|

Another street/strip 440 rebuild

#1638700

Another street/strip 440 rebuild

#1638700

06/26/14 04:50 PM

06/26/14 04:50 PM

|

Joined: Jun 2014

Posts: 41

MA

mopar67440

OP

OP

member

|

OP

OP

member

Joined: Jun 2014

Posts: 41

MA

|

This is my first time posting here...been mostly a reader and have learned a lot, thanks all.

Well, I'm finally at a point in my life where I can finish my life long project.... 1967 Coronet 500. This will be the 6th, 1967 car I've owned since 1985.

Would love some input on the following engine combo that I had built over 20 years ago in my last project. I thought it ran really strong on the track and was very streetable once tuned. Loved it so much, I've decided to pretty much keep everything the same with the exception of new pistons and rods.

1969 block 0.030 over

KB236 piston

Eagle rods

6 qrt pan/pickup/windage tray & HV pump

906 heads

single layer 0.020" head gasket

509/292 108 cam

stock 6 pack rockers & push rods

Torqer single plane intake w/ 1" spacer & no exhaust xover

700CFM DP Holley (50cc pumps, 37 nozzle, 72 prim, 82 sec jets)

Mallory Hyfire ignition sys. w/ 12 initial, 36 total advance (may need to revisit this with change in gas formula)

1 7/8" headers

2.5" dual exhaust w/ xover

3200 stall

3:91 gears

modified B727

26" BF Goodrich

super stock leaf springs

My only concern would be with the new KB pistons and compression using the 509 cam. According to the KB website, a KB236 piston with unmodified open chamber heads (approx. 88-90CC) and 0.020" head gasket, compression will be approx. 10-10.5.

Thoughts...

|

|

|

Re: Another street/strip 440 rebuild

[Re: mopar67440]

#1638701

Re: Another street/strip 440 rebuild

[Re: mopar67440]

#1638701

06/26/14 05:19 PM

06/26/14 05:19 PM

|

Joined: Jun 2006

Posts: 5,159

CT

GTX MATT

master

|

master

Joined: Jun 2006

Posts: 5,159

CT

|

Would be a good runnner. Nowadays lots of guys are running 440Source aluminum heads or Eddy RPMs instead of 906s. If you're starting from scratch they cost about the same, and make more power than stock 906s. 10:1 or 10.5:1 compression would be fine with aluminum heads and good quench (not sure if you're familiar with that). It will probably be trouble with 906s. You're actual compression with those pistons would likely be closer to 9.5:1 though. Lots of guys will tell you to run a different cam (newer design), but theres nothing wrong with the 509s. Modern cams have more aggressive ramps which require more spring pressure and will wipe a lobe faster. The 509s are also fine with stock rockers. If you run the Stealths or Eddy RPMs the supplied valve springs should be adequate also. Comp also sells a version of the 509 that works well. Lots of guys run 3 inch exhaust now since it is more readily available. Id run a 750 or 800, but a 700 isn't terrible. Overall, that combo still pulls hard. I've had 4 '67 B bodies since 2007 myself

Last edited by GTX MATT; 06/26/14 05:20 PM.

Now I need to pin those needles, got to feel that heat

Hear my motor screamin while I'm tearin up the street

|

|

|

Re: Another street/strip 440 rebuild

[Re: mopar67440]

#1638702

Re: Another street/strip 440 rebuild

[Re: mopar67440]

#1638702

06/26/14 05:32 PM

06/26/14 05:32 PM

|

Joined: Jan 2003

Posts: 74,947

U.S.S.A.

JohnRR

I Win

|

I Win

Joined: Jan 2003

Posts: 74,947

U.S.S.A.

|

Quote:

My only concern would be with the new KB pistons and compression using the 509 cam. According to the KB website, a KB236 piston with unmodified open chamber heads (approx. 88-90CC) and 0.020" head gasket, compression will be approx. 10-10.5.

Thoughts...

That's going to be a problem unless you don't have a problem running race gas .

Hopefully you haven't wasted money on those pistons yet .

|

|

|

Re: Another street/strip 440 rebuild

[Re: JohnRR]

#1638706

Re: Another street/strip 440 rebuild

[Re: JohnRR]

#1638706

06/26/14 05:44 PM

06/26/14 05:44 PM

|

Joined: Jan 2003

Posts: 21,064

Niles , Ohio

therocks

oh wait.but hey.lets see.oh yeah.

|

oh wait.but hey.lets see.oh yeah.

Joined: Jan 2003

Posts: 21,064

Niles , Ohio

|

I run 12.5 Ross domes in my street 440.It did have 516 reworked heads.Now it has Stealths with .039 gaskets.It will run all day long on pump gas.Only time I get clatter is if I really lay into it in like 1st.It has a Comp .588 cam with IIRC around 325 duration.Now when I really want to have fun I add 112 race gas.Same thing at the track.Rocky

Chrysler Firepower

|

|

|

Re: Another street/strip 440 rebuild

[Re: mopar67440]

#1638707

Re: Another street/strip 440 rebuild

[Re: mopar67440]

#1638707

06/26/14 06:40 PM

06/26/14 06:40 PM

|

Joined: Jun 2006

Posts: 5,159

CT

GTX MATT

master

|

master

Joined: Jun 2006

Posts: 5,159

CT

|

Quote:

I already have the 906's w/ heavy springs/dampers. The aluminum heads are just a little rich for my blood at the moment.

Also, the engine ran strong with the 700cfm right up to 6500. At the suggestion of a friend, I tried both a 750 & 850, and after tuning them both, I found the larger carbs were not as responsive, and there was really no diff in the et's, so I went back to the 700.

Stick with it then.

I thought the 236s were the flat tops and 237s the quench domes, which is why I said you'd probably be lower compression above. As far as the compression goes, you have all the parts. Why don't you measure and figure out what it actually is? Did the shop take your heads and actually set the quench distance? If you have the quench set up right you might get away with 10:1 with the 509 cam.

