|

Re: US Car Tool stiff kit

[Re: AndyF]

#2583208

Re: US Car Tool stiff kit

[Re: AndyF]

#2583208

11/26/18 02:08 PM

11/26/18 02:08 PM

|

Joined: Jan 2010

Posts: 667

Los Osos, Ca

CKessel

mopar

|

mopar

Joined: Jan 2010

Posts: 667

Los Osos, Ca

|

On my 65 B, I made up an entirely new core support for it. Had some 1x2 formed up for the upper tie bar, used some 1" or so square for the verticals off the rails, some 2" square for the lower support and some formed 16a for the side baffles. All of this was fitted for my Be Cool unit with holes punched for bulkhead fitting pass throughs for a/c lines, oil coolers.

Carl Kessel

|

|

|

Re: US Car Tool stiff kit

[Re: AndyF]

#2583537

Re: US Car Tool stiff kit

[Re: AndyF]

#2583537

11/27/18 02:32 AM

11/27/18 02:32 AM

|

Joined: Nov 2016

Posts: 200

Colorado

Bob J

enthusiast

|

enthusiast

Joined: Nov 2016

Posts: 200

Colorado

|

I already installed the lower radiator support in my GTX. I have the fender bracing but I haven't installed them yet as the car is already painted. I don't want to mess with the paint but I will. If you have the dash and windshield out you can also weld up the cowl lip, the steering column support And any where the seams are spot welded. Just doing that made the whole cowl so much stiffer. You can also run weld the frame to the floor as the spot welds let the body flex too much.

07 Porsche C2 997.1 6spd DD and SCCA Solo II SS

68 Plymouth GTX Convert. 493cu Hotkiss Wilwood Classic air, Building for Solo II Cam

65 Chrysler 300 Convert. project

57 Desoto 2dr. Firesweep 392 Hemi,Wilwood Project with son

2003 Dodge Dakota R/T "DEAD"

|

|

|

Re: US Car Tool stiff kit

[Re: AndyF]

#2595189

Re: US Car Tool stiff kit

[Re: AndyF]

#2595189

12/21/18 08:00 PM

12/21/18 08:00 PM

|

Joined: Feb 2010

Posts: 18,493

Granite Bay CA

Kern Dog

Striving for excellence

|

Striving for excellence

Joined: Feb 2010

Posts: 18,493

Granite Bay CA

|

It is a lot better than trying to make all this stuff myself! Parts like this aren't going to fit perfectly since the car is 50 years old plus there are lots of production tolerances in a car. So a guy just needs to understand that it takes some cutting and fitting to work. YOU know that. I know that....but there will still be some guys that cry and complain that it didn't fit "Out of the box". Losers. Life isn't perfect. Nothing is. A man knows that and adjusts as needed to keep moving.

|

|

|

Re: US Car Tool stiff kit

[Re: Kern Dog]

#2595272

Re: US Car Tool stiff kit

[Re: Kern Dog]

#2595272

12/21/18 11:05 PM

12/21/18 11:05 PM

|

Joined: Dec 2003

Posts: 22,695

Bitopia

jcc

If you can't dazzle em with diamonds..

|

If you can't dazzle em with diamonds..

Joined: Dec 2003

Posts: 22,695

Bitopia

|

It is a lot better than trying to make all this stuff myself! Parts like this aren't going to fit perfectly since the car is 50 years old plus there are lots of production tolerances in a car. So a guy just needs to understand that it takes some cutting and fitting to work. YOU know that. I know that....but there will still be some guys that cry and complain that it didn't fit "Out of the box". Losers. Life isn't perfect. Nothing is. A man knows that and adjusts as needed to keep moving. And what(?) is worse, welding misc brackets on a car because there is supposed to be some un documented improvement ( a video clip by itself is not documentation), when the installer has zero clue what the weakest structural area is in the first place on the chassis/frame, and always couched with when questioned, the time honored response, "it can't hurt"?  Reminds me of the days when members raced to install the largest Dia 40lb? front discs for bragging rights, when they maybe had a 255 front tire.

Reality check, that half the population is smarter then 50% of the people and it's a constantly contested fact.

|

|

|

Re: US Car Tool stiff kit

[Re: AndyF]

#2595651

Re: US Car Tool stiff kit

[Re: AndyF]

#2595651

12/22/18 11:12 PM

12/22/18 11:12 PM

|

Joined: Jan 2003

Posts: 3,704

MICHIGAN

DynoDave

master

|

master

Joined: Jan 2003

Posts: 3,704

MICHIGAN

|

It is a lot better than trying to make all this stuff myself! Parts like this aren't going to fit perfectly since the car is 50 years old plus there are lots of production tolerances in a car. So a guy just needs to understand that it takes some cutting and fitting to work. Thanks Andy. Old dog here, fully understand they won't install themselves. Don't expect them to be spot on, or maybe even in the ballpark. But the right zip code would be nice. You have your hands on them, so that makes your thoughts on the matter valuable, IMO.

|

|

|

Re: US Car Tool stiff kit

[Re: Kern Dog]

#2600437

Re: US Car Tool stiff kit

[Re: Kern Dog]

#2600437

01/02/19 02:34 PM

01/02/19 02:34 PM

|

Joined: Nov 2013

Posts: 111

Connecticut, USA

MRGTX

member

|

member

Joined: Nov 2013

Posts: 111

Connecticut, USA

|

...

YOU know that. I know that....but there will still be some guys that cry and complain that it didn't fit "Out of the box".

Losers. Life isn't perfect. Nothing is. A man knows that and adjusts as needed to keep moving. Any company making these products and selling them for profit has to expect to serve folks who aren't experts or who may not have an engineering degree. The company's job will be to put their emotions aside and figure out how to help their customers get the job done, even if they're in "the wrong" to complain. They don't have to accommodate this kind of customer...but they can also expect to go out of business pretty quickly if they don't. The narrow band of customers who are savvy enough to modify, weld in parts like this...but not quite savvy enough to make their own parts, will only take them so far.

Last edited by MRGTX; 01/02/19 02:52 PM.

|

|

|

Re: US Car Tool stiff kit

[Re: MRGTX]

#2600457

Re: US Car Tool stiff kit

[Re: MRGTX]

#2600457

01/02/19 03:20 PM

01/02/19 03:20 PM

|

Joined: Sep 2007

Posts: 14,889

up yours

Supercuda

About to go away

|

About to go away

Joined: Sep 2007

Posts: 14,889

up yours

|

The narrow band of customers who are savvy enough to modify, weld in parts like this...but not quite savvy enough to make their own parts, will only take them so far.

You forget the narrow band of customers that can weld them in and trim them to fit but don't have the tools to make them from flat sheet I don't have a bead roller, or a brake or a shear or a hole dimple and it is way cheaper to buy something close enough to trim to fit than it is to buy all the tools to make something that well to be honest you are trimming to fit too in a round about way too. Of course that narrow band of customer isn't going to call in and whine about having to trim to fit. Dealing with retail customers is having to deal with a lot of stupid.

They say there are no such thing as a stupid question.

They say there is always the exception that proves the rule.

Don't be the exception.

|

|

|

Re: US Car Tool stiff kit

[Re: Supercuda]

#2601395

Re: US Car Tool stiff kit

[Re: Supercuda]

#2601395

01/04/19 11:29 AM

01/04/19 11:29 AM

|

Joined: Nov 2013

Posts: 111

Connecticut, USA

MRGTX

member

|

member

Joined: Nov 2013

Posts: 111

Connecticut, USA

|

...

