get new bolts and use anti sieze.Same with the hard lines.I also have SnapOn bleeder wernchs.They will turn the bleeders 99% pf the time without snapping.Yeha they are pricey but they work.I had to have them for work but also had them at home.You havent seen rust till you work on Upstate New York stuff.I just hope your helper has some tools and can flare lines.Best to replace them if they are rusty.Rocky

and corrected

and corrected

All my line wrenches and sockets I've been using are brand new Craftsmans I've bought within the past 3 months. Idk where Harbor Freight came from.  I know for a fact my friend has the tools, he used to flip tools off of CL for extra money. Not only that but he did the brakes on his car and is going to convert the front to discs soon. Even when I showed him the pics of the fastener he said to me, "You do realize they have specific tools to take those off, right?"

I know for a fact my friend has the tools, he used to flip tools off of CL for extra money. Not only that but he did the brakes on his car and is going to convert the front to discs soon. Even when I showed him the pics of the fastener he said to me, "You do realize they have specific tools to take those off, right?"

I mentioned Habor Freight. I didn't realize you all ready had Craftsman line wrenches that look exactly like the one pictured above correct? If you are on a uber budget a HF line wrench is better than nothing.

And no reason you need to step up to Snap On tools right now just after you bought your first hydraulic jack. Walk before you run!

I still think you are making this a bigger project than necessary. And everytime you do that you run the risk of the car sitting there forever until you figure out how to get yourself out of that jamb or get fustrated.

Go jack up the other side of the car and see if that wheel cylinder is leaking. And see how much brake shoe/pad material is left.

If ok, just change the master cylinder today.

Anyways, at least TODAY spray some penetrating fluid on the bleeder screws of the other rear drum, front disks, and master clyinder line connections. That will give it soak in time.

Posted By: MuuMuu101

Re: Proper Way to Jack a Car... - 10/07/12 08:29 PM

O, so that's when Harbor Freight came into the mix. I kind of just glazed through the last couple posts. I just have standard line wrenches (3 contact points) not the flare nut wrenches.

I honestly don't have the time at all today to work on anything on the car. I have homework to catch up on and a group lab I'll be working on later tonight. The earliest I may be able to work on it will be Tuesday, but if not then, maybe Thursday... I'll spray those guys today real quick and check how much of my pads I have left.

Posted By: autoxcuda

Re: Proper Way to Jack a Car... - 10/07/12 08:40 PM

Quote:

O, so that's when Harbor Freight came into the mix. I kind of just glazed through the last couple posts. I just have standard line wrenches (3 contact points) not the flare nut wrenches.

....

He're getting caught up in terminology.

Some people call those Flare Nut Wrenches, Line Wrenches. I think because you use them on Hydraulic/Air lines.

You need set of those to do brake work.

The bleeder screws can be loosened with a 6-point socket of the correct size. DO NOT use a 12-point socket on those.

It would take you 5 minutes to spray the bleeder screws with penetrate. You don't need to jack up the car again.

If you only have one day of limited time to fix your brakes next weekend, just replace what is bad (master cly.) and bleed the brakes.

Do you have new brake shoes for the back?

Posted By: MuuMuu101

Re: Proper Way to Jack a Car... - 10/07/12 08:56 PM

Quote:

Quote:

O, so that's when Harbor Freight came into the mix. I kind of just glazed through the last couple posts. I just have standard line wrenches (3 contact points) not the flare nut wrenches.

....

He're getting caught up in terminology.

Some people call those Flare Nut Wrenches, Line Wrenches. I think because you use them on Hydraulic/Air lines.

You need set of those to do brake work.

The bleeder screws can be loosened with a 6-point socket of the correct size. DO NOT use a 12-point socket on those.

It would take you 5 minutes to spray the bleeder screws with penetrate. You don't need to jack up the car again.

If you only have one day of limited time to fix your brakes next weekend, just replace what is bad (master cly.) and bleed the brakes.

Do you have new brake shoes for the back?

I already sprayed the screws again. After Thursday I'll get some time. I can work on the MC on Friday before my friend comes on Saturday. But if I don't finish that, I'll make it our first priority. And that's a negative on the brake shoes.

Thanks for the help everyone! I actually need to head out now. I won't be back till much much later.

Posted By: mikemee1331

Re: Proper Way to Jack a Car... - 10/07/12 09:12 PM

I still think you are making this a bigger project than necessary. And everytime you do that you run the risk of the car sitting there forever until you figure out how to get yourself out of that jamb or get fustrated.

Go jack up the other side of the car and see if that wheel cylinder is leaking. And see how much brake shoe/pad material is left.

If ok, just change the master cylinder today.

Anyways, at least TODAY spray some penetrating fluid on the bleeder screws of the other rear drum, front disks, and master clyinder line connections. That will give it soak in time.

and i think WE have made the job bigger than it is!

and i think WE have made the job bigger than it is!

Posted By: MuuMuu101

Re: Proper Way to Jack a Car... - 10/09/12 08:33 PM

So, just thinking during my lunch break today. Main priorities for the brake system for Friday and Saturday...

1) Bench Bleed and replace the Master Cylinder.

2) If time and skills permit... Replace wheel cylinders...

3) If more time and skills permit... Replace lines.

Good/Bad? Do you think I will be fine with just replacing the Master Cylinder instead of making this too complicated or burdensome than it should be?

Posted By: mikemee1331

Re: Proper Way to Jack a Car... - 10/09/12 10:26 PM

i think that's a fine plan BUT....... be prepared to replace ALL the lines once you start trying to break them free. also understand that the only reference point i have are cars from rust belt areas. it's entirely possible that the connections can be loosened with just oil, a torch (hand-held propane) and decent tools (which it appears you have). i have no idea what a Cali car looks like after 45 years.

or tips will be appreciated... I was thinking WD40 might loosen it up, but I don't think I have any at home.

or tips will be appreciated... I was thinking WD40 might loosen it up, but I don't think I have any at home.

and corrected

and corrected  I know for a fact my friend has the tools, he used to flip tools off of CL for extra money. Not only that but he did the brakes on his car and is going to convert the front to discs soon. Even when I showed him the pics of the fastener he said to me, "You do realize they have specific tools to take those off, right?"

I know for a fact my friend has the tools, he used to flip tools off of CL for extra money. Not only that but he did the brakes on his car and is going to convert the front to discs soon. Even when I showed him the pics of the fastener he said to me, "You do realize they have specific tools to take those off, right?"