Now I need to pin those needles, got to feel that heat

Hear my motor screamin while I'm tearin up the street

|

|

|

Re: Another street/strip 440 rebuild

[Re: GTX MATT]

#1638708

Re: Another street/strip 440 rebuild

[Re: GTX MATT]

#1638708

06/26/14 09:35 PM

06/26/14 09:35 PM

|

Joined: Mar 2005

Posts: 3,138

Central NC

gch

master

|

master

Joined: Mar 2005

Posts: 3,138

Central NC

|

The lazy response on the larger carbs may have been due to the Torker intake.Maybe not  509 cams like compression and it should run well you will just have to be careful not to get into detonation in the upper rpms once you build some cylinder pressure.I bet it would like more initial advance. I would thin an RPM intake or street dominator intake would be a better choice and would run at least a 750cfm carb if it were mine. If you could sell your heads and get the 440 source heads you would be great on compression and likely run faster.

|

|

|

Re: Another street/strip 440 rebuild

[Re: gch]

#1638709

Re: Another street/strip 440 rebuild

[Re: gch]

#1638709

06/27/14 12:45 AM

06/27/14 12:45 AM

|

Joined: Aug 2006

Posts: 2,141

junction city oregon

viperblue72

top fuel

|

top fuel

Joined: Aug 2006

Posts: 2,141

junction city oregon

|

I agree that it's a good combination. Pushing it for pump fuel though. Just throw in a gallon of 110 with every tank if it pings a little. May as well run a thicker head gasket as well. Either that or run aluminum edelbrock rpm heads. Run a 1.6 rocker. I would install a proform hp main body on that carburetor also. I would bump the stall up another 500.

Last edited by viperblue72; 06/27/14 12:48 AM.

|

|

|

Re: Another street/strip 440 rebuild

[Re: JohnRR]

#1638710

Re: Another street/strip 440 rebuild

[Re: JohnRR]

#1638710

06/27/14 12:49 AM

06/27/14 12:49 AM

|

Joined: Aug 2006

Posts: 2,141

junction city oregon

viperblue72

top fuel

|

top fuel

Joined: Aug 2006

Posts: 2,141

junction city oregon

|

Quote:

Quote:

Yup...the lower end is a done deal at this point...balanced and assembled. No cam yet though and I can always change the head gaskets if need be.

the KB is a step head piston , what is the distance between the step head and the open part of the chamber ? That piston was designed to mimic a closed chamber head when setup properly , you chose the worst people KB made for that application , but probably because it was the only one they had.

I had my hands in a build with 452's and step head pistons , Diamond made me these to get 9.5 with 89cc head.

A flat top 0 decked will get you 9.5

|

|

|

Re: Another street/strip 440 rebuild

[Re: Mr.Yuck]

#1638712

Re: Another street/strip 440 rebuild

[Re: Mr.Yuck]

#1638712

06/27/14 12:24 PM

06/27/14 12:24 PM

|

Joined: Jun 2014

Posts: 41

MA

mopar67440

OP

OP

member

|

OP

OP

member

Joined: Jun 2014

Posts: 41

MA

|

I was considering a thicker composite head gasket as suggested(0.020 to 0.040) to reduce compression, but this will certainly reduce quench, and I fear it may result in either no change, or even increase the likelihood of detonation at heavy loads.

As suggested, I will up the initial 12 degrees, and note any detonation at 36 and drop total back a bit if need be to keep it in check. But I'm also thinking if I can get away with the 160 therm verses 180 now that I have a 3 core high efficiency rad/shroud combo, plus dialing in the right octane, I may be able to keep it at 36 degrees total.

As for the carb tuning, I was very meticulous when dialing in all 3 carbs (700, 750 and 850), and definitely proved the smaller carb gave me better throttle response, quicker 0-60, slightly better 1/4 mile et's, and the same upper rpm limit of 6k.

|

|

|

Re: Another street/strip 440 rebuild

[Re: mopar67440]

#1638714

Re: Another street/strip 440 rebuild

[Re: mopar67440]

#1638714

06/27/14 01:14 PM

06/27/14 01:14 PM

|

Joined: Jan 2003

Posts: 74,947

U.S.S.A.

JohnRR

I Win

|

I Win

Joined: Jan 2003

Posts: 74,947

U.S.S.A.

|

Quote:

I was considering a thicker composite head gasket as suggested(0.020 to 0.040) to reduce compression, but this will certainly reduce quench, and I fear it may result in either no change, or even increase the likelihood of detonation at heavy loads.

You said the heads were stock , 88-90 cc , how far above the deck is the step above the deck and did you have the chamber depths equalized ?

|

|

|

Re: Another street/strip 440 rebuild

[Re: GTX MATT]

#1638718

Re: Another street/strip 440 rebuild

[Re: GTX MATT]

#1638718

06/27/14 03:12 PM

06/27/14 03:12 PM

|

Joined: Jan 2003

Posts: 16,376

dogdays

I Live Here

|

I Live Here

Joined: Jan 2003

Posts: 16,376

|

According to the KB catalog, the piston has comp height of 2.057, the step head is 0.075". The total of the dome and the valve reliefs ADDS 4.8cc to the head volume. This is a common mistake, KB is the only company that talks about reducing chamber volume with a dome as NEGATIVE ccs. So adding to the volume above the piston comes in at POSITIVE ccs.

According to the KB website, their stated compression ratios are for zero deck, 0.040" head gasket, 0.030 overbore.

For the KB236 and 88cc heads the stated compression ratio of 9.9:1.

If you do a Web search for the KB236 you will most likely go to the Summit catalog page and they have their own compression ratio computer, which uses the positive ccs for the piston dome and dish as subtracting from the combustion chamber volume. If you use the KB numbers in the Summit calculator you are guaranteed to get wrong answers. Guaranteed.

Using a deck height of 10.725 and stock piston and rod lengths puts the piston 0.025" down in the hole, which with your 0.020" gasket puts your setup the same as the KB standard, give or take a few cc. But if your heads have not been milled, they are 88 to as much as 93cc, meaning your actual compression ratio should come out between 9.75:1 and 9.9:1.

It might run on pump premium, or need a little water injection. IMHO it's on the upper limit.

One other thing, the thinner head gasket and the 0.075" step are helping fight detonation, I wouldn't change that.

Other things that will help are keeping the engine and intake manifold cool, and keeping the mixture on the rich side.

