|

Re: Shock Tech

[Re: EricatAFCO]

#932008

Re: Shock Tech

[Re: EricatAFCO]

#932008

02/19/11 10:18 AM

02/19/11 10:18 AM

|

Anonymous

Unregistered

|

Anonymous

Unregistered

|

Quote:

Quote:

I have been having this issue for awhile now. Car initially hooks then spins bad....I have had my double adj shocks all over with the adjustments and nothing seems to work at all. Have had 3 diff rear springs on it as well 150, 130, and now currently. 110s. Made no change. I run ladder bars. Im thinking I need a stiff sidewall tire. I run a 29.5x11.5 mt. Car runs mid to upper 1.3 s and 9.60s and weighs 3100. Should be in the high 1.2s. I feel with my alky injection. Any suggestions? Thanks for your time.

We want to spring the car as softly as possible without causing the spring to bow. The softer choice should provide the most consistent performance given multiple track conditions... If your car weights 3100 and is something like 55% front, 45% rear or so, The 110#'s should be ok, again as long as they aren't hitting the springs..

Ladder bar cars usually respond well to a fair amount of pinion angle. I have seen cars go from not trying to work with 2-3 degrees to hanging the front end with 5 degrees. Again, the front end has to work too. If it is dead, we may not get maximum performance out of the car. Also, we have to make sure we are bind free...

It was my understanding that Ladder bars only need 2-3 degrees of nose down pinion angle.

What's the benefit of 5 degrees?

|

|

|

Re: Shock Tech

[Re: HEMIFRED]

#932009

Re: Shock Tech

[Re: HEMIFRED]

#932009

02/19/11 12:04 PM

02/19/11 12:04 PM

|

Joined: Feb 2011

Posts: 43

IN

EricatAFCO

OP

OP

member

|

OP

OP

member

Joined: Feb 2011

Posts: 43

IN

|

Quote:

Quote:

I would like to know the difference in shocks, how they work, what makes one better than another, how effective the different types are etc

same here what is so different about the valving used by Santhuff as opposed to most other brands. What are the negatives of using them other than the outrageous costs.

A shock is defined as a hydraulic device that resists movement. Basic shocks have a piston on the end of the shaft with small ports machined in it. As the piston moves thru the column of oil, resistance is created. Only so much fluid can pass thru. The more force that is applied to the shock shaft, the more resistance is generated. Adjustable shocks are manufactured in many ways. Basic adjustable shocks utilize a ported plate that can be turned (by the adjustment mechanism) to cover (or uncover) the ports in the piston. If no restriction is selected, full flow occurs and the shock would be at the full soft setting for that shock. As you dial in more restriction, the shock gets stiffer. More advanced shocks use shims stacked on top of the piston. These shims vary in thickness, may have notches machined in them to allow flow and typically are stacked in a pyramid pattern. The theory here is that as force is applied to the shock, the oil acts on the shims causing them to "blow off". That is to say the shims go into a controlled flex. This action allows the shims to come away from the piston allowing more flow of oil. Now, add to this design a needle and seat mechanism. A needle and seat mechanism when used in a shock will control flow as well. The rule of thumb, like on a fuel pressure regulator is the deeper the needle is in the seat, the more flow is restricted>>>the more resistance is created.

So when you marry a shock design that has a properly ported piston, shim stacks that are built specifically to create the shape (on the dyno) that you are looking for and the needle and seat option, you can manufacture a shock that can control low, medium and high speed shock movements and make the transaction between all ranges very smoothly.

The real secret sauce is in how a shock company develops the valve curves and applys that technology to the type of racing one is working on..That is to say, if you can capture the data from a given application-you can measure how fast shocks move on a given car or typical suspension system, you can then manufacture a shock that adjusts within that proper operating range.

My example is that if you intend to work your engine in a range of 5000 to 7500 rpm, there is not much use in dynoing above that range.

Data acquistion systems are used to measure shock speeds to help shape the valving baselines of a shock program.

Some shocks are designed to be digressive in nature. Some linear and some progressive.

Digressive shocks blow off and do not get stiffer at the same rate as speed increases. (Picture two lines beginning in parallel lines. Speed is the top line, dampening is the bottom. As speed continues in a straight line, dampening begins to curve down.

Linear shock valving has both lines following each other all the way up.

Progressive shock valving is one where the dampening line goes up at a faster rate than the speed line...