Dealing with retail customers is having to deal with a lot of stupid.

Those are all valid reasons to buy a pre-fab part that needs modifications. I totally get that. The kind of attitude displayed in the line I quoted above, if it came from a retailer, would merely prove that they're out of their depth in the retail world. Dealing with customers who ask "stupid" questions or who make "invalid" complaints should be considered overhead. It's the cost of doing business...and it's exactly why we need to hire people who have the communication and interpersonal skills to accommodate customers while still protecting the company's interests. It's a purely human reaction to receive a complaint and to become defensive but in this case, it's kinda like building a boat and being angry about the waves that lap against the hull. Being confronted by difficult customers is an absolute inevitability. Smart retailers will look inward and adjust their design of the boat so it can handle the waves. They have absolutely no logical or ethical standing to complain about the source of their income. If I was financially backing a business that took this approach to customers, I'd pull my support so fast, their heads would spin. Nobody has to personally like dealing with rude or "stupid" people...but you can always find a new line of work if you can't handle it. If the problem is pervasive, it might represent a need to change advertising to properly align customer expectations. Maybe this means a company needs to beef up technical support. Negative interactions are valuable information! I just don't know how a vendor could hope to be successful without understanding the simple fact that "people are people" and being totally unprepared to work with them. So I've been car-crazy since I was a small kid. I have spent countless hours reading, watching, talking about, driving old cars... After all these years, I can do most jobs on my cars on my own but I'm absolutely not naturally mechanically inclined. I make mistakes and I ask stupid questions. I also have no sympathy for a retail business who mistakes me for being a stupid person. I have a good education and a good job and I have money to spend on hobbies (like old Mopars). They can earn either my business or they can kick rocks. I've encountered very few bad experiences in the "Mopar parts vendor world" but they are out there. On the other side of that coin, I had to work a return with Summit Racing after the holidays (the new racing helmet was too small)...and I was blown away by their customer service. They were polite, friendly, gave me the benefit of the doubt, paid for the return shipping, emailed updates on the status of the return, etc. There's absolutely no question that this is part of their success. Ok...I'm off of my soap box.

Last edited by MRGTX; 01/04/19 12:54 PM.

|

|

|

Re: US Car Tool stiff kit

[Re: AndyF]

#2601436

Re: US Car Tool stiff kit

[Re: AndyF]

#2601436

01/04/19 01:28 PM

01/04/19 01:28 PM

|

Joined: Sep 2007

Posts: 14,889

up yours

Supercuda

About to go away

|

About to go away

Joined: Sep 2007

Posts: 14,889

up yours

|

I worked retail for a several years and that is exactly where I formed my opinion of the retail world. I don't work retail anymore for a reason. Got tired of pretending the world's stupidest person wanting to return a part be bought from a completely different vendor was the smartest dude I ever met.

There are a number of quality fab companies out there that do not, nor will they ever, handle retail. You buy from their authorized vendors because they don't want to deal with the stupid either.

It works for them. You probably have used or seen their stuff too.

You like dealing with the stupid, kudos to you. Just be aware it's there regardless of what retail line you are in.

They say there are no such thing as a stupid question.

They say there is always the exception that proves the rule.

Don't be the exception.

|

|

|

Re: US Car Tool stiff kit

[Re: Supercuda]

#2601515

Re: US Car Tool stiff kit

[Re: Supercuda]

#2601515

01/04/19 03:33 PM

01/04/19 03:33 PM

|

Joined: Nov 2013

Posts: 111

Connecticut, USA

MRGTX

member

|

member

Joined: Nov 2013

Posts: 111

Connecticut, USA

|

I worked retail for a several years and that is exactly where I formed my opinion of the retail world. I don't work retail anymore for a reason. Got tired of pretending the world's stupidest person wanting to return a part be bought from a completely different vendor was the smartest dude I ever met.

...

You like dealing with the stupid, kudos to you. Just be aware it's there regardless of what retail line you are in. Right on. I give you credit for recognizing that it wasn't for you. Those fab shops that can't deal with "the stupid" are smart to stay in their lane too. They'd also be smart to man-up to quality problems and respond to customer demands that come from down-stream. Something tells me that would be rough for these folks who tend to assume the customer is wrong. I'm speaking from experiences at work as a buyer for aerospace components. Some shops get it, the others tend to lose business until they figure it out. As a hobbyist car-part customer dealing directly with fab shops, I've had very good luck. QA1, Moser, etc. were all prepared to answer my basic questions and I ended up spending lots of money with each. Going way back, a popular Miata performance part vendor gave me a bunch of crap about their screwed up casting issue on a turbo manifold after I dropped $6000 with them. In their defense it was a brand new design and I was willing to forgive some snags...I just resented having to do their R&D work as I tried to figure out why the damn waste gate wouldn't close. In the end they owned up, addressed the issue and proved that they're good people to work with. I wouldn't hesitate to do business with them again when I finally get another Miata into my life. Maybe it's not that hard to treat customers well?

Last edited by MRGTX; 01/04/19 03:37 PM.

|

|

|

Re: US Car Tool stiff kit

[Re: AndyF]

#2601605

Re: US Car Tool stiff kit

[Re: AndyF]

#2601605

01/04/19 05:59 PM

01/04/19 05:59 PM

|

Joined: Nov 2013

Posts: 111

Connecticut, USA

MRGTX

member

|

member

Joined: Nov 2013

Posts: 111

Connecticut, USA

|

Sometimes the customer is right, sometimes the customer is wrong. I've seen both in the 20 years I've been making parts for the Mopar hobby. I've had several customers install their motor plates backwards and then they can't figure out why the engine doesn't fit. I had one very angry customer call me and cuss me out since the motor plate was offset. He told me that he had 40 years of Mopar experience and that the engine in a Mopar was supposed to be in the center of the car. He of course was wrong. Not sure if he was a stupid man or not, but the anger had made him stupid enough that he couldn't accept the truth.

Most aftermarket parts are designed to fit on an original car. Very few if any aftermarket parts are designed to fit with other aftermarket parts. As you add more and more aftermarket parts to a car the odds of stuff fitting and working gets lower and lower and eventually approaches zero. It isn't the mfg responsibility that the oil pump doesn't fit on your billet block which doesn't fit on the stock motor mounts and the headers don't fit on your raised port heads which don't work with your stock intake manifold. Ain't nobody responsible for that mess but the guy building the car....... All very good points. I'll just add that just as the customer may not know when they're flat out wrong, the same could apply to you. I see no traces of humbleness or humility from the folks railing against "stupidity" here and that's a red flag to anyone. Second, when people make a mistake (like thinking that a part should fit when in reality it's not compatible with their non-stock components), the seller's job to explain this to the customer in a way that protects the company's interest...meaning, you don't need to prove that the customer is an idiot to make your point. Sometimes you have to lose to win. Give the fool their money back and figure out if you could have done something to prevent the mistake on the part of the customer. That might be cheaper than a prolonged fight with a customer who is surely gone forever, bad publicity and just bad vibes all around. I hope it goes without saying that this is purely my opinion. I think a business can run however they want so long as they accept the consequences.