R.

|

|

|

Re: Another street/strip 440 rebuild

[Re: mopar67440]

#1638720

Re: Another street/strip 440 rebuild

[Re: mopar67440]

#1638720

06/27/14 06:05 PM

06/27/14 06:05 PM

|

Joined: Jan 2003

Posts: 16,376

dogdays

I Live Here

|

I Live Here

Joined: Jan 2003

Posts: 16,376

|

|

|

|

Re: Another street/strip 440 rebuild

[Re: dogdays]

#1638721

Re: Another street/strip 440 rebuild

[Re: dogdays]

#1638721

06/27/14 10:26 PM

06/27/14 10:26 PM

|

Joined: Jun 2006

Posts: 5,159

CT

GTX MATT

master

|

master

Joined: Jun 2006

Posts: 5,159

CT

|

IMO with .040 quench and 10:1 or less you'd be ok. You could get away with a 509 in a 9.5:1 engine with no quench, so I don't see why half a point more with quench wouldn't work.

Now I need to pin those needles, got to feel that heat

Hear my motor screamin while I'm tearin up the street

|

|

|

Re: Another street/strip 440 rebuild

[Re: mopar67440]

#1638722

Re: Another street/strip 440 rebuild

[Re: mopar67440]

#1638722

06/28/14 12:01 AM

06/28/14 12:01 AM

|

Joined: Feb 2005

Posts: 4,310

Prospect, PA

BSB67

master

|

master

Joined: Feb 2005

Posts: 4,310

Prospect, PA

|

Quote:

I'm guessing what your driving at is, I should have cc'd the heads and equalized them, then measured the piston step to calculate exact compression ratio & quench.

No, what I believe he is getting at is if you want to actually get some benefit of the reverse dome with proper quench, you need to know exactly how far above the deck the piston comes, know what head gasket you will be using, and then measure and work each combustion chamber "flat area" to the same and correct depth to acquire the desired piston to head quench clearance.

|

|

|

Re: Another street/strip 440 rebuild

[Re: BSB67]

#1638723

Re: Another street/strip 440 rebuild

[Re: BSB67]

#1638723

06/29/14 08:44 PM

06/29/14 08:44 PM

|

Joined: Oct 2003

Posts: 3,698

NE Oklahoma

Von

master

|

master

Joined: Oct 2003

Posts: 3,698

NE Oklahoma

|

Are the 236s the same as the 146s, just thinner ring pack for the 146s. Cant remember. If so, i have some real world experience w them on 3 different combos.

I will say, in my experience, most of the compression numbers vs safe pump gas use, being tossed around are very conservative. Yrmv.

Last edited by Von; 06/29/14 08:47 PM.

72 RR, Pump gas 440, 452s, 3800 lbs, Corked, ET Radials,. 11.33@117.72.

Same car, bone stock 346s, 9.5 comp, baby solid. 12.24@110.

|

|

|

Re: Another street/strip 440 rebuild

[Re: Von]

#1638724

Re: Another street/strip 440 rebuild

[Re: Von]

#1638724

07/08/14 04:31 PM

07/08/14 04:31 PM

|

Joined: Jun 2014

Posts: 41

MA

mopar67440

OP

OP

member

|

OP

OP

member

Joined: Jun 2014

Posts: 41

MA

|

Thank you everyone who chimed in. Gave me a lot to think about and made me realize I may have made a few mistakes and false assumptions when bolting the heads on, so I've decided to take a step back and verify some of the critical measurements before going any further with the rebuild.

One mistake was in a suggestion from a friend...who btw is a great mechanic & he meant well, but he's not much on the engineering side. He suggested the Fel Pro 0.037" composite gasket to reduce compression to run on pumped gas. I now realize this is most likely a bad choice at the sacrifice of quench, not knowing for sure if the heads were surfaced, and whether the CC's are equal across all chambers.

The plan is to remove the heads and cc all 8 chambers. A question I have is... once I know this, how close to each other should they be, and what is the best approach to equalizing them?

The second step is to measure the actual quench area across all 8 pistons (both ends and center of piston) to head using the rosin core solder method I've read a lot about. I believe once I know this, I can select the appropriate compressed head gasket thickness.

A few questions;

1) should I make the measurement without gaskets and the heads completely or lightly torqued?

2)Once I have this measurement, where in the 0.035"-0.040" quench area should I strive for...the 0.035" minimum or stay on the safer side of 0.040"? For instance, if I measure 0.018" quench without a head gasket, by using the compressed steel 0.020" gasket, I would be at 0.038" Considering the KB236 pistons, Eagle rods, average rod bearing clearance, and a rev limit of 6000-6500, this would be a good choice.

|

|

|

Re: Another street/strip 440 rebuild

[Re: mopar67440]

#1638725

Re: Another street/strip 440 rebuild

[Re: mopar67440]

#1638725

07/08/14 06:01 PM

07/08/14 06:01 PM

|

Joined: Jan 2003

Posts: 74,947

U.S.S.A.

JohnRR

I Win

|

I Win

Joined: Jan 2003

Posts: 74,947

U.S.S.A.

|

Quote:

The 906's were never milled and I never cc'd each cylinder to check consistency. Going by production numbers, I'm assuming the heads are somewhere in the 88-90cc range, so based on the KB piston specs of 1.8cc piston step & stock stroke, compression is 10.5:1 @85cc's, 10.0:1 @90'cc. with a 0.040" gasket compression, or 10.96:1 @85cc to 10.45:1 @90cc with 0.020" compression.

I'm guessing what your driving at is, I should have cc'd the heads and equalized them, then measured the piston step to calculate exact compression ratio & quench.

WHAT production numbers ??? I've never seen any and YES you should have done all that , especially with those heads and pistons and crank and rods unless you paid to have the crank rods and pistons checked/size matched.

I had a 383 screwed together on it's at least second rebuild , friend I'm helping is on a LOW fixed budget/retired , the piston to deck heights are all over the place, he doesn't have to worry about quench , it has none ...

|

|

|

Re: Another street/strip 440 rebuild

[Re: mopar67440]

#1638726

Re: Another street/strip 440 rebuild

[Re: mopar67440]

#1638726

07/08/14 06:14 PM

07/08/14 06:14 PM

|

Joined: Jan 2003

Posts: 74,947

U.S.S.A.

JohnRR

I Win

|

I Win

Joined: Jan 2003

Posts: 74,947

U.S.S.A.

|

Quote:

Thank you everyone who chimed in. Gave me a lot to think about and made me realize I may have made a few mistakes and false assumptions when bolting the heads on, so I've decided to take a step back and verify some of the critical measurements before going any further with the rebuild.

