|

Small block rocker arm and shaft galling

#721912

Small block rocker arm and shaft galling

#721912

06/11/10 10:05 PM

06/11/10 10:05 PM

|

Joined: Jan 2003

Posts: 1,754

Windsor, ON, Canada

Diplomat360

OP

OP

top fuel

|

OP

OP

top fuel

Joined: Jan 2003

Posts: 1,754

Windsor, ON, Canada

|

I have a hydraulic cam along with adjustable steel roller rockers (tip only). The rockers are not bushed. I am also using a brand new rocker arm shaft with bananna groves in them.

I've just installed the inner springs in my 360 engine, I ran only the single outer spring during the engine break-in per the instructions. The valve tip wear pattern is very good, centered dead on, which I'm happy to see because I spent some time making sure the rocker arm tips were aligned with the valve stem.

However...having had the engine running for only a total of 1 hr or so the shafts and the rocker arms show signs of galling/wear. I have great oil pressure (too much I think actually, about 20 PSI at idle and 55 PSI at about 3K RPM). Before starting the engine up I primed the oiling system, slowly turned the engine over and watched the oil flow out of the rocker arm shafts and onto the valve train to check and make sure that I had good oil flow up top.

Having pulled the shafts off for the valve spring upgrade I figured I'd check them out to see if everything was OK. Surprisingly I found the wear pattern on the rockers and the shafts. The rockers also appear to be somewhat bluish which indicates to me overheating most likely due to poor oil supply. I can't for the life of me figure out why though, the valvetrain appeared to be getting lots of oil and pressure appears to be fine. I'm now wondering if the volume of oil getting to the rockers shafts is just not big enough to keep the rocker arms lubricated.

Pushrods do not show any signs of wear, neither do the valve tips or the rocker arm rollers. So this has me a little stumped.

The cam is a Hughes 3844 piece, 238/244 dur @ 0.050", .535/.540 lift, springs are #1111 pieces, 150 lbs with valve closed and 320 lbs @ 0.550" lift.

|

|

|

Re: Small block rocker arm and shaft galling

[Re: Diplomat360]

#721913

Re: Small block rocker arm and shaft galling

[Re: Diplomat360]

#721913

06/11/10 10:27 PM

06/11/10 10:27 PM

|

Anonymous

Unregistered

|

Anonymous

Unregistered

|

Could be you overtightened the hold downs egging the shafts but also...Comp says NO open pressure above 340 lbs on their SS rockers and I think they have started bushing them after some trouble--Import China jobs may be the culprit as some I have seen had no groove inside the rocker to get oil all way around--but with grooved shafts?? I bet they are Cats maybe? I have used a ton of the Cat H beam rods and am lucky I guess but the rockers they sell usually die before you can throw the box they came in out in the trash--folks on here think that it is a good idea to leave the rockers in the box before you do that--Sorry for your trouble man really--don't mean to make light of it--get some good rockers and you'll be fine--Marsh Performance 336 752 2879 sells some very good bushed sets shafts, billet hold downs and all for about $325 range Good Luck

|

|

|

Re: Small block rocker arm and shaft galling

[Re: Diplomat360]

#721914

Re: Small block rocker arm and shaft galling

[Re: Diplomat360]

#721914

06/11/10 11:21 PM

06/11/10 11:21 PM

|

Joined: Nov 2003

Posts: 36,040

Lincoln Nebraska

RapidRobert

Circle Track

|

Circle Track

Joined: Nov 2003

Posts: 36,040

Lincoln Nebraska

|

(1) reprime it w your drill and hit the 2 sweet spots and see if both sides are NOW getting alot of flow (at each pair) (2) check that the small 15 degree offset (from vertical) oiling holes are on the bottom and offset slightly toward the valve side. (3) not likely that you'd need to remove the shaft end plugs to check for trash plugging it as (1) will take care of that potential prob

live every 24 hour block of time like it's your last day on earth

|

|

|

Re: Small block rocker arm and shaft galling

[Re: RapidRobert]

#721915

Re: Small block rocker arm and shaft galling

[Re: RapidRobert]

#721915

06/11/10 11:55 PM

06/11/10 11:55 PM

|

Joined: Jan 2003

Posts: 9,826

las vegas

70AARcuda

master

|

master

Joined: Jan 2003

Posts: 9,826

las vegas

|

were the shafts installed correctly?