Last edited by MRGTX; 01/04/19 06:00 PM.

|

|

|

Re: US Car Tool stiff kit

[Re: AndyF]

#2601616

Re: US Car Tool stiff kit

[Re: AndyF]

#2601616

01/04/19 06:23 PM

01/04/19 06:23 PM

|

Joined: Sep 2007

Posts: 14,889

up yours

Supercuda

About to go away

|

About to go away

Joined: Sep 2007

Posts: 14,889

up yours

|

You have an interesting way to spin things. No one is railing against stupid people. It is a statement of fact that there are stupid people and that if you work retail you will have to deal with your share. Don't like it don't work retail. It is a statement of fact meant as a heads up, nothing more.

No humbleness or humility needed when stating a fact.

They say there are no such thing as a stupid question.

They say there is always the exception that proves the rule.

Don't be the exception.

|

|

|

Re: US Car Tool stiff kit

[Re: AndyF]

#2601772

Re: US Car Tool stiff kit

[Re: AndyF]

#2601772

01/05/19 01:02 AM

01/05/19 01:02 AM

|

Joined: Dec 2003

Posts: 22,695

Bitopia

jcc

If you can't dazzle em with diamonds..

|

If you can't dazzle em with diamonds..

Joined: Dec 2003

Posts: 22,695

Bitopia

|

It is 12 ga material so about twice as thick as the factory sheet metal. Very heavy duty kit. Sounds like a gauge thickness upgrade for those with 39lb rotors, and there is only one member here who likely understands that comment, and he has me blocked.

Reality check, that half the population is smarter then 50% of the people and it's a constantly contested fact.

|

|

|

Re: US Car Tool stiff kit

[Re: Kern Dog]

#2601873

Re: US Car Tool stiff kit

[Re: Kern Dog]

#2601873

01/05/19 12:41 PM

01/05/19 12:41 PM

|

Joined: Dec 2003

Posts: 22,695

Bitopia

jcc

If you can't dazzle em with diamonds..

|

If you can't dazzle em with diamonds..

Joined: Dec 2003

Posts: 22,695

Bitopia

|

No, some of us just don't care for the negativity... I'm optimist, I hope people can see eventually the error of their ways when appropriate, even if requires a reverse change of course. Patting people on the head and passing out candy sends mixed messages in that regard. But I'm not a perfectionist.  Back OT, adding any weight in front of the front axle, and/or above cars COG, from a handling non drag use standpoint, will seldom ever offer any benefits. 12 gauge is plain excessive, and I wonder if just a misstatement.

Reality check, that half the population is smarter then 50% of the people and it's a constantly contested fact.

|

|

|

Re: US Car Tool stiff kit

[Re: AndyF]

#2601932

Re: US Car Tool stiff kit

[Re: AndyF]

#2601932

01/05/19 03:20 PM

01/05/19 03:20 PM

|

Joined: Jan 2003

Posts: 30,994

Oregon

AndyF

OP

OP

I Win

|

OP

OP

I Win

Joined: Jan 2003

Posts: 30,994

Oregon

|

|

|

|

Re: US Car Tool stiff kit

[Re: jcc]

#2602267

Re: US Car Tool stiff kit

[Re: jcc]

#2602267

01/06/19 12:33 AM

01/06/19 12:33 AM

|

Joined: Feb 2010

Posts: 18,493

Granite Bay CA

Kern Dog

Striving for excellence

|

Striving for excellence

Joined: Feb 2010

Posts: 18,493

Granite Bay CA

|

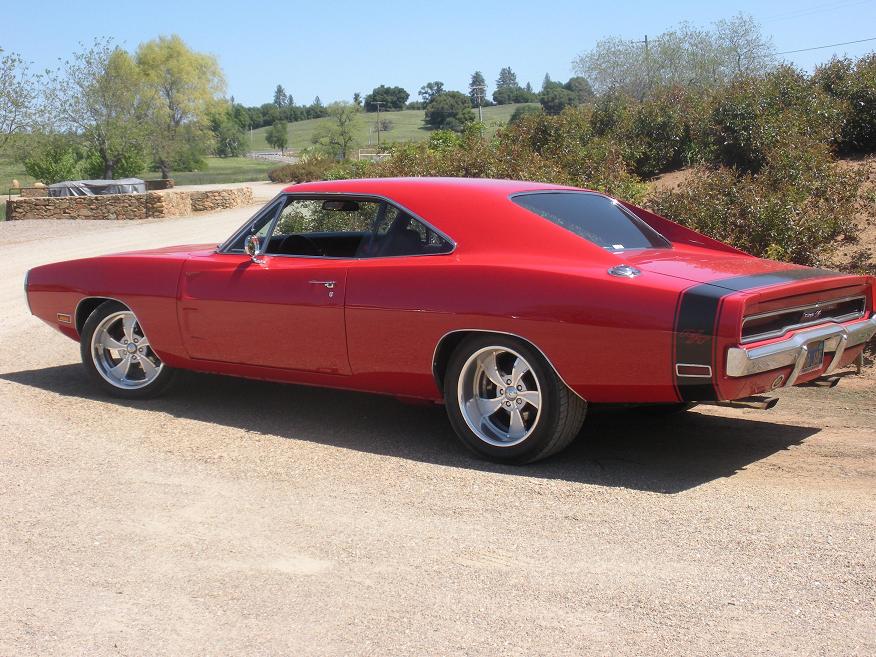

It is 12 ga material so about twice as thick as the factory sheet metal. Very heavy duty kit. Sounds like a gauge thickness upgrade for those with 39lb rotors, and there is only one member here who likely understands that comment, and he has me blocked.  I've been thinking about your comments and am wondering what is driving them. It appears that you have the opinion that some people are adding things to their cars that do not make much of a difference except to add weight. If that is your take on it, I can see your point. Maybe there are some people that are buying into a story. I do not have a chassis jig to test any of this stuff. I rely on trusted professionals to do the testing and display their observations. It is obvious to me that the OEM factory stuff was a compromise of cost and durability. Cast iron rotors and calipers were part of that. These cars were built in a different time too. The factories were trying to comply with crash standards, emission standards, fuel economy demands, etc. Handling was not a huge priority yet then. Rick Ehrenberg has written for years about how to make our classics handle better than stock. He is a proponent of frame connectors. XV Motorsports did extensive testing in chassis stiffness. Now maybe they spoke about their findings to establish a false belief that their products were necessary....OR Maybe they were right. US Cartool offers some things that look similar to some stuff XV had. The stuff they offer don't seem to be very heavy. I don't know if you have ever cut apart one of these cars but I have. The frame rails are pretty flimsy on their own. So is the core support. Sure, welded together they are a lot stiffer but they do still flex a bit. The brace inside the front wheelhouse that fits between the cowl and upper control arm mount area ...To me, that seems to make sense. The one that runs under the radiator does too. I have a pair of A body front frame rails out back with the torsion bar crossmember and core support, all welded together as original. It will twist torsionally and you can see it in the core support area. This is just with two men twisting it. No engine or trans weight, no suspension, just 2 guys of average strength. The bracing there in the form of square tubing would probably be impressive. For me personally, I have a few of these chassis stiffening items in my own car and I can attest that they did make a difference. I welded the K member and added gussets around the steering box mounts. There is no flex there like before. I made my own torque boxes, essentially copies of factory versions. I added them after welding in 3x3" frame connectors. I may have been able to get similar results with smaller or lighter 2x2" units but the car felt much more solid after the installation. My car, a 1970 Charger weighs 3940 lbs with a 440/727/8.75 axle with HD torsion bars, front and rear sway bars and a full interior. Whats a few extra lbs if it actually helps?

