|

Engine Build Philosophy: Port Size vs Application

#2415380

Engine Build Philosophy: Port Size vs Application

#2415380

12/08/17 07:52 PM

12/08/17 07:52 PM

|

Joined: Jan 2003

Posts: 15,439

Val-haul-ass... eventually

BradH

OP

OP

Taking time off to work on my car

|

OP

OP

Taking time off to work on my car

Joined: Jan 2003

Posts: 15,439

Val-haul-ass... eventually

|

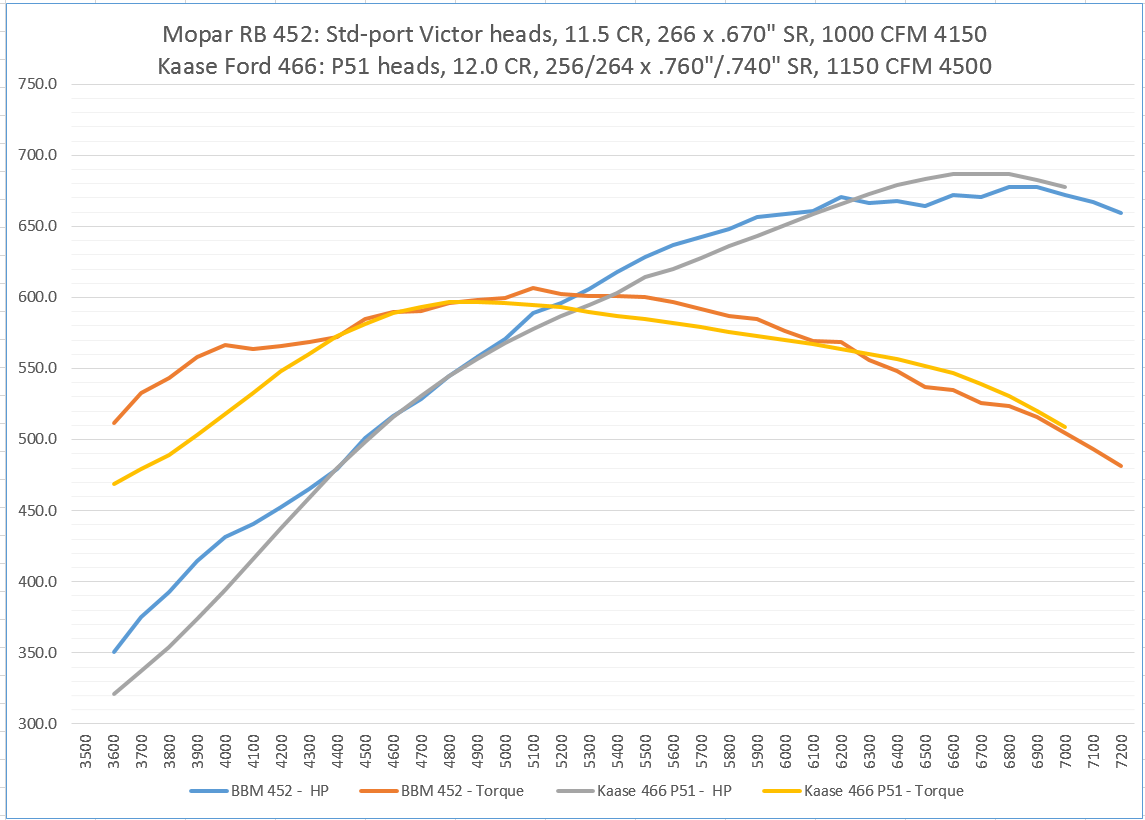

>> OK, THIS IS WHAT HAPPENS WHEN WORK IS REALLY SLOW AND I HAVE TOO MANY STOOPID IDEAS RUNNING THRU MY HEAD << Let's suspend reality for the moment and proceed under the assumption that the dyno results from three (3) different dynos referenced below can be compared without needing to apply "fudge factors". What I'm trying to cover here is not intended to be based on the absolute #s, but point out the trends and findings that I believe can be gleaned from the information. Also, it's NOT a way to bad-mouth OR praise one selection of parts over another, but to highlight the design implications of certain of parts choices. So, what's going thru my mind here? 1. Lower flowing heads with better velocity can peform as well as -- or better than -- higher flowing heads with less velocity... IF used with the appropriate application 2. Impressive flow #s won't help as much for limited-displacement applications that aren't able to take full advantage of the head's potential 3. It's a balancing act of optimizing what you have (or are required to use) and minimizing the compromises that go along with it 4. Be careful what you wish for 5. The numbers on the dyno may not translate to the numbers on the ET slip... or, at least, not the way you were expecting them to What got me thinking about this? 1. The recent dyno session of my new combination, which is a 452 RB w/ standard-port E Victor heads and my first time using a solid roller w/ a street/strip car 2. My review & analysis of the 2008 Mopar Muscle Engine Challenge where the engines were limited to stock-stroke 440-based builds, required to use Indy SR heads, and run on Rockett-brand 93 octane fuel. There was a wide range of outcomes as far as final parts combinations and dyno results, but I saw some of the same performance characteristics with almost all the builds. - http://www.hotrod.com/articles/mopp-0910-2008-amsoil-mopar-muscle-engine-challenge-wrapup and the invdividual articles that were written about each entry 3. An article I read about the Kaase P51 BBF heads for the 429-460 platform when these heads were introduced around 2007. That test used OOB P51 heads on a basic 460 performance rebuild w/ an aggressive -- although not especially big duration -- solid roller, and made close to 700 HP on pump gas and about 600 torque. - http://www.hotrod.com/articles/0707phr-p51-cylinder-heads/Keep in mind that my understanding is that all of these builds, irrespective of brand, were "supposed" to be targeted to what I'll call "real-world serious street/strip applications" that were expected to get by on pump fuel if required, although a blend of race fuel might be needed on track day. >> NEXT >>