One of the questions here specifically calls out a shock brand, what are the negatives of it other than cost etc.....It would not be proper for me to offer a comment here. I am not as familiar with that brand as they would be so my thought is it would be best to contact that company direct. Not ducking that question, just want to be fair.

|

|

|

Re: Shock Tech

#932011

Re: Shock Tech

#932011

02/19/11 12:31 PM

02/19/11 12:31 PM

|

Joined: Feb 2011

Posts: 43

IN

EricatAFCO

OP

OP

member

|

OP

OP

member

Joined: Feb 2011

Posts: 43

IN

|

Quote:

Quote:

Quote:

I have been having this issue for awhile now. Car initially hooks then spins bad....I have had my double adj shocks all over with the adjustments and nothing seems to work at all. Have had 3 diff rear springs on it as well 150, 130, and now currently. 110s. Made no change. I run ladder bars. Im thinking I need a stiff sidewall tire. I run a 29.5x11.5 mt. Car runs mid to upper 1.3 s and 9.60s and weighs 3100. Should be in the high 1.2s. I feel with my alky injection. Any suggestions? Thanks for your time.

We want to spring the car as softly as possible without causing the spring to bow. The softer choice should provide the most consistent performance given multiple track conditions... If your car weights 3100 and is something like 55% front, 45% rear or so, The 110#'s should be ok, again as long as they aren't hitting the springs..

Ladder bar cars usually respond well to a fair amount of pinion angle. I have seen cars go from not trying to work with 2-3 degrees to hanging the front end with 5 degrees. Again, the front end has to work too. If it is dead, we may not get maximum performance out of the car. Also, we have to make sure we are bind free...

It was my understanding that Ladder bars only need 2-3 degrees of nose down pinion angle.

What's the benefit of 5 degrees?

More pinion angle can be a benefit up to a point..as the pinion climbs the ring, it creates downforce. We want those vector forces going directly to the tire contact patch. Two things occur as the pinion gets parallel to the drive shaft, that downforce decreases and moves away from the tire contact patch. I have had the benefit of working with many chassis builders that tell me when they get a chance to work on a car that is not hooking consistently, and they find out the car is lacking some pinion angle, they immediately know that they can help that customer.

Remember, as in most cases, too much of a good thing can be a bad thing. Our u-joints cannot stand excessive angle. The weld yoke will crash into the pinion yoke or slip yoke. Also, as the pinion climbs the ring, the drive shaft moves into the transmission under acceleration....As you let off on the big end, the pinion drops. It then pulls the driveshaft out of the trans. The length of the slip yoke is crutial here..We need enough engagement to cover total movement..Contact your driveline company here for specs..

I would strongly encourage testing of all systems in your car (vary tire pressure, fuel pressure, shock settings, rear suspension changes, front suspension changes). We never know what we leave on the table unless we try something different.

I have personal experience in dialing in more pinion angle. I broke a rear end on a car that was working very well. (Spun the center center section on the tubes at 3 cars in a 5 grand race and killed her on the tree. However, my pass ended about 15 feet out). Replaced the housing but didn't have the same amount of pinion angle. The car didn't work the same. I sent my converter off. I replaced springs. I swapped slicks with no real success. Finally, I made it back to the rear end and added more angle. The car was instantly better-back to where it was previously.

|

|

|

Re: Shock Tech

[Re: Quicktree]

#932012

Re: Shock Tech

[Re: Quicktree]

#932012

02/19/11 12:49 PM

02/19/11 12:49 PM

|

Joined: Feb 2011

Posts: 43

IN

EricatAFCO

OP

OP

member

|

OP

OP

member

Joined: Feb 2011

Posts: 43

IN

|

Quote:

Eric do you pics of different shocks and explain what each does with out naming brands? and maybe some diagrams of the flow each provide?

I understand your end goal here is to gain some understanding of shocks....I believe that an answer to this question could conflict with one my personal beliefs which is to sell on the benefits of ones own product, not talk down the competition...Integrity is very important to me. I hope everyone understands. The shock company I work for uses billet pistions, shim stack design and needle & seat control to develop the curves that are targeted...This design allows for consistent performance, shock after shock. Each shock gets dynoed. Go-no tolerances are held close and the shock techs need to be able to confidently build a run of shocks as efficiently as possible. Also, this design lends itself very well to custom valving options/big power, small tire, drag radials etc.

|

|

|

Re: Shock Tech

[Re: EricatAFCO]

#932013

Re: Shock Tech

[Re: EricatAFCO]

