MIG Welder Question

#1693991

MIG Welder Question

#1693991

11/03/14 09:21 PM

11/03/14 09:21 PM

|

Joined: Sep 2009

Posts: 1,377

Tennessee

WyleECoyote

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Sep 2009

Posts: 1,377

Tennessee

|

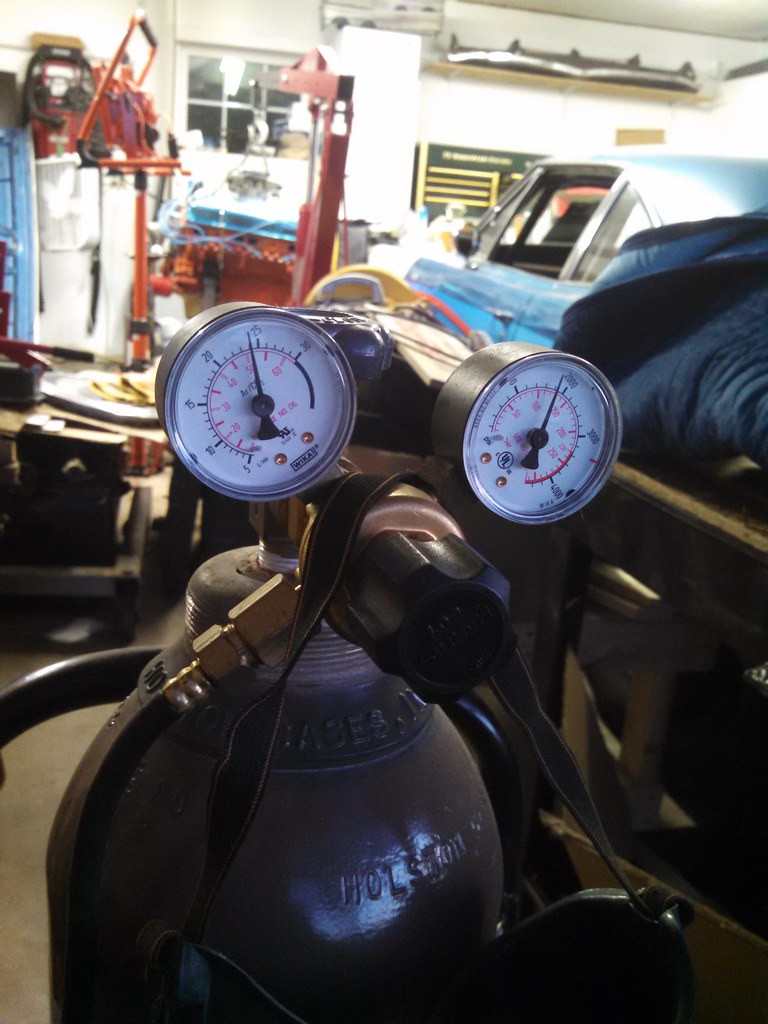

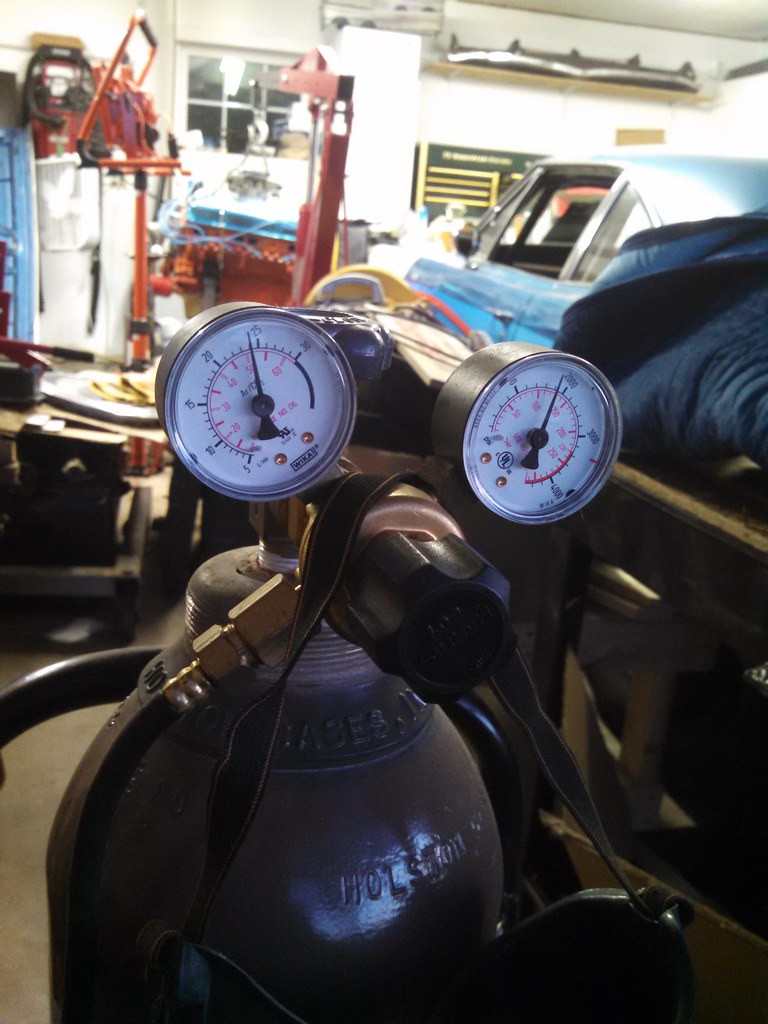

LINCOLN PRO-MIG 140 - What do I set this gauge on? And I presume I read the numbers in black, not red?

Wile E. Coyote

Super Genius, Lover of FCA US LLC Products

*************

68 Road Runner (440 4-spd), 71 Superbee (383 slap), 71 Charger 500 (383 4-spd wA/C 1of 182), 72 Imperial, 74 Charger SE (440 sunroof), 84 D350 Crew-cab Dually (440), 75 D300 Dually Tandem (318 4-speed)

|

|

|

Re: MIG Welder Question

[Re: WyleECoyote]

#1693994

Re: MIG Welder Question

[Re: WyleECoyote]

#1693994

11/03/14 09:45 PM

11/03/14 09:45 PM

|

Joined: Feb 2005

Posts: 28,312

Cincinnati, Ohio

Challenger 1

Too Many Posts

|

Too Many Posts

Joined: Feb 2005

Posts: 28,312

Cincinnati, Ohio

|

Quote:

LINCOLN PRO-MIG 140 - What do I set this gauge on? And I presume I read the numbers in black, not red?

The gauge on the right is how much is left in the bottle, the one on the left is flow as you know I'm betting.

It's set too high in the picture above IMO for most welding. You need just enough flow to keep your welds pure and no more. Got to experiment to find what's best for what your welding. Got to keep your gas nozzle clean so there's un interrupted gas flow. I use nozzle dip to keep splatter from sticking to my nozzle.

I'd start down around 10 and go from there.

Does anyone remember the flow meters with the floating ball?

The gauge above I believe is reading in cubic foot of air per minute or hour or something like that, not psi.

|

|

|

Re: MIG Welder Question

[Re: justinp61]

#1693997

Re: MIG Welder Question

[Re: justinp61]

#1693997

11/04/14 01:15 AM

11/04/14 01:15 AM

|

Joined: Sep 2009

Posts: 1,377

Tennessee

WyleECoyote

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Sep 2009

Posts: 1,377

Tennessee

|

Alcon - Thank you!   I appreciate all the welding sensei advice!  I will be doing some novice welding tomorrow and I didn't have a clue where the gas pressure needed to be. Now, thanks to those of you that commented, I have an idea and will do as suggested by you. Tomorrow should be smooth sailing!