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: BradH]

#2415381

Re: Engine Build Philosophy: Port Size vs Application

[Re: BradH]

#2415381

12/08/17 07:55 PM

12/08/17 07:55 PM

|

Joined: Jan 2003

Posts: 15,439

Val-haul-ass... eventually

BradH

OP

OP

Taking time off to work on my car

|

OP

OP

Taking time off to work on my car

Joined: Jan 2003

Posts: 15,439

Val-haul-ass... eventually

|

General observations & opinions from 2008 Mopar Muscle Engine Challenge:

1. All the legit competitors in the 2008 Mopar Muscle Engine Challenge used MW-sized ported versions of the spec Indy SR head. Some started out using ICH's 295 CNC program and at least one used MCH's CNC program. It's probably fair to say those were at least 355+ CFM heads, depending upon any additional work done. Most used MW-sized single-plane intakes (ICH RB and Edelbrock Super Victor) and two entries used ICH's tunnel ram intake. The cams, when the specs were provided, ranged from 260 to 276+ at .050" and most builders used 1.7 rockers to get the lift well over .700".

2. The dyno tests were run from 3000 to 7000 RPM and, not unexpectedly IMO, every one of those MW-head 440s had a big freakin' dip in the torque curve around 4000 RPM. The engine with the smallest cam listed that also used one of the tunnel ram setups actually had one of the biggest holes in the torque curve. None of them hit their torque peaks below 5500+, and only one actually got close to, or exceeded, 600 lbs-ft. That was the 750+ HP ICH build with the offset heads, custom T&D rocker setup, and a 276/280 at .050" cam. Yeah, it was the HP and torque King, but peak torque was almost 6000 RPM and it probably hadn't even maxed out on HP at the 7000 limit from the look of the dyno chart (still climbing).

3. One of the single-plane Dominator combinations made about 735 HP at 7000, 585 torque at 5500 and, oh yeah, they didn't provide their cam specs. Im' guessing... pretty bleepin' big. A more "mild" single-plane Dominator combination made almost 700 HP, but only 560-something torque at around 5600, and used a 270/280-ish at .050" cam.

Anybody see the obvious (to me, at least) pattern?

- 450-ish cubes

- Octane-limited CR

- MW ports

- Big dips in the torque curves right at the bottom of the range of where I'd expect a typical street/strip 440 needs the converter to stall

- Big HP at high RPM at the expense of the rest of the torque curve

>> NEXT >>

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: BradH]

#2415384

Re: Engine Build Philosophy: Port Size vs Application

[Re: BradH]

#2415384

12/08/17 07:58 PM

12/08/17 07:58 PM

|

Joined: Jan 2003

Posts: 15,439

Val-haul-ass... eventually

BradH

OP

OP

Taking time off to work on my car

|

OP

OP

Taking time off to work on my car

Joined: Jan 2003

Posts: 15,439

Val-haul-ass... eventually

|

What about the Kaase P51 466?

