|

Re: CHEAP Tremec 600 installation pics

[Re: CJK440]

#15642

Re: CHEAP Tremec 600 installation pics

[Re: CJK440]

#15642

06/29/05 08:41 PM

06/29/05 08:41 PM

|

Joined: Jan 2003

Posts: 8,128

New Mexico

UCUDANT

Troll Hunter

|

Troll Hunter

Joined: Jan 2003

Posts: 8,128

New Mexico

|

Quote:

Looks like you lost a bit of rigidity when you cut the support

|

|

|

Re: CHEAP Tremec 600 installation pics

[Re: UCUDANT]

#15644

Re: CHEAP Tremec 600 installation pics

[Re: UCUDANT]

#15644

06/30/05 12:54 AM

06/30/05 12:54 AM

|

Joined: Jan 2003

Posts: 1,692

Las Vegas, NV---Back Home!

Mooosman

super gas

|

super gas

Joined: Jan 2003

Posts: 1,692

Las Vegas, NV---Back Home!

|

Okay, I'm trying to compile a parts list, please check me:  -Trans: TKO 600 (what cars used them, stock?) -Throwout: Late Dodge/Jeep -Pilot bearing: Mustang? Dodge? Jeep? It wasn't really clear to me?  -Tranny mount: Gm standard (can you provide a part # for the mount you used?) -Slip yolk: Ford AOD, C6, others -Crossmember: Custom, must cut out stock hoop -Bell housing: Scatter shield (I assume that you could modify a stock one if needed?)  -Pressure plate: ???  -Clutch disc: ???  -Clutch arm: Stock Mopar -Clutch linkage: Stock Mopar?  Your pictures were very informative, I am just unclear about a few things from your first post.  Thanks! Nick  Also, did you have to shorten the driveshaft for the application? What U-joint # did you use to go from Ford yolk to Mopar driveline? How did you adapt the speedometer cable to this trans? Thanks again!

Last edited by Mooosman; 06/30/05 01:01 AM.

1970 Plymouth Valiant

|

|

|

Re: CHEAP Tremec 600 installation pics

[Re: Mooosman]

#15645

Re: CHEAP Tremec 600 installation pics

[Re: Mooosman]

#15645

06/30/05 02:45 AM

06/30/05 02:45 AM

|

Joined: Jan 2003

Posts: 2,734

Charlotte, NC

446acuda

OP

OP

master

|

OP

OP

master

Joined: Jan 2003

Posts: 2,734

Charlotte, NC

|

Trans: no TKO-600's in stock applications. Closest thing might be a Tremec 3550? used in mustang cobras, i think. Not many used TKO-500 or 600 out there yet so new is really your only choice.Mine is Ford application #5008 w/ 0.64 overdrive ratio. A 0.8X ratio is also available just make sure you get the one for a Ford application since the GM version has a much shorter input shaft and since mopar used the longer input shaft than Ford or GM it really help having the added length of the ford shaft.

Throwout bearing:I found this bearing while installing a clutch in a '97 4.0 wrangler. it is Napa # N4093. also used in many later dodge trucks too.

Pilot bearing: 2 parts are required. One is Mopar # 4338876 and the other is Napa # B65174('95 Mustang GT application, i believe) Both parts are 2 piece. Use the bearing (inner piece from B65174 and outer piece from Mopar 4338876) press bearing from B65174 into housing from 4338876. It will be very clear once you have these in hand. used a big washer(1/8" thick) to space these forward to ensure that the bearing has maximum contact with the tremec pilot bearing surface on the input shaft.