Tony

70 AARCuda Vitamin C

71 Dart Swinger 360 10.318 @ 128.22(10-04-14 Bakersfield)

71 Demon 360 10.666 @122.41 (01-29-17 @ Las Vegas)

71 Duster 408 (10.29 @ 127.86 3/16/19 Las Vegas)

|

|

|

Re: Small block rocker arm and shaft galling

[Re: 70AARcuda]

#721916

Re: Small block rocker arm and shaft galling

[Re: 70AARcuda]

#721916

06/12/10 06:58 AM

06/12/10 06:58 AM

|

Joined: Jan 2003

Posts: 25,200

Upper Midwest

MoparforLife

Too Many Posts

|

Too Many Posts

Joined: Jan 2003

Posts: 25,200

Upper Midwest

|

Quote:

were the shafts installed correctly?

Must have hr has flow to both sides.

Quote:

I have great oil pressure (too much I think actually, about 20 PSI at idle and 55 PSI at about 3K RPM).

Oil pressure is fine but far from too much

|

|

|

Re: Small block rocker arm and shaft galling

[Re: Dave Watt]

#721918

Re: Small block rocker arm and shaft galling

[Re: Dave Watt]

#721918

06/12/10 08:16 AM

06/12/10 08:16 AM

|

Joined: Jan 2003

Posts: 25,200

Upper Midwest

MoparforLife

Too Many Posts

|

Too Many Posts

Joined: Jan 2003

Posts: 25,200

Upper Midwest

|

Quote:

I agree with a few replies above. You need to have the shafts indexed so the oiling holes properly oil the rockers.

This is very true but if you go back and read he states that he had good oil flow to both sides while priming. This would not be if the shafts were wrong.

|

|

|

Re: Small block rocker arm and shaft galling

[Re: MoparforLife]

#721919

Re: Small block rocker arm and shaft galling

[Re: MoparforLife]

#721919

06/12/10 09:07 AM

06/12/10 09:07 AM

|

Joined: Nov 2003

Posts: 5,048

Atlanta Indiana

Dave Watt

master

|

master

Joined: Nov 2003

Posts: 5,048

Atlanta Indiana

|

Quote:

Quote:

I agree with a few replies above. You need to have the shafts indexed so the oiling holes properly oil the rockers.

This is very true but if you go back and read he states that he had good oil flow to both sides while priming. This would not be if the shafts were wrong.

You would still get oil flow to the rockers regardless of shaft orientation, but it wouldn't be concentrated at the main contact/friction area of the rocker arm.

|

|

|

Re: Small block rocker arm and shaft galling

[Re: Dave Watt]

#721920

Re: Small block rocker arm and shaft galling

[Re: Dave Watt]

#721920

06/12/10 09:53 AM

06/12/10 09:53 AM

|

Joined: Jan 2003

Posts: 25,200

Upper Midwest

MoparforLife

Too Many Posts

|

Too Many Posts

Joined: Jan 2003

Posts: 25,200

Upper Midwest

|

Quote:

Quote:

Quote:

I agree with a few replies above. You need to have the shafts indexed so the oiling holes properly oil the rockers.

This is very true but if you go back and read he states that he had good oil flow to both sides while priming. This would not be if the shafts were wrong.

You would still get oil flow to the rockers regardless of shaft orientation, but it wouldn't be concentrated at the main contact/friction area of the rocker arm.

Very Little to none.