IMO, P51s are way better heads than any of the Indy-headed combinations in the MM Challenge: Kaase claims almost 400 CFM OOB, has a more oval-shaped intake port that is better for the velocity gradient in the port and results in less fuel drop-out, definitely has a better chamber design w/ canted valves, and the chamber's more centrally-located over the bore to reduce shrouding. This design is also more detonation-resistent, since the P51 build has 12.0:1 CR and was still able to pull solid #s on "real" pump gas.

Kaase stuffed an aggressive (not really "streetable" lobes IMO) 256/262 at 0.050" x 0.761"/0.743" roller in it and put an Edelbrock Victor with an 1150 CFM 4500-series carb on it. The cool stuff is that it made almost the same HP and torque on pump swill as it did on 100 oct race fuel, and it made 597 lbs-ft at only 4900 RPM and 687 HP at 6700 RPM on pump. And there was no "hole" in the torque curve across the 3000 to 7000 RPM dyno pull.

Sooo... going back to my opening statement "Let's suspend reality for the moment and proceed under the assumption that the dyno results from three (3) different dynos... can be compared", then consider why my 11.5:1, "small-block sized" standard-port 350 CFM head, 266 at .050" x .670" endurance-type solid roller, 4150-carbed RB 452:

- Had a broader torque curve than everything above except the Kaase 466, and out-grunted the Kaase 466 below 4000

- Made more torque than everything except the insane ICH 750+ HP combination

- Had a torque peak at a lower RPM than everthing except the Kaase 466, about 500 RPM lower than any MW-head combination in the MM Engine Challenge

- Made comparable HP to the Kaase 466 when used w/ the 2" spacer, and was less than 10 HP down with a 1" spacer... and this was testing 1.52" v downleg and 1.59" v annular 4150 carbs, rather than a Dominator

- Actually idles well at 1200 RPM and won't eat valve springs in the first 1000 miles on the street

- Can get away with a dual-purpose 4500-stall converter, even though it would probably 60-ft better with a 5000+ stall

FWIW, the Kaase 466 was tested at Westech in CA, the MM Engine Challenge was held at COMP Cams in TN, and my results came from dyno testing w/ Porter Racing Heads in VT. I know that the results from that dyno in Vermont correlate quite accurately to the in-car results, so I have faith in at least one of them.

>> NEXT >>

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: BradH]

#2415390

Re: Engine Build Philosophy: Port Size vs Application

[Re: BradH]

#2415390

12/08/17 08:13 PM

12/08/17 08:13 PM

|

Joined: Feb 2005

Posts: 20,144

PA.

pittsburghracer

"Little"John

|

"Little"John

Joined: Feb 2005

Posts: 20,144

PA.

|

I have nothing to add. Lol

1970 Duster

Edelbrock headed 408

5.984@112.52

422 Indy headed small block

5.982@112.56 mph

9.42@138.27

Livin and lovin life one day at a time

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: AndyF]

#2415435

Re: Engine Build Philosophy: Port Size vs Application

[Re: AndyF]

#2415435

12/08/17 09:48 PM

12/08/17 09:48 PM

|

Joined: Aug 2003

Posts: 43,095

Bend,OR USA

Cab_Burge

I Win

|

I Win

Joined: Aug 2003

Posts: 43,095

Bend,OR USA

|

As Andy pointed out, engine dyno tests are not always a good indication on how those motors will perform in the car  The torque converter, exhaust system and every other part on the car contributes to the in car feelings  One of my old pump gas Duster(that I traded to 9second Phil) with a mild 360 motor and 4 speed ran mid 14.40 at LACR with 3.55 gears and slicks, we swap the third member to a set of 4.89 and the car felt way faster on the street, at the track it might have pickup .2 ET and maybe 1/2 MPH   My other bracket Duster picked up .8 ET and 7 MPH by changing the carb. from 600 DP on a Eddy TM7 intake to a 1050 Holley Dominator carb. and Mopar M1 4500 single plane intake manifold with no other changes  Theory is one thing , real world results are different  I should add, put that motor in the car and go drive it and flog that rascal a bunch   Have fun

Last edited by Cab_Burge; 12/08/17 09:49 PM.

