|

"Dynamic Comp Ratio" doesn't mean ZIP!!!

#2473992

"Dynamic Comp Ratio" doesn't mean ZIP!!!

#2473992

03/29/18 07:47 PM

03/29/18 07:47 PM

|

Joined: Jan 2003

Posts: 15,439

Val-haul-ass... eventually

BradH

OP

OP

Taking time off to work on my car

|

OP

OP

Taking time off to work on my car

Joined: Jan 2003

Posts: 15,439

Val-haul-ass... eventually

|

I've seen another round of posts here and elsewhere recently where the belief is that you can calculate a "Dynamic" CR based on the engine's static CR and IVC event to determine the octane requirement (tolerance?) of an engine. It's bullsh!t. Shoving a big-a$$ cam in a high CR engine in order to lower the cranking pressure is nothing but a Band-Aid to lower the operating compression ratio (the engine's Volumetric Efficiency % vs the calc'd "static" CR at at a given RPM) up to the RPM point where the engine is operating at 100%+ VE. At that point, the REAL "dynamic" cylinder pressure is going to be the calc'd "static" CR + the additional cylinder filling resulting from the VE efficiency exceeding 100%. It's not me who is trying, or has tried, to get people to understand that DCR isn't telling you what you think it does. ==> Tim Wusz (formerly of Union 76 Racing Fuel and currently with Rockett Brand Racing Fuel) was quoted in Hot Rod at least 20 years ago that you can crutch the octane needed by bleeding off more pressure with extra duration, but that it only works up to a certain RPM point for a given engine, and you'll most likely need to run the ignition pulled back from optimum for an additional margin of safety. Beyond that point, you're at a very high risk of detonating. ==> Years ago on SpeedTalk, the late Harold Brookshire (the founder of UltraDyne Cams) and Mike Jones (of Jones Racing Cams) were involved in a lengthy thread where they both tried to get people to understand how the "Dynamic" CR calculation is anything BUT dynamic, and should not be used as a parameter for either building an engine or targeting a particular octane to use with that build. And today I stumbled across a short article (since I'm not going to go digging thru the SpeedTalk archives to revive that old thread) where the author does a pretty decent job of explaining it, IMO: http://www.matrixgarage.com/content/why-dynamic-compression-ratio-nearly-uselessDo I expect everyone is going to agree with this? He11 no!  There are still some well-known engine builders who push the DCR approach in their pump-gas builds. If it works for them...  Agree or not, IMO you should at least read about it so that your understanding of this approach -- and why it's considered seriously flawed by some -- is clearer. Carry on!

|

|

|

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!!

[Re: BradH]

#2474020

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!!

[Re: BradH]

#2474020

03/29/18 08:40 PM

03/29/18 08:40 PM

|

Joined: Oct 2007

Posts: 4,206

New York

polyspheric

master

|

master

Joined: Oct 2007

Posts: 4,206

New York

|

I agree, well said, thanks.

Boffin Emeritus

|

|

|

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!!

[Re: BradH]

#2474027

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!!

[Re: BradH]

#2474027

03/29/18 08:55 PM

03/29/18 08:55 PM

|

Joined: Jan 2005

Posts: 2,540

Milwaukee WI

TRENDZ

master

|

master

Joined: Jan 2005

Posts: 2,540

Milwaukee WI

|

So what your saying is there is no validity in using lsa/ duration to widen the range that low octane fuel will operate in.

Wrong.

"use it 'till it breaks, replace as needed"

|

|

|

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!!

[Re: BradH]

#2474031

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!!

[Re: BradH]

#2474031

03/29/18 09:05 PM

03/29/18 09:05 PM

|

Joined: Jan 2003

Posts: 7,477

Minnesota

Hemi_Joel

master

|

master

Joined: Jan 2003

Posts: 7,477

Minnesota

|

My thinking was the same as BradH, so I asked someone who is pretty smart on this stuff. (A successful enginemasters contestant) If I remember right, he said that peak VE occurs at the same rpm as peak torque. Below that rpm, with a big womping cam, you are bleeding off enuff cylinder pressure to reduce the chance for detonation. And above peak torque, ve drops off naturally, also diminishing the chance for detonation.

[img]http://i.imgur.com/boeexFms.jpg[/img]31 Plymouth Coupe, 392 Hemi, T56 magnum RS23J71 RS27J77 RP23J71 RO23J71 WM21J8A I don't regret the things I've done. I only regret the things I didn't do. "Wise men talk because they have something to say; fools because they have to say something. ~ Plato"

|

|

|

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!!

[Re: BradH]

#2474075

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!!