One mistake was in a suggestion from a friend...who btw is a great mechanic & he meant well, but he's not much on the engineering side. He suggested the Fel Pro 0.037" composite gasket to reduce compression to run on pumped gas. I now realize this is most likely a bad choice at the sacrifice of quench, not knowing for sure if the heads were surfaced, and whether the CC's are equal across all chambers.

The plan is to remove the heads and cc all 8 chambers. A question I have is... once I know this, how close to each other should they be, and what is the best approach to equalizing them?

The second step is to measure the actual quench area across all 8 pistons (both ends and center of piston) to head using the rosin core solder method I've read a lot about. I believe once I know this, I can select the appropriate compressed head gasket thickness.

A few questions;

1) should I make the measurement without gaskets and the heads completely or lightly torqued?

2)Once I have this measurement, where in the 0.035"-0.040" quench area should I strive for...the 0.035" minimum or stay on the safer side of 0.040"? For instance, if I measure 0.018" quench without a head gasket, by using the compressed steel 0.020" gasket, I would be at 0.038" Considering the KB236 pistons, Eagle rods, average rod bearing clearance, and a rev limit of 6000-6500, this would be a good choice.

I wouldn't worry too much about making the chambers equal unless they are really far apart , the IMPORTANT measurement is the distance from the head deck to the cast area that is the open part of the chamber , they are NEVER the same or even flat in any direction ... at least not that I have ever measured on any of the heads I have machined.

As far as the .037 Felpro composite , no such animal , they are .040ish and you do not have a bunch of different thicknesses to choose from. Steel shim head gaskets run .021 for the most common gasket , Cometic has one that is .027 $$$$

You need to know how far above the block deck the step of the piston is sitting , no gasket.

Was the block SQUARED during any of the rebuild processes ? If not that will add to the fun. Don't be surprised to see the steps not all at the same height , even if the block was squared.

Shoot for . 040 , and hope for between .035 and no more than .045, if the heads were never cut you'll need a step that is roughly .0080 above the deck ... assuming a .021 head gasket and .100 chamber depth.

Measure the head bolt boss under the exh ports , uncut heads will be basically 1.000 , if the heads have not been surfaced they should be so you know they are flat, you can take material off the head decks to get quench , but that is going to raise your compression ratio. don't be surprised to get chamber volumes of 90-92 cc.

also make note that KB , and most aftermarket piston makers for mopar think everyone has blocks that have been decked about .020 when calculating compression ratios and picking a compression height.

|

|

|

Re: Another street/strip 440 rebuild

[Re: mopar67440]

#1638730

Re: Another street/strip 440 rebuild

[Re: mopar67440]

#1638730

07/10/14 08:44 PM

07/10/14 08:44 PM

|

Joined: Jun 2008

Posts: 3,916

usa

lewtot184

master

|

master

Joined: Jun 2008

Posts: 3,916

usa

|

Quote:

Thanks for the suggestion. I would hate to have to disassemble the bottom end to mill the deck. I'm still not entirely sure if the heads where ever milled. I'm assuming they have at some point.

I need to make all the critical measurements first, then I can make an informed decision on the course of action that get's me close to ideal without breaking the bank.

the block doesn't have to be milled to get the correct quench but most folks have the block squared up. everything can be done on the head. just use a depth mic to measure the open area in the head. also use some .011" or .012" to square the piston up in the bore when measuring the quench dome's positive deck. it's fairly easy but takes about an hour to do all eight.

|

|

|

Re: Another street/strip 440 rebuild

[Re: lewtot184]

#1638731

Re: Another street/strip 440 rebuild

[Re: lewtot184]

#1638731

07/11/14 01:56 AM

07/11/14 01:56 AM

|

Joined: Aug 2006

Posts: 2,141

junction city oregon

viperblue72

top fuel

|

top fuel

Joined: Aug 2006

Posts: 2,141

junction city oregon

|

If it's already together, I would leave it alone. It's either going to ping or it's not. If it does, then decide what to do. If it were me I would just put some edelbrocks on it.

|

|

|

Re: Another street/strip 440 rebuild

[Re: mopar67440]

#1638733

Re: Another street/strip 440 rebuild

[Re: mopar67440]

#1638733

07/12/14 01:41 AM

07/12/14 01:41 AM

|

Joined: Aug 2006

Posts: 2,141

junction city oregon

viperblue72

top fuel

|

top fuel

Joined: Aug 2006

Posts: 2,141

junction city oregon

|

You are correct and many of us learned the same way you are. There are many variables, but you know approximately what your compression ratio will be. The performance won't be disappointing with 10.5 compression or roughly that.  Your choice of parts are not that bad. I would honestly rather have a little too much compression than not enough. That's when performance will be disappointing. Plus you will have an excuse to pump some good heads on it if it doesn't run on pump fuel.  It would run fine on pump fuel with aluminum heads.

Last edited by viperblue72; 07/12/14 01:47 AM.

|

|

|

Re: Another street/strip 440 rebuild

[Re: viperblue72]

#1638735

Re: Another street/strip 440 rebuild

[Re: viperblue72]

#1638735

07/13/14 12:03 AM

07/13/14 12:03 AM

|

Joined: Jun 2014

Posts: 41

MA

mopar67440

OP

OP

member

|

OP

OP

member

Joined: Jun 2014

Posts: 41

MA

|

Different heads are not a financial option at this point, so I'm going to make the best of the 906 heads I have. So far all the research I've done tells me it's a balancing act between quech and compression. If I can acheive the .040"-.045" quench with compression around 9:5-10:1. Then between octane, air/fuel, timing, fresh air intake and a cool engine temp I should be able to dial it in to perform strong and reliably. I'm actually loving the science and engineering behind it all. I think it will all be well worth the effort when I turn the key, break it in, fine tune it, and get to finally enjoy the fruits of my labor.  It's only been 12 years since it last ran... and I now know so much more about Mopar....thanks to this forum and all the info on the internet...it really got me thinking  Love it love it love it!!!

|

|

|

Re: Another street/strip 440 rebuild

[Re: mopar67440]

#1638738

Re: Another street/strip 440 rebuild

[Re: mopar67440]

#1638738

07/15/14 04:03 PM

07/15/14 04:03 PM

|

Joined: Jan 2003

Posts: 74,947

U.S.S.A.