Mr.Cab Racing and winning with Mopars since 1964. (Old F--t, Huh)

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: BradH]

#2415645

Re: Engine Build Philosophy: Port Size vs Application

[Re: BradH]

#2415645

12/09/17 10:57 AM

12/09/17 10:57 AM

|

Joined: Jan 2003

Posts: 9,982

Frostbitefalls MN (Rocky&Bullw...

gregsdart

master

|

master

Joined: Jan 2003

Posts: 9,982

Frostbitefalls MN (Rocky&Bullw...

|

Picking a cylinder head based on the rpm range of the lower half of each gear makes the most sense to me, which falls right in line with what you are pointing to, Brad. Once another car has a length on you out of the gate, it takes a big top end charge to overcome it, if you even can!

8..603 156 mph best, 2905 lbs 549, indy 572-13, alky

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: BradH]

#2415697

Re: Engine Build Philosophy: Port Size vs Application

[Re: BradH]

#2415697

12/09/17 01:06 PM

12/09/17 01:06 PM

|

Joined: Feb 2006

Posts: 1,048

The Great White North

RAMM

super stock

|

super stock

Joined: Feb 2006

Posts: 1,048

The Great White North

|

[quote=BradH So, what's going thru my mind here? 1. Lower flowing heads with better velocity can peform as well as -- or better than -- higher flowing heads with less velocity... IF used with the appropriate application Here's where you can get tripped up---higher flow equals higher velocity. You need to look at discharge co-efficient for a better view.2. Impressive flow #s won't help as much for limited-displacement applications that aren't able to take full advantage of the head's potential Of course not. A more accurate statement would be RPM limited3. It's a balancing act of optimizing what you have (or are required to use) and minimizing the compromises that go along with it 100% agree4. Be careful what you wish for Don't fall into the bigger is better trap5. The numbers on the dyno may not translate to the numbers on the ET slip... or, at least, not the way you were expecting them to See #4What got me thinking about this? 1. The recent dyno session of my new combination, which is a 452 RB w/ standard-port E Victor heads and my first time using a solid roller w/ a street/strip car 2. My review & analysis of the 2008 Mopar Muscle Engine Challenge where the engines were limited to stock-stroke 440-based builds, required to use Indy SR heads, and run on Rockett-brand 93 octane fuel. There was a wide range of outcomes as far as final parts combinations and dyno results, but I saw some of the same performance characteristics with almost all the builds. - http://www.hotrod.com/articles/mopp-0910-2008-amsoil-mopar-muscle-engine-challenge-wrapup and the invdividual articles that were written about each entry 3. An article I read about the Kaase P51 BBF heads for the 429-460 platform when these heads were introduced around 2007. That test used OOB P51 heads on a basic 460 performance rebuild w/ an aggressive -- although not especially big duration -- solid roller, and made close to 700 HP on pump gas and about 600 torque. - http://www.hotrod.com/articles/0707phr-p51-cylinder-heads/Keep in mind that my understanding is that all of these builds, irrespective of brand, were "supposed" to be targeted to what I'll call "real-world serious street/strip applications" that were expected to get by on pump fuel if required, although a blend of race fuel might be needed on track day. >> NEXT >> J.Rob

2009 PHR\EMC Competitor

2010 PHR\EMC Competitor

2011 PHR\EMC Competitor

2012 PHR\EMC Competitor

2013 PHR\EMC Competitor

2014 HotRod/EMC Competitor

2015 HotRod/EMC NoShow

2016 HotRod/EMC 3rd place SPEC Bigblock

2018 HotRod/EMC 7th place G3

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: RAMM]

#2415702

Re: Engine Build Philosophy: Port Size vs Application

[Re: RAMM]

#2415702

12/09/17 01:17 PM

12/09/17 01:17 PM

|

Joined: Feb 2006

Posts: 1,048

The Great White North

RAMM

super stock

|

super stock

Joined: Feb 2006

Posts: 1,048

The Great White North

|

A few of my own thoughts.

Kaase's P51 heads are excellent and not just because of the flow. They don't flow anywhere near 400 unless you test @ 10" and convert up. However the flow @ .400" is remarkable--I believe 325-330 cfm IIRC. It is the chamber and how it is positioned (which you pointed out) which belies its true flow capability. What is baffling about them is the massive stall they suffer from @ .550" and up. I've tested 3 different sets and they all exhibit the same trend. Is there something more to this?