#932013

02/19/11 01:09 PM

02/19/11 01:09 PM

|

Joined: Jan 2003

Posts: 5,987

Anoka County, MN

Leigh

master

|

master

Joined: Jan 2003

Posts: 5,987

Anoka County, MN

|

Quote:

Quote:

Quote:

Quote:

I have been having this issue for awhile now. Car initially hooks then spins bad....I have had my double adj shocks all over with the adjustments and nothing seems to work at all. Have had 3 diff rear springs on it as well 150, 130, and now currently. 110s. Made no change. I run ladder bars. Im thinking I need a stiff sidewall tire. I run a 29.5x11.5 mt. Car runs mid to upper 1.3 s and 9.60s and weighs 3100. Should be in the high 1.2s. I feel with my alky injection. Any suggestions? Thanks for your time.

We want to spring the car as softly as possible without causing the spring to bow. The softer choice should provide the most consistent performance given multiple track conditions... If your car weights 3100 and is something like 55% front, 45% rear or so, The 110#'s should be ok, again as long as they aren't hitting the springs..

Ladder bar cars usually respond well to a fair amount of pinion angle. I have seen cars go from not trying to work with 2-3 degrees to hanging the front end with 5 degrees. Again, the front end has to work too. If it is dead, we may not get maximum performance out of the car. Also, we have to make sure we are bind free...

It was my understanding that Ladder bars only need 2-3 degrees of nose down pinion angle.

What's the benefit of 5 degrees?

More pinion angle can be a benefit up to a point..as the pinion climbs the ring, it creates downforce. We want those vector forces going directly to the tire contact patch. Two things occur as the pinion gets parallel to the drive shaft, that downforce decreases and moves away from the tire contact patch. I have had the benefit of working with many chassis builders that tell me when they get a chance to work on a car that is not hooking consistently, and they find out the car is lacking some pinion angle, they immediately know that they can help that customer.

Remember, as in most cases, too much of a good thing can be a bad thing. Our u-joints cannot stand excessive angle. The weld yoke will crash into the pinion yoke or slip yoke. Also, as the pinion climbs the ring, the drive shaft moves into the transmission under acceleration....As you let off on the big end, the pinion drops. It then pulls the driveshaft out of the trans. The length of the slip yoke is crutial here..We need enough engagement to cover total movement..Contact your driveline company here for specs..

I would strongly encourage testing of all systems in your car (vary tire pressure, fuel pressure, shock settings, rear suspension changes, front suspension changes). We never know what we leave on the table unless we try something different.

I have personal experience in dialing in more pinion angle. I broke a rear end on a car that was working very well. (Spun the center center section on the tubes at 3 cars in a 5 grand race and killed her on the tree. However, my pass ended about 15 feet out). Replaced the housing but didn't have the same amount of pinion angle. The car didn't work the same. I sent my converter off. I replaced springs. I swapped slicks with no real success. Finally, I made it back to the rear end and added more angle. The car was instantly better-back to where it was previously.

Eric. Sounds like my car to a T. Regarding pinion angle, I read that same idea in 1998. It was dismissed by some, but I always thought it made sense. Looks like it's time to try something other than 2*. Thanks for the tips.

Leigh

|

|

|

Re: Shock Tech

[Re: Leigh]

#932014

Re: Shock Tech

[Re: Leigh]

#932014

02/20/11 12:20 PM

02/20/11 12:20 PM

|

Joined: Jan 2003

Posts: 9,985

Frostbitefalls MN (Rocky&Bullw...

gregsdart

master

|

master

Joined: Jan 2003

Posts: 9,985

Frostbitefalls MN (Rocky&Bullw...

|

When you suggest more pinion angle, are you adjusting the angle itself by adjusting the ladderbar only (no movement of the front mount or vehicle height change) and leaving the instant center in the exact same location?

Last edited by gregsdart; 02/20/11 12:26 PM.

8..603 156 mph best, 2905 lbs 549, indy 572-13, alky

|

|

|

Re: Shock Tech

[Re: gregsdart]

#932015

Re: Shock Tech

[Re: gregsdart]

#932015

02/20/11 12:25 PM

02/20/11 12:25 PM

|

Joined: Jan 2003

Posts: 9,985

Frostbitefalls MN (Rocky&Bullw...

gregsdart

master

|

master

Joined: Jan 2003

Posts: 9,985

Frostbitefalls MN (Rocky&Bullw...

|

I have Afco double adjustables on all four corners. Great shocks, looking to get the most out of them. I have the car in the sig obviously, 3000 lbs, ladder bars 30 inches long, leave off trans brake at 4500 Vs a 6400 stall. The weight dist is now 47.5 rear 52.5 front. I have started testing with the rears soft on extension, medium on compression and have progressed to about the middle of their adjustment for stiffness, seems to be about right as the 60 fts went from 1.28 down to 1.259 and got very consistent. Fronts are still dead soft on extension , fairly stiff on compression to help with the landing.