Last edited by Frankenduster; 01/06/19 12:35 AM.

|

|

|

Re: US Car Tool stiff kit

[Re: AndyF]

#2602567

Re: US Car Tool stiff kit

[Re: AndyF]

#2602567

01/06/19 08:06 PM

01/06/19 08:06 PM

|

Joined: Dec 2003

Posts: 22,695

Bitopia

jcc

If you can't dazzle em with diamonds..

|

If you can't dazzle em with diamonds..

Joined: Dec 2003

Posts: 22,695

Bitopia

|

Intentionally, I haven't a clue. As a human, there are many possibilities. I am to assume then 12 guage is indeed correct?

Reality check, that half the population is smarter then 50% of the people and it's a constantly contested fact.

|

|

|

Re: US Car Tool stiff kit

[Re: AndyF]

#2602575

Re: US Car Tool stiff kit

[Re: AndyF]

#2602575

01/06/19 08:22 PM

01/06/19 08:22 PM

|

Joined: Nov 2006

Posts: 1,074

Manitoba Canada

67autocross

super stock

|

super stock

Joined: Nov 2006

Posts: 1,074

Manitoba Canada

|

I only put frame connectors and weld the k member in my street cars, I personally don’t believe in the core support on the A body platform (which is what I own) as the k member bolts in about 4 inches behind the rad support and that ties the front rails together.

My race cars have roll bars or full cages which stiffen the car up more than any amount of seam welding or body stiffer kit will ever accomplish...plus for the added weight I get the benefit of safety, which if you are truly going to go that fast in one of these tin cans is important to me.

A new iron curtain drawn across the 49th parallel

|

|

|

Re: US Car Tool stiff kit

[Re: Kern Dog]

#2602580

Re: US Car Tool stiff kit

[Re: Kern Dog]

#2602580

01/06/19 08:31 PM

01/06/19 08:31 PM

|

Joined: Dec 2003

Posts: 22,695

Bitopia

jcc

If you can't dazzle em with diamonds..

|

If you can't dazzle em with diamonds..

Joined: Dec 2003

Posts: 22,695

Bitopia

|

It is 12 ga material so about twice as thick as the factory sheet metal. Very heavy duty kit. Sounds like a gauge thickness upgrade for those with 39lb rotors, and there is only one member here who likely understands that comment, and he has me blocked.  I've been thinking about your comments and am wondering what is driving them. It appears that you have the opinion that some people are adding things to their cars that do not make much of a difference except to add weight. If that is your take on it, I can see your point. Maybe there are some people that are buying into a story. I do not have a chassis jig to test any of this stuff. I rely on trusted professionals to do the testing and display their observations. It is obvious to me that the OEM factory stuff was a compromise of cost and durability. Cast iron rotors and calipers were part of that. These cars were built in a different time too. The factories were trying to comply with crash standards, emission standards, fuel economy demands, etc. Handling was not a huge priority yet then. Rick Ehrenberg has written for years about how to make our classics handle better than stock. He is a proponent of frame connectors. XV Motorsports did extensive testing in chassis stiffness. Now maybe they spoke about their findings to establish a false belief that their products were necessary....OR Maybe they were right. US Cartool offers some things that look similar to some stuff XV had. The stuff they offer don't seem to be very heavy. I don't know if you have ever cut apart one of these cars but I have. The frame rails are pretty flimsy on their own. So is the core support. Sure, welded together they are a lot stiffer but they do still flex a bit. The brace inside the front wheelhouse that fits between the cowl and upper control arm mount area ...To me, that seems to make sense. The one that runs under the radiator does too. I have a pair of A body front frame rails out back with the torsion bar crossmember and core support, all welded together as original. It will twist torsionally and you can see it in the core support area. This is just with two men twisting it. No engine or trans weight, no suspension, just 2 guys of average strength. The bracing there in the form of square tubing would probably be impressive. For me personally, I have a few of these chassis stiffening items in my own car and I can attest that they did make a difference. I welded the K member and added gussets around the steering box mounts. There is no flex there like before. I made my own torque boxes, essentially copies of factory versions. I added them after welding in 3x3" frame connectors. I may have been able to get similar results with smaller or lighter 2x2" units but the car felt much more solid after the installation. My car, a 1970 Charger weighs 3940 lbs with a 440/727/8.75 axle with HD torsion bars, front and rear sway bars and a full interior. Whats a few extra lbs if it actually helps? Lot there to digest, but it deserves a response. 1. The vendor that is mentioned as the current supplier, IMO has a long proven track record of supplying "solutions" that are not well designed, including the cantilevered DS safety loop, the "rocky mountain" 3 sided frame connector, and now this essentially, a front bullet deflector/rad support, among others. I would never suggest these items have NO benefits, but the designs are often lacking, and don't appear to be well thought out, and for the average car owner, they should be aware of any shortcomings of these offerings. It's their money, and their car, and can make any decision they chose, including adding weight for little bang. Nobody should refrain from having a fair discussion, warts and all. 2. On to the core support, keep in mind all chassis loads effectively start at the tire contact patch, and migrate thru the suspension to all items of mass of the car. In our cars, the mass in front of the K member is minimal, and often unimportant, from a handing stand point. Up front, keeping the UCA pivot points positioned, is not well achieved with a 12g radiator support, located a distance away, with only some 14g(?) connecting the two. I am not saying it does not make this area stiffer, but I question how important it is in the first place, and what benefit is really gained here. One hyperbole example, it might be like bragging about upgrading your radio antenna with a 1/2" Dia model, so it doesn't shake when the car is driven. when I read about the 4 post XV video from years back  3. OP has a well earned, long respectable reputation in our car world, and made his choices here to suit his needs, but others may have a different set of parameters. 4. I am surprised with this level of an upgrade, no mention has made about making the center upper rad support removable, for easier swaps, etc., which I have done, and will do on all my future cars. 5. To be be perfectly forth coming, my last Rad support I built, is 5/8" thick, weighs 9lbs?, is Carbon Fiber/Kevlar/multi Ply Russian Birch sandwich, it removed approx 3 lbs? from in front of the front axle.

Reality check, that half the population is smarter then 50% of the people and it's a constantly contested fact.

|

|

|

Re: US Car Tool stiff kit

[Re: jcc]

#2602638

Re: US Car Tool stiff kit

[Re: jcc]

#2602638

01/06/19 10:40 PM

01/06/19 10:40 PM

|

Joined: Jan 2003

Posts: 30,994

Oregon

AndyF

OP

OP

I Win

|

OP

OP

I Win

Joined: Jan 2003

Posts: 30,994

Oregon

|

I'd be more interested in the debate if we were all sitting around the CAD station designing a new car. In that situation it would be a worthwhile discussion. However, when we're working on 50 year old cars and have limited options I think it is better to focus on what can be done given the choices.

I'm lucky enough to have a bigger budget, bigger shop and more tools than most guys but I still don't have unlimited time, money, tools, talent, etc. So if I'm going to get a project done I have to work with what I can buy, make, modify, etc. in the budget and time that I have.