Note he says he has good flow.

|

|

|

Re: Small block rocker arm and shaft galling

[Re: Diplomat360]

#721921

Re: Small block rocker arm and shaft galling

[Re: Diplomat360]

#721921

06/12/10 11:04 AM

06/12/10 11:04 AM

|

Joined: Jan 2003

Posts: 1,754

Windsor, ON, Canada

Diplomat360

OP

OP

top fuel

|

OP

OP

top fuel

Joined: Jan 2003

Posts: 1,754

Windsor, ON, Canada

|

I bought the rocker arms used, but they were in excellent shape and had no galling/wear signs. Not sure who the maker of these is, but here is a picture of what they look like :  I installed the shafts correctly, with the rocker arm oiling hole/bananna grove offset towards the rocker arm 'saddle', where the greatest friction occurs between the rocker arm and the shaft. I actually checked this twice: first by physically making sure the oiling passage was offset towards the valve (correct side of the hold-down bolt), then by making sure that the shaft markings were pointing the right way (driver side to the front of the engine, pass side to the rear). The oil pressure I showed is with a hot engine, I was going with the 10 PSI/1000 RPM rule...when cold the pressure pegs the gauge to about 80 PSI. With the shafts off I tried to see if the oil passage feeding the assembly was free of obstructions...problem is that it connects to the head bolt passage and with the headbolt in place you can't get anything past there...well, anything big enough to really tell if the head gasket isn't somehow blocking something. When I was assembling the engine I made sure that the head gasket was not blocking any passages by comparing the deck layout to the head layout...all was good, but maybe I made a mistake somewhere? For now, I put both the assemblies back on. I will go through the oil prime again, hit the sweet spot as RapidRobert suggested and will make sure that there is enough lube getting to the rockers. Visually though it's hard to estimate if there is enough oil there...I definitely had oil when I checked before engine start...but how do I tell if the volume is large enough? With the drill prime I was getting the oil pressure to about 60 PSI...so I'm thinking that should be feeding enough volume at relatively low RPM (drill is about 1600 RPM), sort of equivalent of seeing what the engine is going through just a tad off idle. Thanks for the suggestions guys, I will do the oil prime again and report back.

|

|

|

Re: Small block rocker arm and shaft galling

[Re: MoparforLife]

#721925

Re: Small block rocker arm and shaft galling

[Re: MoparforLife]

#721925

06/12/10 01:24 PM

06/12/10 01:24 PM

|

Joined: Jan 2003

Posts: 74,948

U.S.S.A.

JohnRR

I Win

|

I Win

Joined: Jan 2003

Posts: 74,948

U.S.S.A.

|

Quote:

Very Little to none.

Note he says he has good flow.

Are you saying that if he had the shafts installed so the oil holes were toward the valley instead of the valves that there would be less oil flow than if they were positioned toward the valves ?

|

|

|

Re: Small block rocker arm and shaft galling

[Re: JohnRR]

#721927

Re: Small block rocker arm and shaft galling

[Re: JohnRR]

#721927

06/12/10 03:07 PM

06/12/10 03:07 PM

|

Joined: Jan 2003

Posts: 25,200

Upper Midwest

MoparforLife

Too Many Posts

|

Too Many Posts

Joined: Jan 2003

Posts: 25,200

Upper Midwest

|

Quote:

Quote:

Very Little to none.

Note he says he has good flow.

Are you saying that if he had the shafts installed so the oil holes were toward the valley instead of the valves that there would be less oil flow than if they were positioned toward the valves ?

I am saying that his shafts are not oriented right or he would have little to no oil feed. He says he had good oil feed and that his positioning of the shafts was proper with the notches in the correct direction etc.

|

|

|

Re: Small block rocker arm and shaft galling

[Re: MoparforLife]

#721929

Re: Small block rocker arm and shaft galling

[Re: MoparforLife]

#721929

06/12/10 03:44 PM

06/12/10 03:44 PM

|

Anonymous

Unregistered

|

Anonymous

Unregistered

|

you wanna have the oiling holes point down and towards the valve springs.

If you had the old bushed MP rockers you could get away, well what I mean to say is..the bushings have double banna grooves and depending what shafts, so would they.

I could go outside and look but I'm stuck in bed sick, so I'll ask.

do all shafts have one enlarged hold down hole for the oil?

OR are they all like the mp shafts with all holes enlarged?