Those curves you put up are all indicative of a large port volume AND the wrong header design. My 2013 466 Pro-comp Victor deal had the same trend until we added something like 24" of collector with a .5" reduction in diameter along the way. This knocked out most of that dip. However this is pretty much a Band-Aid to a high flow port that is too large for the application. Min CSA of these heads were exactly 3.125" as calculated by Solidworks.

Learning from this I used a 2.85" CSA on my 2014 EMC 439.9 ci (440) effort. These Victors were dowel shifted, angle milled, guides moved in X and Y and angle changed. Flow was 353 cf. with a 2.19" valve. Torque was impressive 535 tq @ 3000, off the brake zero dip was observed and a peak of 630 was observed. If I could do it again I would make the port even smaller. That engine was easily 100pts better than my 2013 effort. J.Rob

2009 PHR\EMC Competitor

2010 PHR\EMC Competitor

2011 PHR\EMC Competitor

2012 PHR\EMC Competitor

2013 PHR\EMC Competitor

2014 HotRod/EMC Competitor

2015 HotRod/EMC NoShow

2016 HotRod/EMC 3rd place SPEC Bigblock

2018 HotRod/EMC 7th place G3

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: RAMM]

#2415708

Re: Engine Build Philosophy: Port Size vs Application

[Re: RAMM]

#2415708

12/09/17 01:43 PM

12/09/17 01:43 PM

|

Joined: Feb 2006

Posts: 1,048

The Great White North

RAMM

super stock

|

super stock

Joined: Feb 2006

Posts: 1,048

The Great White North

|

After my 2016 EMC build 469 ci SPEC build using RPM heads I have determined some eye opening results. The SPEC rules that year mandated the use of Edelbrocks RPM heads and no welding or epoxy whatsoever was allowed so this limited us to a stock offset rocker. We were also required to use the stem size and head diameter of the valves that Edelbrock states. This meant 2.14/1.81" and that was it. The cylinder heads were ported hastily and a peak of 298-299 cfm was my first and last result--meaning I didn't agonize at all--they were what they were and that is all. I made a best of 592 ft/lbs @ 3500 rpm ZERO dip and 653 ft/lbs @ 4800 rpm with 680 hp @ 6100-6300 rpm IIRC. This build really makes me question the Victors when used with a standard port opening, I mean if you are required to use a big .650" offset rocker then why the heck would you NOT open the port to gain more CSA?

What this means to me is--On your engine Brad, the Victors are a waste. You could have gotten where you are with regular old RPM,s. I've said it before and I'll say it again--I don't know why Edelbrock would even offer them in a standard port. IMO selecting standard port Victors and not targeting BIG power--800-900HP is a dichotomy. Victors should be used only by masochists and those that are hoping for well into the 800+hp range. J.Rob

2009 PHR\EMC Competitor

2010 PHR\EMC Competitor

2011 PHR\EMC Competitor

2012 PHR\EMC Competitor

2013 PHR\EMC Competitor

2014 HotRod/EMC Competitor

2015 HotRod/EMC NoShow

2016 HotRod/EMC 3rd place SPEC Bigblock

2018 HotRod/EMC 7th place G3

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: BradH]

#2415721

Re: Engine Build Philosophy: Port Size vs Application

[Re: BradH]

#2415721

12/09/17 02:21 PM

12/09/17 02:21 PM

|

Joined: Jan 2003

Posts: 14,491

So. Burlington, Vt.

fast68plymouth

I Live Here

|

I Live Here

Joined: Jan 2003

Posts: 14,491

So. Burlington, Vt.

|

IMO, if you replaced Brads Victor heads with a set of 300cfm RPM heads, milled for equal compression, and left everything else the same, the motor would have made way less power.

Additionally, in "engine contest" trim, there would certainly be some more power available from that combo.

More aggressive cam, more rigid rocker arms, ported intake manifold, gas ported pistons, lower tension ring pack, 4500 carb on an HVH SS/adapter...... It easily would have made solidly over 700hp.

When the RPM heads first came out I built a 448 that was very comparable to Brads 452(same cr, similar cam).

I ported the heads to flow in the 300cfm range, and tested them on the motor with a few different intake and carb combos.