Where would you go from here? The car wheelstands and hits the 66 inch wheelie bars fairly hard. I have about four inches of travel up front.

My thoughts are to start stiffening the shock rebound a touch, then after finding a good point for that start shortening front travel, which is about four inch of rise. Any change to that plan?

8..603 156 mph best, 2905 lbs 549, indy 572-13, alky

|

|

|

Re: Shock Tech

[Re: gregsdart]

#932016

Re: Shock Tech

[Re: gregsdart]

#932016

02/20/11 02:51 PM

02/20/11 02:51 PM

|

Joined: Feb 2011

Posts: 43

IN

EricatAFCO

OP

OP

member

|

OP

OP

member

Joined: Feb 2011

Posts: 43

IN

|

Quote:

When you suggest more pinion angle, are you adjusting the angle itself by adjusting the ladderbar only (no movement of the front mount or vehicle height change) and leaving the instant center in the exact same location?

Yes, dial in more pinion angle and leave the front heim joint in the same position..When adjusting pinion angle, take care to adjust both sides equally. It is easy to make an adjustment to pinion angle and change how the car leaves right to left too. If the left tire has too much influence, the car goes right. Same for the right tire...So, if the car is making a move off the line, make an adjustment to the opposite side. Your goal is to make that corner heavier. More static weight=more inherent traction. .Also,a change in ride height will change the IC height.Your are correct in your assumption to leave vehicle height the same too.

As we begin to realize what changes affect the car, we can then apply them when a different problem presents....(travel to another track) That is why I encourage tuning the suspenion as much as we tend to tune the engine..I remember starting out and feeling comfortable with changing jets, timing, lash.

However, changing pinion angle, shock settings, preload was strictly not discussed...like the car was going to make a big ole turn into the wall. Unless something fails, the car should not make a dramatic enough move to cause something real bad. Test N Tune work on the front side should pay dividends (consistency, understanding cause and effect) on the backside.

|

|

|

Re: Shock Tech

[Re: gregsdart]

#932017

Re: Shock Tech

[Re: gregsdart]

#932017

02/20/11 02:59 PM

02/20/11 02:59 PM

|

Joined: Feb 2011

Posts: 43

IN

EricatAFCO

OP

OP

member

|

OP

OP

member

Joined: Feb 2011

Posts: 43

IN

|

Quote:

I have Afco double adjustables on all four corners. Great shocks, looking to get the most out of them. I have the car in the sig obviously, 3000 lbs, ladder bars 30 inches long, leave off trans brake at 4500 Vs a 6400 stall. The weight dist is now 47.5 rear 52.5 front. I have started testing with the rears soft on extension, medium on compression and have progressed to about the middle of their adjustment for stiffness, seems to be about right as the 60 fts went from 1.28 down to 1.259 and got very consistent. Fronts are still dead soft on extension , fairly stiff on compression to help with the landing.

Where would you go from here? The car wheelstands and hits the 66 inch wheelie bars fairly hard. I have about four inches of travel up front.

My thoughts are to start stiffening the shock rebound a touch, then after finding a good point for that start shortening front travel, which is about four inch of rise. Any change to that plan?

I think you are headed in the right direction...I tend to like to initially control front end travel with the shock...It is a more passive way to limit travel when compared to a chain, cable stop or bolt in the upper arm. In your case, tighten the front shocks on rebound until the car slips the tire. The 60' numbers could improve but I am betting that if we continue to hook the HP you have without hitting the bars as hard, we will improve the overall package. Each time we hit the bars, load is relieved from the tire contact patch. Sometimes greater than others...Extreme cases will induce slip.

