Posted By: autoxcuda

Building a custom Fan Shroud: Pic by pic - 07/23/12 06:06 AM

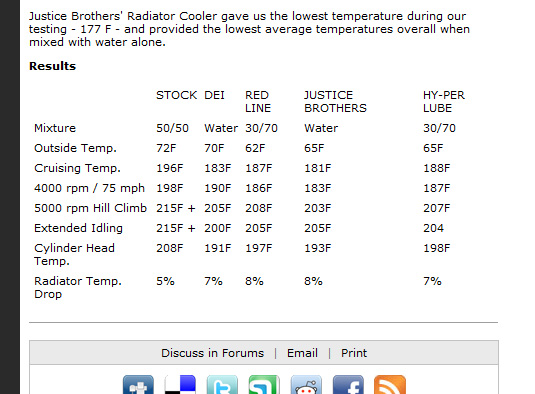

I have a Champion 4 core 22” radiator that has performed well in my new 416 stroker small block. I’ve put 3458 miles the motor in 1 ½ years and driven a few times 80 miles @3700rpm to/from Willow Springs Raceway racing 60 laps/150 miles going about 130 mph @ 5800 rpm on straights. Radiator looks great inside, no rust, and no measured electrolysis. I run distilled water and Justice Brothers Radiator Cooler (RC/22P) and Justice Brothers Cooling System Protector ( CSP/1P). No major cooling problems, but I don’t run a fan shroud.

Once in 88 degree heat I got stuck in road construction barely moving for 20 minutes. Motor got up to 215 degrees. The fan by itself just could not pull enough air without the car moving. Time for a shroud.

When we first built the motor, the Champion upper radiator hose mounted way too close to the center and hit my 18” 5 blade MP fan kit. So I cut 1” off each blade of a 5 blade and made a 16” fan. The car still performed pretty darn good with a skimpy looking 16” fan and no shroud. I run the short Jaguar fan clutch (Hayden #2765) because of the thick radiator and 70-up taller aluminum water pump.

The upper hose inlet tube had to be moved outward to fit any fan shroud. Radiator Works in Northridge, Ca did that and added a aluminum tab on top to help attach a shroud.

The factory 68-69 and 70-72 V-8 shrouds needed cutting to end up with a marginal shroud. So I traded some parts with Troy and he said he’d make me a shroud if I helped.

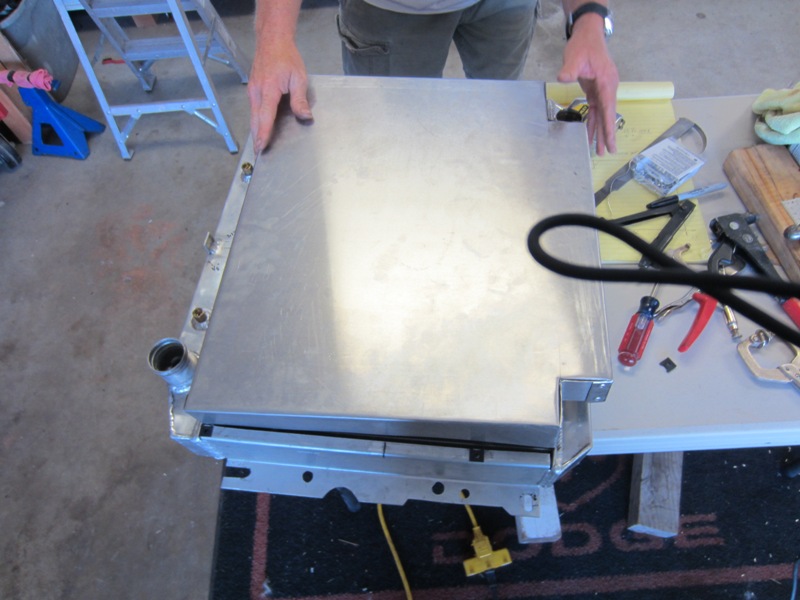

Here’s the pictures that tell the story….

That aluminum angle is 1/16" thick and 3/4" by 1/2". 48" long piece. The 20 gauge aluminum sheet was $21.75 for a 24" x 48" piece.

Once in 88 degree heat I got stuck in road construction barely moving for 20 minutes. Motor got up to 215 degrees. The fan by itself just could not pull enough air without the car moving. Time for a shroud.

When we first built the motor, the Champion upper radiator hose mounted way too close to the center and hit my 18” 5 blade MP fan kit. So I cut 1” off each blade of a 5 blade and made a 16” fan. The car still performed pretty darn good with a skimpy looking 16” fan and no shroud. I run the short Jaguar fan clutch (Hayden #2765) because of the thick radiator and 70-up taller aluminum water pump.

The upper hose inlet tube had to be moved outward to fit any fan shroud. Radiator Works in Northridge, Ca did that and added a aluminum tab on top to help attach a shroud.

The factory 68-69 and 70-72 V-8 shrouds needed cutting to end up with a marginal shroud. So I traded some parts with Troy and he said he’d make me a shroud if I helped.

Here’s the pictures that tell the story….

That aluminum angle is 1/16" thick and 3/4" by 1/2". 48" long piece. The 20 gauge aluminum sheet was $21.75 for a 24" x 48" piece.

....

....