At that point, the best intake/carb combo i tried was the Weiand TR with 2 x 650 Demon carbs on it. That made around 595tq and not quite 640hp.

The next closest single carb test was around 625hp, with a similar drop in tq.

Brads Victor combo made 684hp/605tq with an old school HP950 Holley on it(1.375 venturi), which resulted in the motor using 20cfm less air than when the bigger carbs were being run.

Had the bigger carbs been better optimized for the motor, I have to believe some benefit could have been gleaned from that extra 20cfm of air.

With the current crop of std port offerings available, for me the real litmus test would be how much difference in power there would be if you pulled the Victors off Brads motor and plopped a set of ootb TF240's on it.

If it made within 10-15hp of the Victors, then that would be a good argument against the viability of the std port version of those heads, at least at that power level.

It would be a fun test.

The nuts and bolts of this particular test is that Brad replaced his ported std port Stage 6's and flat tappet cam with the std port Victors and a roller cam and picked up 20ft/lbs and 60hp.

There are a few things I don't really care for in how the Victors are made, but I'd say the biggest "problem" with the std port version for me is the they are cast with the bowls .300 smaller in diameter than they should be.

If they had the bowls sized correctly to begin with(sort of like the original version was), then I would feel better about recommending them for the hot street applications where a high flowing std port head can work.

As they are now though, they're too labor intensive to be cost effective.

I wouldn't mind doing a "low effort" type job with some Pro Comp "Victors" at some point though(since those don't have the ridiculously undersized bowls).

68 Satellite, 383 with stock 906’s, 3550lbs, 11.18@123

Dealer for Comp Cams/Indy Heads

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: mopar dave]

#2415742

Re: Engine Build Philosophy: Port Size vs Application

[Re: mopar dave]

#2415742

12/09/17 03:04 PM

12/09/17 03:04 PM

|

Joined: Jul 2004

Posts: 19,317

State of confusion

Thumperdart

I Live Here

|

I Live Here

Joined: Jul 2004

Posts: 19,317

State of confusion

|

I agree on the velocity thing 100%. Hughes Engines used to advertise their head porting that way yrs back. Dom uses ported Rpm heads on a 470 and i use E MW heads on a 511. Doms engine makes more power than my 511. Compression is not much different between the 2. I think my 511 combo may make more power with RPM heads. Mine may be considered max ported base on Pettis and George Koopals opinions but no flow #`s since I was in a hurry to assemble and the flow bench was tied up. I know that on a chassis dyno years ago it was still makin power to 7000 where I stopped and went home and on the street, it's a beast to me anyhow w/a new best hopefully very soon..........I plan on a max wedge build next year and a bigger cam..............

72 Dart 470 n/a BB stroker street car `THUMPER`...Check me out on FB Dominic Thumper for videos and lots of carb pics......760-900-3895.....

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: fast68plymouth]

#2415756

Re: Engine Build Philosophy: Port Size vs Application

[Re: fast68plymouth]