Also, the rebound on the rear shocks can change how hard you hit the bars too. Stiffening them will slow down separation (which is what we need to manufacture enough traction) Double edge sword. Work with the front shocks first. Find the maximum setting the car will stand and then go back to the rears and make some adjustments. Worse case is it spins, you re-adjust the shocks (back)and go kick some ass!

|

|

|

Re: Shock Tech

[Re: fourgearsavoy]

#932021

Re: Shock Tech

[Re: fourgearsavoy]

#932021

02/21/11 10:31 AM

02/21/11 10:31 AM

|

Joined: Jan 2003

Posts: 10,020

MN

JERICOGTX

I Live Here

|

I Live Here

Joined: Jan 2003

Posts: 10,020

MN

|

I'm still waiting for my catalog I signed up for on Afco's website... That was at least 3 months ago.  Jeff

69 GTX

68 Road Runner

|

|

|

Re: Shock Tech

[Re: JERICOGTX]

#932022

Re: Shock Tech

[Re: JERICOGTX]

#932022

02/21/11 11:21 AM

02/21/11 11:21 AM

|

Joined: Feb 2011

Posts: 43

IN

EricatAFCO

OP

OP

member

|

OP

OP

member

Joined: Feb 2011

Posts: 43

IN

|

Quote:

I'm still waiting for my catalog I signed up for on Afco's website... That was at least 3 months ago.

Jeff

Jeff,

Sorry for the delay. Please send your mailing address to my work email address-we will be sure to get one going ASAP.

eesaffell@afcoracing.com

|

|

|

Re: Shock Tech

[Re: 340Bird]

#932023

Re: Shock Tech

[Re: 340Bird]

#932023

02/21/11 11:33 AM

02/21/11 11:33 AM

|

Joined: Feb 2011

Posts: 43

IN

EricatAFCO

OP

OP

member

|

OP

OP

member

Joined: Feb 2011

Posts: 43

IN

|

Quote:

I,m looking at shocks for my car. I'm in the prosess of installing ladder bars. Would a 7" travel shock on the rear be better than a 5" travel? I am looking at Afco #3875 or #3855 single adjustable.

The car is a four speed,for now, about 3000#.

SK

When thinking about shock selection with regards to stroke, remember that most cars will only use about 3-4" of travel total, up and down combined.Many will use less..Some cars carry the long shock to allow the housing to drop out further making swapping tires easier..

Most back half cars use a 5" stroke shock. Consider if you plan to mount the upper cross shock mount BELOW the trunk pan, and use adjustable lower shock brackets, you will be able to set the shock in the middle of it's stroke, set ride height and be fine....If your plans are to mount the upper shock mount ABOVE the trunk pan in some trick config, a longer shock can be used.

On a shock dyno, if the valving package within the shock is the same, shocks of varying lengths will perform the same. It just comes down to packaging for the vehicle.

|

|

|

Re: Shock Tech

[Re: autoxcuda]

#932024

Re: Shock Tech

[Re: autoxcuda]

#932024

02/21/11 12:14 PM

02/21/11 12:14 PM

|

Joined: Feb 2011

Posts: 43

IN

EricatAFCO

OP

OP

member

|

OP

OP

member

Joined: Feb 2011

Posts: 43

IN

|

Quote:

You said linear shock for autocross. Would you also suggest linear valving also for this car in a Road Race application (Willow Springs)?

What kind of rate range at given IPS of adjustable shocks should I be looking for? Like between the 16, 13, 38, and 32 series which fits the range you suggest? Which ones are linear, digressive, progressive?

What about a non adjustable shock starting point?

Autox,

Tracks like Willow Springs or any faster road course will like the linear valving as well. The heavier the car, the more we can work with shocks to help performance....(Sporty cars are already built for handling, shocks are important to them but really important to guys running American Muscle on road courses)

Regarding valve ranges....we have seen a need to have shocks dampen at rates of 600#'s@6 IPS..That is over 1000# at 10-13 IPS. so I think you could look for a shock to be in this area as a good starting point to begin..Again, how serious your effort is and how aggressive you drive will help shape the shock. The good thing is shocks can be valved to do many different things when you have the shim stack/needle & seat design.

On the question of non-adjustable shocks, a shock package can be built that will give good service. However, you are fixed with that valving. In the case of one shock company I know rather well, one can purchase single adjustable shocks at a similar price and get more bang for the buck..

|

|

|

Re: Shock Tech

[Re: EricatAFCO]

#932025

Re: Shock Tech

[Re: EricatAFCO]

#932025

02/21/11 12:17 PM

02/21/11 12:17 PM

|

Joined: Jun 2003

Posts: 52,972

Romeo MI

MR_P_BODY

Master

|

Master

Joined: Jun 2003

Posts: 52,972

Romeo MI

|

Eric... on a single adjustable shock is the control valve controlling JUST the extension or does it also control the compression.... I have a old set of QA-1s and was told it is only controlling the extension but they are old.... now I hear a lot of shocks are controlling both on a single adjustable shock

|

|

|

Re: Shock Tech

[Re: MR_P_BODY]