[Re: BradH]

#2474075

03/29/18 10:23 PM

03/29/18 10:23 PM

|

Joined: Jul 2013

Posts: 561

USA

B3RE

mopar

|

mopar

Joined: Jul 2013

Posts: 561

USA

|

I've been trying to explain this to guys for years. The IVC alone doesn't acount for volumetric efficiency. The port CSA and approach angle, the intake ram tuning effect, rpm, and several other factors play a role. A 10:1 383 with stock 906s and a long runner dual plane will detonate before the same spec engine with -1s and a large single plane. Higher port velocity is more efficient at filling the cylinder at lower rpm where detonation occurs. That inertia is going to be different among different engine combinations, regardless whether the dynamic number remains the same.

Mike Beachel

I didn't write the rules of math nor create the laws of physics, I am just bound by them.

|

|

|

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!!

[Re: BradH]

#2474311

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!!

[Re: BradH]

#2474311

03/30/18 11:47 AM

03/30/18 11:47 AM

|

Joined: Jan 2005

Posts: 3,635

Oakland, MI

dizuster

master

|

master

Joined: Jan 2005

Posts: 3,635

Oakland, MI

|

DCR is a nice easy way to show how the late intake valve closing point changes effective compression ratio. Sure with the right cylinder head the VE% still gets at or over 100% at some RPM. But with late IVC that RPM is always higher right? (big cams turn more RPM). The higher the RPM, the less prone the engine is to detonation. Meaning without a doubt... late IVC (lower DCR) is better for detonation resistance. This is a GREAT article about detonation if you have time to read it. That being said... some excerpts below about DCR DOES mean ZIP. https://www.sciencedirect.com/science/article/pii/S0360128516300764From section 5.1 "Conventional knock is a race between the flame in the engine and the thermal auto-ignition of the unburned “end gas” [1]. The principle for avoiding engine knock is that the time of flame propagation to the end gas (τ1) is less than the time of the end-gas auto-ignition (τ2)."Obviously the faster the engine is turning, the shorter the combustion time, and the less time the end gas (part of the mixture away from the plug) has to auto-ignite. Since big cams have late IVC, they naturally want to turn more RPM. They also naturally bleed off pressure at lower RPM where detonation is most likely. Again as stated in the paper above... 5.1.5.3. Lowering effective compression ratio [110,127,258,262,317–321]

Variable valve timing (VVT) is a practical way to change effective compression ratio at relatively low cost for the different engine operating regions. Late intake valve closure (LIVC) is commonly used at high load to achieve a lower effective compression ratio to avoid knock. Again... from another SAE paper... Experimental investigation on early and late intake valve closures for knock mitigation... The application of Miller cycle through Late Intake Valve Closure (LIVC) or Early Intake Valve Closure (EIVC) for knock mitigation at high load on a turbocharged downsized spark ignition engine was experimentally investigated. By reducing the effective compression ratio due to a shorter compression stroke and hence achieving lower charge temperatures inside the cylinder, significant mitigation of knock tendency could be obtained. Don't get me wrong... being at the track and trying things is VERY valuable. People want to discredit science based findings because "they saw once" or "I heard once", or "I knew a guy who" type single events in an uncontrolled environment. We as racers have a lot of opinions on technical things based on VERY limited experience compared to the OEM's and universities. These guys are looking at knock at 240,000fps cameras, spending MILLIONS of dollars trying to prevent it to improve horsepower and efficiency. If you look around for these types of published papers, you will see that it's basically common knowledge that a late IVC helps with detonation. Yet here we are still arguing about it...

|

|

|

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!!

[Re: BradH]

#2474348

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!!

[Re: BradH]

#2474348

03/30/18 01:16 PM

03/30/18 01:16 PM

|

Joined: Jan 2003

Posts: 15,439

Val-haul-ass... eventually

BradH

OP

OP

Taking time off to work on my car

|

OP

OP

Taking time off to work on my car

Joined: Jan 2003

Posts: 15,439

Val-haul-ass... eventually

|

Just to be clear, I did NOT say that a later IVC doesn't reduce cylinder pressure at lower RPM. What I said, and then referenced people waaaay smarter than I am in this arena, was that you can't calc a single DCR value and use it for an accurate build parameter and measure of octane requirement. And, that the late(r) IVC approach is basically a crutch with limitations on its effectiveness.

If I had VVT and a computer-controlled ignition that detects knock, etc. and could also adjust the timing as necessary, then that would be a highly sophisticated Band-Aid for the basic scenario of excessive cylinder pressure.

How many people on this board are using that sort of technology w/ their "traditional" SB / BB / Gen II Hemi builds?