If I was designing a new core support from scratch I wouldn't use 12 ga steel but I don't have the time to design my own part and I don't have a big enough brake to bend it. So yeah, maybe it is overkill but so what. I don't really care if there is an extra 5 lbs on the front of the car. It solved a bunch of other problems for me so it was worth it.

I don't think there is anyone on this board who has the ability to fabricate every part they need. I have the tools and resources to fabricate a lot of parts, but it would cost a fortune to custom build every single part so I have to be very strategic about what I custom build vs. what I buy.

|

|

|

Re: US Car Tool stiff kit

[Re: AndyF]

#2602695

Re: US Car Tool stiff kit

[Re: AndyF]

#2602695

01/07/19 12:30 AM

01/07/19 12:30 AM

|

Joined: Nov 2004

Posts: 25,050

Texas

GoodysGotaCuda

5.7L Hemi, 6spd

|

5.7L Hemi, 6spd

Joined: Nov 2004

Posts: 25,050

Texas

|

I'd be more interested in the debate if we were all sitting around the CAD station designing a new car. In that situation it would be a worthwhile discussion. However, when we're working on 50 year old cars and have limited options I think it is better to focus on what can be done given the choices.

I'm lucky enough to have a bigger budget, bigger shop and more tools than most guys but I still don't have unlimited time, money, tools, talent, etc. So if I'm going to get a project done I have to work with what I can buy, make, modify, etc. in the budget and time that I have.

If I was designing a new core support from scratch I wouldn't use 12 ga steel but I don't have the time to design my own part and I don't have a big enough brake to bend it. So yeah, maybe it is overkill but so what. I don't really care if there is an extra 5 lbs on the front of the car. It solved a bunch of other problems for me so it was worth it.

I don't think there is anyone on this board who has the ability to fabricate every part they need. I have the tools and resources to fabricate a lot of parts, but it would cost a fortune to custom build every single part so I have to be very strategic about what I custom build vs. what I buy. Spot on

|

|

|

Re: US Car Tool stiff kit

[Re: AndyF]

#2603600

Re: US Car Tool stiff kit

[Re: AndyF]

#2603600

01/08/19 09:41 PM

01/08/19 09:41 PM

|

Joined: Jan 2003

Posts: 2,766

Appleton, Wisconsin

rtmike

master

|

master

Joined: Jan 2003

Posts: 2,766

Appleton, Wisconsin

|

I bought the frame rail subframe connectors, and the torque boxes. I see in the directions they recommend making sure the doors close and open before welding them in. My doors are off the car right now (and would be for a while), is this step critical, or can I make sure the car is level and weld away and adjust the doors when I go to put them in?

Cars a 2 door hartop by the way.

Its not primer its perma gray.

|

|

|

Re: US Car Tool stiff kit

[Re: jcc]

#2604181

Re: US Car Tool stiff kit

[Re: jcc]

#2604181

01/09/19 11:48 PM

01/09/19 11:48 PM

|

Joined: Sep 2003

Posts: 1,688

Marlboro, NY, USA

Rick_Ehrenberg

top fuel

|

top fuel

Joined: Sep 2003

Posts: 1,688

Marlboro, NY, USA

|

I was "in" on XV's engineering. The guy spent BIG (really big) bucks with some Toronto-based engineering outfit to find out what works, what doesn't. I was there during the test sessions (B-body, 2006). The real surprise was the beefing the top of the rad yoke did NOTHING. This was done on a "4-post" hydraulic table. The Canadian engineering team was online with an English F-1 engineer in the British Midlands. The fun was hearing the Brit's comments on the stock B-body suspension geometry: "Better than a new BMW...." Photos here: XV Testing May 2006 Toronto The sawtooth frame connectors are, of course, somewhat of a compromise. 2X3" tubing, floor slit, is the way to go. But reality: Very few guys would install that. The sawtooth makes an incredible, immediately-noticeable improvement. The US cartool copies all fit better than the "original" XV stuff. And their service is 10X better. Just installed some recently. Shock tower braces work, but must be huge and triangulated back to the firewall. Again...reality check. Rick

|

|

|

Re: US Car Tool stiff kit

[Re: Rick_Ehrenberg]

#2604834

Re: US Car Tool stiff kit

[Re: Rick_Ehrenberg]

#2604834

01/11/19 11:52 AM

01/11/19 11:52 AM

|

Joined: Nov 2013

Posts: 111

Connecticut, USA

MRGTX

member

|

member

Joined: Nov 2013

Posts: 111

Connecticut, USA

|

^Awesome insights there, Rick. It's always amazing to hear how "right" Mopar got a lot of things back in the day. The front suspension design in particular is apparently standing the test of time admirably. ...

Shock tower braces work, but must be huge and triangulated back to the firewall. Again...reality check.

It seems like this could take some of the stress off of the K-member and if so, this might be a much cheaper/easier/less intrusive process than having the K-Member seam-welded...and it might provide at least some of the benefits. Does anyone make a bolt-in shock tower brace like this or are we talking about fabbing our own? If so, where on the firewall would be the right place to mount?

Last edited by MRGTX; 01/11/19 11:53 AM.

|

|

|

Re: US Car Tool stiff kit

[Re: MRGTX]

#2604915

Re: US Car Tool stiff kit

[Re: MRGTX]

#2604915

01/11/19 01:34 PM

01/11/19 01:34 PM

|

Joined: Dec 2003

Posts: 22,695

Bitopia

jcc

If you can't dazzle em with diamonds..

|

If you can't dazzle em with diamonds..

Joined: Dec 2003

Posts: 22,695

Bitopia

|

I have yet to see IMO, a clean effective design solution for old uni-body mopars. Not sure there is one. I took a few shots at it and wasn't satisfied. And to be clear, my objective was not the shock mount point, but more directed at the upper control arm pivot area, albeit as close as they are anyway.

Reality check, that half the population is smarter then 50% of the people and it's a constantly contested fact.

|

|

|

Re: US Car Tool stiff kit

[Re: MRGTX]

#2604938

Re: US Car Tool stiff kit

[Re: MRGTX]

#2604938

01/11/19 02:08 PM

01/11/19 02:08 PM

|

Joined: Jan 2003

Posts: 5,387

Pikes Peak Country

TC@HP2

master

|

master

Joined: Jan 2003

Posts: 5,387

Pikes Peak Country

|

^Awesome insights there, Rick. It's always amazing to hear how "right" Mopar got a lot of things back in the day. The front suspension design in particular is apparently standing the test of time admirably. ...

Shock tower braces work, but must be huge and triangulated back to the firewall. Again...reality check.