BTW the whole pilot bearing should cost much less than $20

trans mount:I threw the box away but is was the same as Energy Suspension # 355-3-1108G (Jegs number since I have a Jeg's catalog handy) I've seen this same mount at AutoZone. I'm no GM expert but I think any parts store mount from any GM rear wheel drive car from the past 25-30 years is the same as the Energy Suspension mount if you don't want to spend $20+ for the Energy Suspension mount.

trans slip yoke: 31-spline ford found on C6, toploader, some AOD's. If converting from a 904 auto or a 4-spd A-body you will need to shorten driveshaft approximately 1 inch. It is up to you how you want to handle the driveshaft. Slip yoke most likely will use a spicer 1310 or spicer 1330 u-joint. Mopar Driveshaft will have either a Detroit 7260 or a Detroit 7290 u-joint. Do whatever you want to connect these together. There might be a conversion u-joint for your combination or if your slip yoke uses a 1330 u-joint you might want to get the weld yoke on the mopar driveshaft change to a Spicer 1330 style so that you have a strong and commonly available u-joint. If in doubt, talk to your local driveshaft shop. get conversion u-joints at you local napa or spicer driveshaft shop.

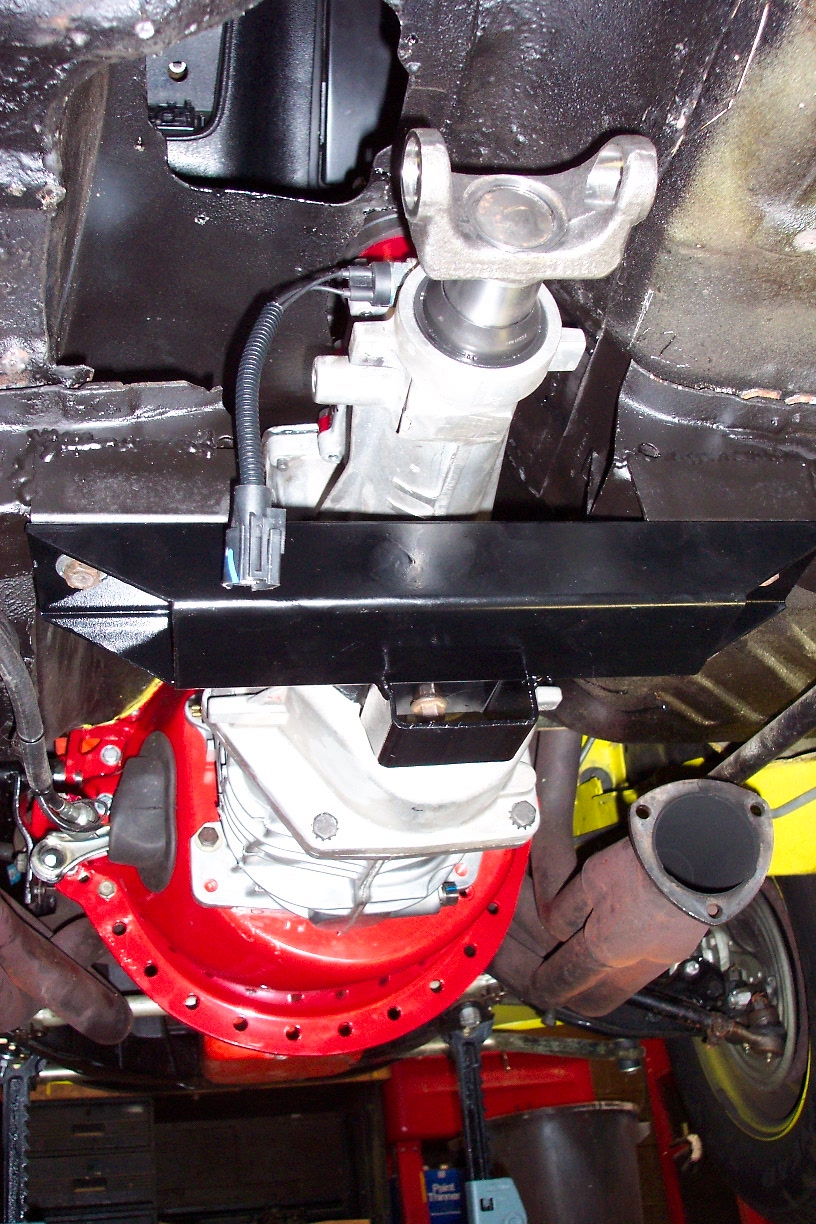

crossmember: you are correct, you need to make one. just make sure you keep the front and rear driveshaft angles within specs. Pretty easy to do on an A-body since the transmissions are within 1" of eachother in length.