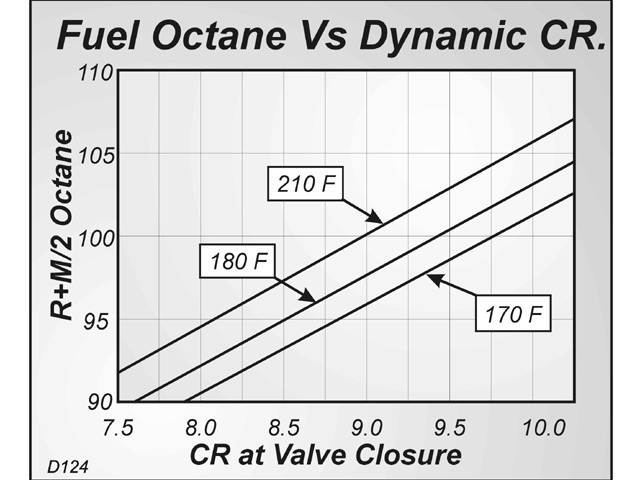

Someone asked where the correlation between DCR and octane was made: David Vizard, well-known engine tech writer, has a chart he's used in articles and his books that I posted below.

I own a LOT of DV books and have learned a bunch from him, but this stuff can't be interpreted as a One Size Fits All thing. You can't even get people to agree on what cam/lift point to use for setting the IVC event, so how can you derive anything about a value for which 5 different people might get an equal number of different answers?

|

|

|

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!!

[Re: BradH]

#2474406

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!!

[Re: BradH]

#2474406

03/30/18 02:53 PM

03/30/18 02:53 PM

|

Joined: May 2008

Posts: 5,399

Aurora, Colorado

451Mopar

master

|

master

Joined: May 2008

Posts: 5,399

Aurora, Colorado

|

Someone asked where the correlation between DCR and octane was made: David Vizard, well-known engine tech writer, has a chart he's used in articles and his books that I posted below.

I own a LOT of DV books and have learned a bunch from him, but this stuff can't be interpreted as a One Size Fits All thing. You can't even get people to agree on what cam/lift point to use for setting the IVC point, so how can you derive anything about a value for which 5 different people might get an equal number of different answers?

Thanks, I was the one wondering where that came from. Your right on the IVC point also, some say to use 0.050 duration numbers, others advertised duration (0.006" hydraulic, and 0.020" solid?) At least the chart does show a difference for different temperatures, usually totally ignored in most discussions. There is also the topic of "quench" distance, but usually no discussion of the "quench" area. There is a good difference between the "closed chamber" RPM / Stealth type heads with a "D" type chamber, and the Victor / Trick Flow heads with a heart shaped chamber. Not to mention the difference in spark plug locations and bore size. For me, I use the advertised duration numbers to estimate IVC, and usually if the effective compression ratio is less than 8:1 I believe that I am giving up some low end torque and efficiency that could be improved with more static compression?

|

|

|

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!!

[Re: BradH]

#2474416

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!!

[Re: BradH]

#2474416

03/30/18 03:14 PM

03/30/18 03:14 PM

|

Joined: Jul 2013

Posts: 561

USA

B3RE

mopar

|

mopar

Joined: Jul 2013

Posts: 561

USA

|

The effective ratio is the same as static once the engine reaches 100% volumetric efficiency. If, for example, 8.5:1 dynamic was the cat's meow for pump gas, then why not build every engine for 8.5:1, and close the intake valve at BDC. I can hear the keyboards pounding already. But Mike, but Mike, you have to close it later so the flow inertia continues to fill the cylinder after BDC, and there is still adequate curtain area at BDC to flow air to fill the cylinder effectively.

Well, EXACTLY! Inertia comes into play as soon as the engine fires off, and there are too many factors involved to "shoot" for a given DCR. The VVT engines, as Brad stated, are computer controlled to run higher static numbers, make more power, and be more efficient.

In short, the engine doesn't give a rat's patootie when the intake valve closes. It only knows how much of a charge is in the cylinder. Make peak torque at a higher rpm, have less chance of detonation. Even the exhaust system will have an effect on peak torque.

Mike Beachel

I didn't write the rules of math nor create the laws of physics, I am just bound by them.

|

|

|

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!!

[Re: BradH]

#2474445

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!!

[Re: BradH]

#2474445

03/30/18 04:28 PM

03/30/18 04:28 PM

|

Joined: Jan 2003

Posts: 15,439

Val-haul-ass... eventually

BradH

OP

OP

Taking time off to work on my car

|

OP

OP

Taking time off to work on my car

Joined: Jan 2003

Posts: 15,439

Val-haul-ass... eventually

|

... you can't calc a single DCR value and use it for an accurate build parameter and measure of octane requirement...

You can't even get people to agree on what cam/lift point to use for setting the IVC event, so how can you derive anything about a value for which 5 different people might get an equal number of different answers?