It seems like this could take some of the stress off of the K-member and if so, this might be a much cheaper/easier/less intrusive process than having the K-Member seam-welded...and it might provide at least some of the benefits. Does anyone make a bolt-in shock tower brace like this or are we talking about fabbing our own? If so, where on the firewall would be the right place to mount? Aside from the caster/camber interdependence, the Mopar design was and still is very good. Welding up the K frame resolves a few other issues than simple engine bay flex. The K is the primary loaded structure in the front end. With supporting the engine, steering box, and the front torsion bar/control arm anchors as well as being spot welded together, welding it up provides a big boost in rigidity to a number of components in addition to the front section of the car. Because the upper control arm mounts and shock mounts are not radically loaded in a mopar, the shock tower braces is less about providing loading support than it is of increasing the rigidity of the simply cube structure that is the engine bay. By turning it into multiple smaller triangles, you can reduce the flex. Percentage of improvement by doing this, I can't quote a number. Because of the lack of loading in the upper parts of the engine bay, mounting a brace to the firewall can be effective in a mopar, but there is a question in my mind about putting structure that mounts in a large flat plane of sheet that doesn't make me think it is the most effective way to do it. I read a white paper on nascar design sometime ago. In it they stated that the most heavily loaded area is the firewall/a pillar area. While we aren't running out cars are near 200 mph speeds on superspeedways, it does seem logical to say that improvements in this area on a performance street car can yield gains as well, especially since we lack all the triangulation structure they have in this spot.

|

|

|

Re: US Car Tool stiff kit

[Re: AndyF]

#2605294

Re: US Car Tool stiff kit

[Re: AndyF]

#2605294

01/12/19 05:01 AM

01/12/19 05:01 AM

|

Joined: Feb 2009

Posts: 342

dracut mass usa

sparcy

enthusiast

|

enthusiast

Joined: Feb 2009

Posts: 342

dracut mass usa

|

wow

Andy your the best. I blow people way in work with your math,, I call it. A good friend of mine says did you do the MATH ? I love that saying. DO THE MATH. He said it all the time when we were TAFC racing. I wonder What makes a pro ? There are guys on here that build amazing stuff in there garage. I sold retail and whole sale used auto parts for over 10 years at a very large salvage operation. Talk about stupid people. on both sides. I just bought US car tool spring relocation kit. I did have a problem rite out of the box, one pocket was NOT SQUARE . I was told it happened in shipping I guess They think I am stupid. They were super nice on phone. but the time it took to replace it was terrible. The directions are useless. website has some smoke and mirrors. Front pockets are in. I have 2 Miller welders a bead roller a 4 foot brake a 4 foot roller. etc and not harbor freight, but I do love the xt gun I bought on black sunday better than my snap on. And at my home I just installed a quincy 5 horse 80 gallon compressor wow its awesome. Got a AMD 1/4 panel from jegs all kinds of bent they were great on the customer service. I did the xv radiator support brace and all the auto rust tech guys in RI 13 years ago. what a difference. I had them bend me up 1/8 inch plate inner rockers too. nice people. The only mopar people to screw me was magnum force sold me A body stuff I needed B body called me a liar told me I installed them and he couldn't take them back. I never took them out of the box. I sold them to a guy on here he got a great deal I lost 100's. I love my bullet proof stuff. The US car tool spring pockets are bullet proof. and I love them they are thicker than my inner rockers LMAO. So what is the gauge of the rear frame rail? AMD makes 15 gauge, good mark does not know the guy told my today its as close to factory as they can get. What does that mean ? Must be me I am stupid customer. Sherman makes a 19 gauge patch rear frame rail. anyone got a left rear frame rail for a 68 charger I only need 2 to 3 feet from the rear bumper. I look forward to talking to ron from R/T specialties. What a nice guy.

IF YOU ARE NOT WRECKING STUFF YOU ARE NOT LEARNING !

|

|

|

Re: US Car Tool stiff kit

[Re: TC@HP2]

#2606168

Re: US Car Tool stiff kit

[Re: TC@HP2]

#2606168

01/13/19 10:17 PM

01/13/19 10:17 PM

|

Joined: Dec 2003

Posts: 22,695

Bitopia

jcc

If you can't dazzle em with diamonds..

|

If you can't dazzle em with diamonds..

Joined: Dec 2003

Posts: 22,695

Bitopia

|

Aside from the caster/camber interdependence, the Mopar design was and still is very good.

I agree, and to a large degree, no single area is less robust then it needs to be relative to all the other components, which to me means a balanced design. Welding up the K frame resolves a few other issues than simple engine bay flex. The K is the primary loaded structure in the front end. With supporting the engine, steering box, and the front torsion bar/control arm anchors as well as being spot welded together, welding it up provides a big boost in rigidity to a number of components in addition to the front section of the car.

I agree also, and the fact that it directly support the largest/highest density single mass on the vehicle. Because the upper control arm mounts and shock mounts are not radically loaded in a mopar, the shock tower braces is less about providing loading support than it is of increasing the rigidity of the simply cube structure that is the engine bay. By turning it into multiple smaller triangles, you can reduce the flex. Percentage of improvement by doing this, I can't quote a number.

Not sure how we define "radically" here. but with my back of the napkin thinking, since most all wheel forces transmit thru the front spindle, and the spindle being vertically approx 1/3 above the lower BJ, and the upper BJ approx 2/3 above the spindle, I think it would safe to assume the loads proportioned between the upper and lower as nearly the same ratio. And IMO, the K frame has much greater designed in robustness then the UCA mounting pivot points, beyond the above mentioned ratio, and the UCA apivot area would be an area next focused on, after the low hanging fruit upgrade of welding up the K member. Because of the lack of loading in the upper parts of the engine bay, mounting a brace to the firewall can be effective in a mopar, but there is a question in my mind about putting structure that mounts in a large flat plane of sheet that doesn't make me think it is the most effective way to do it.

I always assumed two things on a well designed/installed Monte Carlo brace on a Mopar, if achievable, both triangle braces from ea fender area would meet at a center node, and that node would also be on a seamed/flanged 90 degree joint of two metal OEM panels. I read a white paper on nascar design sometime ago. In it they stated that the most heavily loaded area is the firewall/a pillar area. While we aren't running out cars are near 200 mph speeds on superspeedways, it does seem logical to say that improvements in this area on a performance street car can yield gains as well, especially since we lack all the triangulation structure they have in this spot. I wonder in the above if, "Heavily loaded" really means "loaded", or "highly stressed"?

Last edited by jcc; 01/14/19 01:31 PM.

Reality check, that half the population is smarter then 50% of the people and it's a constantly contested fact.

|

|

|

Re: US Car Tool stiff kit

[Re: AndyF]

#2606334

Re: US Car Tool stiff kit

[Re: AndyF]

#2606334

01/14/19 09:25 AM

01/14/19 09:25 AM

|

Joined: Aug 2003

Posts: 2,466

Answering the call of the wild

ThermoQuad

top fuel

|

top fuel

Joined: Aug 2003

Posts: 2,466

Answering the call of the wild

|

nice work Andy I spent hours welding on this car's unibody and k frame,  There is no cage in the car but it does not show any flexing in the unibody after pounding it on the road course. Car is HP limited, not handling limited. Does less than a 2.5 minute lap which is the "bar" at the glen for a good lap. I bet $$$$ it would be nosing/pushing that green brick thing thru the turns without a problem even being hp limited. Absolutely amazing handling large blue concrete block with on center steering feel like rack and pinion steering with factory cruise control.  Concrete beats brick A welded K frame is so critical to the car's handling and rigidity.  I used the frame boxes that used to be available & boxed in the frame rails on this car among with many other strengthening / other welding tricks. Weld weld and weld some more. Remember cop cars had 110 or so more welds on them. The car is very tight but i am sure a shock tower brace back to the firewall will not hurt. Most overlooked flex area by everyone is reinforcing the bracing and package tray behind the rear seat. This is not conjecture but something learned by paying attention to detail.