Bellhousing: A stock bellhousing would require an adaptor plate which means $$$ machine work. A plus is that scattershield are relatively low cost when bought used and keep the trans as far forward as possible eliminating further problems with the pilot bearing and keeping the trans mount in position at the same time. Just by luck the trans mount is very close to the stock location in an a-body when using a scattershield and you really need to keep the trans as far forward as possible since a Ford input shaft is already shorter than a Mopar shaft.

Clutch disc: If you converting a mopar with 10.5 clutch simply get a 10.5 GM disc with 26-spline hub. 11" mopar get 11" Gm with 26 spline hub. If you have a high $$ Ram, McLeod disc talk to them... they might be able to put a 26 spline hub in it for you for much less than a new disc.

Pressure plate: whatever you are using now. The throwout bearing # that I posted ought to work with any style pressure plate i.e. diaphragm(centerforce), O.E. mopar style Borg&Beck or Long style.

Clutch arm: Stock mopar

Clutch linkage stock mopar.

I just need to put a mopar end on a Mustang speedo cable. I've been putting this off since I started driving the car with the Tremec installed over 6 months ago.

NOTE: a lot of this stuff becomes really obvious one you have parts in hand and begin the wrench turning. I will try to post some better AND LARGER pictures in the future hopefully with the car on a lift.Like I said before, the only work you need to farm out it turning the front bearing retainer down to mopar size(Jerry posted above that he will do it for $50) and getting the driveshaft shortened(forgot to include that above). also to fit a box stock tremec in an A-body you must cut out the loop above the trans mount but I really can't comment on B/E bodies.

Last edited by 446acuda; 06/30/05 02:53 AM.

|

|

|

Re: CHEAP Tremec 600 installation pics

[Re: UCUDANT]

#15646

Re: CHEAP Tremec 600 installation pics

[Re: UCUDANT]

#15646

06/30/05 07:41 AM

06/30/05 07:41 AM

|

Joined: Nov 2004

Posts: 533

East Windsor, CT

CFster

super street

|

super street

Joined: Nov 2004

Posts: 533

East Windsor, CT

|

Quote:

Looks like you lost a bit of rigidity when you cut the support

Yeah, really.

The Keisler kit has an offset shifter assembly so you don't have to do that.

Man, I was flipping out when I had to put a slight notch in my crossmember (wasn't even the crossmember, just the support in front of it) in my early B-body. And I'm running an AlterKtion so I'm not using torsion bars at all.

Don't think I could bring myself to cut out the whole thing.

Wonder if he has subframe connectors in his car...

|

|

|

Re: CHEAP Tremec 600 installation pics

[Re: UCUDANT]

#15647

Re: CHEAP Tremec 600 installation pics

[Re: UCUDANT]

#15647

06/30/05 09:46 AM

06/30/05 09:46 AM

|

Joined: Jan 2003

Posts: 9,982

Ansonia, CT

CJK440

master

|

master

Joined: Jan 2003

Posts: 9,982

Ansonia, CT

|

Quote:

Looks like you lost a bit of rigidity when you cut the support

Looks can be deceiving. The size of the X-member where it runs under the hump, flattens out to about 3/4" high by the same width. Thats alot smaller than what you see there.

The T-bars anchor closer to the front frame rails where the T-bar x-member is welded firmly to. I do have weld in subframe connectors which definately help. While I would not drive the car without the bolt in section, I feel when it is bolted in it is fine. Seems to drive just dandy too.

