I haven’t gotten the 37 back in the shop yet, but hopefully that will happen in a couple of days. I have made a bit of progress in on some of the stuff that needed to be done for it however.

I did get out to the junk yard and picked up the gas pedal/emergency brake assembly that will go in the truck.

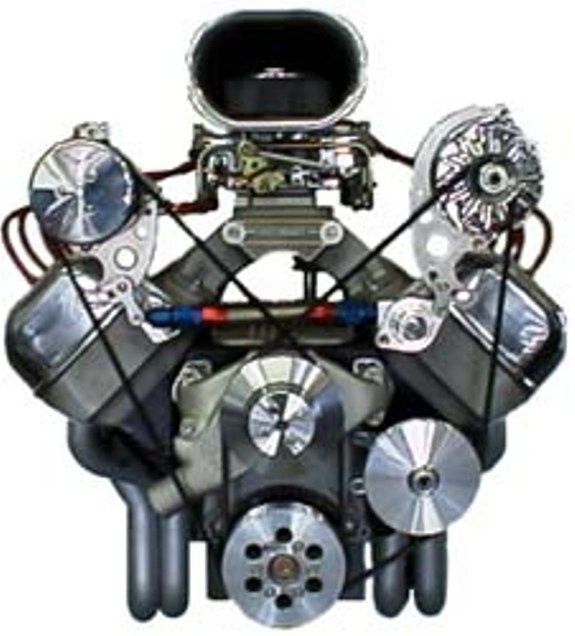

I also got a power steering pump hung on the engine. That was a job I had been dreading for quite a while…….I hate sorting out brackets and pulleys. I have used a combination of Hot Hemi heads and PAW brackets and pulleys on the Hemi in the 57 Plymouth. That system requires Hot Heads timing cover, lower pulleys, and a short BB Chevy water pump. Their good quality parts and I haven’t had any problems with the setup in the Plymouth.

That being said there are a couple of issues I foresee with it on the Dodge. The first one is the amount of belt wrap around the water pump. The system works OK on the 57 Plymouth in part due to the Plymouth running AC. There is belt contact on both sides of the water pump pulley from both the alternator belt and the AC belt. I won’t be running AC on the 37 so the belt contact patch would only be on the one side of the pump…….and the contact patch on the PS pump would also be minimal. Then there is the fact that that is an awful long belt and my experience is that long belts are much more likely to flip off under load on high RPM.

Finally I’d be lying if I said that cost isn’t also a factor. While I used the Hot Heads stuff on the 57 Plymouth, I’m currently using mostly stock parts on the motor for the 37. It has the stock thick timing chain cover, stock BB Mopar 4 groove crank pulley, modified Corvette alternator bracket, a 2 groove water pump pulley of unknown origin that happens to fit and line up and the cheaper long style BB Chevy water pump. Buying the timing cover, pulleys, brackets and more expensive short BB Chevy water pump would set me back about $500.

Mostly because of the belt contact issues, I decided to see if I could come up with something different than is currently being offered. I had originally planned on using a Saginaw pump like almost everybody uses and reducing the pressure to be more compatible with the Mustang II power rack. While I was going thru my core pile I came across a couple of old Federal pumps. I looked up the pressure on the pump and while it is still a bit high for the Mustang II rack it is lower than the Saginaw units (and I can reduce it further if needed) so I figured why not.

To make a long story short I pretty much stole a page out of Cadillac’s 500 ci engineering manual. To eliminate the long belt and get good belt wrap around the pulleys I’m running a short belt around the crank pulley, water pump and power steering pump using the PS pump as the tensioner. Then I’m running a second short belt from the second groove in the water pump to the alternator.

Everything lines up great and it took less than 45 minutes to actually modify the pump bracket and build a tensioner bracket to lock the pump in place………figuring everything out and test fitting as I was going pretty much used up a whole day.

It still has to come apart 1 more time, the PS pump I used for mock-up is an unknown quantity (the reason I didn’t spend any time cleaning it and painting it). I have a rebuilt coming in today that will go on to replace it.

With luck the transmission should be here this week and I’ll get started on bolting everything together and into the truck.