Last edited by Dilbert; 01/14/19 09:27 AM.

|

|

|

Re: US Car Tool stiff kit

[Re: jcc]

#2606742

Re: US Car Tool stiff kit

[Re: jcc]

#2606742

01/15/19 01:19 AM

01/15/19 01:19 AM

|

Joined: Jan 2003

Posts: 5,387

Pikes Peak Country

TC@HP2

master

|

master

Joined: Jan 2003

Posts: 5,387

Pikes Peak Country

|

Because the upper control arm mounts and shock mounts are not radically loaded in a mopar, the shock tower braces is less about providing loading support than it is of increasing the rigidity of the simply cube structure that is the engine bay. By turning it into multiple smaller triangles, you can reduce the flex. Percentage of improvement by doing this, I can't quote a number.

Not sure how we define "radically" here. but with my back of the napkin thinking, since most all wheel forces transmit thru the front spindle, and the spindle being vertically approx 1/3 above the lower BJ, and the upper BJ approx 2/3 above the spindle, I think it would safe to assume the loads proportioned between the upper and lower as nearly the same ratio. And IMO, the K frame has much greater designed in robustness then the UCA mounting pivot points, beyond the above mentioned ratio, and the UCA apivot area would be an area next focused on, after the low hanging fruit upgrade of welding up the K member. Seem to recall seeing somewhere that on a mopar the load is not equally split and the upper arm loads were a quarter to third of the lower arm loads. Could be recalling this incorrectly. If this is correct, they would not need as much reinforcement as the lower. Because of the lack of loading in the upper parts of the engine bay, mounting a brace to the firewall can be effective in a mopar, but there is a question in my mind about putting structure that mounts in a large flat plane of sheet that doesn't make me think it is the most effective way to do it.

I always assumed two things on a well designed/installed Monte Carlo brace on a Mopar, if achievable, both triangle braces from ea fender area would meet at a center node, and that node would also be on a seamed/flanged 90 degree joint of two metal OEM panels. IMO, a basic monte carlo bar, or any of the other simple triangle braces being sold out there appear to be only marginally effective because they are bolting to stamped sheetmetal in tension without very large mountings plates to distribute the load. But if my point above this is valid, then they would not be supporting a significant load and may be okay after all. I read a white paper on nascar design sometime ago. In it they stated that the most heavily loaded area is the firewall/a pillar area. While we aren't running out cars are near 200 mph speeds on superspeedways, it does seem logical to say that improvements in this area on a performance street car can yield gains as well, especially since we lack all the triangulation structure they have in this spot. I wonder in the above if, "Heavily loaded" really means "loaded", or "highly stressed"? Loaded vs stressed, entirely possible. I read this well over ten years ago, maybe even 20. Its been quite a long time. I'd imagine I've forgotten the finer details of it and in this case, those specifics do denote different factors.

|

|

|

Re: US Car Tool stiff kit

[Re: AndyF]

#2606841

Re: US Car Tool stiff kit

[Re: AndyF]

#2606841

01/15/19 11:47 AM

01/15/19 11:47 AM

|

Joined: Sep 2007

Posts: 14,889

up yours

Supercuda

About to go away

|

About to go away

Joined: Sep 2007

Posts: 14,889

up yours

|

I am building some large cabinets for shop storage. sides are 3/4" plywood, shelves are 1/2" plywood framed with 1.5x1.5" wood. Even screwed and glued together is can rack. So the back (this would be akin to the rear shelf bracing here) is a sheet of 1/4" plywood screwed and glued to the sides and each shelf as well as the top and bottom. It will never rack.

If you would add a sheet metal cover atop that bracing to both seal off the entire opening but you welded it to all the sides and braces you'd pretty much never have flex there. Over kill? Maybe, but I do';t have a supercomputer to run numbers. I know some sanctioning bodies require that to be sealed off if you are running a fuel cell so it may as well pull double duty.

They say there are no such thing as a stupid question.

They say there is always the exception that proves the rule.

Don't be the exception.

|

|

|

Re: US Car Tool stiff kit

[Re: Supercuda]

#2606852

Re: US Car Tool stiff kit

[Re: Supercuda]

#2606852

01/15/19 12:16 PM

01/15/19 12:16 PM

|

Joined: Jul 2005

Posts: 636

Graz, Austria

DGS

mopar

|

mopar

Joined: Jul 2005

Posts: 636

Graz, Austria

|

If you would add a sheet metal cover atop that bracing to both seal off the entire opening but you welded it to all the sides and braces you'd pretty much never have flex there. Over kill? Maybe, but I do';t have a supercomputer to run numbers. I know some sanctioning bodies require that to be sealed off if you are running a fuel cell so it may as well pull double duty.

Basically replacing the cardboard trunk divider with metal and weld it?

|

|

|

Re: US Car Tool stiff kit

[Re: Supercuda]

#2606853

Re: US Car Tool stiff kit

[Re: Supercuda]

#2606853

01/15/19 12:17 PM

01/15/19 12:17 PM

|

Joined: Dec 2003

Posts: 22,695

Bitopia

jcc

If you can't dazzle em with diamonds..

|

If you can't dazzle em with diamonds..

Joined: Dec 2003

Posts: 22,695

Bitopia

|

I agree, adding a simple well attached shear panel, thicker the better (I used Alum/nomex honeycomb), would be most efficient structural upgrade, and you get the safety bonus of a fire barrier. I however am unconvinced this stiffened area in the big picture adds much overall.

Reality check, that half the population is smarter then 50% of the people and it's a constantly contested fact.

|

|

|

Re: US Car Tool stiff kit

[Re: BigBlockMopar]

#2607126

Re: US Car Tool stiff kit

[Re: BigBlockMopar]

#2607126

01/15/19 07:57 PM

01/15/19 07:57 PM

|

Joined: Jan 2003

Posts: 350

central IL

myduster360

enthusiast

|

enthusiast

Joined: Jan 2003

Posts: 350

central IL

|

I've been eyeballing these hollow structures that are conveniently placed near the rear subframe, torque box and extend to the rocker panel. They appear to have some importance but yet never mentioned.

I had a thought I might try some dense structural foam in there.

Last edited by myduster360; 01/15/19 08:00 PM.

1972 Swinger 3.6L Pentastar

Diablo CMR tuner

|

|

|

Re: US Car Tool stiff kit

[Re: myduster360]

#2607136

Re: US Car Tool stiff kit

[Re: myduster360]

#2607136

01/15/19 08:25 PM

01/15/19 08:25 PM

|

Joined: Dec 2003

Posts: 22,695

Bitopia

jcc

If you can't dazzle em with diamonds..

|

If you can't dazzle em with diamonds..

Joined: Dec 2003

Posts: 22,695

Bitopia

|

1. Foam pretty much stymies future welding

2. Not sure what the big picture goal is achieved with foam

3. The unibody pseudo crossmember that you are considering filling, is effectively a big arch, in itself is a beautiful structural solution, but that "arch" requires large immovable abutments at each end, or a lateral member securely tying the two ends together to prevent spreading. The second solution does not exist in your pics. A rollbar with a lower lateral tube somewhat achieves that, OR so does a well designed rear DS safety loop assembly, or just a straight lateral connector attached below the DS, which can also tie in the rear seat/seat belt tie downs more robustly.