More on the comments above, and then I'll let this run its course regardless of what direction is goes. Let's take a real-world example from my latest build on the predictive power of a DCR value: 1. I've profiled my cam lobe curve and know that the SAE seat duration (measured at .004" lobe lift above lash) for my solid roller is 307* with .018" lash. 2. Using Wallace Racing's camshaft event calculator, I've determined that the SAE IVC is 77.5* ABDC 3. Using Wallace Racing's dynamic compression calculator, I've determined that with my static compression ratio of 11.47:1, the dynamic compression ratio is 8.06:1. It also "thinks" my dynamic cranking pressure is 161.44 PSI. 4. According to DV's DC/Octane chart, I can run 91 octane R+M/2 fuel at 170* F water temp (even though my car runs a 160* 'stat). Observations: A. My engine's cranking pressure is more like 190+ B. When we dyno'd the engine using 3500-72000 RPM pulls, there's no doubt in my mind it would have gone into "death rattle" at some point using 91 octane, regardless of .040" quench, aluminum heads & heart-shaped chambers C. Anyone who wants to build an identical engine to prove me wrong is welcome to So... let's "game" the calculator input and use the IVC @ .020" of 74* ABDC, despite that fact that we've now lost all the effect of lash on actual duration: - "Your dynamic compression ratio is 8.37:1" - "Your dynamic cranking pressure is 169.53 PSI" According to DV's DC/Octane chart, I can run 92 or 93 octane R+M/2 fuel. And the 170 PSI calc'd cranking pressure is still waaaay below reality. So... let's totally "crutch" the calculator input and use the IVC @ .050" of 57* ABDC, despite that fact that we've now lost all the effect of lash on actual duration AND have completely ignored the fact that the duration at .050" value can't be used accurately to extrapolate an IVC point due to the wide variety of cam profiles available with approx. the same .050" duration. - "Your dynamic compression ratio is 9.60:1" - "Your dynamic cranking pressure is 202.18 PSI" According to DV's DC/Octane chart, I need to run 98 or 99 octane R+M/2 fuel. Perhaps the last attempt is the most accurate at predicting cranking pressure and octane requirement... but it also required pulling 20* out of the MEASURED SAE IVC point, which is what the engine is actually going to "see" when running. Familiar with the term GIGO? Garbage In, Garbage Out... If you have to f**k with the actual data that much to make your tool's results come out within reason, "something" is flawed.

|

|

|

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!!

[Re: BradH]

#2474542

Re: "Dynamic Comp Ratio" doesn't mean ZIP!!!

[Re: BradH]

#2474542

03/30/18 08:28 PM

03/30/18 08:28 PM

|

Joined: Nov 2015

Posts: 874

Missouri

jwb123

super stock

|

super stock

Joined: Nov 2015

Posts: 874

Missouri

|

Their are a lot of vairables to cylinder pressure in a running engine. Dynamic compression ratio concept is that if the intake or exhaust valve is open its kind of hard to compress the air fuel mixture, so its calculated off of when intake valve closes. In a running engine the ramming effect of the air fuel charge affects cylinder pressure, because you can start to compress the air fuel charge against the in coming air fuel charge. I do not agree with the statement that dynamic compression does not mean ZIP. The comment was in referance to running high static compression pistons with a cam big enough to lower the cylinder pressure to run lower octane fuel. But lets look at the same issue from the other end. Put a big cam in a low compression engine and see what you get, a pig that sounds neat but won't get out of its on way. Before I understood better some of these factors as a youger man back in the 70's my freinds and I made this mistake several times. I am not an engineer and not very good at math, but I have used computer engine software to design my engine combinations for many years. Several years ago I built a couple pulling truck engines that were required by rules to run 91 octane fuel. Those engines had 13 to 1 static compression pistons, they one ran good enough to win the points championship that year, and get pulled for fuel inspection, etc. All legal and on the rules. The software I use calculates the dynamic compression and the cranking compression, idle vaccum, as well as the octane requirements of the engine. Knock on wood it has not let me down yet. Last engine I built for pump gas was a 500 cid wedge with 906 heads, for a roadrunner, it ran 10.90's with full interior and all steel body. It had 11 to 1 pistons, and a smaller cam because the owner wanted a decent idle, it had 16 inches of idle vacuum. One thing I will say all the variables to engine design have been pretty much thrashed out by the 1920's We keep revisiting those variables as technology, and materials improve, but the basic theroies all were worked out 100 years ago. Todays engines use viarable valve timing to run much higher static compression ratios and eliminate need for EGR and run super clean as far as emmissions go, so there is a big role for valve events to play in engine design.

|

|

|

|

|