JohnRR

I Win

|

I Win

Joined: Jan 2003

Posts: 74,947

U.S.S.A.

|

Quote:

ok...so now I have some real numbers to work with. The measurements were taken many times over until I had a fairly confident process with repeatability.

Quench clearance w/no head gasket = 0.045"

- Heads were torqued to approx. 35 lbs

- Used rosin core 60/40 solder over length of step

- Crushed 3 times at TDC

- Both ends & middle of solder measured & averaged

- All cylinder were within 0.005" of each other

- Very little piston rock was noticed across the solder

Piston step head to deck = 0.039"

- Piston brought to TDC with dial indicator

- Measurements made with straight edge & feeler gauge @center of piston

Flat of piston (valve reliefs) to deck = -0.034" below deck

- Piston brought to TDC with dial indicator

- Measurement made with straight edge & feeler gauge @center of piston

Head CC's

- All were 82-83 CC's

- One was at 80 CC

- Double checked all measurements

- Allowed water to sit in chamber for 15 minutes w/ no valve leaks observed.

Head bolt bosses at the exhaust side were also checked as suggested, and were at 0.975" indicating heads were most likely milled.

Looking at the numbers, with a 0.020" head gasket the quench area will end up at 0.065", which is far from ideal.

Also looks like compression is somewhere at 10.5:1.

Any thoughts?

Yes at .065 you basically have no quench , it is what it is unless you want to cut the heads .020 , I'd cut .025 because of your .005 variance  , but then your compression is going to be higher. , but then your compression is going to be higher.

Drop your head gasket on the head and see how much overhang of the chamber there is inside the gasket, scribe the gasket onto the head, drop 1\4" dowels in the head to hold the gasket, and scribe the chamber size and grind all the overhang away and polish the chambers and see how much you raised the chamber CC.

|

|

|

Re: Another street/strip 440 rebuild

[Re: mopar67440]

#1638740

Re: Another street/strip 440 rebuild

[Re: mopar67440]

#1638740

07/15/14 05:20 PM

07/15/14 05:20 PM

|

Joined: Jan 2003

Posts: 74,947

U.S.S.A.

JohnRR

I Win

|

I Win

Joined: Jan 2003

Posts: 74,947

U.S.S.A.

|

Quote:

That's what I figured...no quench & I can hear the pinging already.

So if I mill the heads .015-.020, compression goes up too...and there's real no benefit?

I thought I saw this info somewhere and can't put my finger on it, but what is 0.010" equal to in CC's?

btw...I was thinking about one other measurement I made that I did not publish here. I put a straight edge across the head, and measured 0.073" with a feeler gauge to the flat of the chamber. If I take that value, subtract the quench dome of 0.039", that's 0.034" (0.011" less than the solder test). I wonder if the solder didn't crush down all the way. That would place quench at 0.054"...still 0.014" less than ideal, but better.

Is grinding out the head overhang a typical approach to increasing the CC's? I assume leave the quench area alone.

The solder was obviously causing the piston to rock while crushing, I wouldn't use that to determine a value, doing it with the straight edge and feeler blades, and math is, more accurate.

For BB open chamber head, .005 for every CC , .015 3cc, .020 4cc, .025 5cc

No there is a benefit , but you have iron heads and possibly not high enough octane because of the iron heads not succking out more of the combustion heat, faster, like an alum head does. Quench/squish is not the magic bullet, but it helps.

i'd want .045 MAX  , anymore and you may as well leave it at .065. , anymore and you may as well leave it at .065.

To increase CC, think about it, the chamber needs to be BIGGER ... yes leave the quench area alone except to maybe smooth it, but try not to make it deeper , the smoother/shiner it is the less chance for hotspots that will help cause detonation.

|

|

|

Re: Another street/strip 440 rebuild

[Re: mopar67440]

#1638742

Re: Another street/strip 440 rebuild

[Re: mopar67440]

#1638742

07/21/14 10:31 AM

07/21/14 10:31 AM

|

Joined: Jan 2003

Posts: 74,947

U.S.S.A.

JohnRR

I Win

|

I Win

Joined: Jan 2003

Posts: 74,947

U.S.S.A.

|

Quote:

Thanks John for the cc info. and all your guidance.

So if I use the feeler gauge numbers it looks achievable...

.073 chamber depth

less .039 dome height

less .010 off the heads

add .020 head gasket

.043 total quench

With .010 off the heads, that will reduce CC's to approx 80-81. The piston is .034 in the hole which equates to approx 6.8 cc. Valve reliefs are at 1.8 cc based on KB236 spec. So with a total CC at approx 88.6, what would the SCR be...around 10.0:1?

I'll take your suggestion and polish the chambers the best I can shy of removing valves to accomplish any major ginding.

Not sure if it's worth anything, but while the heads were off, I selected 8 spark plugs that were indexed correctly.

I think if you can get .043 quench you will have a good chance. The pfirst build I helped out on had roughly the same quench, same pistons and 73/75 cc 906 heads, the guy had no issue running on the street with 93 oct, but this was back before Ethanol, but I think the gas had MBTE in it ??

The odd part was that this build mimic'd his friends build, I was just involved with collecting parts and doing chamber mods on the heads, and his friends engine with 9.5 compression and .065 quench woulkd not run on anything less than 93 without pinging, they both ignore KB's recommendation of 34 max advance ?

If it were me I would take the .010 out of the open part of the chamber that way you end up with perfectly matched chamber depths and add CC to the chambers.

What part of Ma. are you in ?

|

|

|

Re: Another street/strip 440 rebuild

[Re: JohnRR]

#1638744

Re: Another street/strip 440 rebuild

[Re: JohnRR]

#1638744

07/21/14 11:41 AM

07/21/14 11:41 AM

|

Joined: Oct 2003

Posts: 3,698

NE Oklahoma

Von

master

|

master

Joined: Oct 2003

Posts: 3,698

NE Oklahoma

|

Using the Diamond compression calc, I come up with 10.47... http://www.diamondracing.net/tools/

72 RR, Pump gas 440, 452s, 3800 lbs, Corked, ET Radials,. 11.33@117.72.

Same car, bone stock 346s, 9.5 comp, baby solid. 12.24@110.

|

|

|

Re: Another street/strip 440 rebuild

[Re: mopar67440]

#1638745

Re: Another street/strip 440 rebuild

[Re: mopar67440]

#1638745

07/21/14 01:34 PM

07/21/14 01:34 PM

|

Joined: Jan 2003

Posts: 74,947

U.S.S.A.