#932026

Re: Shock Tech

[Re: MR_P_BODY]

#932026

02/21/11 12:45 PM

02/21/11 12:45 PM

|

Joined: Nov 2004

Posts: 6,890

North Alabama

Monte_Smith

master

|

master

Joined: Nov 2004

Posts: 6,890

North Alabama

|

I have seen Eric mention it a couple times here, but I don't think emphatically enough...........guys the front of the car, HAS TO WORK, before you can do anything with the rear. The front shocks and suspension, are likely just as important, maybe more so, than the rear. I see guys all the time with nice shocks on the rear and junk 3-ways on the front. When the car still won't work, they surmise the good shocks were a waste of money. Got to make the front work.

And while we are talking about front shocks, let me just say that every car out there, does NOT need 7" of travel and loosey goosey shocks in the front. In these days of power, good tires, good tracks and good suspension, a ton of pitch rotation, like was needed in the past, is just not a requirement these days. Most will work with a relatively stiff front setup.

Hey Eric, I know the guys at TRZ had mentioned to you a project I had going on a Holley. Did you ever get a chance to look into that

Thanks

Monte

|

|

|

Re: Shock Tech

[Re: EricatAFCO]

#932027

Re: Shock Tech

[Re: EricatAFCO]

#932027

02/21/11 01:04 PM

02/21/11 01:04 PM

|

Joined: Jan 2003

Posts: 27,453

So Cal

autoxcuda

Too Many Posts

|

Too Many Posts

Joined: Jan 2003

Posts: 27,453

So Cal

|

Quote:

Quote:

You said linear shock for autocross. Would you also suggest linear valving also for this car in a Road Race application (Willow Springs)?

What kind of rate range at given IPS of adjustable shocks should I be looking for? Like between the 16, 13, 38, and 32 series which fits the range you suggest? Which ones are linear, digressive, progressive?

What about a non adjustable shock starting point?

Autox,

Tracks like Willow Springs or any faster road course will like the linear valving as well. The heavier the car, the more we can work with shocks to help performance....(Sporty cars are already built for handling, shocks are important to them but really important to guys running American Muscle on road courses)

Regarding valve ranges....we have seen a need to have shocks dampen at rates of 600#'s@6 IPS..That is over 1000# at 10-13 IPS. so I think you could look for a shock to be in this area as a good starting point to begin..Again, how serious your effort is and how aggressive you drive will help shape the shock. The good thing is shocks can be valved to do many different things when you have the shim stack/needle & seat design.

On the question of non-adjustable shocks, a shock package can be built that will give good service. However, you are fixed with that valving. In the case of one shock company I know rather well, one can purchase single adjustable shocks at a similar price and get more bang for the buck..

Thank you very much. That gives me some parameters to start with.

Now I look on the Afco website, how do I tell what rate and what liner curves each 16, 13, 38, and 32 series Afco shock has for my car? Or are they custom built to order?

I got these shocks below for song at a Swap Meet that were supposed to be front shocks set up for Road Racing. They are too tall for my car anyway.

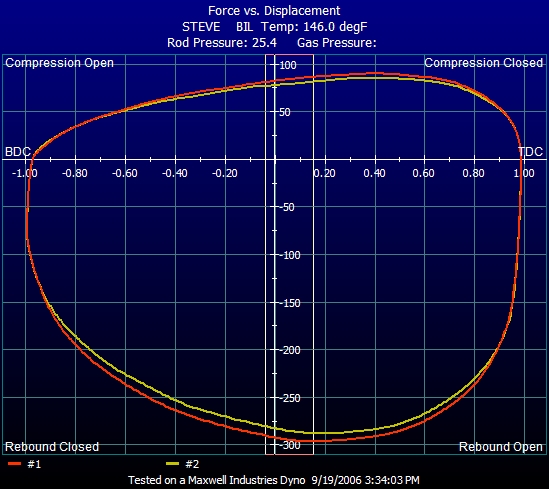

I had them dynod by the guys but I'm like, "Now what?" Just a bunch of numbers that I don't know if they apply to my situation.  But they don't seem to have enough rate from what you are saying? Or are these rear shocks. Should the rears be 600#'s @ 6 IPS But they don't seem to have enough rate from what you are saying? Or are these rear shocks. Should the rears be 600#'s @ 6 IPS

Tests at 6 IPS and shock 100 degrees warmup..

Last edited by autoxcuda; 02/21/11 01:25 PM.

|

|

|

|

|