4. Best to make sure foam has some flame retardant qualities.

5. Those pics are of two different cars?

Reality check, that half the population is smarter then 50% of the people and it's a constantly contested fact.

|

|

|

Re: US Car Tool stiff kit

[Re: AndyF]

#2607143

Re: US Car Tool stiff kit

[Re: AndyF]

#2607143

01/15/19 08:37 PM

01/15/19 08:37 PM

|

Joined: Jan 2003

Posts: 350

central IL

myduster360

enthusiast

|

enthusiast

Joined: Jan 2003

Posts: 350

central IL

|

We're all serious about improving our chassis rigidity but some don't do much but either buy whatever we think might work or just complain manufactures don't provide reams of data that meet some unattainable standard and deride those who buy them anyway without the "proof". Here's a fairly straightforward means to measure the chassis Torsional stiffness. http://forums.pelicanparts.com/porsche-9...-911-coupe.htmlIt would be helpful to everyone and a great reference to have a record of everyone's a car's torsional stiffness and what "mods"(if any) they may have. It's on my to do for my Swinger.

1972 Swinger 3.6L Pentastar

Diablo CMR tuner

|

|

|

Re: US Car Tool stiff kit

[Re: myduster360]

#2607308

Re: US Car Tool stiff kit

[Re: myduster360]

#2607308

01/16/19 01:35 AM

01/16/19 01:35 AM

|

Joined: Dec 2003

Posts: 22,695

Bitopia

jcc

If you can't dazzle em with diamonds..

|

If you can't dazzle em with diamonds..

Joined: Dec 2003

Posts: 22,695

Bitopia

|

That link took an 1.5hr   This from 2006 was pertinent however: "Quote: Originally posted by JanusCole I was just re-reading this idea and I think it is brilliant. And I don't see why it could not be done in an aesthetically pleasing way. For instance, why not coat the entire inner tub from the rear package shelf to the pedal cluster with a strong structural epoxy - the same stuff they use to assemble airplanes. Then lay a dozen or so layers of carbon fiber on top - essentially creating a carbon fiber monocoque using the original unibody tub as a mold. Then you can cover it all with carpeting and the thing should be TOTALLY stiff... Is this too simple? Am I missing something obvious? Kind-of. Just because Carbon fiber makes strong tubs in F1 doesn't mean that it's a wonder material. Carbon fiber is quite strong in some situations (and directions), and not very strong in others. The reason that F1 tubs are so strong has to do with the following: 1) The tubs have very few if any openings in them excepting those required by the rules (such as the cockpit) and by serviceability requirements (such as access ports to the pedals). A convertable or Targa 911 tub is a completely different design. 2) As I said, CF is very strong in some dimensions, and not in others. Just slapping CF down like shredded Fiberglass will not by definition make a strong tub. In reality the tubs come out strong because some clever engineers have figured out subtle ways to align the individual plys, and combine them in certain ways to manage some very specific load paths, both from the suspension as well as in accident situations. 3) In many cases a honeycomb matrix is put between the CF layers in certain areas to increase the cross-sectional area and thus increase the regidity of the tub. So the short form answer is that slapping CF down on the shell of a 911 will most likely not make it a whole lot stronger.

That being said, you did prompt a recollection of an old Formula Ford trick -- which is to squirt some two-part expanding foam into any enclosed cavities in the chassis. This trick was used to good affect in some spec classes (Formula Opel/Vauxhall comes to mind) where the spec chassis was somewhat less stiff then desired. Just as adding honeycomb can increase the stiffness of CF or FG panel, so can adding foam to an enclosed space. The downsides are:

1) A slight increase in weight.

2) Once it's in there, it's never coming out

3) Many of these foams turn into noxious gasses if heated or burned, so consider carefully where you decide to put them.

A clear opportunity for this trick would be in the rockers and frame rails of open 911's.__________________ John '69 911E "It's a poor craftsman who blames their tools" -- Unknown "Any suspension -- no matter how poorly designed -- can be made to work reasonably well if you just stop it from moving." -- Colin Chapman Last edited by jluetjen; 06-21-2006 at 07:28 PM.."

Last edited by jcc; 01/16/19 01:37 AM.

Reality check, that half the population is smarter then 50% of the people and it's a constantly contested fact.

|

|

|

Re: US Car Tool stiff kit

[Re: Kern Dog]

#2607767

Re: US Car Tool stiff kit

[Re: Kern Dog]

#2607767

01/16/19 10:11 PM

01/16/19 10:11 PM

|

Joined: Feb 2010

Posts: 18,493

Granite Bay CA

Kern Dog

Striving for excellence

|

Striving for excellence

Joined: Feb 2010

Posts: 18,493

Granite Bay CA

|

Tom Quad is now Dilbert ? No comment, Mr Quad ?

|

|

|

Re: US Car Tool stiff kit

[Re: AndyF]

#2608258

Re: US Car Tool stiff kit

[Re: AndyF]

#2608258

01/17/19 09:02 PM

01/17/19 09:02 PM

|

Joined: Apr 2012

Posts: 186

B-Body Bull

member

|

member

Joined: Apr 2012

Posts: 186

|

|

|

|

Re: US Car Tool stiff kit

[Re: AndyF]

#2608471

Re: US Car Tool stiff kit

[Re: AndyF]

#2608471

01/18/19 08:30 AM

01/18/19 08:30 AM

|

Joined: Aug 2003

Posts: 2,466

Answering the call of the wild

ThermoQuad

top fuel

|

top fuel

Joined: Aug 2003

Posts: 2,466

Answering the call of the wild

|

LOL here is my comment: I changed my identity because you can and now i am going change it again as in not here anymore as i am done trying to be helpful providing technical support/information in the mopar world from years of experience and great lap times with pos old mopars.  A-holys [sic] like the count and others take the fun out of it.  Playing with the cars on the road course was wayyy too much fun but alas the fun is over. I worked decades on very complicated technology moving from field service to tech support [help desk] and now it's time to just go have fun. The owners of project black and blue have both passed on within one year of each-other and the car is in the hands of the childs guardian. So the car is back in my hands - if all goes well i will bring it to carlisle and all of you experts can anal-ize [sic]it if i let you near it.  Hey Count you must be close friends with that so called tech magazine guy - post some pics of all the iron you flung around the road course for 24 years, better yet show us morons all the cars you built that could actually run laps and not cook the brakes. Yup blah blah blah...... No pics of the flex, just improved lap times an no more cracking paint where the dutchman is welded to the car -it's about paying attention you imbecile. 24 years of road course running 2x year - that's lot's of experience. Whats yours Count? Put up or shut up.

Last edited by Dilbert; 01/18/19 08:53 AM.

|

|

|

Re: US Car Tool stiff kit

[Re: AndyF]

#2608818

Re: US Car Tool stiff kit

[Re: AndyF]

#2608818

01/18/19 11:47 PM

01/18/19 11:47 PM

|

Joined: Nov 2008

Posts: 1,491

Lethbridge, AB, Canada

dangina

pro stock

|

pro stock

Joined: Nov 2008

Posts: 1,491

Lethbridge, AB, Canada

|

other than the standard bracing (kmember, inner fender braces, lower rad braces, sub frame braces and torque boxes) I stitch welded the entire body, and I added these triangular braces from the crossmember brace to the fram rails from left over metal from the subframe braces - I figure with the higher loads from the beefier torsion bars it couldn't hurt

|

|

|

|

|