JohnRR

I Win

|

I Win

Joined: Jan 2003

Posts: 74,947

U.S.S.A.

|

Quote:

Not sure what you mean...

"If it were me I would take the .010 out of the open part of the chamber that way you end up with perfectly matched chamber depths and add CC to the chambers."

Are you referring to grinding back the open part of the chambers to the edge of the head gasket?

I am in Marlborough, MA btw.

I screwed up, I was thinking you needed to make the open part of the chamber deeper, not shallower. What I have done in the past wouldn't help you.

But yes scribe the head gasket opening onto the head and grind it back to that to gain chamber volume.

I like the idea of using the thinner gasket that way if you have to cut the heads again you can just use the thicker gasket and still be safe.

|

|

|

Re: Another street/strip 440 rebuild

[Re: mopar67440]

#1638747

Re: Another street/strip 440 rebuild

[Re: mopar67440]

#1638747

07/21/14 01:48 PM

07/21/14 01:48 PM

|

Joined: Jan 2003

Posts: 74,947

U.S.S.A.

JohnRR

I Win

|

I Win

Joined: Jan 2003

Posts: 74,947

U.S.S.A.

|

Quote:

Where do you think SCR is without this extra work...10.5? With the quench at .043 & timing backed off to around 34 degrees, think it's really necessary? Grinding all 8 chambers back to the 4.320 mark is going to be a lot of work.

It's good practicefor you and your penance for using poor cylinder head choice.

I had 50 hours in the last set of open chambers head setting up for quench I used ... good thing I do it for free ...

|

|

|

Re: Another street/strip 440 rebuild

[Re: mopar67440]

#1638748

Re: Another street/strip 440 rebuild

[Re: mopar67440]

#1638748

07/21/14 02:34 PM

07/21/14 02:34 PM

|

Joined: Oct 2003

Posts: 3,698

NE Oklahoma

Von

master

|

master

Joined: Oct 2003

Posts: 3,698

NE Oklahoma

|

Quote:

think it's really necessary?

As I mentioned earlier I have experience with a setups very similar....Same heads, same cam, with the older style of the pistons you are using. Same specs, different ring pack.

Im not gonna say to not not do the grinding...but I will say with the motor that had basically the same compression on paper (10.25ish), and cam...with around .055 quench I never heard an ounce of detonation. Upon tear down, pistons showed zero issues either...

The same pistons are in my car with the same heads, but no longer using the MP 509. I have a Engle grind on a 106, which doesnt help the detonation issue. Quench is in the high .040s. I can get by with 87 in the cooler months. I have 91 in it right now, but have yet to hear any audible detonation. No hard start issues or any signs of preignition.

Conversely, I had a set of 452s on a flat top motor that had about 10.15 comp. No quench.

Bigger cam than the Engle I currently am using and on a 108. That motor would ping on a hot day on 91 with timing over 34. 2 pistons show signs of light detonation.

So...I think quench is pretty dang important. But, I do believe, based on my experience, that you still get benefit, even if you are in the mid .050s..YRMV.

72 RR, Pump gas 440, 452s, 3800 lbs, Corked, ET Radials,. 11.33@117.72.

Same car, bone stock 346s, 9.5 comp, baby solid. 12.24@110.

|

|

|

Re: Another street/strip 440 rebuild

[Re: mopar67440]

#1638750

Re: Another street/strip 440 rebuild

[Re: mopar67440]

#1638750

07/21/14 06:11 PM

07/21/14 06:11 PM

|

Joined: Jan 2003

Posts: 74,947

U.S.S.A.

JohnRR

I Win

|

I Win

Joined: Jan 2003

Posts: 74,947

U.S.S.A.

|

Quote:

2. Pushrod length

Having non-adjustable 6-pack rockers, I'll need to verify preload is still within spec. Suspecting .030 was already taken off the heads, now I'm taking .010 more, and keeping within .020-.040 preload, I'm hoping the 3/8 x 9.310 rods I currently have will fall within this preload target.

What was it ?

|

|

|

Re: Another street/strip 440 rebuild

[Re: mopar67440]

#1638752

Re: Another street/strip 440 rebuild

[Re: mopar67440]

#1638752

07/22/14 11:11 AM

07/22/14 11:11 AM

|

Joined: Jan 2003

Posts: 74,947

U.S.S.A.

JohnRR

I Win

|

I Win

Joined: Jan 2003

Posts: 74,947

U.S.S.A.

|

Quote:

The pushrods were 5/16 x 9.31. That was with the original flat top pistons and .040 head gasket. Over the years I picked up 3/8 x 9.31 for the heavier valve springs, but as mentioned I will definately have to revisit this as I'll now be .030 less with .010 off the heads and .020 head gasket.

What is the length of a STOCK 440 pushrod? The factory used a steel shim gasket , .021 , just like all the steel shim gaskets sold now  . .

I know this is budget but if you are stuck on using stamped rockers and want specific hyd. preload then I would call Smith Bros and order a set of adjustable pushrods. The last 2 I did have them with stamped rockers because like you I wanted specific preload and it's the only way to get it exact, the valves heights are all a little off from each other unless you had an EXPENSIVE valve job done.

|

|

|

Re: Another street/strip 440 rebuild

[Re: mopar67440]

#1638755

Re: Another street/strip 440 rebuild

[Re: mopar67440]

#1638755

07/25/14 05:49 PM

07/25/14 05:49 PM

|

Joined: Jan 2003

Posts: 74,947

U.S.S.A.

JohnRR

I Win

|

I Win

Joined: Jan 2003

Posts: 74,947

U.S.S.A.

|

Quote:

Must be the difference between a mechanics mentality of time is money, and an engineers attention to detail.

that pretty much sums it up.

You'll be happier knowing it's right .

Also you should have to worry about rocker geometry much with stock stamped steel rockers , what you are checking is lifter preload and if either of them tell you to put shims under the rocker shafts IGNORE THEM . Get adjustable pushrods ...

|

|

|

Re: Another street/strip 440 rebuild

[Re: mopar67440]

#1638756

Re: Another street/strip 440 rebuild

[Re: mopar67440]

#1638756

07/25/14 06:06 PM

07/25/14 06:06 PM

|

Joined: Jun 2003

Posts: 52,972

Romeo MI

MR_P_BODY

Master

|

Master

Joined: Jun 2003

Posts: 52,972

Romeo MI

|

Quote:

Dropped the heads at the machine shop today to have .010 take off. Pretty confident I'll get the quench to around .043.