Quote:

The Keisler kit has an offset shifter assembly so you don't have to do that

Yes we know, but as you know the kit is 50% more than what I spent. If you got the money and or are to aprehensive to do metal work underneath, by all means spring for the Keisler. This is merely a different option for guys willing to do some extra work to save some cash.

Mooos...

446 got most of it covered but I'll add a bit.

I got my TO bearing from Autozone, for the same application. Its a Timken bearing for $50.

You really need to use a scattershield. I though about an adapter plate but as it is the engine side of the clutch disk splines is lines right up with the end of the splines on the input. If you use an adapter plate, you will pull the input splines out of the clutch by that much.

Pilot bearing- I didn't use 446's idea. I seems good however I made my own that presses into the crank.

Slip yoke- It takes a C6 yoke. I bought one that uses a 1330 joint and also purchased a 1330 to 7290 conversion joint. My driveshaft guy talked me into buying a 1350 slipyoke to match the 1350 join on my dana. Let me know if you can use the 1330 yoke & conversion joint.

Chevy clutch. The guy at Ram said that chevy's and mopars use the same pressure plate bolt patterns. Based on this you can just buy a 26 spline disk (10.5 or 11") or a whole clutch. I bought the whole clutch. I bought a steel flywheel with a million patterns and forgot to verify this on the stock mopar flywheel.

2017 Contusion Blue Challenger T/A 392 M6 "BLKNBLU"

|

|

|

Re: CHEAP Tremec 600 installation pics

[Re: Jerry]

#15649

Re: CHEAP Tremec 600 installation pics

[Re: Jerry]

#15649

06/30/05 10:25 AM

06/30/05 10:25 AM

|

Joined: Jan 2003

Posts: 9,982

Ansonia, CT

CJK440

master

|

master

Joined: Jan 2003

Posts: 9,982

Ansonia, CT

|

I would not cut the X-member without "bridging" the sides with a permanent weld in piece or a bolt in section. It is a structural piece because it anchors the T-bars.

As for the clutch, thats what the Ram tech support guy told me when I was shopping for a disk to fit my Centerforce DF pressure plate 11" (maybe 10.5 is different) and he talked me into one of their clutch sets. I would call the clutch company first to verify.

Some 3550's and TKO's have ford input splines & different shifters so make sure you know what your getting.

2017 Contusion Blue Challenger T/A 392 M6 "BLKNBLU"

|

|

|

Re: CHEAP Tremec 600 installation pics

[Re: JeffC]

#15652

Re: CHEAP Tremec 600 installation pics

[Re: JeffC]

#15652

06/30/05 03:19 PM

06/30/05 03:19 PM

|

Anonymous

Unregistered

|

Anonymous

Unregistered

|

The Keisler kits are very nice no doubt, but there are a couple of things I noticed about how they are setup. If you look at the web site, they have a required add on kit that's like $1800. I priced out what it would cost to set up my 72 Charger with a complete setup and it was about $5-$6 grand. Then the other thing, a low cost kit would be great. I'm setting up a 74 Duster to drive everyday. Eventually it'll have a stock 318 in it. I want to put a 5 speed in it also, but I don't need a 450hp kit for a stock 318 (not to mention I don't want to put a $3K+ kit in a $700 car). So what do I do? I've been thinking about adapting a T-5 out of a Fox body Mustang. Otherwise, the kits look great and I'd be proud to own one, unfortunatly I'm pretty broke.

|

|

|

Re: CHEAP Tremec 600 installation pics

#15653

Re: CHEAP Tremec 600 installation pics

#15653

06/30/05 03:43 PM

06/30/05 03:43 PM

|

Joined: Jan 2003

Posts: 1,692

Las Vegas, NV---Back Home!