#2415756

12/09/17 03:51 PM

12/09/17 03:51 PM

|

Joined: Aug 2003

Posts: 43,095

Bend,OR USA

Cab_Burge

I Win

|

I Win

Joined: Aug 2003

Posts: 43,095

Bend,OR USA

|

My first 400 block stroker motor made 612 HP at 5500 RPM and 644 Ft. lbs. torque at 4500 RPM, that was with 9.25 to 1 compression using a set of mildly ported 906 heads (flowed 266 at 28.0 inches at .700 lift on Pettis 600 Super flow bench) with 2.14 intake and 1.81 ex. valves. Comp Cams solid roller custom ground for Benschoff racing (SP?) in WI. the testing was done on Vrbansic Bros. (Ontario, CA) DTS engine dyno in 2003 or 2004, CRS  We tested three different sets of six pack carbs and multiple air cleaners combination. the best results are posted where with the stock air cleaner base with no air cleaner and a set of the Holley mechanical carbs with stock jetting, the worst results where with a set of replacement Holley 1971 440 automatic carbs with stock jetting that bogged horribly when open but still made 605 HP at 5400 RPM  I put the motor in my Duster and took it to Woodburn drag strip in October of 2005 after we moved to Oregon, it ran a best of 10.69 at 124. MPH. I swapped the heads that winter to a set of MCH CNC ported Eddy RPM heads that flowed 319 CFM at .700 on MCH flow bench and flowed 310 CFM on Pettis bench at .700 lift with 28 inches of water on his Super Flow bench  Both sets of heads had 84 CC so the motor ended up having the same compression ratio and a different set of 1.6 rockers, I took the CAT 1.6 ratio rockers off(they where wearing the shafts out nmaking metal  ) and put a set of Harland sharp 1.65 ratio on the Eddy heads, those two changes ended up making the car go 10.49 at 126 MPH  I ended up changing a lot of other things on the motor including the cranks shaft increasing the stroke .050 to make the same pistons and rods end up with 10.29 to 1 compression ratio and increased the C.I. from 511 to 517, that change made the car go 10.30s ET at 127.+ MPH  The last change was going to a set of Indy SR M.W. size ports not CNC ported with a Indy 400-3 intake with a Wilson manifold 1.5 inch reversion spacer with a 19x3.0 inch air cleaner instead of the stock type six pack air cleaner with two K&N six pack elements on it. I ended up using several different Holley 1050 CFM Dominator carbs on the motor that ended up with a best ET of 9.993 at 134.+ MPH through the 3.0 inch exhaust with the 16x3.0 inch tall paper air cleaner element on using 91 octane non ethanol pump swill, the car weighed 3450 Lbs. with me in it. I had a lot of fun and learned a bunch from that car and different engine combinations  I did try a set of 440-1 heads with 2.25 intake valves that where CNC ported by MCH, on the DTS engine dyno in Klamath Falls OR they made 50 HP more on my Duster motor with the same compression ratio, those heads flowed 30 CFM more at .700 (370 CFM)than the SR heads did on the same bench  I would of loved to try a set of B1 heads that flowed over 400 CFM with that short block making less than 11.0 to 1 compression   My message is results on the dyno compared to at the track may or may not make what you think it should, go test that motor Brad in the car

Last edited by Cab_Burge; 12/09/17 03:55 PM.

Mr.Cab Racing and winning with Mopars since 1964. (Old F--t, Huh)

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: jwb123]

#2415964

Re: Engine Build Philosophy: Port Size vs Application

[Re: jwb123]

#2415964

12/09/17 11:34 PM

12/09/17 11:34 PM

|

Joined: Jan 2003

Posts: 9,870

Weddington, N.C.

Streetwize

master

|

master

Joined: Jan 2003

Posts: 9,870

Weddington, N.C.

|

Where drivability (I define as off idle to <WOT) throttle torque is important (and for most dual purpose cars it's way more important than most will admit) having a slightly undersized higher velocity port will be more responsive and fun to drive. At the track and with the optimal gearing (critically important) a larger port will et quicker, though driving it around on the street it will feel more sluggish or will be far more dependent on stall/flash....which means pretty inefficient if only in terms of how it's mainly going to be used.

Brad do you have Steve Dulcich's hp/tq graph from his 2003 EM 470/Chapman or our own EM Stage VI high velocity/epoxied MW entry? I don't think those had much if/any perceivable dip, but 470's hit a little quicker and harder on a dyno than a 440 of the same peak power. I think a big part of the strategy for EM is the fixed rate of acceleration in 100R's/sec against WOT standardized testing. I think guys like Kaase and Bischoff figured out very early that tight lobe centers combined with early ICL's get the motors a harder dyno "hit" and perhaps help the combo carry momentum...like 'pedaling downhill' of sorts. in other words the gains in torque below the peak more than offset perhaps losing a couple up top, the motors are obviously much more "lift dependant" from peak torque to peak power because the durations have to be kept relatively short to achieve mid range velocity at the slower RPM/piston speeds.

On the street or at the strip with a high stall converter or a clutch that 3500-4000 won't have much bearing with the right converter, but velocity has a TON to do with responsiveness. My approach has always been on a big 500" motor it shouldn't need to be so converter dependent to get to the sweet spot, so I'm a huge fan of velocity. But of course my philosophy for dual purpose cars is more likened to a road-race shortblock with killer heads for the best (or near best) of both worlds. My 517 Chapman design was based a lot on what I learned from Steve's 470 motor and discussions with Dwayne and Dan Costello....and it's the flattest/broadest torque and fastest revving wedge I've ever built...by a mile.

Last edited by Streetwize; 12/11/17 11:52 PM.

|

|

|

|

|