Funny...both my life long friend of 40 yrs, who's restored dozens of mopars, and the machinist...both think I'm being way to meticulous. When I mentioned checking rocker arm geometry & possibly ordering shorter pushrods, they both gave me the look of disbelief, and insist I just put it together already. Must be the difference between a mechanics mentality of time is money, and an engineers attention to detail.

The engineers that I dealt with just wanted to see the

end results.. they left it up to me how to get there

|

|

|

Re: Another street/strip 440 rebuild

[Re: mopar67440]

#1638758

Re: Another street/strip 440 rebuild

[Re: mopar67440]

#1638758

07/29/14 03:51 PM

07/29/14 03:51 PM

|

Joined: Jan 2003

Posts: 74,947

U.S.S.A.

JohnRR

I Win

|

I Win

Joined: Jan 2003

Posts: 74,947

U.S.S.A.

|

Quote:

Well...got the heads back with .010" off, and ready to hit the shop Fri to start assembly. Now that the heads have a nice clean, machined surface, I'll clean the block really good using acetone until the rags are clean before installing the heads. Hopefully get a good seal.

I'm hearing a couple diff schools of thought on using the VHT Copper Cote on the steel head gaskets. A light coat and install and torque when tacky was my thought. Also head bolts to 70 lbs. They are ARP. Mopar suggests 35lbs, then 70, and ARP suggests 3 equal torques to 70.

Copper coat is a good idea and I would torque it like ARP suggests.

|

|

|

Re: Another street/strip 440 rebuild

[Re: mopar67440]

#1638759

Re: Another street/strip 440 rebuild

[Re: mopar67440]

#1638759

07/29/14 07:26 PM

07/29/14 07:26 PM

|

Joined: Jun 2003

Posts: 52,972

Romeo MI

MR_P_BODY

Master

|

Master

Joined: Jun 2003

Posts: 52,972

Romeo MI

|

Quote:

Well...got the heads back with .010" off, and ready to hit the shop Fri to start assembly. Now that the heads have a nice clean, machined surface, I'll clean the block really good using acetone until the rags are clean before installing the heads. Hopefully get a good seal.

I'm hearing a couple diff schools of thought on using the VHT Copper Cote on the steel head gaskets. A light coat and install and torque when tacky was my thought. Also head bolts to 70 lbs. They are ARP. Mopar suggests 35lbs, then 70, and ARP suggests 3 equal torques to 70.

I've done the 3 step for ever.. it works.. then go

back over them at the total torque just to make sure

it hasnt moved

|

|

|

Re: Another street/strip 440 rebuild

[Re: mopar67440]

#1638761

Re: Another street/strip 440 rebuild

[Re: mopar67440]

#1638761

08/04/14 01:59 PM

08/04/14 01:59 PM

|

Joined: Aug 2003

Posts: 43,097

Bend,OR USA

Cab_Burge

I Win

|

I Win

Joined: Aug 2003

Posts: 43,097

Bend,OR USA

|

Quote:

I already have the 906's w/ heavy springs/dampers. The aluminum heads are just a little rich for my blood at the moment.

Also, the engine ran strong with the 700cfm right up to 6500. At the suggestion of a friend, I tried both a 750 & 850, and after tuning them both, I found the larger carbs were not as responsive, and there was really no diff in the et's, so I went back to the 700.

Iron heads with todays fuel and that compression ratio may not be compatable   If you have to retard the timing or run the motor fatter than best performance to keep it from detonation your not getting the best performance from the parts, are you If you have to retard the timing or run the motor fatter than best performance to keep it from detonation your not getting the best performance from the parts, are you  I would lower the compression to no more than 9.5 to 1 so I could tune it for best performance I would lower the compression to no more than 9.5 to 1 so I could tune it for best performance   As far as your motor not liking the bigger carb. that is a abnormality with all the 440 I've tuned and tested, I would bet money that you had a fuel restriction in the car limiting the fuel supply at WOT on both carbs As far as your motor not liking the bigger carb. that is a abnormality with all the 440 I've tuned and tested, I would bet money that you had a fuel restriction in the car limiting the fuel supply at WOT on both carbs   My reasoning for saying this is I have tested carbs. from 600 CFM to a 1050 Dominator on the same motor, one intake swap for the Dominator carb. and the car would pick up with each larger carb. All the 4150 carbs, 600 DP Holley to a Holley 950 HP DP, where tested on the same intake and jetted for best performance My reasoning for saying this is I have tested carbs. from 600 CFM to a 1050 Dominator on the same motor, one intake swap for the Dominator carb. and the car would pick up with each larger carb. All the 4150 carbs, 600 DP Holley to a Holley 950 HP DP, where tested on the same intake and jetted for best performance  I even tested a BG Holley 750 stage three modded carb. that flowed 920 CFM and it ran better than any of the stock 4150 Holleys jetted I even tested a BG Holley 750 stage three modded carb. that flowed 920 CFM and it ran better than any of the stock 4150 Holleys jetted   Good luck on your build Good luck on your build  Think twice, act once Think twice, act once   Edit, I should have read pages 2,3 and 4 before posting this post Edit, I should have read pages 2,3 and 4 before posting this post  To late for my To late for my   Good luck Good luck  BTW, a colder spark plug will help control detonation. I like to set my BB total timing at 34 to 36, depending on which compression ratio and fuel. I do shorten up the advance so I can get 14 to 18 degrees at idle and then have the timing come all in by 2000 to 2500 RPM. BTW, a colder spark plug will help control detonation. I like to set my BB total timing at 34 to 36, depending on which compression ratio and fuel. I do shorten up the advance so I can get 14 to 18 degrees at idle and then have the timing come all in by 2000 to 2500 RPM.

Last edited by Cab_Burge; 08/04/14 02:18 PM.

|

|

|

Re: Another street/strip 440 rebuild

[Re: mopar67440]

#1638762

Re: Another street/strip 440 rebuild

[Re: mopar67440]

#1638762

08/04/14 07:02 PM

08/04/14 07:02 PM

|

Joined: Jan 2003

Posts: 74,947

U.S.S.A.