Last edited by 1wild&crazyguy; 06/12/10 03:45 PM.

|

|

|

Re: Small block rocker arm and shaft galling

[Re: BSB67]

#721930

Re: Small block rocker arm and shaft galling

[Re: BSB67]

#721930

06/12/10 07:57 PM

06/12/10 07:57 PM

|

Joined: Jan 2003

Posts: 1,754

Windsor, ON, Canada

Diplomat360

OP

OP

top fuel

|

OP

OP

top fuel

Joined: Jan 2003

Posts: 1,754

Windsor, ON, Canada

|

Quote:

Exactly which ones are galled? Which one are blue and where? Do you have pic of the galling? You put it back together with the rocker/shaft galled? How much side clearance?

No, no pictures of the galling...but the marks on the rocker arm shaft would barely catch a finger nail...in fact, they appear more like scuff marks. The rocker arms themselves still show the factory (I believe) cross-hatch hone pattern, but the metal is coloured slightly bluish in the areas where the shaft is scuffed. I thought that indicated the rocker arms were beginning to gall in those spots.

Not all rocker arms show this...and those that do have visible scuff marks on the shaft, but these again are not necessairly deep enough to catch a finger nail.

So...am I just being overly cautious maybe?

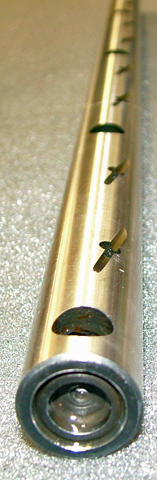

The shafts I'm using were new Hughes pieces (part #1600), here is a pic (Hughes web site) showing the shaft oiling hole along with the bananna grove:

All of the retaining bolt holes are the same size, there are no oversized holes, so whatever oil is making it through to the shaft to oil the rocker arms is squeezing through the same openning as what the bolt is using. I'm going to compare this to a stock shaft to see if there is an actual difference in size and will measure the Hughes pieces as well.

The reason why I put it back on is basically this: not sure that I can do anything about the wear, and we have a house moving coming up soon so I really need to have this car up and running (time is tight). I have also heard in the past that these SS rocker arms were prone to galling, especially if mounted on a hard shaft like the one I'm using. I was sort of expecting to see some of this, but only after having put some serious miles/RPMs on the engine. So at this point in time my thinking is as follows: I will re-check the oil flow, if that's good then I will run these and check them out again after some time. If they get worse I will probably pull them and send them off to get bushed (any suggestions where?), either way I will have to get new shafts.

BTW: Side clearance is about 0.010-0.015 per rocker arm pair...currently they are perfectly centered over the valve stem and I have great sweep pattern on the stem. I have heard of rocker being ran as tight as 0.005"...so I left mine a bit looser.

|

|

|

Re: Small block rocker arm and shaft galling

[Re: BSB67]

#721932

Re: Small block rocker arm and shaft galling

[Re: BSB67]

#721932

06/13/10 01:43 AM

06/13/10 01:43 AM

|

Anonymous

Unregistered

|

Anonymous

Unregistered

|

I would dull the edges of the grooves on the shafts, looks to have sharp edges on the banana grooves.

jmo

|

|

|

Re: Small block rocker arm and shaft galling

[Re: MoparforLife]

#721934

Re: Small block rocker arm and shaft galling

[Re: MoparforLife]

#721934

06/13/10 03:37 PM

06/13/10 03:37 PM

|

Joined: Jan 2003

Posts: 74,948

U.S.S.A.

JohnRR

I Win

|

I Win

Joined: Jan 2003

Posts: 74,948

U.S.S.A.

|

Quote:

Quote:

Quote:

Very Little to none.

Note he says he has good flow.

Are you saying that if he had the shafts installed so the oil holes were toward the valley instead of the valves that there would be less oil flow than if they were positioned toward the valves ?

I am saying that his shafts are not oriented right or he would have little to no oil feed. He says he had good oil feed and that his positioning of the shafts was proper with the notches in the correct direction etc.

ok

|

|

|

|

|