Mooosman

super gas

|

super gas

Joined: Jan 2003

Posts: 1,692

Las Vegas, NV---Back Home!

|

The relocation kit looks interesting; would you use the rear mount, mid-mount, or front mount shifter in an A-body application?  If I were buying all the clutch parts new (say, for converting an automatic car), did the GM vehicles just use a standard clutch setup. I mean, did they just distinguish by clutch disc size, or by transmission type? Does anyone know if an aftermarket clutch setup like a Centerforce, etc. will work with the stock-type flywheels?  Thanks, guys! You guys did some excellent R&D on this for everyone.  I hope the Mods put this in the Archive.  Nick, Web surfin'

1970 Plymouth Valiant

|

|

|

Re: CHEAP Tremec 600 installation pics

[Re: Mooosman]

#15654

Re: CHEAP Tremec 600 installation pics

[Re: Mooosman]

#15654

06/30/05 04:21 PM

06/30/05 04:21 PM

|

Joined: Jan 2003

Posts: 9,982

Ansonia, CT

CJK440

master

|

master

Joined: Jan 2003

Posts: 9,982

Ansonia, CT

|

Lars,

First thing is the required "install kit" is $130, what I think your talking about is the complete auto to stick conversion with pedals, links, humps etc.

It sounds like you could get by with one of the higher rated World Class 87-93 Mustang T-5's. They made many different strength T-5's, I think up to 330 Ft/lbs torque cap, do your research and get the right one. Swap would be very similar but the Ford T-5 uses a different mounting pattern than the tremec (which is the same as a Toploader). Pilot should be the same, shifter location should be similar, you'l just need a ford disk and a different slip yoke than what we were using.

Mooos, according to the pics that 446 supplied, the standard mustang shifter location is darn close to the factory A-body position except its on center not off to the driver side. Scroll through those attachments on page 1.

As for the clutch, 26 spline is a pretty standard GM clutch setup I beleive. I would call the clutch company to verify but I was told that a GM Pressure plate has the same bolt pattern as a mopar.

|

|

|

Re: CHEAP Tremec 600 installation pics

[Re: CJK440]

#15656

Re: CHEAP Tremec 600 installation pics

[Re: CJK440]

#15656

06/30/05 04:57 PM

06/30/05 04:57 PM

|

Anonymous

Unregistered

|

Anonymous

Unregistered

|

CJ, Yeah I'm familiar with the T-5, I had an 89 5.0 with a T-5 that I rebuilt to T-5Z specs. It was a pretty tough tranny. Ever since I got my Duster I have been thinking about the swap. Wasn't sure how to do the bellhousing until I saw this thread. Another guy on another forum adapted an old SROD Mustang tranny by having a input shaft machined that would press fit over the Ford's snout, it ended up mimicking the A833 shaft. Pretty cool stuff.

|

|

|

Re: CHEAP Tremec 600 installation pics

#15657

Re: CHEAP Tremec 600 installation pics

#15657

07/02/05 12:29 AM

07/02/05 12:29 AM

|

Joined: Jan 2003

Posts: 2,734

Charlotte, NC

446acuda

OP

OP

master

|

OP

OP

master

Joined: Jan 2003

Posts: 2,734

Charlotte, NC

|

Here are some typical applications for 26 and 10 spline discs. 26spline, 10.4" diameter(use as replacement for Mopar 10.5 disc: 82-3 5.0 camaro. 26 spline 11" diameter:'70-4 454 4-spd Chevelle, '78-80 Corvette. 10-spline 10.4" diameter: '70-1 350 corvette 10-spline 11" diameter:'67-9 427 corvette. These are just a few of the many application for these disc diameter/spline combinations. These are from the Centerforce catalog. Ram clutch has a better breakdown in their catalog but I couldn't find it. I don't know how correct these applications are so you might want to be sure that if you order by application that you get what you think you are going to get.  Also for any of you considering using an O.E. bellhousing with an adaptor plate you might be able to get away with it even with the shorten than mopar input on the Tremec but getting Liberty gear in michigan or possibly Jamie Passon to put a long Chrysler pilot end on the Tremec. You probably need to check how much the input splines move out of the disc(with adaptor plate in place) before going this route though.

Last edited by 446acuda; 07/02/05 12:35 AM.

|

|

|

|

|