Wile E. Coyote

Super Genius, Lover of FCA US LLC Products

*************

68 Road Runner (440 4-spd), 71 Superbee (383 slap), 71 Charger 500 (383 4-spd wA/C 1of 182), 72 Imperial, 74 Charger SE (440 sunroof), 84 D350 Crew-cab Dually (440), 75 D300 Dually Tandem (318 4-speed)

|

|

|

Re: MIG Welder Question

[Re: WyleECoyote]

#1693998

Re: MIG Welder Question

[Re: WyleECoyote]

#1693998

11/04/14 02:12 AM

11/04/14 02:12 AM

|

Joined: Oct 2005

Posts: 1,305

Lakewood, Colorado

herkamer

pro stock

|

pro stock

Joined: Oct 2005

Posts: 1,305

Lakewood, Colorado

|

For most mig welding you want 20cf/hr. Your left gauge is liters/min on the outside black scale. Can't see what the is under the bottom of the needle to determine what scale the red is. Based on math and what the old interweb says for conversion from l/min to cf/hr, it should be cf/hr. 20cf/hr is 9.4l/min. Adds up with the scale. Keep in mind that gauge is calibrated for argon/CO2 blend gas. If you are running pure CO2, the flow rates are a little different. Start at 10 on the black and adjust from there.

Matt

69 Dart Swinger 340

83 W350, Megasquirted with 46RH

Old news: 72 Demon street/race mobile

Latest: 70 Duster backhalf car

and even more

|

|

|

Re: MIG Welder Question

[Re: herkamer]

#1693999

Re: MIG Welder Question

[Re: herkamer]

#1693999

11/04/14 06:19 AM

11/04/14 06:19 AM

|

Joined: Mar 2007

Posts: 3,277

West Coast, USA

jbc426

master

|

master

Joined: Mar 2007

Posts: 3,277

West Coast, USA

|

I weld outside a lot with the usual breeze. I have mine jacked up to 40 psi.

Thanks for the enlightenment,

and gas savings.

1970 Plymouth 'Cuda #'s 440-6(block in storage)currently 493" 6 pack, Shaker, 5 speed Passon, 4.10's

1968 Plymouth Barracuda Convertible 408 Magnum EFI with 4 speed automatic overdrive, 3800 stall lock-up converter and 4.30's (closest thing to an automatic 5 speed going)

|

|

|

Re: MIG Welder Question

[Re: DDodger]

#1694004

Re: MIG Welder Question

[Re: DDodger]

#1694004

11/05/14 07:44 PM

11/05/14 07:44 PM

|

Joined: Oct 2003

Posts: 11,684

W. Kentucky

justinp61

I Live Here

|

I Live Here

Joined: Oct 2003

Posts: 11,684

W. Kentucky

|

Quote:

i think you gonna find both those gauges are pressure, not flow. most flow indicators are long tall ball in a tube deal use whatever gives good weld outdoors in wind, needs more gas

Wrong, the gauge on the left is flow, CHF. My miller has the same exact setup.

|

|

|

Re: MIG Welder Question

[Re: justinp61]

#1694005

Re: MIG Welder Question

[Re: justinp61]

#1694005

11/05/14 09:18 PM

11/05/14 09:18 PM

|

Joined: Dec 2003

Posts: 22,695

Bitopia

jcc

If you can't dazzle em with diamonds..

|

If you can't dazzle em with diamonds..

Joined: Dec 2003

Posts: 22,695

Bitopia

|

Quote:

Quote:

i think you gonna find both those gauges are pressure, not flow. most flow indicators are long tall ball in a tube deal use whatever gives good weld outdoors in wind, needs more gas

Wrong, the gauge on the left is flow, CHF. My miller has the same exact setup.

My first impression was it was a pressure gauge, and others were confusing to me commenting on flow, it was difficult for me to make out the markings, but I assume those that can see it are reading cfm, and yes, proper flow is of course only measured in CFM. Has it been mentioned yet that too much flow can have a downside by sucking small amounts of air?

Reality check, that half the population is smarter then 50% of the people and it's a constantly contested fact.

|

|

|

|

|