JohnRR

I Win

|

I Win

Joined: Jan 2003

Posts: 74,947

U.S.S.A.

|

Quote:

Next is 6 qrt pan, windage tray, pickup, and HV pump. Also ordered the Billet rear main seal kit from Mancini which I hear never leak.

High volume pump , as is the billet rear cap , is a waste of money , not needed and it's overkill.

If you have a stock crank best money spent is on a ROPE SEAL from BEST gasket , 383 I fired up last weekend does not leak on drop.

|

|

|

Re: Another street/strip 440 rebuild

[Re: viperblue72]

#1857389

Re: Another street/strip 440 rebuild

[Re: viperblue72]

#1857389

06/26/15 01:49 PM

06/26/15 01:49 PM

|

Joined: Jun 2014

Posts: 41

MA

mopar67440

OP

OP

member

|

OP

OP

member

Joined: Jun 2014

Posts: 41

MA

|

Just wanted to update everyone on the rebuild.

Started the engine Saturday, broke in the 509 cam, dumped the oil, and now have about 5 hrs and 75 miles on it...mostly hard accel & deaccel under 5k rpms to seat the rings. So far so good.

Cooling was a big concern to head of detonation w/ an estimated 10.5:1 CR & 906 cast heads,, so I found a 1969 2949054 max cool 3 core radiator w/ shroud and 7 blade 18" x 2.5" viscous fan. Running a 185 degree, high flow therm, and she's running nice and cool, even with the Coan 11" 2600 stall converter & 3:91 gears.

With Sunoco 93, I set initial timing to 14, w/ 22 mechanical for 36 total by 3000 rpm (I may want to revisit this). Autolight 85's are gapped at 0.045" using a Mallory Hyfire ignition w/ Promaster coil and sidewinder wires.

Carb is a 4150 (700cfm) with 74 jets prim/84 sec (may also want to revisit this with a chassis dyno)

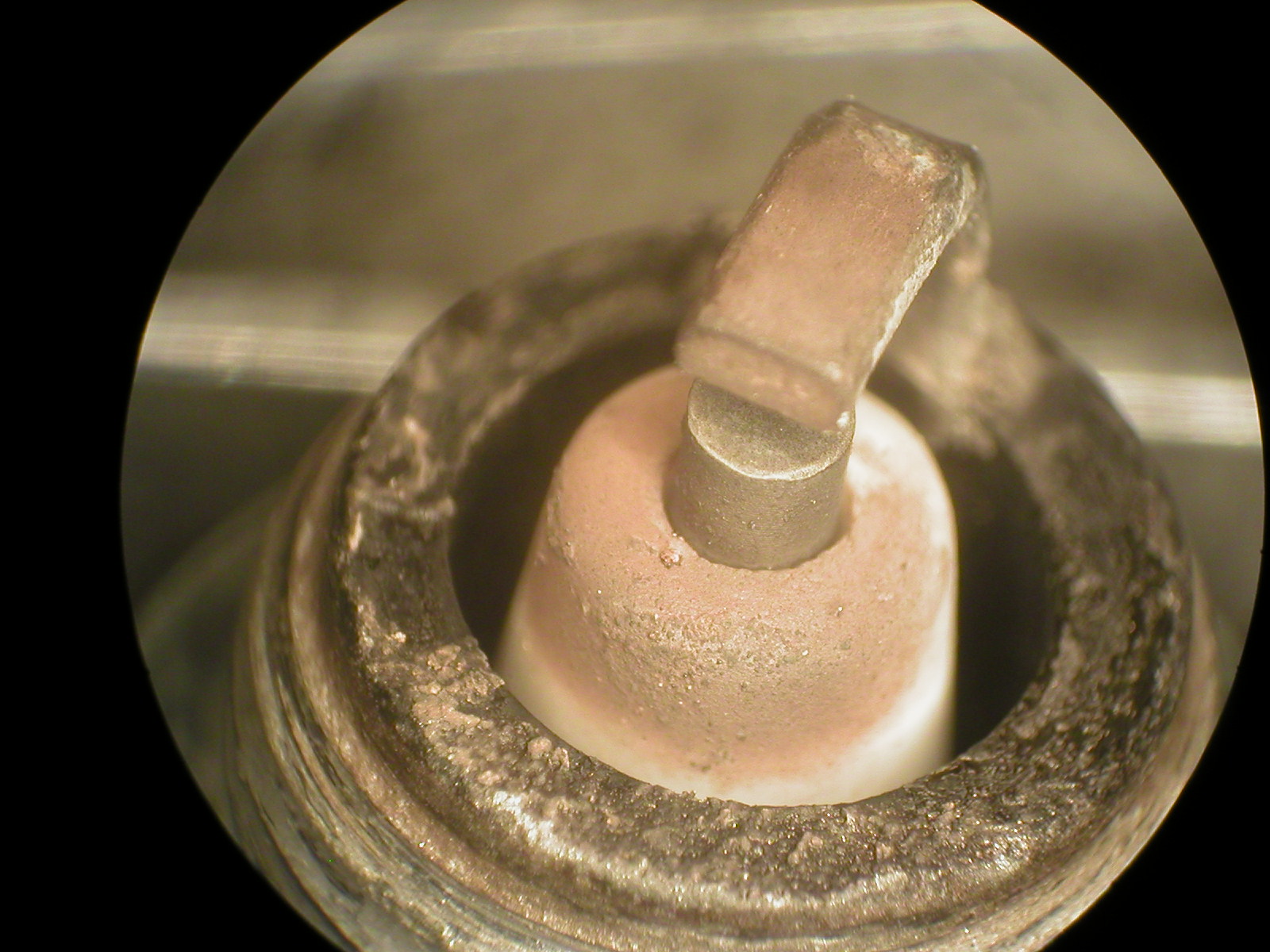

Decided to pull all 8 spark plugs this morning to inspect. I included a pic of cycl 1 (all 8 are close to the same). I'm pretty much just staying on the carb primaries at speeds of 30-50mph.

Would love some feedback on the spark plug. I'm thinking they look pretty good...maybe on the lean side, but I'm by no means an expert at plug reading.

Last edited by mopar67440; 06/26/15 06:23 PM.

|

|

|

|

|